Stoas Vilentum University is a unique, small-scale research-based institute which provides training for students who wish to take up careers as educators in agriculture, horticulture, food technology or animal husbandry. Situated in Wageningen in the centre of the Netherlands, Stoas has a strong environmental focus and is a member of the international Green Business School network.

When the University decided to build a new campus in Wageningen, they stipulated that the structure should be as sustainable as possible. BDG Architecten from Zwolle in the Netherlands was selected to design and engineer the new building. Thanks to its sustainability credentials, steel was a natural choice for this landmark new addition to Stoas’ Wageningen campus.

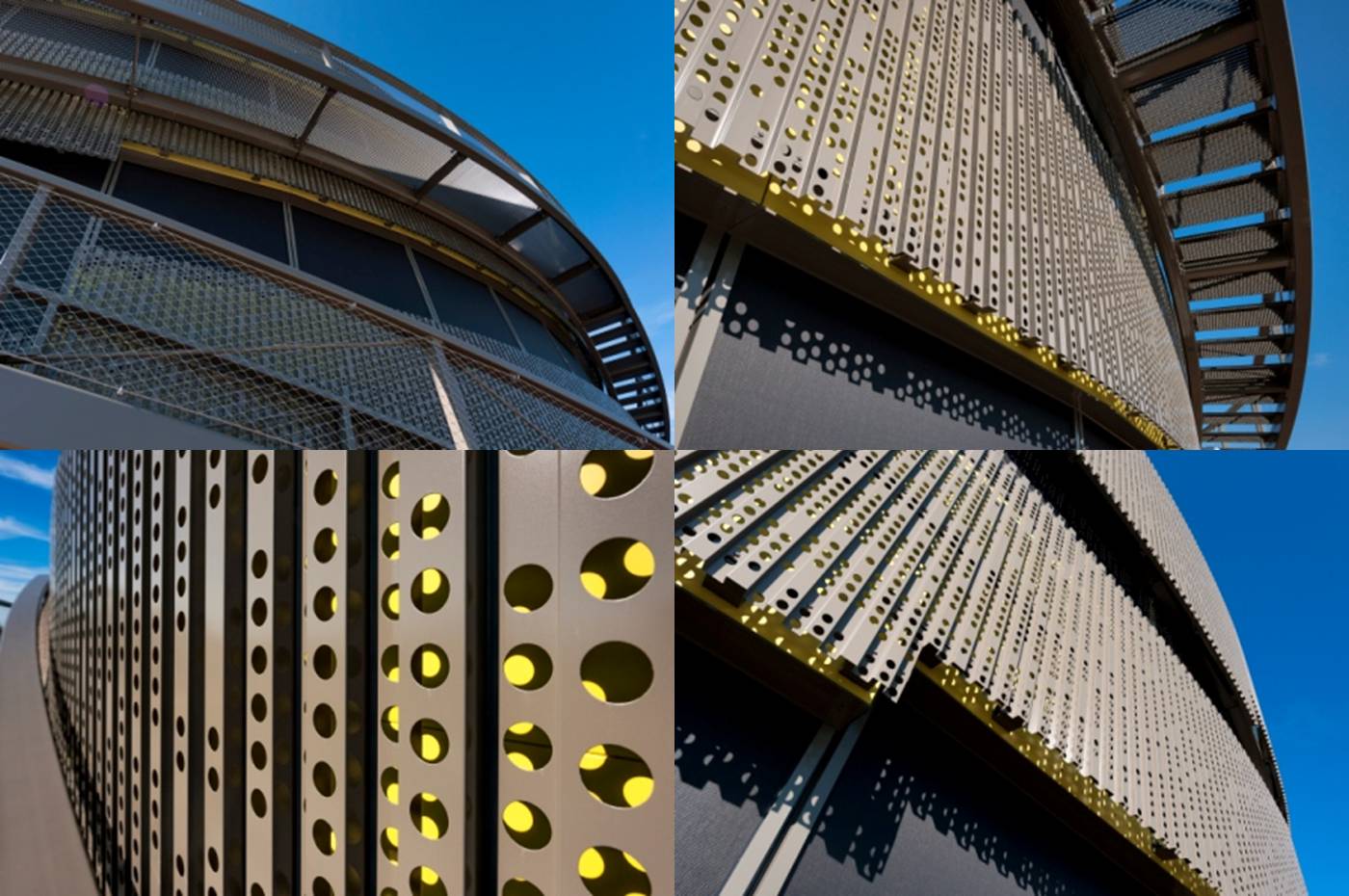

BDG Architecten’s design starts from a basic cylinder. Like the culture at Stoas, a cylinder is non-hierarchical. Each floor essentially has the same shape and view, reflecting the equality between teachers and students which is one of the school’s key values. A cylindrical shape also provides the most favourable ratio between floor area and exterior wall surface.

The building is clad in ArcelorMittal Europe – Flat Products’ Granite® HDX – part of our range of organic coated steel building solutions. All of our organic coated steels are free from heavy metals and chromates.

The Granite® HDX was perforated with circles which reveal the yellow external wall of the building behind the cladding. Sunlight and clouds create a constant play of light and shadow which add visual interest and highlight the landmark nature of the building.

The Granite® HDX coils were fabricated into sheets by Jack Muller B.V. (jackmuller.nl), a steel service centre in the Netherlands which specialises in pre-painted steel.

Initially another material was selected by the architects. However, Jack Muller questioned the suitability of the material for this project. In cooperation with ArcelorMittal, Jack Muller suggested our double-sided Granite® HDX paint system to BDG Architecten. As the project was at an advanced stage, the architect quickly required a sample before giving final approval.

“ArcelorMittal performed a colour match and had the matched Granite® HDX sample on the architect’s desk within two weeks of our request,” notes Glenn Muller, Chief Technical Officer at Jack Muller B.V.

While they had the right material, colour and paint system, the architects wanted reassurance from ArcelorMittal that Granite® HDX could withstand corrosion after perforation. Granite® HDX comes with a standard substrate which is zinc coated to 275 g/m², enough to guarantee it against corrosion for an automatic 30-year guarantee. However, BDG Architecten was concerned that the perforations may compromise the integrity of the substrate over time.

ArcelorMittal’s R&D team calculated different options before specifying a 350 g/m² (Z350) zinc substrate. The cathodic protection of zinc will prevent the cut edges of the perforations from corroding for many decades. “The direct technical support ArcelorMittal provided was a key reason why the architects selected Granite® HDX,” notes Glenn Muller.

The 70 tonnes of steel used in the construction can be fully recycled at the end of the building’s life. As the steel was pre-painted and formed offsite, the total environmental impact of the construction was lowered.

The new Stoas Vilentum University building was opened in September 2013. The building occupies a prominent place on the Wageningen campus and is surrounded by grass slopes which echo its green credentials. Over the coming years the university hopes the building’s environmentally friendly qualities will inspire a new generation of educators.