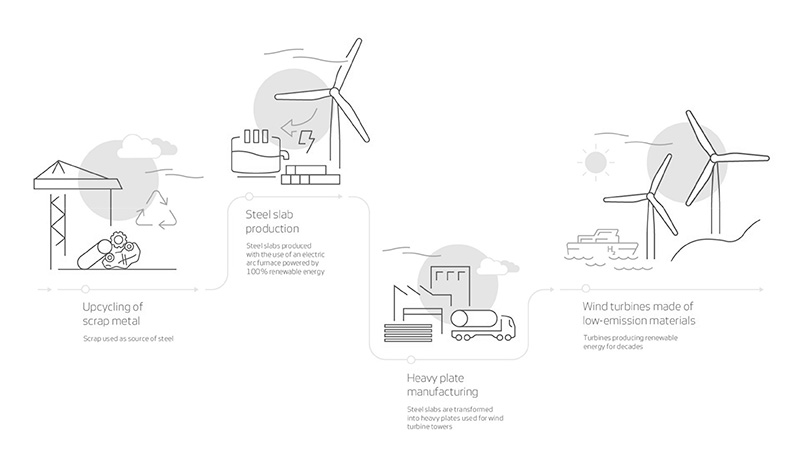

ArcelorMittal Europe – Flat Products and Vestas, the energy industry’s global partner on sustainable energy solutions, have established a partnership to deploy low carbon-emissions heavy plate in wind turbine towers. The turbines will be supplied by Vestas and situated in a new wind farm off the coast of Poland which will be operated by Baltic Power. The slabs are produced at ArcelorMittal’s Industeel steel mill in Charleroi (Belgium) using almost 100-percent steel scrap which is melted in an electric arc furnace powered by 100% wind energy. The steel slabs are then transformed into XCarb® recycled and renewably produced heavy plates at ArcelorMittal’s heavy plate mill in Gijón, Spain.

From left to right: Dieter Dehoorne (Head of Global Procurement at Vestas), Geert Van Poelvoorde (CEO ArcelorMittal Europe) and Henrik Andersen (CEO Vestas), Laurent Plasman (CMO Industry at ArcelorMittal Europe – Flat Products)

The 1.2 GW Baltic Power wind farm will consist of 76, V236-15.0 MW offshore wind turbines which will supply power to around 1.5 million homes in Poland. Fifty-two of the towers will utilise the low carbon-emissions steel. “Heavy plates for towers are one of the biggest contributors to Vestas’ Scope 3 emissions,” notes Dieter Dehoorne, Head of Global Procurement at Vestas. “So they are a key focus of our sustainability transformation as a company and this announcement is a massive leap towards tackling this challenge. We expect the interest in low carbon-emissions plates to grow in the coming years.”

Laurent Plasman, CMO Industry at ArcelorMittal Europe – Flat Products believes the Baltic Power project could be the first of many low-carbon emissions projects which will provide electricity for homes and industry across Europe: “This partnership sends a strong message that it is possible to start building the renewable energy infrastructure Europe needs with low carbon-emissions steel made in a European supply chain. Having a strong partnership throughout the supply chain is vital to achieve this.”

“It was a pleasure to meet Henrik Andersen to discuss our partnership with Vestas. This cooperation illustrates the power of partnerships that span the whole supply chain: they accelerate change and move us closer to the large-scale use of low carbon-emissions steel to build the infrastructure of the future”, notes Geert Van Poelvoorde, CEO of ArcelorMittal Europe.

A 66-percent reduction in CO2 emission intensity per kilogram of heavy plate is achieved using recycled steel and renewable electricity

XCarb® recycled and renewably produced heavy plates can be used to form both on- and offshore wind turbine towers. The low carbon-emissions heavy plate steel has an Environmental Product Declaration (EPD), certified by an independent party. The EPD details the complete environmental footprint of the product, allowing easier comparison between competing products. ArcelorMittal is the only steel producer to produce low-carbon emissions heavy plate steel in large dimensions, minimising the need for welding and associated CO₂ emissions.

“XCarb® recycled and renewably produced steel provides ArcelorMittal Europe with a unique opportunity to lead the transition towards near-zero emission steel,” says Dieter Dehoorne. “Wind farm developers see value in low carbon-emissions steel. It is a key lever in their efforts to reduce the carbon footprint of wind projects, and demonstrates their commitment to a net-zero energy transition.”

The Baltic Power offshore wind farm will be the first project where Vestas uses low carbon-emissions steel. Construction will begin during 2025 with completion expected in 2026. Vestas will supply, install, and commission the wind turbines in the project for Baltic Power.

“As the first offshore wind farm in the world to utilise low carbon-emissions steel, Baltic Power, a joint venture between ORLEN and Northland Power, is pioneering a sustainable future in the renewable energy sector,” notes Jarosław Broda, CEO Baltic Power. “Being the largest investment in renewable sources in this part of Europe, our project is setting new benchmarks. The use of low carbon-emissions steel from Vestas and ArcelorMittal in our wind farm underscores our commitment to innovation and environmental stewardship. We are proud to lead the way in transforming Poland's energy landscape as we progress towards completing the construction by 2026.”

Although Vestas is active in global projects, the company is very happy to use European-made steel in local projects. Dieter Dehoorne concludes: “When we use low carbon-emissions steel on European projects, there is a clear benefit to also source steel made in Europe. It reduces transport emissions and, in some cases, helps us to meet local content requirements. In the larger picture, we need to find solutions to decarbonise projects globally, and make low carbon-emissions steel a possibility for projects in all geographies.”

Read other customer success stories in the March 2024 edition of our client newsletter

Read other customer success stories in the March 2024 edition of our client newsletter

The slabs are produced at ArcelorMittal’s Industeel steel mill in Charleroi (Belgium) using almost 100-percent steel scrap which is melted in an electric arc furnace powered by 100% wind energy.

XCarb® recycled and renewably produced heavy plate steels are initially suitable for the entire onshore wind turbine towers and the top section of offshore wind turbine towers.

Vestas is the energy industry’s global partner on sustainable energy solutions. With more than 166 GW of wind turbines in 88 countries, Vestas has installed more wind power than anyone else. Together with its customers, Vestas’ more than 28,000 employees are bringing the world sustainable energy solutions to power a bright future.

Visit the website of Vestas

Copyright pictures: Vestas and ArcelorMittal