ArcelorMittal Poland Świętochłowice is a steel plant in Poland which has more than 170 years of history. To give the plant’s old office building a fresh look, the facade was completely renovated using products manufactured largely on site. These included ArcelorMittal Europe – Flat Products’ Granite® Quartz and Granite® HDX organic coated steels in the corporate colours of orange and grey. In just over one month, the building was transformed from a run-down office block to a modern, contemporary headquarters for the plant’s operations.

Granite® Quartz and Granite® HDX are organic coated steels which were specifically developed for external facade and roofing applications. Both products are free of hexavalent chromium and heavy metals and meet the European Union’s REACH regulations.

The main goal of the recent renovation was to improve the visual aspect of the plant's main office building. An additional building and garages located near the plant’s main gate were also partially renovated at the same time. During the project, the existing cladding sheets were removed and replaced with Hairplan 300 panels, an innovative and aesthetic cladding solution fabricated with steel coated in Granite® Quartz. Hairplan is an easy-to-assemble facade system developed by ArcelorMittal Construction for the building market.

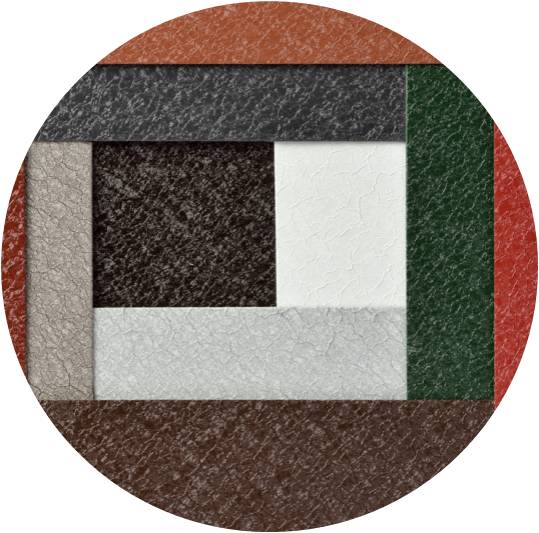

Granite® Quartz has a slightly textured surface which imitates natural quartz. The intrinsic glimmer of Granite® Quartz gives the finished facade a beautiful, crystalline look. Light reflects randomly off the crystal faces to give the surface an ever-changing texture. The 45 µm organic coating is available in 10 modern and classic colours to suit any roof or facade project. Granite® Quartz is guaranteed for up to 20 years depending on the environment.

To complete the envelope, downpipes and roof and wall edges were clad in curved Softline 35 sheets coated with Granite® HDX. The 55 μm, high-quality Granite® HDX coating was specifically developed for roofing, cladding and architectural applications in harsh climatic or environmental conditions. It is supplied with a guarantee against corrosion and peeling of up to 35 years. Softline was also developed by ArcelorMittal Construction and enables architects and designers to soften the harsh lines of structures with curved steel cladding panels.

Following cleaning work to ready the facade, more than 500 square metres of new Granite® Quartz and Granite® HDX panels had to be installed and 2,300 square metres of the facade were re-plastered. Renovation of both facades began on 6 April 2015 and was completed less than five weeks later.

The project was undertaken by ArcelorMittal Construction which produced the panels and carried out the work on the buildings. The Granite® Quartz and Granite® HDX used in the project were produced at ArcelorMittal Poland Świętochłowice. The project acts as an excellent example of the suitability of these aesthetic organic coated steels in both urban and industrial environments.

ArcelorMittal Poland Świętochłowice has a history of steelmaking stretching back over 170 years. In the 1930s the mill was renamed Huta Florian when the Polish state acquired the Silesian metallurgy business which occupied the site.

Over subsequent years the mill went through many changes. In the late 1970s the blast furnaces were stopped, and the plant closed completely in the early 1990s. In 2001, ArcelorMittal Poland Świętochłowice underwent a complete restructure to turn the site from a steel production, to a steel processing plant. Today ArcelorMittal Poland Świętochłowice produces the highest quality organic coated steels.