ArcelorMittal’s Amstrong® range of advanced high strength steels enable manufacturers to reduce the structural thickness and weight of their applications while improving load-bearing capacity. One company making full use of these properties is SAMAG, a producer of truck body solutions for major OEMs. SAMAG has been able to make maximum use of Amstrong® thanks to the advice provided by ArcelorMittal’s customer support teams. The effective combination of ArcelorMittal’s state-of-the-art steels and excellent technical support have enabled SAMAG to optimise its sourcing processes and secure market advantage.

SAMAG Truck Components can produce almost every component of a truck chassis, whether it is for a light commercial or heavy vehicle. One of its most popular products is container swap bodies which are delivered to truck OEMs fully assembled. Swap bodies are like standard shipping containers, but are designed to optimise the transport of pallets by road.

SAMAG Truck Components can produce almost every component of a truck chassis

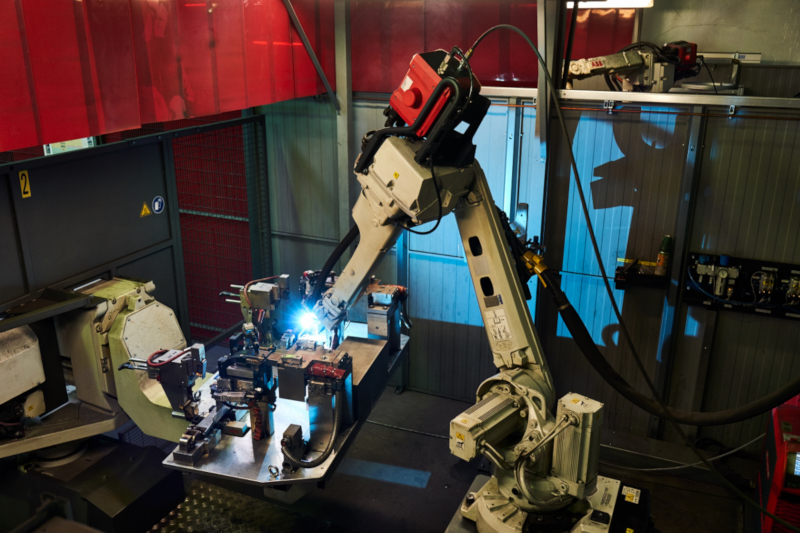

“We realise all of the production steps in-house,” explains Markus Schempp, general manager of SAMAG Truck Components. “Our core processes include laser cutting, bending, welding, and powder coating. We are proud of the depth of our processing skills.”

All core processes are carried out in-house

SAMAG were first introduced to Amstrong® at the 2018 EuroBLECH trade fair for sheet metal-working technology. “We discovered that the Amstrong® range could fully cover our needs thanks to the various grades available and their dimensional feasibility,” says Markus Schempp. “Today, around 95 percent of the steel we use comes from the Amstrong® range. It perfectly meets the requirements of our customers.”

Amstrong® steels from ArcelorMittal account for up to 95 percent of the steel used by SAMAG in its products

Although the material was technically perfect, there were some issues at the start of the relationship. Markus Schempp explains: “We produce one long laser-welded part from 8 mm sheets of Amstrong®. The initial production step involves laser cutting long, narrow strips from the sheet. However, we found that this process liberated internal stresses in the steel which made the strips bend, stopping our equipment. Jan de Moor, ArcelorMittal’s customer relations engineer, analysed the material, our nesting plans, and processes. He was able to propose Amstrong® 360MC laser, an alternative grade from the range. Jan also arranged delivery of a batch of material so we could carry out more extensive testing. The results were very positive, and we immediately switched to the new grade.”

State-of-the-art equipment is used for core processes such as laser cutting, bending, welding, and powder coating

For SAMAG, the benefits of working with a single steel supplier mean that ordering and manufacturing are simplified. “By working with ArcelorMittal for all our steel needs, we have optimised our sourcing and procurement processes,” notes Markus Schempp. “But it also means our operators can trust in the homogeneity of the material. With one machine set-up, they can apply the same process to the material from every batch. We appreciate that consistency.”

Another advantage of working with ArcelorMittal is our flexibility says Markus Schempp: “We are exposed to significant variations in demand from our customers. That means our steel supplier needs to ‘breathe’ with us and adapt to short-term changes in our forecasts and call-offs. This is possible thanks to the security stocks ArcelorMittal holds for us.”

Packaging is another area that is very important for SAMAG due to their highly flexible manufacturing process. “Often SAMAG use a few sheets from a package and then store the rest,” notes Jan de Moor, ArcelorMittal customer service representative. “Initially we supplied material stacked on standard pallets made from fibrous wood. But the constant handling is too much for this type of pallet and they can break-up, causing problems in SAMAG’s machinery. Once we understood the issue, ArcelorMittal changed SAMAG’s deliveries to pallets made from solid wood and this resolved the problem.”

Copyright images: SAMAG