The Faymonville Group is the world’s leading manufacturer of exceptional trailers for both on- and off-road applications. Whether you need to transport glass panels, wind turbines, or rocket components for Cape Canaveral – the Faymonville Group can create a trailer for your application. To maximise the strength and payload of its solutions, Faymonville utilises high strength Amstrong® and Amstrong® Ultra steels from ArcelorMittal Europe – Flat Products. And thanks to Faymonville’s decades of experience in the haulage sector, most trailers can be quickly adapted to transport different loads – increasing the return on investment for customers.

The heart of every Faymonville product is the high strength steel framework which gives the trailer its strength and rigidity. But whether it’s an on-road trailer used to transport building panels, or an off-road solution which carries the world’s largest bridge girders, safety is always a key consideration.

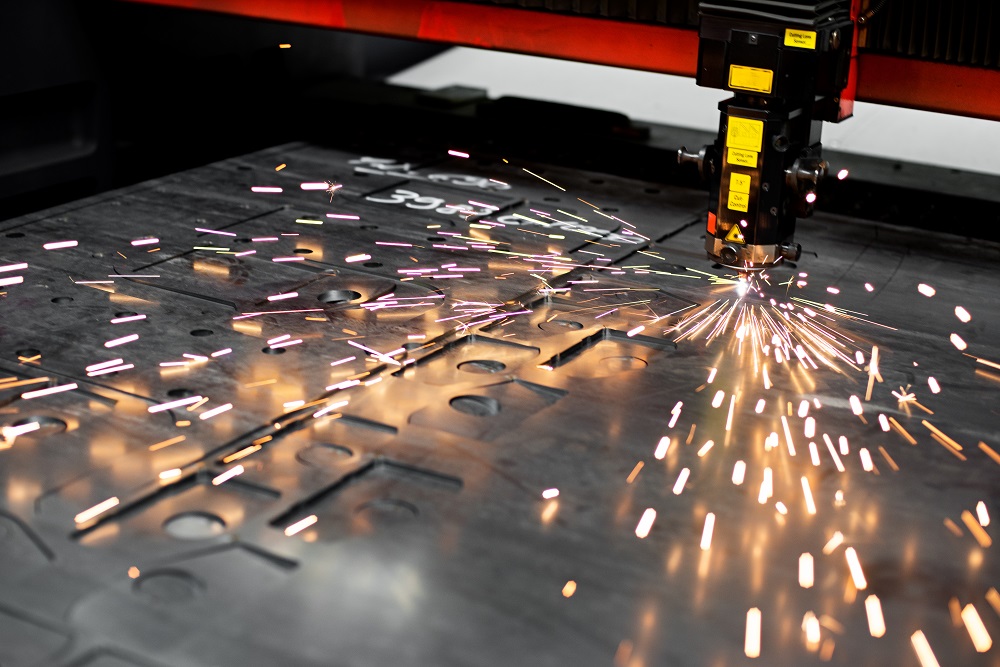

All production steps are carried out in-house

Guy Fickers, technical director for Faymonville, explains: “Our design and manufacturing know-how is Faymonville’s strength and we understand that safety is key. The framework of our trailers must be able to perform in challenging situations, even if it is carrying a payload weighing hundreds of tonnes. That’s why our internal standards go way beyond those of the transport industry in general.”

Faymonville’s business strategy means they create the best solution for heavy transport applications. “For the past 20 years we have focused on ‘flow efficiency’,” says Guy Fickers. “Every trailer starts as a metal sheet and follows a process-oriented production flow. This enables us to tailor the solution in production and end up with a very short throughput time. Depending on the customer’s specifications, a MAX Trailer can be manufactured in two to four weeks.”

The use of high strength steels such as Amstrong® and Amstrong® Ultra from ArcelorMittal enables Faymonville to create trailers which are lighter. This allows the payload of on-road vehicles to be higher. “That’s why we use steels with very high tensile strengths,” explains Guy Fickers. “Around 85 percent of the steel we use has a tensile strength above 690 megapascals (MPa). Another five percent has a tensile strength of 960 MPa.”

The use of high strength steels such as Amstrong® and Amstrong® Ultra from ArcelorMittal enables Faymonville to create trailers which are lighter

Every Faymonville trailer begins its life as a single sheet of high strength steel

Cometto’s off-road, self-propelled modular trailers enable the largest and heaviest loads to be moved easily

Faymonville trailers are used to transport anything tall, long, wide, or heavy – from lock gates to rockets

Faymonville’s on-road trailers have been used to transport some unique cargoes as Guy Fickers explains: “A few years ago we made a trailer to transport trees for the president of a central Asian country. Each tree weighed several hundred tonnes. We’ve also created a trailer which was used to transport a church. Whatever cargo you can imagine, Faymonville has probably made a trailer to move it.”

Copyright images: Faymonville Group, Benoit Mahaux, and Ann Sophie Lindström