ArcelorMittal’s Magnelis® coating – perfect for tubular applications

Magnelis® was developed by ArcelorMittal Europe – Flat Products as a coating for flat steel products and is used in a wide range of applications. Thanks to the combination of zinc, magnesium, and aluminium, Magnelis® forms an almost impenetrable barrier to corrosion which self-heals on cut edges and scratches. Now this remarkable coating is finding new applications in ArcelorMittal’s tubular products.

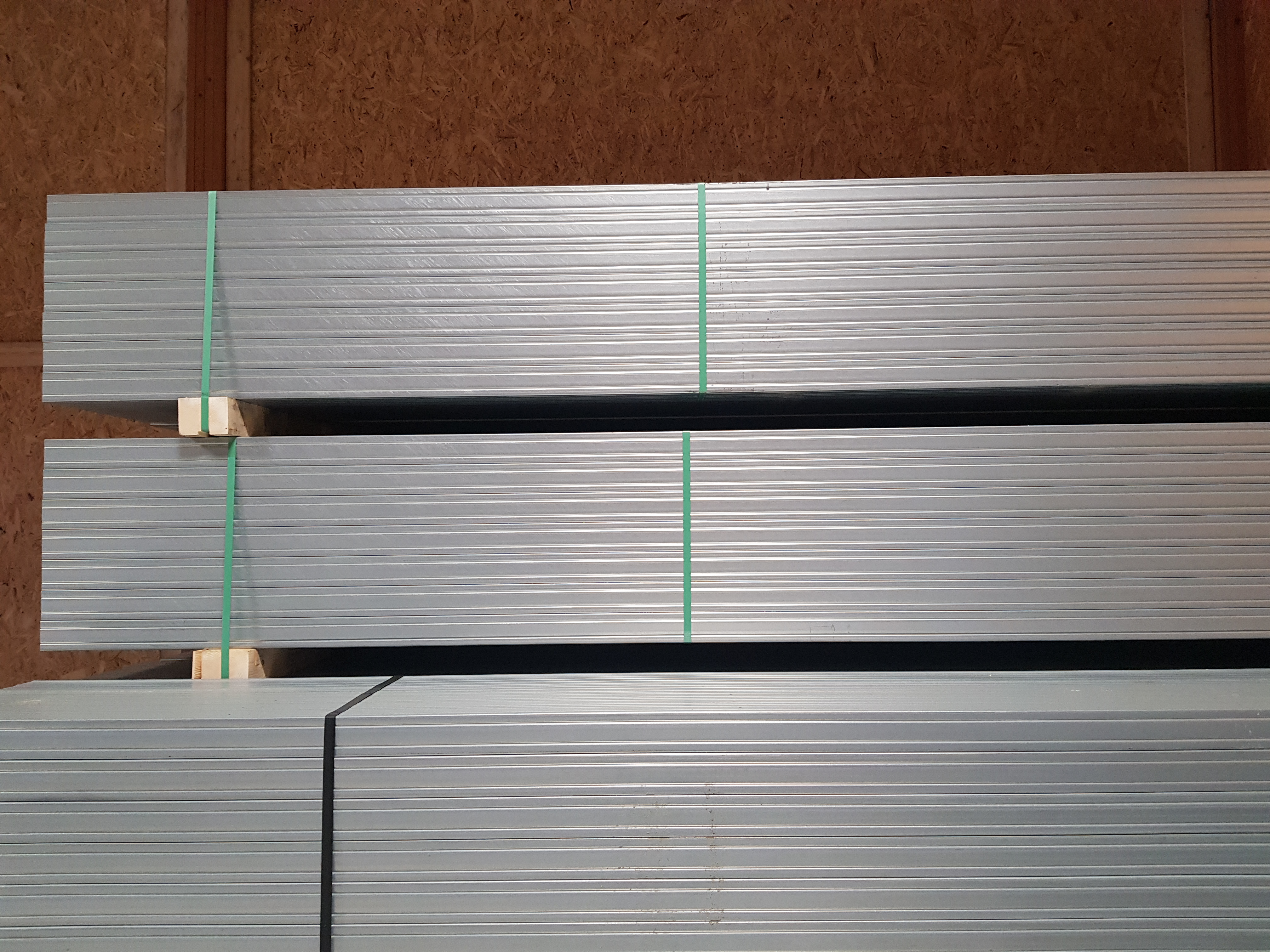

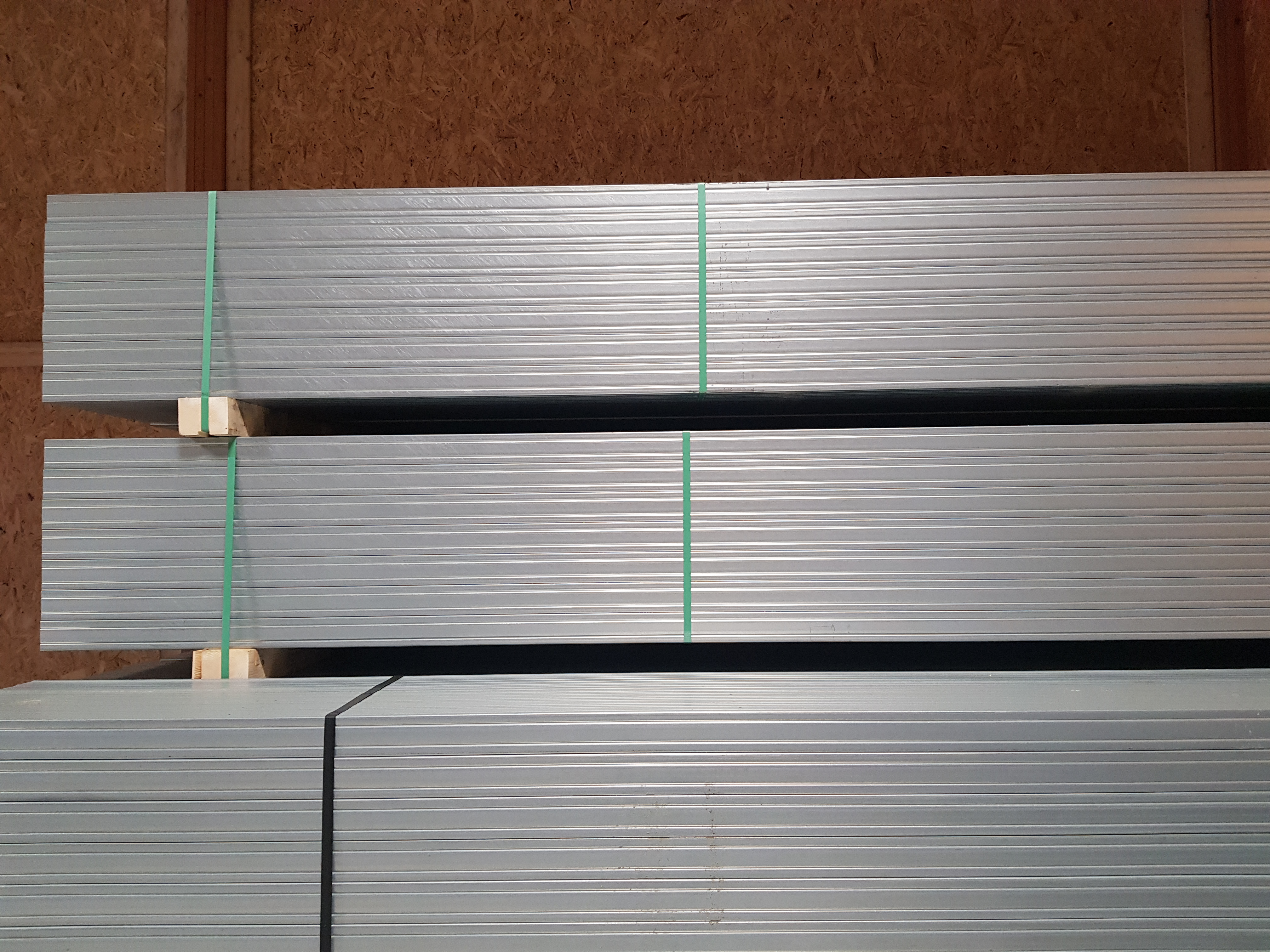

Thanks to its high level of corrosion protection, Magnelis® coated tubes have many applications – particularly in those where post-galvanization is normally specified. The coating helps to extend the life of tubular applications including agricultural spacers, greenhouses, signal poles, solar structures with trackers, and water pipes.

When exposed to the air, Magnelis® forms a very dense zinc-based protective film. The film also forms on edges, welds, perforations, and scratches. It is almost impossible for the environment to penetrate this film. The result is perfect protection of the whole structure.

Simplified process with Magnelis®

Unlike post-galvanisation, Magnelis® is already applied to the substrate when the steel is delivered to the tube manufacturer. “The biggest advantage of Magnelis® is that you can create a product and then cut or drill it, and there is no need for additional corrosion protection thanks to the coating’s self-healing properties,” says Jan-Olof Övergård, CEO of Swedish fencing manufacturer and long-term ArcelorMittal Tubular customer Halsängs Stängsel. “And you don’t need to send the product out to be hot-dip galvanised after forming. This saves at least two trips and further contributes to the reputation of Magnelis® as an environmentally friendly coating.”

“Post galvanisation, particularly of thin gauges, long and straight parts, or high strength steels (HSS) is a difficult process,” says Jérôme Guth from the ArcelorMittal Europe – Flat Products Marketing team. “And it is time-consuming which adds to the customer’s supply chain and costs. By contrast, steels coated with Magnelis® can be formed and assembled without the need for additional corrosion protection. The final product can also be arc welded or post-painted if required.”

“It’s hard to make an argument why Magnelis® should not be specified,” notes Jan-Olof Övergård. “Our customers are demanding more environmentally friendly products and Magnelis® is a perfect fit. It uses less zinc than galvanisation, and the zinc remains on the application – it doesn’t wash off into the soil or drains where it can have a negative impact on the environment. We believe in this product so much that we use the brand name in our own promotional material.”

New era of corrosion protection

“Magnelis® represents a new era of corrosion protection for highly durable tubular applications,” notes Jean-Philippe Haye, chief marketing officer for precision tubes at ArcelorMittal Tubular Products Europe. “Our customers now have access to one of the most advanced coatings on the market today.”

Magnelis® offers far better corrosion resistance than a pure-zinc coating of the same thickness. “Even on deformed steel shapes such as bent tubes, Magnelis® creates a dense layer of protection,” says Jérôme Guth. “When combined with an adequate high frequency weld reprotection process, this gives the tube the same protection as a flat surface.”

It’s also easy to combine flat and tubular products if they share a Magnelis® coating as Jean-Philippe Haye explains: “Photovoltaic (PV) systems are a perfect example of an application which combines tubular and flat steel products. By using Magnelis® to protect both, you are ensuring the overall integrity of the PV system and maximising its lifespan.”

Tubular applications for Magnelis®

More info on Magnelis®: industry.arcelormittal.com/magnelis

About Halsängs Stängsel

Founded in 1971, Halsängs Stängsel manufactures a range of mobile and fixed fencing solutions for almost any application from high security to swimming pools. The company also makes posts, gates, turnstiles, and movable barriers to complete the fencing solution.

More info visit: http://www.halsang.se

copyrigth images: Halsängs Stängsel, VBI, 5³ Architecten