ArcelorMittal RZK Çelik brings Amstrong® Ultra and Relia® grades to Turkey and beyond

ArcelorMittal RZK Çelik Servis Merkezi is one of the most technologically advanced steel service centres in Europe with a range of equipment that can process some of the toughest hot rolled steels on the market. Just three years after the joint venture was formed, the company has managed to capture a sizeable portion of the Turkish market for wear resistant grades such as Amstrong® Ultra and Relia®. And it’s not just down to their state-of-the-art equipment – ArcelorMittal RZK Çelik has a service philosophy to match!

The company is renowned for its customer-centric service philosophy. “We’re the service centre that doesn’t stop until we’re proud of what we do,” notes Igal Zakuto, Deputy CEO of ArcelorMittal RZK Çelik. “Clients are the sole reason we are here so we welcome them effusively, put them at the centre of everything, and make sure they are satisfied. We continue to invest in our state-of-the-art processing equipment and our people to meet those customer needs. After all, we are a success-driven service provider, and if we don’t have the right human capital in place, nothing would be possible.”

Short lead time beats the competition

ArcelorMittal RZK Çelik also offers customers extremely short lead times for ultra high strength steels (UHSS) and wear-resistant grades. “Our competition offers a 10-week lead time, while our lead time can be as little as 24 hours if the material is in stock – and it usually is!” says Igal Zakuto.

Coils are delivered from ArcelorMittal with a Test Report in accordance with EN 10204. As ArcelorMittal RZK Çelik operates an accredited testing laboratory, they can sample the coil and provide a detailed Inspection Certificate which includes the result of their specific investigation. This allows the company to match coils to specific customer projects as Faruk Kartal, sales manager for high added value (HAV) products explains: “Once we know the details of the customer’s project, we can identify which coil has the best processing and bending parameters for that application.”

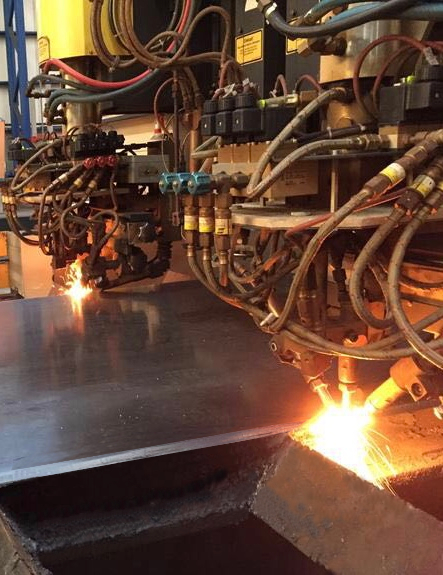

ArcelorMittal RZK Çelik operates some of the most advanced steel processing equipment including the world’s strongest skin passing/temper mill line. That allows it to bend rolls in any direction – even ultra high strength steels (UHSS) in the Amstrong® Ultra range and tough wear-resistant grades from the Relia® family.

Early involvement ensures project success

With its strong focus on service, it’s no surprise that ArcelorMittal RZK Çelik’s customers get the company involved at an early stage of product design. “We start by helping our customers select the correct grade of steel for their specific application,” explains Faruk Kartal. “The exact grade depends on the final application. For example, ArcelorMittal’s Amstrong® Ultra is ideal for crane applications – but there is a range of grades available with strengths ranging from 650 to 1100 megapascal (MPa). Selecting the right one depends on what loads the crane will be required to carry and its reach. Together with the customer we define the right grade every time.”

The ArcelorMittal RZK Çelik team can also help the customer define the correct steel thickness required for each part of the equipment they are making. “By selecting the right thickness, we can reduce the weight of the truck or earthmoving equipment and improve its efficiency,” says Faruk Kartal. “With our experience and modelling tools, we are able to accurately specify the correct thickness for a long life.”

Advanced steels lead to lightweighting

A key advantage of ArcelorMittal’s UHSS and wear resistant grades is their ability to lightweight applications such as cranes, trucks, and earthmoving equipment as Faruk Kartal explains: “Trailer chassis which carry heavy loads normally require a thicker gauge of commodity steel. That reduces the payload of the vehicle. When UHSS grades are used, total steel consumption and the initial weight of the application are reduced while reliability is improved. This ensures payload is maximised, emissions and fuel consumption are reduced, and the lifespan of the application is extended in many cases.”

With its full range of processing equipment, extremely short lead times, and unparalleled customer service attitude, it’s no surprise that the company is quickly capturing market share from its competitors. “There’s an old saying that you can go fast alone, or far together,” says Igal Zakuto. “At ArcelorMittal RZK Çelik, we’re in this business for the long haul.”

Images : ©ArcelorMittal RZK Çelik