In order to offer you the best possible experience, we suggest that you accept the deposit and reading of cookies and the use of technology necessary for their proper functioning:

These steels can be used to manufacture multifunctional and complex parts.

This is a range of cold rolled non-alloyed mild steel grades with guaranteed maximum yield and tensile strength, guaranteed minimum ductility (elongation at fracture) and good formability (n and r values). These grades comply with the requirements of the EN 10130:2006 standard and are obtained after either batch or continuous annealing.

These steel grades have excellent formability, which facilitates cold forming operations, and are ideal for deep drawing.

ArcelorMittal's range of steels for cold forming offer excellent forming performance, due to the low scattering of their chemical composition and their mechanical properties, which guarantees processing consistency.

They are used for bending and deep drawing forming processes for applications where strength, rigidity and ductility are required. Typical applications are to be found in the automotive industry, the domestic appliance sector, metal furniture, drums, radiators, fans, small welded tubes and small profiles. Uncoated cold rolled steels for cold forming are suitable for food contact, under certain conditions laid down in the Regulation (EC) No. 1935/2004 and the French standard NF A 36-714. Please contact us for further information on this subject.

Surface appearance

ArcelorMittal offers two types of surface quality for these grades:

Surface roughness

A wide range of roughness levels according to the EN 10130 standard can be supplied. Unless otherwise specified when ordering, coils will be supplied with standard roughness (0.6 µm < Ra < 1.9 µm).

Surface cleanliness

If improved surface cleanliness is required, ArcelorMittal also offers this range with compulsory use of hydrogen annealing: DCxxxCS AM FCE grades.

ArcelorMittal steels for cold forming (grades DC03 to DC07) have excellent drawability in all types of forming processes. They can be used to manufacture complex, multifunctional parts, and allow significant savings.

Forming limit curves can be used to define the maximum strains not to be exceeded when forming steel by various methods, so as to avoid the risk of incipient necking. These curves are available on request.

Weldability is guaranteed when using the usual processes. Please specify which process you intend to use when ordering.

Fatigue resistance is generally expressed as an endurance limit, corresponding to the maximum stress resisted for a given number of cycles before failure. The table below gives some examples of 5 million cycle endurance limits under fluctuating tension with a stress ratio Rs = 0.1.

| Thickness | 5 million cycle endurance limit (MPa) | |

|---|---|---|

| DC04 AM FCE | 2 mm | 267 |

| DC05 AM FCE | 1.2 mm | 235 |

| DC06 AM FCE | 1 mm | 211 |

A complete database of fatigue resistance data on this range of steels is available on request.

| EN 10130:2006 | CSN | PN-81/H-92121:1981 | PN-87/H-92143:1987 | ASTM | JIS G3141:1996 | EN 10027-2:1992 | Old brand names | |

|---|---|---|---|---|---|---|---|---|

| DC01 EN 10130 | DC01 | 11331 | (B,G) | A 366 CQ | SPCC | 1.0330 | ||

| DC02 AM FCE | ||||||||

| DC03 EN 10130 | DC03 | |||||||

| DC03 AM FCE | DC03 | 11301 | (SB) | A 619 DQ | SPCD | 1.0347 | Solstamp 03 | |

| DC04 EN 10130 | DC04 | |||||||

| DC04 AM FCE | DC04 | 11305 | (SSB) | A 620 DQSK | SPCE | 1.0338 | Solstamp 04 | |

| DC05 EN 10130 | DC05 | (USB) | 1.0312 | Solstamp 05 | ||||

| DC06 EN 10130 | DC06 | 1.0873 | Solstamp 06 | |||||

| DC07 EN 10130 | DC07 | 1.0898 |

Grades in italics: not included in the standard

() Closest grade as no fully equivalent grade exists.

| DC01 EN 10130 | |

|---|---|

| EN 10130:2006 | DC01 |

| CSN | 11331 |

| PN-81/H-92121:1981 | (B,G) |

| PN-87/H-92143:1987 | |

| ASTM | A 366 CQ |

| JIS G3141:1996 | SPCC |

| EN 10027-2:1992 | 1.0330 |

| Old brand names | |

() Closest grade as no fully equivalent grade exists.

| DC02 AM FCE | |

|---|---|

| EN 10130:2006 | |

| CSN | |

| PN-81/H-92121:1981 | |

| PN-87/H-92143:1987 | |

| ASTM | |

| JIS G3141:1996 | |

| EN 10027-2:1992 | |

| Old brand names | |

Grades in italics: not included in the standard

| DC03 EN 10130 | DC03 AM FCE | |

|---|---|---|

| EN 10130:2006 | DC03 | DC03 |

| CSN | 11301 | |

| PN-81/H-92121:1981 | ||

| PN-87/H-92143:1987 | (SB) | |

| ASTM | A 619 DQ | |

| JIS G3141:1996 | SPCD | |

| EN 10027-2:1992 | 1.0347 | |

| Old brand names | Solstamp 03 | |

() Closest grade as no fully equivalent grade exists.

| DC04 EN 10130 | DC04 AM FCE | |

|---|---|---|

| EN 10130:2006 | DC04 | DC04 |

| CSN | 11305 | |

| PN-81/H-92121:1981 | ||

| PN-87/H-92143:1987 | (SSB) | |

| ASTM | A 620 DQSK | |

| JIS G3141:1996 | SPCE | |

| EN 10027-2:1992 | 1.0338 | |

| Old brand names | Solstamp 04 | |

() Closest grade as no fully equivalent grade exists.

| DC05 EN 10130 | |

|---|---|

| EN 10130:2006 | DC05 |

| CSN | |

| PN-81/H-92121:1981 | |

| PN-87/H-92143:1987 | (USB) |

| ASTM | |

| JIS G3141:1996 | |

| EN 10027-2:1992 | 1.0312 |

| Old brand names | Solstamp 05 |

() Closest grade as no fully equivalent grade exists.

| DC06 EN 10130 | |

|---|---|

| EN 10130:2006 | DC06 |

| CSN | |

| PN-81/H-92121:1981 | |

| PN-87/H-92143:1987 | |

| ASTM | |

| JIS G3141:1996 | |

| EN 10027-2:1992 | 1.0873 |

| Old brand names | Solstamp 06 |

| DC07 EN 10130 | |

|---|---|

| EN 10130:2006 | DC07 |

| CSN | |

| PN-81/H-92121:1981 | |

| PN-87/H-92143:1987 | |

| ASTM | |

| JIS G3141:1996 | |

| EN 10027-2:1992 | 1.0898 |

| Old brand names | |

Grades in italics: not included in the standard

() Closest grade as no fully equivalent grade exists.

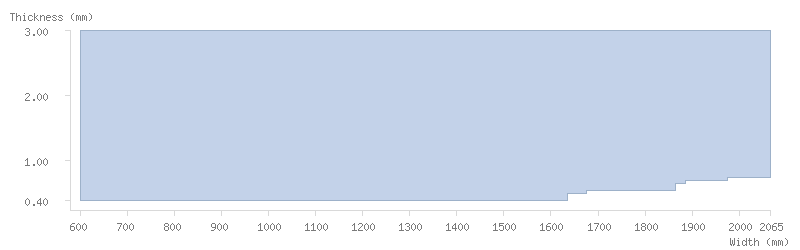

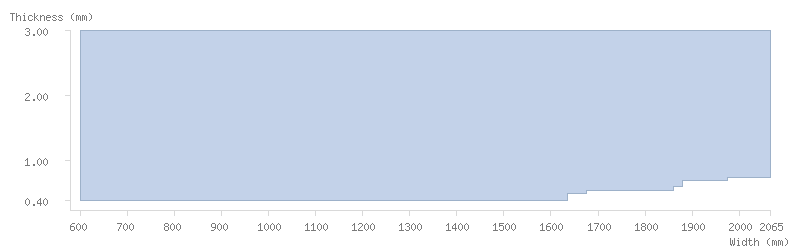

| Thickness (mm) | Min width | DC01 EN 10130, DC02 AM FCE | DC03 EN 10130, DC03 AM FCE, DC04 EN 10130, DC04 AM FCE | DC05 EN 10130 | DC06 EN 10130 | DC07 EN 10130 |

|---|---|---|---|---|---|---|

| Max width | Max width | Max width | Max width | Max width | ||

| 0.40 ≤ th < 0.45 | 600 | 1635 | 1635 | 1635 | 1480 | - |

| 0.45 ≤ th < 0.50 | ||||||

| 0.50 ≤ th < 0.55 | 1675 | 1675 | 1650 | 1590 | 1640 | |

| 0.55 ≤ th < 0.60 | 1865 | 1860 | 1860 | 1640 | 1750 | |

| 0.60 ≤ th < 0.65 | 1880 | 1880 | 1835 | 1865 | ||

| 0.65 ≤ th < 0.70 | 1885 | |||||

| 0.70 ≤ th < 0.75 | 1975 | 1975 | 1975 | 1920 | ||

| 0.75 ≤ th < 0.80 | 2065 | 2065 | 2065 | 2000 | ||

| 0.80 ≤ th < 2.85 | 2065 | |||||

| 2.85 ≤ th < 3.00 |

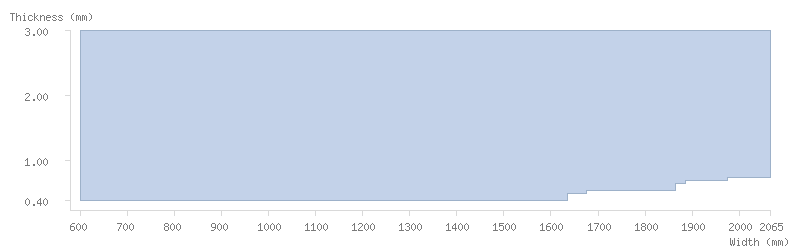

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 0.40 ≤ th < 0.45 | 600 | 1635 |

| 0.45 ≤ th < 0.50 | ||

| 0.50 ≤ th < 0.55 | 1675 | |

| 0.55 ≤ th < 0.60 | 1865 | |

| 0.60 ≤ th < 0.65 | ||

| 0.65 ≤ th < 0.70 | 1885 | |

| 0.70 ≤ th < 0.75 | 1975 | |

| 0.75 ≤ th < 0.80 | 2065 | |

| 0.80 ≤ th < 2.85 | ||

| 2.85 ≤ th < 3.00 |

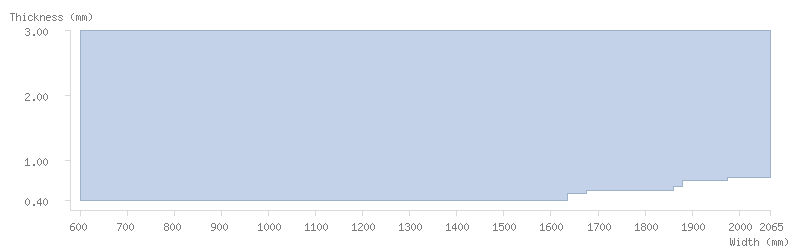

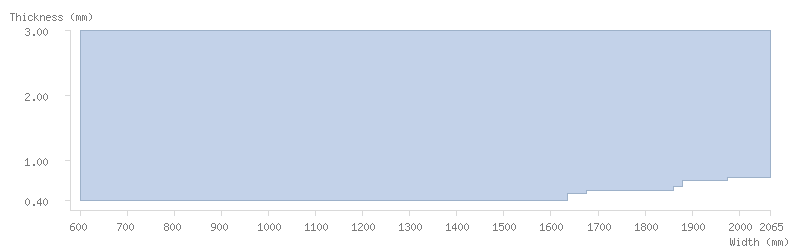

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 0.40 ≤ th < 0.45 | 600 | 1635 |

| 0.45 ≤ th < 0.50 | ||

| 0.50 ≤ th < 0.55 | 1675 | |

| 0.55 ≤ th < 0.60 | 1865 | |

| 0.60 ≤ th < 0.65 | ||

| 0.65 ≤ th < 0.70 | 1885 | |

| 0.70 ≤ th < 0.75 | 1975 | |

| 0.75 ≤ th < 0.80 | 2065 | |

| 0.80 ≤ th < 2.85 | ||

| 2.85 ≤ th < 3.00 |

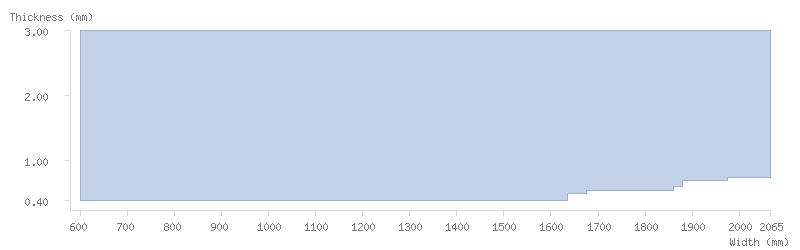

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 0.40 ≤ th < 0.45 | 600 | 1635 |

| 0.45 ≤ th < 0.50 | ||

| 0.50 ≤ th < 0.55 | 1675 | |

| 0.55 ≤ th < 0.60 | 1860 | |

| 0.60 ≤ th < 0.65 | 1880 | |

| 0.65 ≤ th < 0.70 | ||

| 0.70 ≤ th < 0.75 | 1975 | |

| 0.75 ≤ th < 0.80 | 2065 | |

| 0.80 ≤ th < 2.85 | ||

| 2.85 ≤ th < 3.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 0.40 ≤ th < 0.45 | 600 | 1635 |

| 0.45 ≤ th < 0.50 | ||

| 0.50 ≤ th < 0.55 | 1675 | |

| 0.55 ≤ th < 0.60 | 1860 | |

| 0.60 ≤ th < 0.65 | 1880 | |

| 0.65 ≤ th < 0.70 | ||

| 0.70 ≤ th < 0.75 | 1975 | |

| 0.75 ≤ th < 0.80 | 2065 | |

| 0.80 ≤ th < 2.85 | ||

| 2.85 ≤ th < 3.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 0.40 ≤ th < 0.45 | 600 | 1635 |

| 0.45 ≤ th < 0.50 | ||

| 0.50 ≤ th < 0.55 | 1675 | |

| 0.55 ≤ th < 0.60 | 1860 | |

| 0.60 ≤ th < 0.65 | 1880 | |

| 0.65 ≤ th < 0.70 | ||

| 0.70 ≤ th < 0.75 | 1975 | |

| 0.75 ≤ th < 0.80 | 2065 | |

| 0.80 ≤ th < 2.85 | ||

| 2.85 ≤ th < 3.00 |

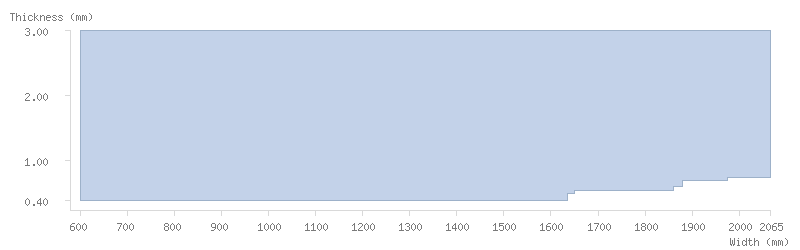

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 0.40 ≤ th < 0.45 | 600 | 1635 |

| 0.45 ≤ th < 0.50 | ||

| 0.50 ≤ th < 0.55 | 1675 | |

| 0.55 ≤ th < 0.60 | 1860 | |

| 0.60 ≤ th < 0.65 | 1880 | |

| 0.65 ≤ th < 0.70 | ||

| 0.70 ≤ th < 0.75 | 1975 | |

| 0.75 ≤ th < 0.80 | 2065 | |

| 0.80 ≤ th < 2.85 | ||

| 2.85 ≤ th < 3.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 0.40 ≤ th < 0.45 | 600 | 1635 |

| 0.45 ≤ th < 0.50 | ||

| 0.50 ≤ th < 0.55 | 1650 | |

| 0.55 ≤ th < 0.60 | 1860 | |

| 0.60 ≤ th < 0.65 | 1880 | |

| 0.65 ≤ th < 0.70 | ||

| 0.70 ≤ th < 0.75 | 1975 | |

| 0.75 ≤ th < 0.80 | 2065 | |

| 0.80 ≤ th < 2.85 | ||

| 2.85 ≤ th < 3.00 |

| Direction | Thickness (mm) | Re (MPa) | Rm (MPa) | A80 (%) | MP guarantees (Months) | r90 | n90 | |

|---|---|---|---|---|---|---|---|---|

| DC01 EN 10130 | T | 0.3 - 0.5 | 140 - 320 | 270 - 410 | ≥ 24 | - | - | - |

| 0.5 - 0.7 | 140 - 300 | ≥ 26 | ||||||

| 0.7 - 3 | 140 - 280 | ≥ 28 | ||||||

| DC02 AM FCE | T | 0.3 - 0.5 | 170 - 320 | 270 - 400 | ≥ 26 | - | - | - |

| 0.5 - 0.7 | 170 - 300 | ≥ 28 | ||||||

| 0.7 - 3 | 170 - 280 | ≥ 30 | ||||||

| DC03 EN 10130 | T | 0.3 - 0.5 | 140 - 280 | 270 - 370 | ≥ 30 | ≥ 6 | - | - |

| 0.5 - 0.7 | 140 - 260 | ≥ 32 | ≥ 1.3 | |||||

| 0.7 - 2 | 140 - 240 | ≥ 34 | ||||||

| 2 - 3 | ≥ 1.1 | |||||||

| DC03 AM FCE | T | 0.3 - 0.5 | 140 - 280 | 280 - 360 | ≥ 30 | ≥ 6 | - | - |

| 0.5 - 0.7 | 140 - 260 | ≥ 32 | ≥ 1.3 | ≥ 0.160 | ||||

| 0.7 - 2 | 180 - 230 | ≥ 34 | ||||||

| 2 - 3 | ≥ 1.1 | |||||||

| DC04 EN 10130 | T | 0.3 - 0.5 | 140 - 250 | 270 - 350 | ≥ 34 | ≥ 6 | - | - |

| 0.5 - 0.7 | 140 - 230 | ≥ 36 | ≥ 1.6 | ≥ 0.180 | ||||

| 0.7 - 2 | 140 - 210 | ≥ 38 | ||||||

| 2 - 3 | ≥ 1.4 | |||||||

| DC04 AM FCE | T | 0.3 - 0.5 | 140 - 250 | 270 - 350 | ≥ 34 | ≥ 6 | - | - |

| 0.5 - 0.7 | 140 - 230 | ≥ 36 | ≥ 1.8 | ≥ 0.190 | ||||

| 0.7 - 2 | 140 - 210 | ≥ 38 | ||||||

| 2 - 3 | ≥ 1.6 | |||||||

| DC05 EN 10130 | T | 0.3 - 0.5 | 140 - 220 | 270 - 330 | ≥ 36 | ≥ 6 | - | - |

| 0.5 - 0.7 | 140 - 200 | ≥ 38 | ≥ 1.9 | ≥ 0.200 | ||||

| 0.7 - 2 | 140 - 180 | ≥ 40 | ||||||

| 2 - 3 | ≥ 1.7 | |||||||

| DC06 EN 10130 | T | 0.3 - 0.5 | 120 - 210 | 270 - 330 | ≥ 37 | ≥ 6 | - | - |

| 0.5 - 0.7 | 120 - 190 | ≥ 39 | ≥ 2.1 | ≥ 0.220 | ||||

| 0.7 - 2 | 120 - 170 | ≥ 41 | ||||||

| 2 - 3 | ≥ 1.9 | |||||||

| DC07 EN 10130 | T | 0.5 - 0.7 | 100 - 170 | 250 - 310 | ≥ 42 | ≥ 6 | ≥ 2.5 | ≥ 0.230 |

| 0.7 - 2 | 100 - 150 | ≥ 44 | ||||||

| 2 - 3 | ≥ 2.3 |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

| Direction | Thickness (mm) | DC01 EN 10130 | |

|---|---|---|---|

| Re (MPa) | T | 0.3 - 0.5 | 140 - 320 |

| 0.5 - 0.7 | 140 - 300 | ||

| 0.7 - 3 | 140 - 280 | ||

| Rm (MPa) | T | 0.3 - 3 | 270 - 410 |

| A80 (%) | T | 0.3 - 0.5 | ≥ 24 |

| 0.5 - 0.7 | ≥ 26 | ||

| 0.7 - 3 | ≥ 28 |

| Direction | Thickness (mm) | DC02 AM FCE | |

|---|---|---|---|

| Re (MPa) | T | 0.3 - 0.5 | 170 - 320 |

| 0.5 - 0.7 | 170 - 300 | ||

| 0.7 - 3 | 170 - 280 | ||

| Rm (MPa) | T | 0.3 - 3 | 270 - 400 |

| A80 (%) | T | 0.3 - 0.5 | ≥ 26 |

| 0.5 - 0.7 | ≥ 28 | ||

| 0.7 - 3 | ≥ 30 |

Grades in italics: not included in the standard

| Direction | Thickness (mm) | DC03 EN 10130 | DC03 AM FCE | |

|---|---|---|---|---|

| Re (MPa) | T | 0.3 - 0.5 | 140 - 280 | 140 - 280 |

| 0.5 - 0.7 | 140 - 260 | 140 - 260 | ||

| 0.7 - 3 | 140 - 240 | 180 - 230 | ||

| Rm (MPa) | T | 0.3 - 3 | 270 - 370 | 280 - 360 |

| A80 (%) | T | 0.3 - 0.5 | ≥ 30 | ≥ 30 |

| 0.5 - 0.7 | ≥ 32 | ≥ 32 | ||

| 0.7 - 3 | ≥ 34 | ≥ 34 | ||

| MP guarantees (Months) | T | 0.3 - 3 | ≥ 6 | ≥ 6 |

| r90 | T | 0.5 - 2 | ≥ 1.3 | ≥ 1.3 |

| 2 - 3 | ≥ 1.1 | ≥ 1.1 | ||

| n90 | T | 0.5 - 3 | - | ≥ 0.160 |

Values in bold: tighter than the standard

| Direction | Thickness (mm) | DC04 EN 10130 | DC04 AM FCE | |

|---|---|---|---|---|

| Re (MPa) | T | 0.3 - 0.5 | 140 - 250 | 140 - 250 |

| 0.5 - 0.7 | 140 - 230 | 140 - 230 | ||

| 0.7 - 3 | 140 - 210 | 140 - 210 | ||

| Rm (MPa) | T | 0.3 - 3 | 270 - 350 | 270 - 350 |

| A80 (%) | T | 0.3 - 0.5 | ≥ 34 | ≥ 34 |

| 0.5 - 0.7 | ≥ 36 | ≥ 36 | ||

| 0.7 - 3 | ≥ 38 | ≥ 38 | ||

| MP guarantees (Months) | T | 0.3 - 3 | ≥ 6 | ≥ 6 |

| r90 | T | 0.5 - 2 | ≥ 1.6 | ≥ 1.8 |

| 2 - 3 | ≥ 1.4 | ≥ 1.6 | ||

| n90 | T | 0.5 - 3 | ≥ 0.180 | ≥ 0.190 |

Values in bold: tighter than the standard

| Direction | Thickness (mm) | DC05 EN 10130 | |

|---|---|---|---|

| Re (MPa) | T | 0.3 - 0.5 | 140 - 220 |

| 0.5 - 0.7 | 140 - 200 | ||

| 0.7 - 3 | 140 - 180 | ||

| Rm (MPa) | T | 0.3 - 3 | 270 - 330 |

| A80 (%) | T | 0.3 - 0.5 | ≥ 36 |

| 0.5 - 0.7 | ≥ 38 | ||

| 0.7 - 3 | ≥ 40 | ||

| MP guarantees (Months) | T | 0.3 - 3 | ≥ 6 |

| r90 | T | 0.5 - 2 | ≥ 1.9 |

| 2 - 3 | ≥ 1.7 | ||

| n90 | T | 0.5 - 3 | ≥ 0.200 |

| Direction | Thickness (mm) | DC06 EN 10130 | |

|---|---|---|---|

| Re (MPa) | T | 0.3 - 0.5 | 120 - 210 |

| 0.5 - 0.7 | 120 - 190 | ||

| 0.7 - 3 | 120 - 170 | ||

| Rm (MPa) | T | 0.3 - 3 | 270 - 330 |

| A80 (%) | T | 0.3 - 0.5 | ≥ 37 |

| 0.5 - 0.7 | ≥ 39 | ||

| 0.7 - 3 | ≥ 41 | ||

| MP guarantees (Months) | T | 0.3 - 3 | ≥ 6 |

| r90 | T | 0.5 - 2 | ≥ 2.1 |

| 2 - 3 | ≥ 1.9 | ||

| n90 | T | 0.5 - 3 | ≥ 0.220 |

| Direction | Thickness (mm) | DC07 EN 10130 | |

|---|---|---|---|

| Re (MPa) | T | 0.5 - 0.7 | 100 - 170 |

| 0.7 - 3 | 100 - 150 | ||

| Rm (MPa) | T | 0.5 - 3 | 250 - 310 |

| A80 (%) | T | 0.5 - 0.7 | ≥ 42 |

| 0.7 - 3 | ≥ 44 | ||

| MP guarantees (Months) | T | 0.5 - 3 | ≥ 6 |

| r90 | T | 0.5 - 2 | ≥ 2.5 |

| 2 - 3 | ≥ 2.3 | ||

| n90 | T | 0.5 - 3 | ≥ 0.230 |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

| C (%) | Mn (%) | P (%) | S (%) | Si (%) | Al (%) | Ti (%) | Galvanisation | |

|---|---|---|---|---|---|---|---|---|

| DC01 EN 10130 | ≤ 0.120 | ≤ 0.60 | ≤ 0.045 | ≤ 0.045 | - | - | - | No |

| DC02 AM FCE | 0.020 - 0.100 | ≤ 0.60 | ≤ 0.025 | ≤ 0.025 | ≤ 0.03 | ≥ 0.020 | - | Class 1 |

| DC03 EN 10130 | ≤ 0.100 | ≤ 0.45 | ≤ 0.035 | ≤ 0.035 | - | - | - | - |

| DC03 AM FCE | ≤ 0.100 | ≤ 0.45 | ≤ 0.025 | ≤ 0.025 | ≤ 0.03 | ≥ 0.020 | - | Class 1 |

| DC04 EN 10130 | ≤ 0.080 | ≤ 0.40 | ≤ 0.030 | ≤ 0.030 | - | - | - | - |

| DC04 AM FCE | ≤ 0.080 | ≤ 0.40 | ≤ 0.025 | ≤ 0.025 | ≤ 0.03 | ≥ 0.020 | - | Class 1 |

| DC05 EN 10130 | ≤ 0.060 | ≤ 0.35 | ≤ 0.025 | ≤ 0.025 | - | - | - | - |

| DC06 EN 10130 | ≤ 0.020 | ≤ 0.25 | ≤ 0.020 | ≤ 0.020 | - | - | ≤ 0.300 | - |

| DC07 EN 10130 | ≤ 0.010 | ≤ 0.20 | ≤ 0.020 | ≤ 0.020 | - | - | ≤ 0.200 | - |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

| DC01 EN 10130 | |

|---|---|

| C (%) | ≤ 0.120 |

| Mn (%) | ≤ 0.60 |

| P (%) | ≤ 0.045 |

| S (%) | ≤ 0.045 |

| Si (%) | - |

| Al (%) | - |

| Ti (%) | - |

| Galvanisation | No |

| DC02 AM FCE | |

|---|---|

| C (%) | 0.020 - 0.100 |

| Mn (%) | ≤ 0.60 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.025 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.020 |

| Ti (%) | - |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

| DC03 EN 10130 | DC03 AM FCE | |

|---|---|---|

| C (%) | ≤ 0.100 | ≤ 0.100 |

| Mn (%) | ≤ 0.45 | ≤ 0.45 |

| P (%) | ≤ 0.035 | ≤ 0.025 |

| S (%) | ≤ 0.035 | ≤ 0.025 |

| Si (%) | - | ≤ 0.03 |

| Al (%) | - | ≥ 0.020 |

| Ti (%) | - | - |

| Galvanisation | - | Class 1 |

Values in bold: tighter than the standard

| DC04 EN 10130 | DC04 AM FCE | |

|---|---|---|

| C (%) | ≤ 0.080 | ≤ 0.080 |

| Mn (%) | ≤ 0.40 | ≤ 0.40 |

| P (%) | ≤ 0.030 | ≤ 0.025 |

| S (%) | ≤ 0.030 | ≤ 0.025 |

| Si (%) | - | ≤ 0.03 |

| Al (%) | - | ≥ 0.020 |

| Ti (%) | - | - |

| Galvanisation | - | Class 1 |

Values in bold: tighter than the standard

| DC05 EN 10130 | |

|---|---|

| C (%) | ≤ 0.060 |

| Mn (%) | ≤ 0.35 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.025 |

| Si (%) | - |

| Al (%) | - |

| Ti (%) | - |

| Galvanisation | - |

| DC06 EN 10130 | |

|---|---|

| C (%) | ≤ 0.020 |

| Mn (%) | ≤ 0.25 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.020 |

| Si (%) | - |

| Al (%) | - |

| Ti (%) | ≤ 0.300 |

| Galvanisation | - |

| DC07 EN 10130 | |

|---|---|

| C (%) | ≤ 0.010 |

| Mn (%) | ≤ 0.20 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.020 |

| Si (%) | - |

| Al (%) | - |

| Ti (%) | ≤ 0.200 |

| Galvanisation | - |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

Any questions?

Ask them via our contact form on

https://industry.arcelormittal.com/getintouch

All details provided in the ArcelorMittal Flat Carbon Europe S.A. catalogue are for information purposes only. ArcelorMittal Flat Carbon Europe S.A. reserves the right to change its product range at any time without prior notice.

Download

Download