ArcelorMittal Europe quarto plate offer now available with XCarb®

ArcelorMittal Europe – Flat Products has enhanced our offer of low carbon-emissions steel plate. In addition to XCarb® green steel certificates, XCarb® recycled and renewably produced heavy plates are now available. Produced from slabs made in an electric arc furnace (EAF) using almost 100-percent scrap and 100-percent renewable electricity, ArcelorMittal’s XCarb® recycled and renewably produced heavy plates have with a 65-percent lower carbon footprint than heavy plates made via the conventional blast furnace route. ArcelorMittal is also the first steelmaker in Europe that can offer low-carbon emissions steel plate with a unit weight of up to 18 tonnes.

Heavy plate has a wide range of applications in markets such as wind energy, shipbuilding, bridges and civil engineering, pressure vessels, and line pipe for the transportation of energy such as hydrogen and oil and gas. Using XCarb® green steel certificates or recycled and renewably produced steel plate in these applications enables ArcelorMittal’s customers to significantly reduce their Scope 3 (supply chain) emissions.

“We are immensely proud that we can now provide heavy plate with with a 65-percent lower carbon footprint than the same product made via the conventional steelmaking route,” notes Denis Parein, Commercial Head of Heavy Plate for ArcelorMittal Europe – Flat Products. “As well as meeting growing customer demand, it also addresses the legitimate concerns of local authorities and end users who want to significantly reduce the carbon footprint of projects related to the energy transition and construction.”

To further enhance the sustainability credentials of our XCarb® recycled and renewably produced heavy plate, ArcelorMittal has prepared an Environmental Product Declaration (EPD). “The EPD was published by an independent third-party accreditation organisation, and it meets the EN 15804 European standard”, says Denis Parein.

XCarb® green steel certificates reduce Scope 3 emissions

ArcelorMittal can also supply heavy plate with XCarb® green steel certificates. The certificates enable customers to benefit from CO2 reductions realised by ArcelorMittal, but which are not necessarily connected to the steel production site. XCarb® green steel certificates enable customers to reduce their Scope 3 emissions in line with the Greenhouse Gas Reporting protocol.

“The CO2 savings, and corresponding volume of XCarb® green steel certificates, are assured by DNV, an independent expert in verification and assurance,” explains Denis Parein. “The certificates can be redeemed by ArcelorMittal’s direct customer, or the end customer for the product.”

Several customers active in the civil engineering and wind sectors have already ordered heavy plates with XCarb® green steel certificates. “This is part of a growing interest in reliable decarbonisation solutions by industrial customers,” notes Denis Parein. “Often this is in response to the specific targets of their end customers.”

Dimensional feasibility and support

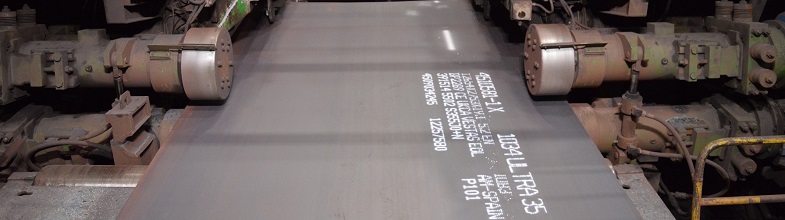

In addition to its low carbon footprint, ArcelorMittal has also enhanced the dimensional feasibility of our heavy plate offer. Denis Parein explains: “We already offer plates in widths up to 3300 mm and lengths from 4 to 21 metres. Following investments at our plate mill at Gijon (Spain), we will increase the maximum length of our plate to 25 metres from the third quarter of 2023. The investments have addressed the needs of our customers who require very long plates which are typically used in the latest offshore wind structures and demanding civil engineering projects.”

More info

ArcelorMittal heavy plate offers best dimensional feasibility

ArcelorMittal Europe’s heavy plate offer is available in a wide range of dimensions. We can offer:

|

Thickness:

|

6 to 150 mm for heavy plates

Up to 365 mm for slabs

|

|

Width:

|

Up to 3300 mm

|

|

Length:

|

From 4 to 25 metres

|

|

Plate weight:

|

Up to 18 tonnes

|

|

Finishing:

|

Shotblasting and painting

Cutting and bevelling

|