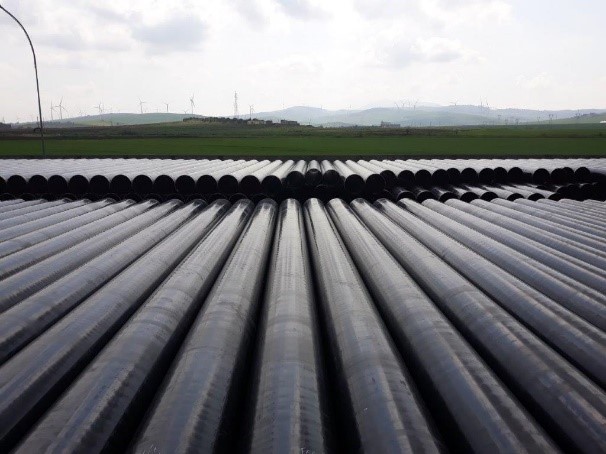

Corinth Pipeworks (CPW) has delivered the first pipes for a 440 kilometre, high-pressure pipeline network across Italy. The pipeline has been designed to transport hydrogen at concentrations up to 100 percent.

The CPW pipes are made from ArcelorMittal’s L415ME steel grade and have been certified against the requirements of the ASME B31.12 Option B standard. The steel for the pipes was produced by ArcelorMittal Europe – Flat Products at its mills in Fos-sur-Mer (France) and Bremen (Germany).

Finished pipes have an outside diameter of 26 inches (660 mm) and thicknesses of 11.1 and 15.9 mm. To meet these specifications, ArcelorMittal produced extra-wide 2,100 mm coils. After forming by CPW, the pipes were laboratory tested at maximum pressure and 100 percent hydrogen.

Green hydrogen is critical to Europe’s efforts to create a carbon-neutral circular economy

The availability of hydrogen made using renewable energy (known as green hydrogen) – and its transport – are integral to European efforts to create a carbon-neutral circular economy. “While steel is the best material available to transport hydrogen, a key challenge is the effect that the gas has on the metal,” explains Frederic Bouchaud, ArcelorMittal account manager for oil and gas pipelines. “For this project we have created a robust new steel which will resist embrittlement and transport hydrogen gas safely throughout Europe. The result is a very wide, high-quality steel with low carbon content, excellent cleanliness, a homogenous microstructure, and low levels of sulfur and phosphorous.”

“We are very excited to be an innovative producer and early adopter, providing certified, large-diameter/high strength steel pipes for hydrogen transportation through a high-pressure network,” notes Ilias Bekiros, CEO of Corinth Pipeworks. “The potential of hydrogen to build a sustainable energy mix in the future and achieve global decarbonisation targets is significant. Corinth Pipeworks aims to be an integral part in providing solutions to its customers to reach their goals.”

ArcelorMittal has also launched an R&D project with the OCAS research centre in Gent (Belgium) to define new grades of steel for pipelines used in hydrogen transport. Tests are being carried out with Corinth Pipeworks to ensure the new grades will work in the field. Results are expected to be announced before the end of 2021.

ArcelorMittal Europe has a target to reduce carbon emissions by 30 percent by 2030 and a longer-term goal to be carbon-neutral by 2050. The wide availability of green hydrogen, at a competitive price, is key to ensuring carbon neutrality in steelmaking.

CPW media release on the first hydrogen-certified pipeline for Snam

ArcelorMittal’s L415ME steel was used by CPW to manufacture the hydrogen pipes for Snam

Snam is one of the world’s leading energy infrastructure companies and one of Italy’s largest listed companies by market capitalisation. The company operates through subsidiaries around the world and operates an energy transport network that is more than 41,000 km in length. The company is committed to the transition to cleaner energy and has made investments in biomethane, energy efficiency, sustainable mobility, and hydrogen. Snam has set itself the goal of achieving carbon neutrality (Scope 1 and Scope 2) by 2040.

More info: www.snam.it

Copyright pictures: Corinth Pipeworks