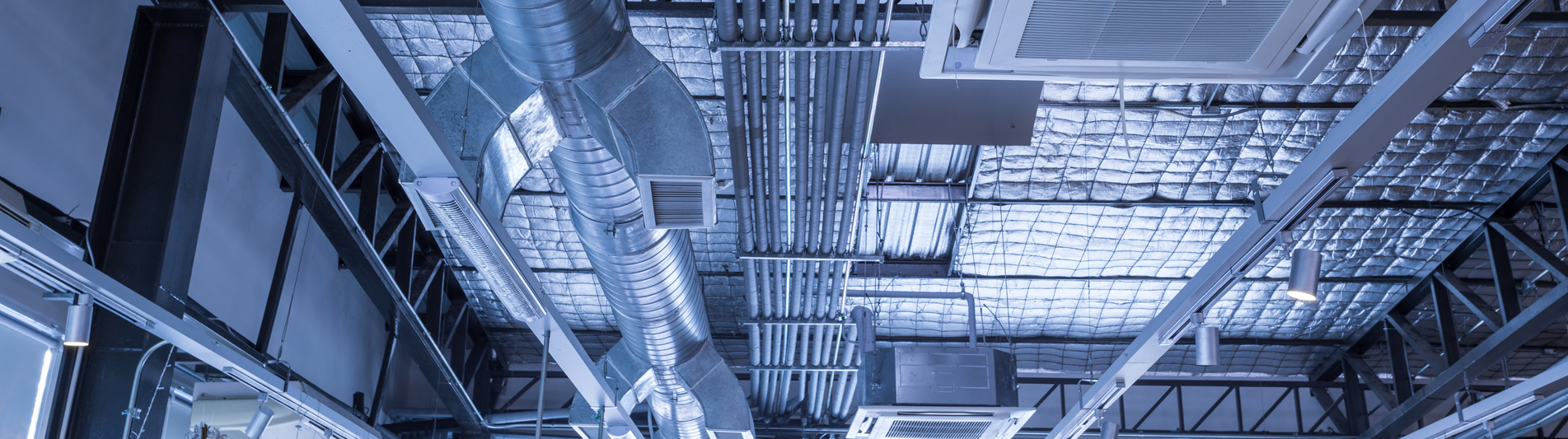

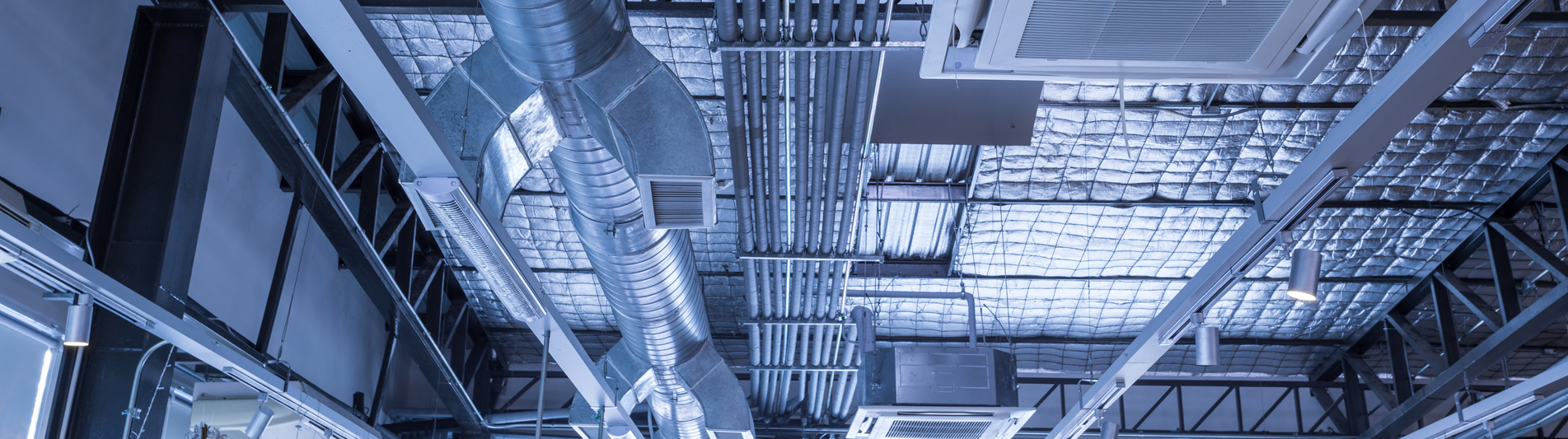

Aware of the HVAC industry's challenges, ArcelorMittal provides you several products meeting the HVAC equipment needs: fighting corrosion, aesthetic features, weight reduction, strength and heat protection.

Magnelis®: for corrosion resistant HVAC equipment

ArcelorMittal provides you an exceptional steel coating which provides breakthrough corrosion protection: Magnelis®

Magnelis® is produced on a classic hot dip galvanising line which molten bath has a unique chemical composition including Zinc, 3.5% Aluminium, and 3% Magnesium.

HVAC equipment can be at risk of oxidation due to condensation or extreme environments. This makes durability a key consideration when selecting materials for HVAC systems. As a durable coating with excellent corrosion resistance properties, Magnelis® is ideally suited for HVAC applications.

Steels coated with Magnelis® are highly suitable for heating, ventilation, and air conditioning (HVAC) equipment in many types of building including: residential, commercial, industrial, data centres, hospitals, marine structures, warehouses, waste treatment centres, swimming pools and sports centres, and agricultural buildings and animal housing.

Advantages of using Magnelis® for HVAC equipment

Apply Magnelis® to your HVAC components

Thanks to the innovative composition of Magnelis® and its compatibility with high strength steels, the coating is an ideal solution for durable casings, frames, structures, ducts, ventilators, blades, supports, containers, air handling units and ventilation grills in HVAC systems.

Alusi®: for corrosion and fire-resistant HVAC equipment

Alusi® is a metallic-coated steel covered on both sides by an aluminium (90%) and silicon (10%) coating. If the temperature of the heating system will exceed 200°C, ArcelorMittal recommends using Alusi®.

Alusi® offers

Get more information about Alusi®

Granite®: prepainted corrosion resistant steels for outdoor HVAC equipment

Granite® enables HVAC manufacturers to differentiate themselves thanks to its wide range of colours and shades and different textures.

Granite® is recommended for insulated panels.

Estetic®: prepainted corrosion resistant steels for indoor HVAC equipment

Estetic® is free of chromates and heavy metals and adds visual impact, texture, colour and elegance while ensuring robustness and durability performance to indoor HVAC equipment such as air conditioners and air curtains.

Estetic® is recommended for insulated panels.

Jetskin®: for corrosion resistant indoor HVAC equipment

Jetskin® is a metallic coating for steel which is applied using Jet Vapor Deposition (JVD). Jetskin® provides a homogeneous coating on one or both sides of the steel. It offers excellent corrosion protection particularly for indoor applications such as air conditioners and air curtains. Jetskin® behaves better than conventional electrogalvanised steel when it comes to resistance spot welding.

Check out our video and leaflet on Jetskin®