F20 - Estetic® organic coated steels for indoor building and general industry

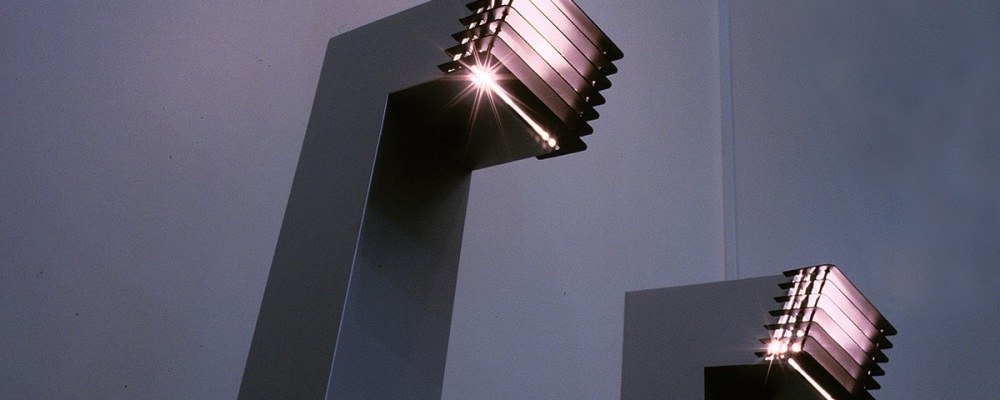

This range of products is suitable for all contemporary interior decoration: ceiling panels, room dividers, decorative walls and lights, as well as for metal furniture, air conditioning units etc.

Download

Download

Available products:

Properties

The ArcelorMittal Estetic® range of organic coated steels covers all possible applications for indoor building and general industry.

The range comprises conventional organic coated steels produced by applying liquid paint to a substrate by means of a continuous process. The coatings used in the Estetic® range are based on thermosetting resins. One product in this range is a colaminated steel with an inert film.

Advantages

Specifically developed for interior building/general industry applications, this product range meets all requirements in terms of aesthetic quality (appearance and gloss) and properties such as flexibility, surface hardness, coating adhesion, corrosion resistance etc. Several products in the Estetic® range have been developed to meet the requirements of the W.E.E.E. and R.o.H.S. European directives. The composition of the various organic paint layers also complies with the requirements of these directives.

Organic coated steel products are a better alternative to post-painted finished products. The process is environmentally friendly, economical and guarantees a consistent product quality.

Applications

The table below shows the whole Estetic® range as well as its main applications.

| Name |

Main properties |

Surface appearance |

Gloss |

Applications |

| Estetic® Access |

Economical |

Smooth |

30 GU |

Inner surface of sandwich panels, metal furniture, indoor use |

| Estetic® Standard |

Good compromise flexibility/surface hardness |

Indoor use: shelves, radiators, casings |

| Estetic® Flex |

Flexibility: very good formability |

Smooth, grained |

30 - 80 GU |

Water heater casings and other casings, deep drawn components etc |

| Estetic® Tex |

Surface hardness, very good abrasion resistance |

Textured |

30 - 50 GU |

Metal furniture, shelves, radiators, air conditioning units, casings etc |

| Estetic® Mat |

Flexibility, matt appearance |

Smooth, wrinkled |

Usual: 15 GU, possible: 5 - 20 GU, ≤ 5 GU for wrinkled surfaces |

Metal ceilings (capping, perforated panels, accessories), indoor panels |

| Estetic® Lighting 82 |

Very high reflectance |

Smooth |

50 - 90 GU |

Lighting |

| Estetic® Clean |

Resistant to aggressive and very wet environments. Inert to chemicals, highly resistant to stains, cleaning products and disinfectants |

17 GU |

Panels for cold rooms (ceilings, wall partitions, doors etc), food stores |

| Estetic® Wipe Board |

High-gloss finish. Wipeability after marking with dry marker pens |

80 - 90 GU |

Wipe boards |

Standards

Estetic® products are in compliance with standard EN 10169.

Estetic® Lighting 82 is compliant with the R.o.H.S. directive.

Technical properties

The technical properties of these Estetic® products depend on the chemical composition and thickness of the coating. The choice of the paint system depends on the end use.

The substrates used for these applications are galvanised steel or Optigal® (Zn-Al-Mg).

For more information on the available metallic substrates and the technical properties of the different products, please consult the technical data sheets.

Please contact us for advice on the choice of the most suitable grade.

A temporary removable protective film can be applied on the top side, depending on the type of coating. Please contact us for further information.

Food contact

For information on food contact, please contact us.

Recommendations for use

Estetic® products can be processed by cold forming and deep drawing without damaging the top surface. They can be joined using techniques such as clinching, riveting and adhesive bonding.

Mechanical properties

Estetic® products are available with a wide range of mechanical properties, depending on the substrate used and the intended application. See properties of the different substrates.

Dimensions

| Thickness (mm) |

Min width |

Estetic® Access |

Estetic® Standard, Estetic® Flex, Estetic® Mat |

Estetic® Tex, Estetic® Lighting 82 |

Estetic® Clean |

Estetic® Wipe Board |

| Max width |

Max width |

Max width |

Max width |

Max width |

| 0.28 ≤ th < 0.30 |

600 |

1800 |

1800 |

- |

- |

- |

| 0.30 ≤ th < 0.38 |

1800 |

| 0.38 ≤ th < 0.40 |

1500 |

| 0.40 ≤ th < 2.00 |

1520 |

| 2.00 ≤ th < 2.75 |

- |

| 2.75 ≤ th < 3.00 |

- |

Not all thickness/width combinations are available. Please contact us for further information.

Coating properties

All details provided in the ArcelorMittal Flat Carbon Europe S.A. catalogue are for information purposes only. ArcelorMittal Flat Carbon Europe S.A. reserves the right to change its product range at any time without prior notice.

For more information on our products, visit the document centre.