D52 - Hot rolled pole sheet grades

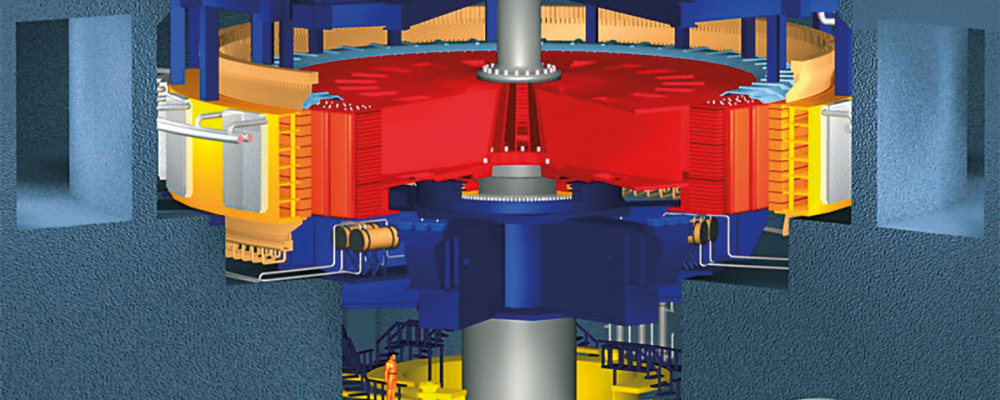

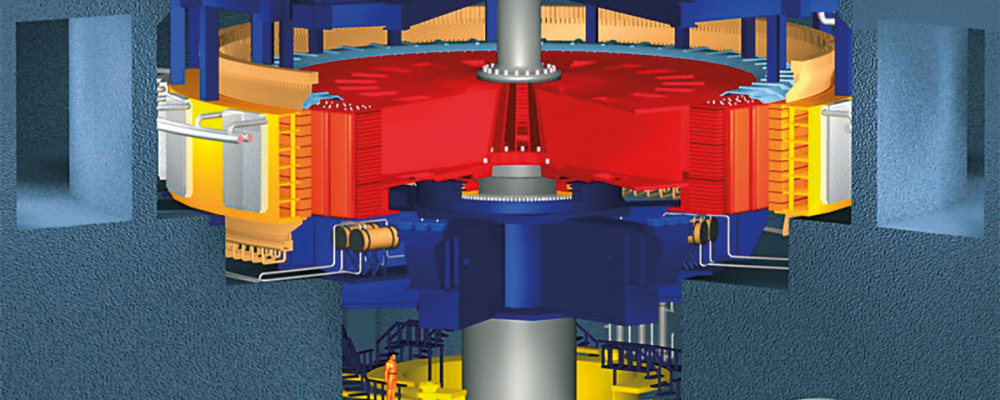

High yield strength values allow these grades to withstand strong centrifugal and electromechanical forces, both in static and dynamic conditions, which is indispensable for hydroelectric power stations, as illustrated here.

Download

Download

Available grades:

Properties

Hot rolled pole sheet grades are classified according to their yield strength (EN 10265:1995). As well as guaranteed mechanical properties, they have guaranteed magnetic properties, but unlike other electrical steel grades, their magnetic characterisation is determined under direct current (DC) conditions.

Advantages

High yield strength values allow these grades to withstand strong centrifugal and electromechanical forces, both in static and dynamic conditions. The DC magnetic properties are excellent and significantly superior to the requirements of the standard.

For the hot rolled pole sheets with yield strength guarantee up to 400 MPa the flatness guarantee is maintained after laser cutting of the laminations.

For the hot rolled pole sheets with yield strength guarantee beyond 400 MPa the flatness remains excellent, even after laser cutting of the laminations.

Applications

Hot rolled pole sheet grades can be supplied in the form of coils or sheets.

Hot rolled pole sheet grades are designed for large high-speed machines because of their excellent combination of mechanical strength and good magnetic performance. Good magnetic properties are of major importance for the performance of the poles, whereas excellent mechanical properties are needed for the rims.

Recommendations for use

The above properties are obtained without heat treatment, whatever be the mechanical or thermal cutting process used to obtain the desired lamination diameter. The material as supplied possesses all the required magnetic properties.

Brand correspondence

Full table

| |

EN 10265:1995 |

IEC/CEI 60404-8-5:1989 |

Old brand names |

| 250-150-TG 180 |

250-150-TG 180 |

250-150-TG 180 |

Usinalter 250 |

| 250-200-TG 180 |

250-200-TG 180 |

250-200-TG 180 |

Usinalter 250 |

| 250-300-TG 180 |

250-300-TG 180 |

250-300-TG 180 |

Usinalter 250 |

| 250-400-TG 180 |

250-400-TG 180 |

250-400-TG 180 |

Usinalter 250 |

| 250-500-TG 180 |

250-500-TG 180 |

250-500-TG 180 |

Usinalter 250 |

| 300-150-TG 180 |

300-150-TG 180 |

300-150-TG 180 |

Usinalter 300 |

| 300-200-TG 180 |

300-200-TG 180 |

300-200-TG 180 |

Usinalter 300 |

| 300-300-TG 180 |

300-300-TG 180 |

300-300-TG 180 |

Usinalter 300 |

| 300-400-TG 180 |

300-400-TG 180 |

300-400-TG 180 |

Usinalter 300 |

| 300-500-TG 180 |

300-500-TG 180 |

300-500-TG 180 |

Usinalter 300 |

| 350-150-TG 179 |

350-150-TG 179 |

350-150-TG 179 |

Usinalter 350 |

| 350-200-TG 179 |

350-200-TG 179 |

350-200-TG 179 |

Usinalter 350 |

| 350-250-TG 179 |

350-250-TG 179 |

350-250-TG 179 |

Usinalter 350 |

| 350-300-TG 179 |

350-300-TG 179 |

350-300-TG 179 |

Usinalter 350 |

| 350-400-TG 179 |

350-400-TG 179 |

350-400-TG 179 |

Usinalter 350 |

| 350-500-TG 179 |

350-500-TG 179 |

350-500-TG 179 |

Usinalter 350 |

| 400-180-TG 179 |

400-180-TG 179 |

400-180-TG 179 |

Usinalter 400 |

| 400-200-TG 179 |

400-200-TG 179 |

400-200-TG 179 |

Usinalter 400 |

| 400-240-TG 179 |

400-240-TG 179 |

400-240-TG 179 |

Usinalter 400 |

| 400-300-TG 179 |

400-300-TG 179 |

400-300-TG 179 |

Usinalter 400 |

| 400-400-TG 179 |

400-400-TG 179 |

400-400-TG 179 |

Usinalter 400 |

| 400-500-TG 179 |

400-500-TG 179 |

400-500-TG 179 |

Usinalter 400 |

| 450-180-TG 179 * |

450-180-TG 179 |

450-180-TG 179 |

Usinalter 450 |

| 450-200-TG 179 * |

450-200-TG 179 |

450-200-TG 179 |

Usinalter 450 |

| 450-300-TG 179 * |

450-300-TG 179 |

450-300-TG 179 |

Usinalter 450 |

| 450-400-TG 179 * |

450-400-TG 179 |

450-400-TG 179 |

Usinalter 450 |

| 450-500-TG 179 * |

450-500-TG 179 |

450-500-TG 179 |

Usinalter 450 |

| 500-200-TG 179 * |

500-200-TG 179 |

500-200-TG 179 |

Usinalter 500 |

| 500-300-TG 179 * |

500-300-TG 179 |

500-300-TG 179 |

Usinalter 500 |

| 500-400-TG 179 * |

500-400-TG 179 |

500-400-TG 179 |

Usinalter 500 |

| 500-500-TG 179 * |

500-500-TG 179 |

500-500-TG 179 |

Usinalter 500 |

| 550-200-TG 178 * |

550-200-TG 178 |

550-200-TG 178 |

Usinalter 550 |

| 550-220-TG 178 * |

550-220-TG 178 |

550-220-TG 178 |

Usinalter 550 |

| 550-250-TG 178 * |

550-250-TG 178 |

550-250-TG 178 |

Usinalter 550 |

| 550-300-TG 178 * |

550-300-TG 178 |

550-300-TG 178 |

Usinalter 550 |

| 550-400-TG 178 * |

550-400-TG 178 |

550-400-TG 178 |

Usinalter 550 |

| 550-500-TG 178 * |

550-500-TG 178 |

550-500-TG 178 |

Usinalter 550 |

| 600-200-TG 178 * |

600-200-TG 178 |

600-200-TG 178 |

Usinalter 600 |

| 600-250-TG 178 * |

600-250-TG 178 |

600-250-TG 178 |

Usinalter 600 |

| 600-300-TG 178 * |

600-300-TG 178 |

600-300-TG 178 |

Usinalter 600 |

| 600-400-TG 178 * |

600-400-TG 178 |

600-400-TG 178 |

Usinalter 600 |

| 600-500-TG 178 * |

600-500-TG 178 |

600-500-TG 178 |

Usinalter 600 |

| 650-200-TG 178 * |

650-200-TG 178 |

650-200-TG 178 |

Usinalter 650 |

| 650-250-TG 178 * |

650-250-TG 178 |

650-250-TG 178 |

Usinalter 650 |

| 650-300-TG 178 * |

650-300-TG 178 |

650-300-TG 178 |

Usinalter 650 |

| 650-400-TG 178 * |

650-400-TG 178 |

650-400-TG 178 |

Usinalter 650 |

| 650-500-TG 178 * |

650-500-TG 178 |

650-500-TG 178 |

Usinalter 650 |

| 700-200-TG 178 * |

700-200-TG 178 |

700-200-TG 178 |

Usinalter 700 |

| 700-250-TG 178 * |

700-250-TG 178 |

700-250-TG 178 |

Usinalter 700 |

| 700-300-TG 178 * |

700-300-TG 178 |

700-300-TG 178 |

Usinalter 700 |

| 700-400-TG 178 * |

700-400-TG 178 |

700-400-TG 178 |

Usinalter 700 |

| 700-500-TG 178 * |

700-500-TG 178 |

700-500-TG 178 |

Usinalter 700 |

250-150-TG 180

| |

250-150-TG 180 |

| EN 10265:1995 |

250-150-TG 180 |

| IEC/CEI 60404-8-5:1989 |

250-150-TG 180 |

| Old brand names |

Usinalter 250 |

250-200-TG 180

| |

250-200-TG 180 |

| EN 10265:1995 |

250-200-TG 180 |

| IEC/CEI 60404-8-5:1989 |

250-200-TG 180 |

| Old brand names |

Usinalter 250 |

250-300-TG 180

| |

250-300-TG 180 |

| EN 10265:1995 |

250-300-TG 180 |

| IEC/CEI 60404-8-5:1989 |

250-300-TG 180 |

| Old brand names |

Usinalter 250 |

250-400-TG 180

| |

250-400-TG 180 |

| EN 10265:1995 |

250-400-TG 180 |

| IEC/CEI 60404-8-5:1989 |

250-400-TG 180 |

| Old brand names |

Usinalter 250 |

250-500-TG 180

| |

250-500-TG 180 |

| EN 10265:1995 |

250-500-TG 180 |

| IEC/CEI 60404-8-5:1989 |

250-500-TG 180 |

| Old brand names |

Usinalter 250 |

300-150-TG 180

| |

300-150-TG 180 |

| EN 10265:1995 |

300-150-TG 180 |

| IEC/CEI 60404-8-5:1989 |

300-150-TG 180 |

| Old brand names |

Usinalter 300 |

300-200-TG 180

| |

300-200-TG 180 |

| EN 10265:1995 |

300-200-TG 180 |

| IEC/CEI 60404-8-5:1989 |

300-200-TG 180 |

| Old brand names |

Usinalter 300 |

300-300-TG 180

| |

300-300-TG 180 |

| EN 10265:1995 |

300-300-TG 180 |

| IEC/CEI 60404-8-5:1989 |

300-300-TG 180 |

| Old brand names |

Usinalter 300 |

300-400-TG 180

| |

300-400-TG 180 |

| EN 10265:1995 |

300-400-TG 180 |

| IEC/CEI 60404-8-5:1989 |

300-400-TG 180 |

| Old brand names |

Usinalter 300 |

300-500-TG 180

| |

300-500-TG 180 |

| EN 10265:1995 |

300-500-TG 180 |

| IEC/CEI 60404-8-5:1989 |

300-500-TG 180 |

| Old brand names |

Usinalter 300 |

350-150-TG 179

| |

350-150-TG 179 |

| EN 10265:1995 |

350-150-TG 179 |

| IEC/CEI 60404-8-5:1989 |

350-150-TG 179 |

| Old brand names |

Usinalter 350 |

350-200-TG 179

| |

350-200-TG 179 |

| EN 10265:1995 |

350-200-TG 179 |

| IEC/CEI 60404-8-5:1989 |

350-200-TG 179 |

| Old brand names |

Usinalter 350 |

350-250-TG 179

| |

350-250-TG 179 |

| EN 10265:1995 |

350-250-TG 179 |

| IEC/CEI 60404-8-5:1989 |

350-250-TG 179 |

| Old brand names |

Usinalter 350 |

350-300-TG 179

| |

350-300-TG 179 |

| EN 10265:1995 |

350-300-TG 179 |

| IEC/CEI 60404-8-5:1989 |

350-300-TG 179 |

| Old brand names |

Usinalter 350 |

350-400-TG 179

| |

350-400-TG 179 |

| EN 10265:1995 |

350-400-TG 179 |

| IEC/CEI 60404-8-5:1989 |

350-400-TG 179 |

| Old brand names |

Usinalter 350 |

350-500-TG 179

| |

350-500-TG 179 |

| EN 10265:1995 |

350-500-TG 179 |

| IEC/CEI 60404-8-5:1989 |

350-500-TG 179 |

| Old brand names |

Usinalter 350 |

400-180-TG 179

| |

400-180-TG 179 |

| EN 10265:1995 |

400-180-TG 179 |

| IEC/CEI 60404-8-5:1989 |

400-180-TG 179 |

| Old brand names |

Usinalter 400 |

400-200-TG 179

| |

400-200-TG 179 |

| EN 10265:1995 |

400-200-TG 179 |

| IEC/CEI 60404-8-5:1989 |

400-200-TG 179 |

| Old brand names |

Usinalter 400 |

400-240-TG 179

| |

400-240-TG 179 |

| EN 10265:1995 |

400-240-TG 179 |

| IEC/CEI 60404-8-5:1989 |

400-240-TG 179 |

| Old brand names |

Usinalter 400 |

400-300-TG 179

| |

400-300-TG 179 |

| EN 10265:1995 |

400-300-TG 179 |

| IEC/CEI 60404-8-5:1989 |

400-300-TG 179 |

| Old brand names |

Usinalter 400 |

400-400-TG 179

| |

400-400-TG 179 |

| EN 10265:1995 |

400-400-TG 179 |

| IEC/CEI 60404-8-5:1989 |

400-400-TG 179 |

| Old brand names |

Usinalter 400 |

400-500-TG 179

| |

400-500-TG 179 |

| EN 10265:1995 |

400-500-TG 179 |

| IEC/CEI 60404-8-5:1989 |

400-500-TG 179 |

| Old brand names |

Usinalter 400 |

450-180-TG 179

| |

450-180-TG 179 * |

| EN 10265:1995 |

450-180-TG 179 |

| IEC/CEI 60404-8-5:1989 |

450-180-TG 179 |

| Old brand names |

Usinalter 450 |

450-200-TG 179

| |

450-200-TG 179 * |

| EN 10265:1995 |

450-200-TG 179 |

| IEC/CEI 60404-8-5:1989 |

450-200-TG 179 |

| Old brand names |

Usinalter 450 |

450-300-TG 179

| |

450-300-TG 179 * |

| EN 10265:1995 |

450-300-TG 179 |

| IEC/CEI 60404-8-5:1989 |

450-300-TG 179 |

| Old brand names |

Usinalter 450 |

450-400-TG 179

| |

450-400-TG 179 * |

| EN 10265:1995 |

450-400-TG 179 |

| IEC/CEI 60404-8-5:1989 |

450-400-TG 179 |

| Old brand names |

Usinalter 450 |

450-500-TG 179

| |

450-500-TG 179 * |

| EN 10265:1995 |

450-500-TG 179 |

| IEC/CEI 60404-8-5:1989 |

450-500-TG 179 |

| Old brand names |

Usinalter 450 |

500-200-TG 179

| |

500-200-TG 179 * |

| EN 10265:1995 |

500-200-TG 179 |

| IEC/CEI 60404-8-5:1989 |

500-200-TG 179 |

| Old brand names |

Usinalter 500 |

500-300-TG 179

| |

500-300-TG 179 * |

| EN 10265:1995 |

500-300-TG 179 |

| IEC/CEI 60404-8-5:1989 |

500-300-TG 179 |

| Old brand names |

Usinalter 500 |

500-400-TG 179

| |

500-400-TG 179 * |

| EN 10265:1995 |

500-400-TG 179 |

| IEC/CEI 60404-8-5:1989 |

500-400-TG 179 |

| Old brand names |

Usinalter 500 |

500-500-TG 179

| |

500-500-TG 179 * |

| EN 10265:1995 |

500-500-TG 179 |

| IEC/CEI 60404-8-5:1989 |

500-500-TG 179 |

| Old brand names |

Usinalter 500 |

550-200-TG 178

| |

550-200-TG 178 * |

| EN 10265:1995 |

550-200-TG 178 |

| IEC/CEI 60404-8-5:1989 |

550-200-TG 178 |

| Old brand names |

Usinalter 550 |

550-220-TG 178

| |

550-220-TG 178 * |

| EN 10265:1995 |

550-220-TG 178 |

| IEC/CEI 60404-8-5:1989 |

550-220-TG 178 |

| Old brand names |

Usinalter 550 |

550-250-TG 178

| |

550-250-TG 178 * |

| EN 10265:1995 |

550-250-TG 178 |

| IEC/CEI 60404-8-5:1989 |

550-250-TG 178 |

| Old brand names |

Usinalter 550 |

550-300-TG 178

| |

550-300-TG 178 * |

| EN 10265:1995 |

550-300-TG 178 |

| IEC/CEI 60404-8-5:1989 |

550-300-TG 178 |

| Old brand names |

Usinalter 550 |

550-400-TG 178

| |

550-400-TG 178 * |

| EN 10265:1995 |

550-400-TG 178 |

| IEC/CEI 60404-8-5:1989 |

550-400-TG 178 |

| Old brand names |

Usinalter 550 |

550-500-TG 178

| |

550-500-TG 178 * |

| EN 10265:1995 |

550-500-TG 178 |

| IEC/CEI 60404-8-5:1989 |

550-500-TG 178 |

| Old brand names |

Usinalter 550 |

600-200-TG 178

| |

600-200-TG 178 * |

| EN 10265:1995 |

600-200-TG 178 |

| IEC/CEI 60404-8-5:1989 |

600-200-TG 178 |

| Old brand names |

Usinalter 600 |

600-250-TG 178

| |

600-250-TG 178 * |

| EN 10265:1995 |

600-250-TG 178 |

| IEC/CEI 60404-8-5:1989 |

600-250-TG 178 |

| Old brand names |

Usinalter 600 |

600-300-TG 178

| |

600-300-TG 178 * |

| EN 10265:1995 |

600-300-TG 178 |

| IEC/CEI 60404-8-5:1989 |

600-300-TG 178 |

| Old brand names |

Usinalter 600 |

600-400-TG 178

| |

600-400-TG 178 * |

| EN 10265:1995 |

600-400-TG 178 |

| IEC/CEI 60404-8-5:1989 |

600-400-TG 178 |

| Old brand names |

Usinalter 600 |

600-500-TG 178

| |

600-500-TG 178 * |

| EN 10265:1995 |

600-500-TG 178 |

| IEC/CEI 60404-8-5:1989 |

600-500-TG 178 |

| Old brand names |

Usinalter 600 |

650-200-TG 178

| |

650-200-TG 178 * |

| EN 10265:1995 |

650-200-TG 178 |

| IEC/CEI 60404-8-5:1989 |

650-200-TG 178 |

| Old brand names |

Usinalter 650 |

650-250-TG 178

| |

650-250-TG 178 * |

| EN 10265:1995 |

650-250-TG 178 |

| IEC/CEI 60404-8-5:1989 |

650-250-TG 178 |

| Old brand names |

Usinalter 650 |

650-300-TG 178

| |

650-300-TG 178 * |

| EN 10265:1995 |

650-300-TG 178 |

| IEC/CEI 60404-8-5:1989 |

650-300-TG 178 |

| Old brand names |

Usinalter 650 |

650-400-TG 178

| |

650-400-TG 178 * |

| EN 10265:1995 |

650-400-TG 178 |

| IEC/CEI 60404-8-5:1989 |

650-400-TG 178 |

| Old brand names |

Usinalter 650 |

650-500-TG 178

| |

650-500-TG 178 * |

| EN 10265:1995 |

650-500-TG 178 |

| IEC/CEI 60404-8-5:1989 |

650-500-TG 178 |

| Old brand names |

Usinalter 650 |

700-200-TG 178

| |

700-200-TG 178 * |

| EN 10265:1995 |

700-200-TG 178 |

| IEC/CEI 60404-8-5:1989 |

700-200-TG 178 |

| Old brand names |

Usinalter 700 |

700-250-TG 178

| |

700-250-TG 178 * |

| EN 10265:1995 |

700-250-TG 178 |

| IEC/CEI 60404-8-5:1989 |

700-250-TG 178 |

| Old brand names |

Usinalter 700 |

700-300-TG 178

| |

700-300-TG 178 * |

| EN 10265:1995 |

700-300-TG 178 |

| IEC/CEI 60404-8-5:1989 |

700-300-TG 178 |

| Old brand names |

Usinalter 700 |

700-400-TG 178

| |

700-400-TG 178 * |

| EN 10265:1995 |

700-400-TG 178 |

| IEC/CEI 60404-8-5:1989 |

700-400-TG 178 |

| Old brand names |

Usinalter 700 |

700-500-TG 178

| |

700-500-TG 178 * |

| EN 10265:1995 |

700-500-TG 178 |

| IEC/CEI 60404-8-5:1989 |

700-500-TG 178 |

| Old brand names |

Usinalter 700 |

Prev grade

Next grade

Dimensions

Full table

| |

Mill finish |

Side trimmed* |

| Min width |

Max width |

Min width |

Max width |

| 250-150-TG 180 |

675 |

1350 |

595 |

1270 |

| 250-200-TG 180 |

1550 |

1470 |

| 250-300-TG 180 |

2037 |

1957 |

| 250-400-TG 180 |

2137 |

2057 |

| 250-500-TG 180 |

| 300-150-TG 180 |

1055 |

975 |

| 300-200-TG 180 |

1550 |

1470 |

| 300-300-TG 180 |

1610 |

1530 |

| 300-400-TG 180 |

1887 |

1807 |

| 300-500-TG 180 |

2137 |

2057 |

| 350-150-TG 179 |

1055 |

975 |

| 350-200-TG 179 |

1550 |

1470 |

| 350-250-TG 179 |

1400 |

1320 |

| 350-300-TG 179 |

1610 |

1530 |

| 350-400-TG 179 |

1887 |

1807 |

| 350-500-TG 179 |

2137 |

2057 |

| 400-180-TG 179 |

1055 |

975 |

| 400-200-TG 179 |

1255 |

1175 |

| 400-240-TG 179 |

1330 |

1250 |

| 400-300-TG 179 |

1550 |

1470 |

| 400-400-TG 179 |

1840 |

1760 |

| 400-500-TG 179 |

2137 |

2057 |

| 450-180-TG 179 |

1055 |

975 |

| 450-200-TG 179 |

1255 |

1175 |

| 450-300-TG 179 |

1550 |

1470 |

| 450-400-TG 179 |

1840 |

1760 |

| 450-500-TG 179 |

2137 |

2057 |

| 500-200-TG 179 |

1255 |

1175 |

| 500-300-TG 179 |

1550 |

1470 |

| 500-400-TG 179 |

| 500-500-TG 179 |

1640 |

1560 |

| 550-200-TG 178 |

1105 |

1025 |

| 550-220-TG 178 |

1180 |

1100 |

| 550-250-TG 178 |

1255 |

1175 |

| 550-300-TG 178 |

1350 |

1270 |

| 550-400-TG 178 |

1550 |

1470 |

| 550-500-TG 178 |

1640 |

1560 |

| 600-200-TG 178 |

1225 |

1145 |

| 600-250-TG 178 |

| 600-300-TG 178 |

1520 |

1440 |

| 600-400-TG 178 |

1620 |

1540 |

| 600-500-TG 178 |

1720 |

1640 |

| 650-200-TG 178 |

1225 |

1145 |

| 650-250-TG 178 |

| 650-300-TG 178 |

1520 |

1440 |

| 650-400-TG 178 |

1620 |

1540 |

| 650-500-TG 178 |

1720 |

1640 |

| 700-200-TG 178 |

1225 |

1145 |

| 700-250-TG 178 |

| 700-300-TG 178 |

1520 |

1440 |

| 700-400-TG 178 |

1620 |

1540 |

| 700-500-TG 178 |

1720 |

1640 |

Please contact us for other dimensions.

* Smaller widths are available after slitting.

250-150-TG 180

| Mill finish |

Min width |

675 |

| Max width |

1350 |

| Side trimmed* |

Min width |

595 |

| Max width |

1270 |

250-200-TG 180

| Mill finish |

Min width |

675 |

| Max width |

1550 |

| Side trimmed* |

Min width |

595 |

| Max width |

1470 |

250-300-TG 180

| Mill finish |

Min width |

675 |

| Max width |

2037 |

| Side trimmed* |

Min width |

595 |

| Max width |

1957 |

250-400-TG 180

| Mill finish |

Min width |

675 |

| Max width |

2137 |

| Side trimmed* |

Min width |

595 |

| Max width |

2057 |

250-500-TG 180

| Mill finish |

Min width |

675 |

| Max width |

2137 |

| Side trimmed* |

Min width |

595 |

| Max width |

2057 |

300-150-TG 180

| Mill finish |

Min width |

675 |

| Max width |

1055 |

| Side trimmed* |

Min width |

595 |

| Max width |

975 |

300-200-TG 180

| Mill finish |

Min width |

675 |

| Max width |

1550 |

| Side trimmed* |

Min width |

595 |

| Max width |

1470 |

300-300-TG 180

| Mill finish |

Min width |

675 |

| Max width |

1610 |

| Side trimmed* |

Min width |

595 |

| Max width |

1530 |

300-400-TG 180

| Mill finish |

Min width |

675 |

| Max width |

1887 |

| Side trimmed* |

Min width |

595 |

| Max width |

1807 |

300-500-TG 180

| Mill finish |

Min width |

675 |

| Max width |

2137 |

| Side trimmed* |

Min width |

595 |

| Max width |

2057 |

350-150-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1055 |

| Side trimmed* |

Min width |

595 |

| Max width |

975 |

350-200-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1550 |

| Side trimmed* |

Min width |

595 |

| Max width |

1470 |

350-250-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1400 |

| Side trimmed* |

Min width |

595 |

| Max width |

1320 |

350-300-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1610 |

| Side trimmed* |

Min width |

595 |

| Max width |

1530 |

350-400-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1887 |

| Side trimmed* |

Min width |

595 |

| Max width |

1807 |

350-500-TG 179

| Mill finish |

Min width |

675 |

| Max width |

2137 |

| Side trimmed* |

Min width |

595 |

| Max width |

2057 |

400-180-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1055 |

| Side trimmed* |

Min width |

595 |

| Max width |

975 |

400-200-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1255 |

| Side trimmed* |

Min width |

595 |

| Max width |

1175 |

400-240-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1330 |

| Side trimmed* |

Min width |

595 |

| Max width |

1250 |

400-300-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1550 |

| Side trimmed* |

Min width |

595 |

| Max width |

1470 |

400-400-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1840 |

| Side trimmed* |

Min width |

595 |

| Max width |

1760 |

400-500-TG 179

| Mill finish |

Min width |

675 |

| Max width |

2137 |

| Side trimmed* |

Min width |

595 |

| Max width |

2057 |

450-180-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1055 |

| Side trimmed* |

Min width |

595 |

| Max width |

975 |

450-200-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1255 |

| Side trimmed* |

Min width |

595 |

| Max width |

1175 |

450-300-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1550 |

| Side trimmed* |

Min width |

595 |

| Max width |

1470 |

450-400-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1840 |

| Side trimmed* |

Min width |

595 |

| Max width |

1760 |

450-500-TG 179

| Mill finish |

Min width |

675 |

| Max width |

2137 |

| Side trimmed* |

Min width |

595 |

| Max width |

2057 |

500-200-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1255 |

| Side trimmed* |

Min width |

595 |

| Max width |

1175 |

500-300-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1550 |

| Side trimmed* |

Min width |

595 |

| Max width |

1470 |

500-400-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1550 |

| Side trimmed* |

Min width |

595 |

| Max width |

1470 |

500-500-TG 179

| Mill finish |

Min width |

675 |

| Max width |

1640 |

| Side trimmed* |

Min width |

595 |

| Max width |

1560 |

550-200-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1105 |

| Side trimmed* |

Min width |

595 |

| Max width |

1025 |

550-220-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1180 |

| Side trimmed* |

Min width |

595 |

| Max width |

1100 |

550-250-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1255 |

| Side trimmed* |

Min width |

595 |

| Max width |

1175 |

550-300-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1350 |

| Side trimmed* |

Min width |

595 |

| Max width |

1270 |

550-400-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1550 |

| Side trimmed* |

Min width |

595 |

| Max width |

1470 |

550-500-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1640 |

| Side trimmed* |

Min width |

595 |

| Max width |

1560 |

600-200-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1225 |

| Side trimmed* |

Min width |

595 |

| Max width |

1145 |

600-250-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1225 |

| Side trimmed* |

Min width |

595 |

| Max width |

1145 |

600-300-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1520 |

| Side trimmed* |

Min width |

595 |

| Max width |

1440 |

600-400-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1620 |

| Side trimmed* |

Min width |

595 |

| Max width |

1540 |

600-500-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1720 |

| Side trimmed* |

Min width |

595 |

| Max width |

1640 |

650-200-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1225 |

| Side trimmed* |

Min width |

595 |

| Max width |

1145 |

650-250-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1225 |

| Side trimmed* |

Min width |

595 |

| Max width |

1145 |

650-300-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1520 |

| Side trimmed* |

Min width |

595 |

| Max width |

1440 |

650-400-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1620 |

| Side trimmed* |

Min width |

595 |

| Max width |

1540 |

650-500-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1720 |

| Side trimmed* |

Min width |

595 |

| Max width |

1640 |

700-200-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1225 |

| Side trimmed* |

Min width |

595 |

| Max width |

1145 |

700-250-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1225 |

| Side trimmed* |

Min width |

595 |

| Max width |

1145 |

700-300-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1520 |

| Side trimmed* |

Min width |

595 |

| Max width |

1440 |

700-400-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1620 |

| Side trimmed* |

Min width |

595 |

| Max width |

1540 |

700-500-TG 178

| Mill finish |

Min width |

675 |

| Max width |

1720 |

| Side trimmed* |

Min width |

595 |

| Max width |

1640 |

Prev grade

Next grade

Please contact us for other dimensions.

* Smaller widths are available after slitting.

Magnetic properties

Full table

| |

Min polarisation (T) in DC at 5000 A/m |

Min polarisation (T) in DC at 15,000 A/m |

| Guaranteed |

Guaranteed |

| 250-150-TG 180 |

1.60 |

1.80 |

| 250-200-TG 180 |

| 250-300-TG 180 |

| 250-400-TG 180 |

| 250-500-TG 180 |

| 300-150-TG 180 |

| 300-200-TG 180 |

| 300-300-TG 180 |

| 300-400-TG 180 |

| 300-500-TG 180 |

| 350-150-TG 179 |

1.55 |

1.79 |

| 350-200-TG 179 |

| 350-250-TG 179 |

| 350-300-TG 179 |

| 350-400-TG 179 |

| 350-500-TG 179 |

| 400-180-TG 179 |

| 400-200-TG 179 |

| 400-240-TG 179 |

| 400-300-TG 179 |

| 400-400-TG 179 |

| 400-500-TG 179 |

| 450-180-TG 179 |

1.54 |

| 450-200-TG 179 |

| 450-300-TG 179 |

| 450-400-TG 179 |

| 450-500-TG 179 |

| 500-200-TG 179 |

1.53 |

| 500-300-TG 179 |

| 500-400-TG 179 |

| 500-500-TG 179 |

| 550-200-TG 178 |

1.52 |

1.78 |

| 550-220-TG 178 |

| 550-250-TG 178 |

| 550-300-TG 178 |

| 550-400-TG 178 |

| 550-500-TG 178 |

| 600-200-TG 178 |

1.50 |

| 600-250-TG 178 |

| 600-300-TG 178 |

| 600-400-TG 178 |

| 600-500-TG 178 |

| 650-200-TG 178 |

1.48 |

| 650-250-TG 178 |

| 650-300-TG 178 |

| 650-400-TG 178 |

| 650-500-TG 178 |

| 700-200-TG 178 |

1.46 |

| 700-250-TG 178 |

| 700-300-TG 178 |

| 700-400-TG 178 |

| 700-500-TG 178 |

250-150-TG 180

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.60 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.80 |

250-200-TG 180

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.60 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.80 |

250-300-TG 180

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.60 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.80 |

250-400-TG 180

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.60 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.80 |

250-500-TG 180

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.60 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.80 |

300-150-TG 180

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.60 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.80 |

300-200-TG 180

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.60 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.80 |

300-300-TG 180

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.60 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.80 |

300-400-TG 180

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.60 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.80 |

300-500-TG 180

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.60 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.80 |

350-150-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.55 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

350-200-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.55 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

350-250-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.55 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

350-300-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.55 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

350-400-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.55 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

350-500-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.55 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

400-180-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.55 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

400-200-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.55 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

400-240-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.55 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

400-300-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.55 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

400-400-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.55 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

400-500-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.55 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

450-180-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.54 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

450-200-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.54 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

450-300-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.54 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

450-400-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.54 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

450-500-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.54 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

500-200-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.53 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

500-300-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.53 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

500-400-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.53 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

500-500-TG 179

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.53 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.79 |

550-200-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.52 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

550-220-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.52 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

550-250-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.52 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

550-300-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.52 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

550-400-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.52 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

550-500-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.52 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

600-200-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.50 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

600-250-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.50 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

600-300-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.50 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

600-400-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.50 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

600-500-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.50 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

650-200-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.48 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

650-250-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.48 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

650-300-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.48 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

650-400-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.48 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

650-500-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.48 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

700-200-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.46 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

700-250-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.46 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

700-300-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.46 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

700-400-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.46 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

700-500-TG 178

| |

|

|

| Min polarisation (T) in DC at 5000 A/m |

Guaranteed |

1.46 |

| Min polarisation (T) in DC at 15,000 A/m |

Guaranteed |

1.78 |

Prev grade

Next grade

Mechanical properties

Guaranteed mechanical properties:

Full table

| |

Notes |

Direction |

Thickness (mm) |

Re (MPa) |

Rm (MPa) |

A 5.65√So (%) |

A80 (%) |

| 250-150-TG 180 |

|

T |

1.5 - 1.5 |

≥ 250 |

350 - 480 |

- |

≥ 20 |

| 250-200-TG 180 |

|

T |

2 - 2 |

≥ 250 |

350 - 480 |

- |

≥ 20 |

| 250-300-TG 180 |

|

T |

3 - 3 |

≥ 250 |

350 - 480 |

≥ 26 |

- |

| 250-400-TG 180 |

|

T |

4 - 4 |

≥ 250 |

350 - 480 |

≥ 26 |

- |

| 250-500-TG 180 |

|

T |

5 - 5 |

≥ 250 |

350 - 480 |

≥ 26 |

- |

| 300-150-TG 180 |

|

T |

1.5 - 1.5 |

≥ 300 |

400 - 520 |

- |

≥ 20 |

| 300-200-TG 180 |

|

T |

2 - 2 |

≥ 300 |

400 - 520 |

- |

≥ 20 |

| 300-300-TG 180 |

|

T |

3 - 3 |

≥ 300 |

400 - 520 |

≥ 24 |

- |

| 300-400-TG 180 |

|

T |

4 - 4 |

≥ 300 |

400 - 520 |

≥ 24 |

- |

| 300-500-TG 180 |

|

T |

5 - 5 |

≥ 300 |

400 - 520 |

≥ 24 |

- |

| 350-150-TG 179 |

|

L |

1.5 - 1.5 |

≥ 350 |

450 - 600 |

- |

≥ 18 |

| T |

1.5 - 1.5 |

≥ 350 |

450 - 600 |

- |

≥ 18 |

| 350-200-TG 179 |

|

L |

2 - 2 |

≥ 350 |

450 - 600 |

- |

≥ 18 |

| T |

2 - 2 |

≥ 350 |

450 - 600 |

- |

≥ 18 |

| 350-250-TG 179 |

|

L |

2.5 - 2.5 |

≥ 350 |

450 - 600 |

- |

≥ 18 |

| T |

2.5 - 2.5 |

≥ 350 |

450 - 600 |

- |

≥ 18 |

| 350-300-TG 179 |

|

L |

3 - 3 |

≥ 350 |

450 - 600 |

≥ 22 |

- |

| T |

3 - 3 |

≥ 350 |

450 - 600 |

≥ 22 |

- |

| 350-400-TG 179 |

|

L |

4 - 4 |

≥ 350 |

450 - 600 |

≥ 22 |

- |

| T |

4 - 4 |

≥ 350 |

450 - 600 |

≥ 22 |

- |

| 350-500-TG 179 |

|

L |

5 - 5 |

≥ 350 |

450 - 600 |

≥ 22 |

- |

| T |

5 - 5 |

≥ 350 |

450 - 600 |

≥ 22 |

- |

| 400-180-TG 179 |

|

L |

1.8 - 1.8 |

≥ 400 |

500 - 680 |

- |

≥ 16 |

| T |

1.8 - 1.8 |

≥ 400 |

500 - 680 |

- |

≥ 16 |

| 400-200-TG 179 |

|

L |

2 - 2 |

≥ 400 |

500 - 680 |

- |

≥ 16 |

| T |

2 - 2 |

≥ 400 |

500 - 680 |

- |

≥ 16 |

| 400-240-TG 179 |

|

L |

2.4 - 2.4 |

≥ 400 |

500 - 680 |

- |

≥ 16 |

| T |

2.4 - 2.4 |

≥ 400 |

500 - 680 |

- |

≥ 16 |

| 400-300-TG 179 |

|

L |

3 - 3 |

≥ 400 |

500 - 680 |

≥ 19 |

- |

| T |

3 - 3 |

≥ 400 |

500 - 680 |

≥ 19 |

- |

| 400-400-TG 179 |

|

L |

4 - 4 |

≥ 400 |

500 - 680 |

≥ 19 |

- |

| T |

4 - 4 |

≥ 400 |

500 - 680 |

≥ 19 |

- |

| 400-500-TG 179 |

|

L |

5 - 5 |

≥ 400 |

500 - 680 |

≥ 19 |

- |

| T |

5 - 5 |

≥ 400 |

500 - 680 |

≥ 19 |

- |

| 450-180-TG 179 |

|

L |

1.8 - 1.8 |

≥ 450 |

550 - 750 |

- |

≥ 16 |

| T |

1.8 - 1.8 |

≥ 450 |

550 - 750 |

- |

≥ 16 |

| 450-200-TG 179 |

|

L |

2 - 2 |

≥ 450 |

550 - 750 |

- |

≥ 16 |

| T |

2 - 2 |

≥ 450 |

550 - 750 |

- |

≥ 16 |

| 450-300-TG 179 |

|

L |

3 - 3 |

≥ 450 |

550 - 750 |

≥ 17 |

- |

| T |

3 - 3 |

≥ 450 |

550 - 750 |

≥ 17 |

- |

| 450-400-TG 179 |

|

L |

4 - 4 |

≥ 450 |

550 - 750 |

≥ 17 |

- |

| T |

4 - 4 |

≥ 450 |

550 - 750 |

≥ 17 |

- |

| 450-500-TG 179 |

|

L |

5 - 5 |

≥ 450 |

550 - 750 |

≥ 17 |

- |

| T |

5 - 5 |

≥ 450 |

550 - 750 |

≥ 17 |

- |

| 500-200-TG 179 |

|

L |

2 - 2 |

≥ 500 |

600 - 800 |

- |

≥ 14 |

| T |

2 - 2 |

≥ 500 |

600 - 800 |

- |

≥ 14 |

| 500-300-TG 179 |

|

L |

3 - 3 |

≥ 500 |

600 - 800 |

≥ 14 |

- |

| T |

3 - 3 |

≥ 500 |

600 - 800 |

≥ 14 |

- |

| 500-400-TG 179 |

|

L |

4 - 4 |

≥ 500 |

600 - 800 |

≥ 14 |

- |

| T |

4 - 4 |

≥ 500 |

600 - 800 |

≥ 14 |

- |

| 500-500-TG 179 |

|

L |

5 - 5 |

≥ 500 |

600 - 800 |

≥ 14 |

- |

| T |

5 - 5 |

≥ 500 |

600 - 800 |

≥ 14 |

- |

| 550-200-TG 178 |

|

L |

2 - 2 |

≥ 550 |

650 - 850 |

- |

≥ 12 |

| T |

2 - 2 |

≥ 550 |

650 - 850 |

- |

≥ 12 |

| 550-220-TG 178 |

|

L |

2.2 - 2.2 |

≥ 550 |

650 - 850 |

- |

≥ 12 |

| T |

2.2 - 2.2 |

≥ 550 |

650 - 850 |

- |

≥ 12 |

| 550-250-TG 178 |

|

L |

2.5 - 2.5 |

≥ 550 |

650 - 850 |

- |

≥ 12 |

| T |

2.5 - 2.5 |

≥ 550 |

650 - 850 |

- |

≥ 12 |

| 550-300-TG 178 |

|

L |

3 - 3 |

≥ 550 |

650 - 850 |

≥ 14 |

- |

| T |

3 - 3 |

≥ 550 |

650 - 850 |

≥ 14 |

- |

| 550-400-TG 178 |

|

L |

4 - 4 |

≥ 550 |

650 - 850 |

≥ 14 |

- |

| T |

4 - 4 |

≥ 550 |

650 - 850 |

≥ 14 |

- |

| 550-500-TG 178 |

|

L |

5 - 5 |

≥ 550 |

650 - 850 |

≥ 14 |

- |

| T |

5 - 5 |

≥ 550 |

650 - 850 |

≥ 14 |

- |

| 600-200-TG 178 |

|

L |

2 - 2 |

≥ 600 |

700 - 900 |

- |

≥ 10 |

| T |

2 - 2 |

≥ 600 |

700 - 900 |

- |

≥ 10 |

| 600-250-TG 178 |

|

L |

2.5 - 2.5 |

≥ 600 |

700 - 900 |

- |

≥ 10 |

| T |

2.5 - 2.5 |

≥ 600 |

700 - 900 |

- |

≥ 10 |

| 600-300-TG 178 |

|

L |

3 - 3 |

≥ 600 |

700 - 900 |

≥ 12 |

- |

| T |

3 - 3 |

≥ 600 |

700 - 900 |

≥ 12 |

- |

| 600-400-TG 178 |

|

L |

4 - 4 |

≥ 600 |

700 - 900 |

≥ 12 |

- |

| T |

4 - 4 |

≥ 600 |

700 - 900 |

≥ 12 |

- |

| 600-500-TG 178 |

|

L |

5 - 5 |

≥ 600 |

700 - 900 |

≥ 12 |

- |

| T |

5 - 5 |

≥ 600 |

700 - 900 |

≥ 12 |

- |

| 650-200-TG 178 |

|

L |

2 - 2 |

≥ 650 |

750 - 900 |

- |

≥ 10 |

| T |

2 - 2 |

≥ 650 |

750 - 900 |

- |

≥ 10 |

| 650-250-TG 178 |

|

L |

2.5 - 2.5 |

≥ 650 |

750 - 900 |

- |

≥ 10 |

| T |

2.5 - 2.5 |

≥ 650 |

750 - 900 |

- |

≥ 10 |

| 650-300-TG 178 |

|

L |

3 - 3 |

≥ 650 |

750 - 900 |

≥ 12 |

- |

| T |

3 - 3 |

≥ 650 |

750 - 900 |

≥ 12 |

- |

| 650-400-TG 178 |

|

L |

4 - 4 |

≥ 650 |

750 - 900 |

≥ 12 |

- |

| T |

4 - 4 |

≥ 650 |

750 - 900 |

≥ 12 |

- |

| 650-500-TG 178 |

|

L |

5 - 5 |

≥ 650 |

750 - 900 |

≥ 12 |

- |

| T |

5 - 5 |

≥ 650 |

750 - 900 |

≥ 12 |

- |

| 700-200-TG 178 |

1 |

L |

2 - 2 |

≥ 700 |

750 - 900 |

- |

≥ 10 |

| T |

2 - 2 |

≥ 700 |

750 - 900 |

- |

≥ 10 |

| 700-250-TG 178 |

1 |

L |

2.5 - 2.5 |

≥ 700 |

750 - 900 |

- |

≥ 10 |

| T |

2.5 - 2.5 |

≥ 700 |

750 - 900 |

- |

≥ 10 |

| 700-300-TG 178 |

1 |

L |

3 - 3 |

≥ 700 |

750 - 900 |

≥ 12 |

- |

| T |

3 - 3 |

≥ 700 |

750 - 900 |

≥ 12 |

- |

| 700-400-TG 178 |

1 |

L |

4 - 4 |

≥ 700 |

750 - 900 |

≥ 12 |

- |

| T |

4 - 4 |

≥ 700 |

750 - 900 |

≥ 12 |

- |

| 700-500-TG 178 |

1 |

L |

5 - 5 |

≥ 700 |

750 - 900 |

≥ 12 |

- |

| T |

5 - 5 |

≥ 700 |

750 - 900 |

≥ 12 |

- |

250-150-TG 180

| |

Direction |

Thickness (mm) |

250-150-TG 180 |

| Re (MPa) |

T |

1.5 - 1.5 |

≥ 250 |

| Rm (MPa) |

T |

1.5 - 1.5 |

350 - 480 |

| A80 (%) |

T |

1.5 - 1.5 |

≥ 20 |

250-200-TG 180

| |

Direction |

Thickness (mm) |

250-200-TG 180 |

| Re (MPa) |

T |

2 - 2 |

≥ 250 |

| Rm (MPa) |

T |

2 - 2 |

350 - 480 |

| A80 (%) |

T |

2 - 2 |

≥ 20 |

250-300-TG 180

| |

Direction |

Thickness (mm) |

250-300-TG 180 |

| Re (MPa) |

T |

3 - 3 |

≥ 250 |

| Rm (MPa) |

T |

3 - 3 |

350 - 480 |

| A 5.65√So (%) |

T |

3 - 3 |

≥ 26 |

250-400-TG 180

| |

Direction |

Thickness (mm) |

250-400-TG 180 |

| Re (MPa) |

T |

4 - 4 |

≥ 250 |

| Rm (MPa) |

T |

4 - 4 |

350 - 480 |

| A 5.65√So (%) |

T |

4 - 4 |

≥ 26 |

250-500-TG 180

| |

Direction |

Thickness (mm) |

250-500-TG 180 |

| Re (MPa) |

T |

5 - 5 |

≥ 250 |

| Rm (MPa) |

T |

5 - 5 |

350 - 480 |

| A 5.65√So (%) |

T |

5 - 5 |

≥ 26 |

300-150-TG 180

| |

Direction |

Thickness (mm) |

300-150-TG 180 |

| Re (MPa) |

T |

1.5 - 1.5 |

≥ 300 |

| Rm (MPa) |

T |

1.5 - 1.5 |

400 - 520 |

| A80 (%) |

T |

1.5 - 1.5 |

≥ 20 |

300-200-TG 180

| |

Direction |

Thickness (mm) |

300-200-TG 180 |

| Re (MPa) |

T |

2 - 2 |

≥ 300 |

| Rm (MPa) |

T |

2 - 2 |

400 - 520 |

| A80 (%) |

T |

2 - 2 |

≥ 20 |

300-300-TG 180

| |

Direction |

Thickness (mm) |

300-300-TG 180 |

| Re (MPa) |

T |

3 - 3 |

≥ 300 |

| Rm (MPa) |

T |

3 - 3 |

400 - 520 |

| A 5.65√So (%) |

T |

3 - 3 |

≥ 24 |

300-400-TG 180

| |

Direction |

Thickness (mm) |

300-400-TG 180 |

| Re (MPa) |

T |

4 - 4 |

≥ 300 |

| Rm (MPa) |

T |

4 - 4 |

400 - 520 |

| A 5.65√So (%) |

T |

4 - 4 |

≥ 24 |

300-500-TG 180

| |

Direction |

Thickness (mm) |

300-500-TG 180 |

| Re (MPa) |

T |

5 - 5 |

≥ 300 |

| Rm (MPa) |

T |

5 - 5 |

400 - 520 |

| A 5.65√So (%) |

T |

5 - 5 |

≥ 24 |

350-150-TG 179

| |

Direction |

Thickness (mm) |

350-150-TG 179 |

| Re (MPa) |

L |

1.5 - 1.5 |

≥ 350 |

| T |

1.5 - 1.5 |

≥ 350 |

| Rm (MPa) |

L |

1.5 - 1.5 |

450 - 600 |

| T |

1.5 - 1.5 |

450 - 600 |

| A80 (%) |

/ |

1.5 - 1.5 |

≥ 18 |

350-200-TG 179

| |

Direction |

Thickness (mm) |

350-200-TG 179 |

| Re (MPa) |

L |

2 - 2 |

≥ 350 |

| T |

2 - 2 |

≥ 350 |

| Rm (MPa) |

L |

2 - 2 |

450 - 600 |

| T |

2 - 2 |

450 - 600 |

| A80 (%) |

/ |

2 - 2 |

≥ 18 |

350-250-TG 179

| |

Direction |

Thickness (mm) |

350-250-TG 179 |

| Re (MPa) |

L |

2.5 - 2.5 |

≥ 350 |

| T |

2.5 - 2.5 |

≥ 350 |

| Rm (MPa) |

L |

2.5 - 2.5 |

450 - 600 |

| T |

2.5 - 2.5 |

450 - 600 |

| A80 (%) |

/ |

2.5 - 2.5 |

≥ 18 |

350-300-TG 179

| |

Direction |

Thickness (mm) |

350-300-TG 179 |

| Re (MPa) |

L |

3 - 3 |

≥ 350 |

| T |

3 - 3 |

≥ 350 |

| Rm (MPa) |

L |

3 - 3 |

450 - 600 |

| T |

3 - 3 |

450 - 600 |

| A 5.65√So (%) |

L |

3 - 3 |

≥ 22 |

| T |

3 - 3 |

≥ 22 |

350-400-TG 179

| |

Direction |

Thickness (mm) |

350-400-TG 179 |

| Re (MPa) |

L |

4 - 4 |

≥ 350 |

| T |

4 - 4 |

≥ 350 |

| Rm (MPa) |

L |

4 - 4 |

450 - 600 |

| T |

4 - 4 |

450 - 600 |

| A 5.65√So (%) |

L |

4 - 4 |

≥ 22 |

| T |

4 - 4 |

≥ 22 |

350-500-TG 179

| |

Direction |

Thickness (mm) |

350-500-TG 179 |

| Re (MPa) |

L |

5 - 5 |

≥ 350 |

| T |

5 - 5 |

≥ 350 |

| Rm (MPa) |

L |

5 - 5 |

450 - 600 |

| T |

5 - 5 |

450 - 600 |

| A 5.65√So (%) |

L |

5 - 5 |

≥ 22 |

| T |

5 - 5 |

≥ 22 |

400-180-TG 179

| |

Direction |

Thickness (mm) |

400-180-TG 179 |

| Re (MPa) |

L |

1.8 - 1.8 |

≥ 400 |

| T |

1.8 - 1.8 |

≥ 400 |

| Rm (MPa) |

L |

1.8 - 1.8 |

500 - 680 |

| T |

1.8 - 1.8 |

500 - 680 |

| A80 (%) |

/ |

1.8 - 1.8 |

≥ 16 |

400-200-TG 179

| |

Direction |

Thickness (mm) |

400-200-TG 179 |

| Re (MPa) |

L |

2 - 2 |

≥ 400 |

| T |

2 - 2 |

≥ 400 |

| Rm (MPa) |

L |

2 - 2 |

500 - 680 |

| T |

2 - 2 |

500 - 680 |

| A80 (%) |

/ |

2 - 2 |

≥ 16 |

400-240-TG 179

| |

Direction |

Thickness (mm) |

400-240-TG 179 |

| Re (MPa) |

L |

2.4 - 2.4 |

≥ 400 |

| T |

2.4 - 2.4 |

≥ 400 |

| Rm (MPa) |

L |

2.4 - 2.4 |

500 - 680 |

| T |

2.4 - 2.4 |

500 - 680 |

| A80 (%) |

/ |

2.4 - 2.4 |

≥ 16 |

400-300-TG 179

| |

Direction |

Thickness (mm) |

400-300-TG 179 |

| Re (MPa) |

L |

3 - 3 |

≥ 400 |

| T |

3 - 3 |

≥ 400 |

| Rm (MPa) |

L |

3 - 3 |

500 - 680 |

| T |

3 - 3 |

500 - 680 |

| A 5.65√So (%) |

L |

3 - 3 |

≥ 19 |

| T |

3 - 3 |

≥ 19 |

400-400-TG 179

| |

Direction |

Thickness (mm) |

400-400-TG 179 |

| Re (MPa) |

L |

4 - 4 |

≥ 400 |

| T |

4 - 4 |

≥ 400 |

| Rm (MPa) |

L |

4 - 4 |

500 - 680 |

| T |

4 - 4 |

500 - 680 |

| A 5.65√So (%) |

L |

4 - 4 |

≥ 19 |

| T |

4 - 4 |

≥ 19 |

400-500-TG 179

| |

Direction |

Thickness (mm) |

400-500-TG 179 |

| Re (MPa) |

L |

5 - 5 |

≥ 400 |

| T |

5 - 5 |

≥ 400 |

| Rm (MPa) |

L |

5 - 5 |

500 - 680 |

| T |

5 - 5 |

500 - 680 |

| A 5.65√So (%) |

L |

5 - 5 |

≥ 19 |

| T |

5 - 5 |

≥ 19 |

450-180-TG 179

| |

Direction |

Thickness (mm) |

450-180-TG 179 |

| Re (MPa) |

L |

1.8 - 1.8 |

≥ 450 |

| T |

1.8 - 1.8 |

≥ 450 |

| Rm (MPa) |

L |

1.8 - 1.8 |

550 - 750 |

| T |

1.8 - 1.8 |

550 - 750 |

| A80 (%) |

/ |

1.8 - 1.8 |

≥ 16 |

450-200-TG 179

| |

Direction |

Thickness (mm) |

450-200-TG 179 |

| Re (MPa) |

L |

2 - 2 |

≥ 450 |

| T |

2 - 2 |

≥ 450 |

| Rm (MPa) |

L |

2 - 2 |

550 - 750 |

| T |

2 - 2 |

550 - 750 |

| A80 (%) |

/ |

2 - 2 |

≥ 16 |

450-300-TG 179

| |

Direction |

Thickness (mm) |

450-300-TG 179 |

| Re (MPa) |

L |

3 - 3 |

≥ 450 |

| T |

3 - 3 |

≥ 450 |

| Rm (MPa) |

L |

3 - 3 |

550 - 750 |

| T |

3 - 3 |

550 - 750 |

| A 5.65√So (%) |

L |

3 - 3 |

≥ 17 |

| T |

3 - 3 |

≥ 17 |

450-400-TG 179

| |

Direction |

Thickness (mm) |

450-400-TG 179 |

| Re (MPa) |

L |

4 - 4 |

≥ 450 |

| T |

4 - 4 |

≥ 450 |

| Rm (MPa) |

L |

4 - 4 |

550 - 750 |

| T |

4 - 4 |

550 - 750 |

| A 5.65√So (%) |

L |

4 - 4 |

≥ 17 |

| T |

4 - 4 |

≥ 17 |

450-500-TG 179

| |

Direction |

Thickness (mm) |

450-500-TG 179 |

| Re (MPa) |

L |

5 - 5 |

≥ 450 |

| T |

5 - 5 |

≥ 450 |

| Rm (MPa) |

L |

5 - 5 |

550 - 750 |

| T |

5 - 5 |

550 - 750 |

| A 5.65√So (%) |

L |

5 - 5 |

≥ 17 |

| T |

5 - 5 |

≥ 17 |

500-200-TG 179

| |

Direction |

Thickness (mm) |

500-200-TG 179 |

| Re (MPa) |

L |

2 - 2 |

≥ 500 |

| T |

2 - 2 |

≥ 500 |

| Rm (MPa) |

L |

2 - 2 |

600 - 800 |

| T |

2 - 2 |

600 - 800 |

| A80 (%) |

/ |

2 - 2 |

≥ 14 |

500-300-TG 179

| |

Direction |

Thickness (mm) |

500-300-TG 179 |

| Re (MPa) |

L |

3 - 3 |

≥ 500 |

| T |

3 - 3 |

≥ 500 |

| Rm (MPa) |

L |

3 - 3 |

600 - 800 |

| T |

3 - 3 |

600 - 800 |

| A 5.65√So (%) |

L |

3 - 3 |

≥ 14 |

| T |

3 - 3 |

≥ 14 |

500-400-TG 179

| |

Direction |

Thickness (mm) |

500-400-TG 179 |

| Re (MPa) |

L |

4 - 4 |

≥ 500 |

| T |

4 - 4 |

≥ 500 |

| Rm (MPa) |

L |

4 - 4 |

600 - 800 |

| T |

4 - 4 |

600 - 800 |

| A 5.65√So (%) |

L |

4 - 4 |

≥ 14 |

| T |

4 - 4 |

≥ 14 |

500-500-TG 179

| |

Direction |

Thickness (mm) |

500-500-TG 179 |

| Re (MPa) |

L |

5 - 5 |

≥ 500 |

| T |

5 - 5 |

≥ 500 |

| Rm (MPa) |

L |

5 - 5 |

600 - 800 |

| T |

5 - 5 |

600 - 800 |

| A 5.65√So (%) |

L |

5 - 5 |

≥ 14 |

| T |

5 - 5 |

≥ 14 |

550-200-TG 178

| |

Direction |

Thickness (mm) |

550-200-TG 178 |

| Re (MPa) |

L |

2 - 2 |

≥ 550 |

| T |

2 - 2 |

≥ 550 |

| Rm (MPa) |

L |

2 - 2 |

650 - 850 |

| T |

2 - 2 |

650 - 850 |

| A80 (%) |

/ |

2 - 2 |

≥ 12 |

550-220-TG 178

| |

Direction |

Thickness (mm) |

550-220-TG 178 |

| Re (MPa) |

L |

2.2 - 2.2 |

≥ 550 |

| T |

2.2 - 2.2 |

≥ 550 |

| Rm (MPa) |

L |

2.2 - 2.2 |

650 - 850 |

| T |

2.2 - 2.2 |

650 - 850 |

| A80 (%) |

/ |

2.2 - 2.2 |

≥ 12 |

550-250-TG 178

| |

Direction |

Thickness (mm) |

550-250-TG 178 |

| Re (MPa) |

L |

2.5 - 2.5 |

≥ 550 |

| T |

2.5 - 2.5 |

≥ 550 |

| Rm (MPa) |

L |

2.5 - 2.5 |

650 - 850 |

| T |

2.5 - 2.5 |

650 - 850 |

| A80 (%) |

/ |

2.5 - 2.5 |

≥ 12 |

550-300-TG 178

| |

Direction |

Thickness (mm) |

550-300-TG 178 |

| Re (MPa) |

L |

3 - 3 |

≥ 550 |

| T |

3 - 3 |

≥ 550 |

| Rm (MPa) |

L |

3 - 3 |

650 - 850 |

| T |

3 - 3 |

650 - 850 |

| A 5.65√So (%) |

L |

3 - 3 |

≥ 14 |

| T |

3 - 3 |

≥ 14 |

550-400-TG 178

| |

Direction |

Thickness (mm) |

550-400-TG 178 |

| Re (MPa) |

L |

4 - 4 |

≥ 550 |

| T |

4 - 4 |

≥ 550 |

| Rm (MPa) |

L |

4 - 4 |

650 - 850 |

| T |

4 - 4 |

650 - 850 |

| A 5.65√So (%) |

L |

4 - 4 |

≥ 14 |

| T |

4 - 4 |

≥ 14 |

550-500-TG 178

| |

Direction |

Thickness (mm) |

550-500-TG 178 |

| Re (MPa) |

L |

5 - 5 |

≥ 550 |

| T |

5 - 5 |

≥ 550 |

| Rm (MPa) |

L |

5 - 5 |

650 - 850 |

| T |

5 - 5 |

650 - 850 |

| A 5.65√So (%) |

L |

5 - 5 |

≥ 14 |

| T |

5 - 5 |

≥ 14 |

600-200-TG 178

| |

Direction |

Thickness (mm) |

600-200-TG 178 |

| Re (MPa) |

L |

2 - 2 |

≥ 600 |

| T |

2 - 2 |

≥ 600 |

| Rm (MPa) |

L |

2 - 2 |

700 - 900 |

| T |

2 - 2 |

700 - 900 |

| A80 (%) |

/ |

2 - 2 |

≥ 10 |

600-250-TG 178

| |

Direction |

Thickness (mm) |

600-250-TG 178 |

| Re (MPa) |

L |

2.5 - 2.5 |

≥ 600 |

| T |

2.5 - 2.5 |

≥ 600 |

| Rm (MPa) |

L |

2.5 - 2.5 |

700 - 900 |

| T |

2.5 - 2.5 |

700 - 900 |

| A80 (%) |

/ |

2.5 - 2.5 |

≥ 10 |

600-300-TG 178

| |

Direction |

Thickness (mm) |

600-300-TG 178 |

| Re (MPa) |

L |

3 - 3 |

≥ 600 |

| T |

3 - 3 |

≥ 600 |

| Rm (MPa) |

L |

3 - 3 |

700 - 900 |

| T |

3 - 3 |

700 - 900 |

| A 5.65√So (%) |

L |

3 - 3 |

≥ 12 |

| T |

3 - 3 |

≥ 12 |

600-400-TG 178

| |

Direction |

Thickness (mm) |

600-400-TG 178 |

| Re (MPa) |

L |

4 - 4 |

≥ 600 |

| T |

4 - 4 |

≥ 600 |

| Rm (MPa) |

L |

4 - 4 |

700 - 900 |

| T |

4 - 4 |

700 - 900 |

| A 5.65√So (%) |

L |

4 - 4 |

≥ 12 |

| T |

4 - 4 |

≥ 12 |

600-500-TG 178

| |

Direction |

Thickness (mm) |

600-500-TG 178 |

| Re (MPa) |

L |

5 - 5 |

≥ 600 |

| T |

5 - 5 |

≥ 600 |

| Rm (MPa) |

L |

5 - 5 |

700 - 900 |

| T |

5 - 5 |

700 - 900 |

| A 5.65√So (%) |

L |

5 - 5 |

≥ 12 |

| T |

5 - 5 |

≥ 12 |

650-200-TG 178

| |

Direction |

Thickness (mm) |

650-200-TG 178 |

| Re (MPa) |

L |

2 - 2 |

≥ 650 |

| T |

2 - 2 |

≥ 650 |

| Rm (MPa) |

L |

2 - 2 |

750 - 900 |

| T |

2 - 2 |

750 - 900 |

| A80 (%) |

L |

2 - 2 |

≥ 10 |

| T |

2 - 2 |

≥ 10 |

650-250-TG 178

| |

Direction |

Thickness (mm) |

650-250-TG 178 |

| Re (MPa) |

L |

2.5 - 2.5 |

≥ 650 |

| T |

2.5 - 2.5 |

≥ 650 |

| Rm (MPa) |

L |

2.5 - 2.5 |

750 - 900 |

| T |

2.5 - 2.5 |

750 - 900 |

| A80 (%) |

/ |

2.5 - 2.5 |

≥ 10 |

650-300-TG 178

| |

Direction |

Thickness (mm) |

650-300-TG 178 |

| Re (MPa) |

L |

3 - 3 |

≥ 650 |

| T |

3 - 3 |

≥ 650 |

| Rm (MPa) |

L |

3 - 3 |

750 - 900 |

| T |

3 - 3 |

750 - 900 |

| A 5.65√So (%) |

L |

3 - 3 |

≥ 12 |

| T |

3 - 3 |

≥ 12 |

650-400-TG 178

| |

Direction |

Thickness (mm) |

650-400-TG 178 |

| Re (MPa) |

L |

4 - 4 |

≥ 650 |

| T |

4 - 4 |

≥ 650 |

| Rm (MPa) |

L |

4 - 4 |

750 - 900 |

| T |

4 - 4 |

750 - 900 |

| A 5.65√So (%) |

/ |

4 - 4 |

≥ 12 |

650-500-TG 178

| |

Direction |

Thickness (mm) |

650-500-TG 178 |

| Re (MPa) |

L |

5 - 5 |

≥ 650 |

| T |

5 - 5 |

≥ 650 |

| Rm (MPa) |

L |

5 - 5 |

750 - 900 |

| T |

5 - 5 |

750 - 900 |

| A 5.65√So (%) |

/ |

5 - 5 |

≥ 12 |

700-200-TG 178

| |

Notes |

Direction |

Thickness (mm) |

700-200-TG 178 |

| Re (MPa) |

1 |

L |

2 - 2 |

≥ 700 |

| T |

2 - 2 |

≥ 700 |

| Rm (MPa) |

L |

2 - 2 |

750 - 900 |

| T |

2 - 2 |

750 - 900 |

| A80 (%) |

L |

2 - 2 |

≥ 10 |

| T |

2 - 2 |

≥ 10 |

700-250-TG 178

| |

Notes |

Direction |

Thickness (mm) |

700-250-TG 178 |

| Re (MPa) |

1 |

L |

2.5 - 2.5 |

≥ 700 |

| T |

2.5 - 2.5 |

≥ 700 |

| Rm (MPa) |

L |

2.5 - 2.5 |

750 - 900 |

| T |

2.5 - 2.5 |

750 - 900 |

| A80 (%) |

/ |

2.5 - 2.5 |

≥ 10 |

700-300-TG 178

| |

Notes |

Direction |

Thickness (mm) |

700-300-TG 178 |

| Re (MPa) |

1 |

L |

3 - 3 |

≥ 700 |

| T |

3 - 3 |

≥ 700 |

| Rm (MPa) |

L |

3 - 3 |

750 - 900 |

| T |

3 - 3 |

750 - 900 |

| A 5.65√So (%) |

L |

3 - 3 |

≥ 12 |

| T |

3 - 3 |

≥ 12 |

700-400-TG 178

| |

Notes |

Direction |

Thickness (mm) |

700-400-TG 178 |

| Re (MPa) |

1 |

L |

4 - 4 |

≥ 700 |

| T |

4 - 4 |

≥ 700 |

| Rm (MPa) |

L |

4 - 4 |

750 - 900 |

| T |

4 - 4 |

750 - 900 |

| A 5.65√So (%) |

/ |

4 - 4 |

≥ 12 |

700-500-TG 178

| |

Notes |

Direction |

Thickness (mm) |

700-500-TG 178 |

| Re (MPa) |

1 |

L |

5 - 5 |

≥ 700 |

| T |

5 - 5 |

≥ 700 |

| Rm (MPa) |

L |

5 - 5 |

750 - 900 |

| T |

5 - 5 |

750 - 900 |

| A 5.65√So (%) |

/ |

5 - 5 |

≥ 12 |

Prev grade

Next grade

Coating properties

Hot rolled pole sheet grades are available non-insulated. They can be supplied with the hot rolled oxide layer or pickled.

When pickled, they are protected with Easyfilm® dry coating, which offers protection against atmospheric corrosion for a period of three months.

All details provided in the ArcelorMittal Flat Carbon Europe S.A. catalogue are for information purposes only. ArcelorMittal Flat Carbon Europe S.A. reserves the right to change its product range at any time without prior notice.

For more information on our products, visit the document centre.

Download

Download