In order to offer you the best possible experience, we suggest that you accept the deposit and reading of cookies and the use of technology necessary for their proper functioning:

These grades are especially recommended for forming by bending or profiling, for furniture, shelving etc.

These cold rolled thin gauge steels are obtained by continuous annealing, which gives them very good surface cleanliness, excellent uniformity of their mechanical properties and a high standard of flatness. HC180CA AM FCE grade complies with the EN 10130:2006 standard for DC01.

The excellent properties of these steels allow smooth and continuous operation of the various process steps, which is particularly important on high productivity automated lines. These grades are especially recommended for forming by bending or profiling.

These steels are used for the manufacture of casing panels for domestic appliances, heating equipment, furniture, shelving, drums and generally all applications where surface cleanliness is required.

The weldability of these cold rolled grades using conventional processes is guaranteed. Nevertheless, it is recommended that the welding process should be specified when ordering.

These grades are also suitable substrates for coatings such as phosphating, painting, electroplating and batch galvanisation.

These cold rolled steels are available with surface types A or B as defined in the EN 10130 standard.

| Old brand names | |

|---|---|

| HC180CA AM FCE | HQE 200/Solrec 230 |

| HC220CA AM FCE | Sidca SE-220/HQE 240/Solrec 270 |

| HC240CA AM FCE | |

| HC260CA AM FCE | Sidca SE-260/HQE 280/Solrec 290 |

Grades in italics: not included in the standard

| HC180CA AM FCE | |

|---|---|

| Old brand names | HQE 200/Solrec 230 |

Grades in italics: not included in the standard

| HC220CA AM FCE | |

|---|---|

| Old brand names | Sidca SE-220/HQE 240/Solrec 270 |

Grades in italics: not included in the standard

| HC240CA AM FCE | |

|---|---|

| Old brand names | |

Grades in italics: not included in the standard

| HC260CA AM FCE | |

|---|---|

| Old brand names | Sidca SE-260/HQE 280/Solrec 290 |

Grades in italics: not included in the standard

Grades in italics: not included in the standard

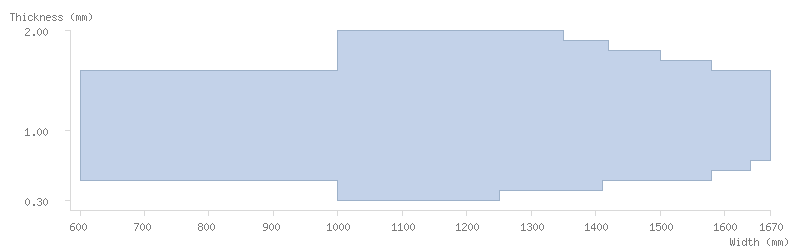

| Thickness (mm) | HC180CA AM FCE | HC220CA AM FCE, HC240CA AM FCE, HC260CA AM FCE | ||

|---|---|---|---|---|

| Min width | Max width | Min width | Max width | |

| 0.30 ≤ th < 0.40 | 1000 | 1250 | 1000 | 1250 |

| 0.40 ≤ th < 0.50 | 1410 | 1410 | ||

| 0.50 ≤ th < 0.60 | 600 | 1580 | 600 | 1580 |

| 0.60 ≤ th < 0.70 | 1640 | 1640 | ||

| 0.70 ≤ th < 1.60 | 1670 | 1670 | ||

| 1.60 ≤ th < 1.70 | 1000 | 1580 | 1580 | |

| 1.70 ≤ th < 1.80 | 1500 | 1500 | ||

| 1.80 ≤ th < 1.90 | 1420 | 1420 | ||

| 1.90 ≤ th < 2.00 | 1350 | 1350 | ||

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 0.30 ≤ th < 0.40 | 1000 | 1250 |

| 0.40 ≤ th < 0.50 | 1410 | |

| 0.50 ≤ th < 0.60 | 600 | 1580 |

| 0.60 ≤ th < 0.70 | 1640 | |

| 0.70 ≤ th < 1.60 | 1670 | |

| 1.60 ≤ th < 1.70 | 1000 | 1580 |

| 1.70 ≤ th < 1.80 | 1500 | |

| 1.80 ≤ th < 1.90 | 1420 | |

| 1.90 ≤ th < 2.00 | 1350 |

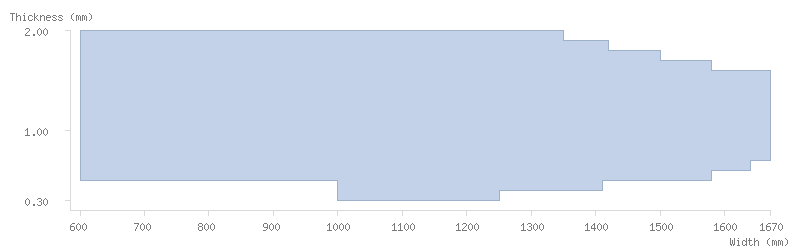

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 0.30 ≤ th < 0.40 | 1000 | 1250 |

| 0.40 ≤ th < 0.50 | 1410 | |

| 0.50 ≤ th < 0.60 | 600 | 1580 |

| 0.60 ≤ th < 0.70 | 1640 | |

| 0.70 ≤ th < 1.60 | 1670 | |

| 1.60 ≤ th < 1.70 | 1580 | |

| 1.70 ≤ th < 1.80 | 1500 | |

| 1.80 ≤ th < 1.90 | 1420 | |

| 1.90 ≤ th < 2.00 | 1350 |

| Direction | Thickness (mm) | Re (MPa) | Rm (MPa) | A80 (%) | |

|---|---|---|---|---|---|

| HC180CA AM FCE | T | 0.3 - 2 | 180 - 280 | 300 - 360 | ≥ 32 |

| HC220CA AM FCE | T | 0.3 - 2 | 220 - 280 | 320 - 380 | ≥ 30 |

| HC240CA AM FCE | T | 0.3 - 2 | 240 - 320 | 330 - 380 | ≥ 30 |

| HC260CA AM FCE | T | 0.3 - 2 | 260 - 330 | 360 - 420 | ≥ 28 |

Grades in italics: not included in the standard

| Direction | Thickness (mm) | HC180CA AM FCE | |

|---|---|---|---|

| Re (MPa) | T | 0.3 - 2 | 180 - 280 |

| Rm (MPa) | T | 0.3 - 2 | 300 - 360 |

| A80 (%) | T | 0.3 - 2 | ≥ 32 |

Grades in italics: not included in the standard

| Direction | Thickness (mm) | HC220CA AM FCE | |

|---|---|---|---|

| Re (MPa) | T | 0.3 - 2 | 220 - 280 |

| Rm (MPa) | T | 0.3 - 2 | 320 - 380 |

| A80 (%) | T | 0.3 - 2 | ≥ 30 |

Grades in italics: not included in the standard

| Direction | Thickness (mm) | HC240CA AM FCE | |

|---|---|---|---|

| Re (MPa) | T | 0.3 - 2 | 240 - 320 |

| Rm (MPa) | T | 0.3 - 2 | 330 - 380 |

| A80 (%) | T | 0.3 - 2 | ≥ 30 |

Grades in italics: not included in the standard

| Direction | Thickness (mm) | HC260CA AM FCE | |

|---|---|---|---|

| Re (MPa) | T | 0.3 - 2 | 260 - 330 |

| Rm (MPa) | T | 0.3 - 2 | 360 - 420 |

| A80 (%) | T | 0.3 - 2 | ≥ 28 |

Grades in italics: not included in the standard

Grades in italics: not included in the standard

| C (%) | Mn (%) | P (%) | S (%) | Si (%) | Al (%) | Galvanisation | |

|---|---|---|---|---|---|---|---|

| HC180CA AM FCE | ≤ 0.080 | ≤ 0.50 | ≤ 0.030 | ≤ 0.025 | ≤ 0.03 | ≥ 0.020 | Class 1 |

| HC220CA AM FCE | ≤ 0.085 | ≤ 0.50 | ≤ 0.030 | ≤ 0.025 | ≤ 0.03 | ≥ 0.020 | Class 1 |

| HC240CA AM FCE | ≤ 0.085 | ≤ 0.50 | ≤ 0.030 | ≤ 0.025 | ≤ 0.03 | ≥ 0.020 | Class 1 |

| HC260CA AM FCE | ≤ 0.100 | ≤ 0.75 | ≤ 0.030 | ≤ 0.025 | ≤ 0.03 | ≥ 0.020 | Class 1 |

Grades in italics: not included in the standard

| HC180CA AM FCE | |

|---|---|

| C (%) | ≤ 0.080 |

| Mn (%) | ≤ 0.50 |

| P (%) | ≤ 0.030 |

| S (%) | ≤ 0.025 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.020 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

| HC220CA AM FCE | |

|---|---|

| C (%) | ≤ 0.085 |

| Mn (%) | ≤ 0.50 |

| P (%) | ≤ 0.030 |

| S (%) | ≤ 0.025 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.020 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

| HC240CA AM FCE | |

|---|---|

| C (%) | ≤ 0.085 |

| Mn (%) | ≤ 0.50 |

| P (%) | ≤ 0.030 |

| S (%) | ≤ 0.025 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.020 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

| HC260CA AM FCE | |

|---|---|

| C (%) | ≤ 0.100 |

| Mn (%) | ≤ 0.75 |

| P (%) | ≤ 0.030 |

| S (%) | ≤ 0.025 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.020 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

Grades in italics: not included in the standard

Any questions?

Ask them via our contact form on

https://industry.arcelormittal.com/getintouch

All details provided in the ArcelorMittal Flat Carbon Europe S.A. catalogue are for information purposes only. ArcelorMittal Flat Carbon Europe S.A. reserves the right to change its product range at any time without prior notice.

Download

Download