B20 - HSLA-High Strength Low Alloy steels

HSLA steels are particularly suitable for structural parts that do not require severe forming, such as industrial shelving systems or furniture and also radiators and racks.

Download

Download

Available grades:

Properties

These high strength steels are characterised by their low content of both carbon and micro-alloying elements. This gives HSLA steels outstanding functional properties, such as weldability and coatability. The hardening achieved by controlled internal purity and fine grain size structure ensures excellent mechanical strength. The grades available are in compliance with EN 10268:2006+A1:2013 and are obtained after either batch or continuous annealing.

Steel grades with yield strength ≥ 460 MPa are only produced by the continuous annealing process.

Advantages

They combine improved weldability with good formability. The narrow variation margins for their mechanical properties make it easy to shape the steel (presses or automated lines). They also have good fatigue and impact resistance.

Applications

They are particularly suitable for structural parts that do not require severe forming (profiling, bending or light drawing): automotive structures and reinforcements, industrial shelving systems, radiators, racking systems, furniture, mechanical engineering applications etc.

Formability

The deep drawing performance of the HC260LA AM FCE grade is equivalent to that of mild steel. Drawability decreases as the yield strength increases.

Forming limit curves can be used to define the maximum strains not to be exceeded when forming steel by various methods, so as to avoid the risk of incipient necking. These curves are available on request.

Please contact us for other forming data on HSLA products for particular sheet thicknesses.

Weldability

HSLA AM FCE steel grades have good weldability in all welding processes.

Based on many years’ practical experience in arc and resistance spot welding of its products, ArcelorMittal can provide valuable technical assistance in defining the welding parameters for all products in the HSLA range.

Fatigue resistance

Fatigue resistance is generally expressed as an endurance limit, corresponding to the maximum stress resisted for a given number of cycles before failure. The table below gives some examples of 5 million cycle endurance limits under fluctuating tension with a stress ratio Rs = 0.1.

| |

Thickness |

5 million cycle endurance limit (MPa) |

| HC300LA AM FCE |

1 mm |

362 |

| HC380LA AM FCE |

0.8 mm |

403 |

A complete database of fatigue resistance data on this range of common steels is available on request.

Surface quality

Surface cleanliness

If improved surface cleanliness is required, ArcelorMittal also offers this range of steel grades with compulsory use of continuous annealing or hydrogen annealing.

Brand correspondence

Full table

| |

EN 10268:2006+A1:2013 |

EN 10268:1998 |

ASTM 607:1993 |

Old brand names |

| HC260LA EN 10268 |

HC260LA |

H240LA |

|

|

| HC260LA AM FCE |

HC260LA |

H240LA |

|

Profilar 260 |

| HC300LA EN 10268 |

HC300LA |

H280LA |

|

|

| HC300LA AM FCE |

HC300LA |

H280LA |

|

Profilar 300/Sidca M-300/Soldur 280 |

| HC340LA EN 10268 |

HC340LA |

H320LA |

|

|

| HC340LA AM FCE |

HC340LA |

H320LA |

Grade 607-45 |

Profilar 340/Sidca M-340/Soldur 320 |

| HC380LA EN 10268 |

HC380LA |

H360LA |

|

|

| HC380LA AM FCE |

HC380LA |

H360LA |

Grade 607-50 |

Profilar 380/Soldur 360 |

| HC420LA EN 10268 |

HC420LA |

H400LA |

|

|

| HC420LA AM FCE |

HC420LA |

H400LA |

Grade 607-55 |

Profilar 420 |

| HC460LA EN 10268 |

HC460LA |

|

|

|

| HC460LA AM FCE |

HC460LA |

|

|

|

| HC500LA EN 10268 |

HC500LA |

|

|

|

| HC500LA AM FCE |

HC500LA |

|

|

|

HC260LA EN 10268, HC260LA AM FCE

| |

HC260LA EN 10268 |

HC260LA AM FCE |

| EN 10268:2006+A1:2013 |

HC260LA |

HC260LA |

| EN 10268:1998 |

H240LA |

H240LA |

| ASTM 607:1993 |

|

|

| Old brand names |

|

Profilar 260 |

HC300LA EN 10268, HC300LA AM FCE

| |

HC300LA EN 10268 |

HC300LA AM FCE |

| EN 10268:2006+A1:2013 |

HC300LA |

HC300LA |

| EN 10268:1998 |

H280LA |

H280LA |

| ASTM 607:1993 |

|

|

| Old brand names |

|

Profilar 300/Sidca M-300/Soldur 280 |

HC340LA EN 10268, HC340LA AM FCE

| |

HC340LA EN 10268 |

HC340LA AM FCE |

| EN 10268:2006+A1:2013 |

HC340LA |

HC340LA |

| EN 10268:1998 |

H320LA |

H320LA |

| ASTM 607:1993 |

|

Grade 607-45 |

| Old brand names |

|

Profilar 340/Sidca M-340/Soldur 320 |

HC380LA EN 10268, HC380LA AM FCE

| |

HC380LA EN 10268 |

HC380LA AM FCE |

| EN 10268:2006+A1:2013 |

HC380LA |

HC380LA |

| EN 10268:1998 |

H360LA |

H360LA |

| ASTM 607:1993 |

|

Grade 607-50 |

| Old brand names |

|

Profilar 380/Soldur 360 |

HC420LA EN 10268, HC420LA AM FCE

| |

HC420LA EN 10268 |

HC420LA AM FCE |

| EN 10268:2006+A1:2013 |

HC420LA |

HC420LA |

| EN 10268:1998 |

H400LA |

H400LA |

| ASTM 607:1993 |

|

Grade 607-55 |

| Old brand names |

|

Profilar 420 |

HC460LA EN 10268, HC460LA AM FCE

| |

HC460LA EN 10268 |

HC460LA AM FCE |

| EN 10268:2006+A1:2013 |

HC460LA |

HC460LA |

| EN 10268:1998 |

|

|

| ASTM 607:1993 |

|

|

| Old brand names |

|

|

HC500LA EN 10268, HC500LA AM FCE

| |

HC500LA EN 10268 |

HC500LA AM FCE |

| EN 10268:2006+A1:2013 |

HC500LA |

HC500LA |

| EN 10268:1998 |

|

|

| ASTM 607:1993 |

|

|

| Old brand names |

|

|

Prev grade

Next grade

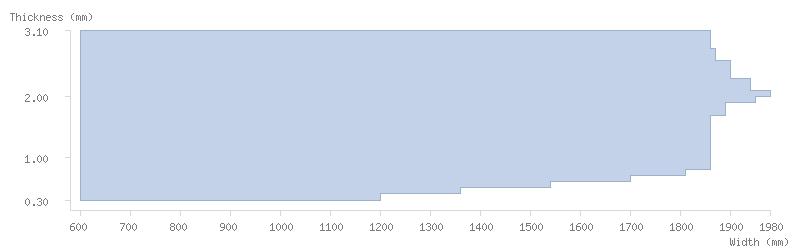

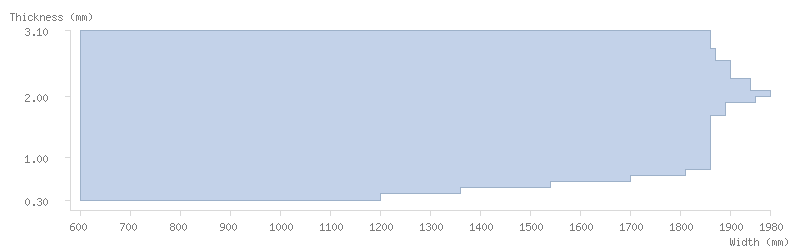

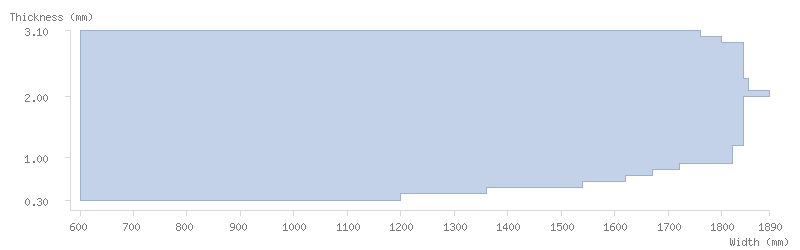

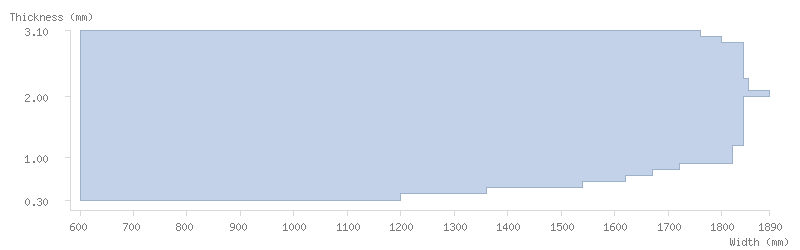

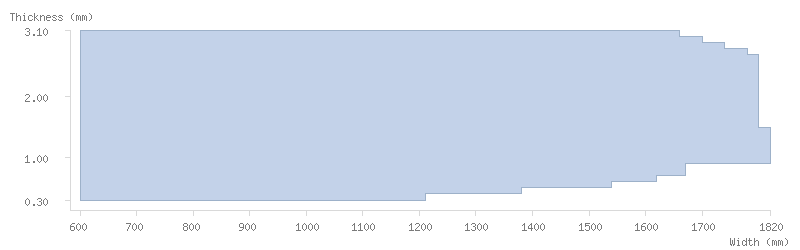

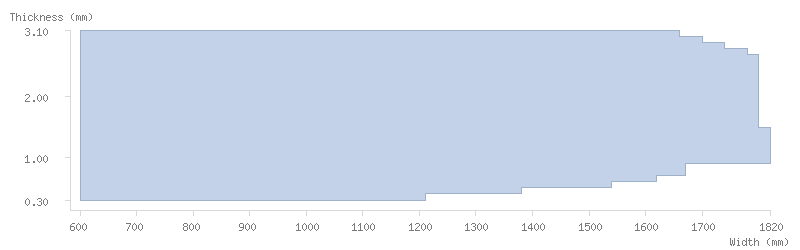

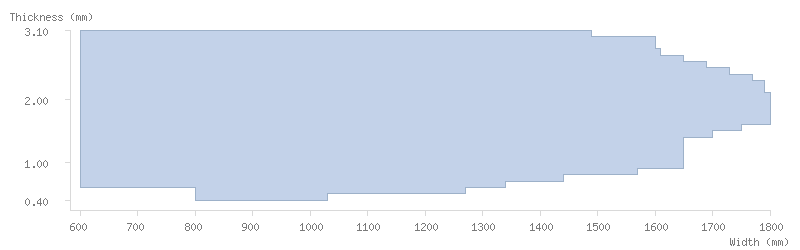

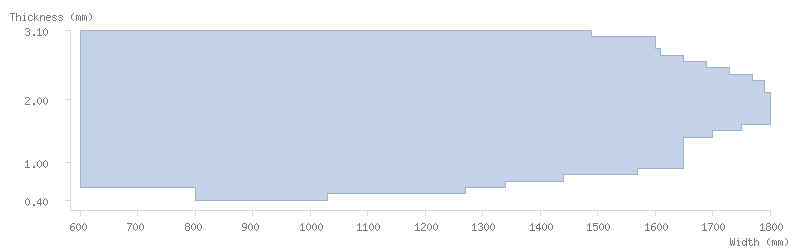

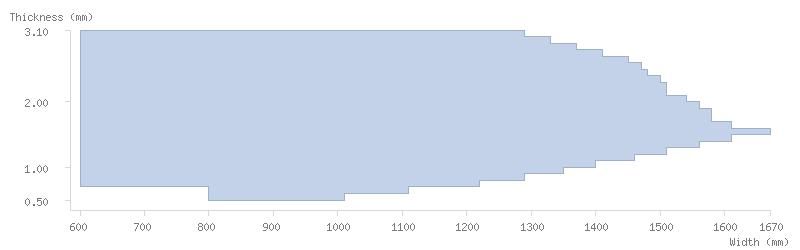

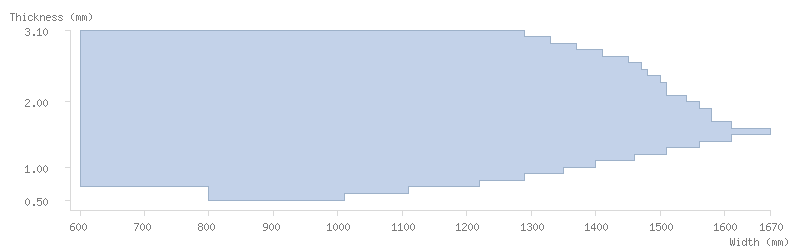

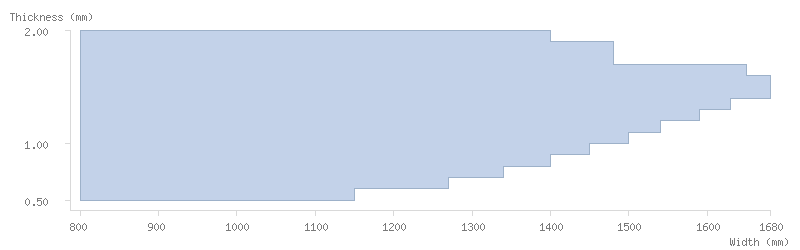

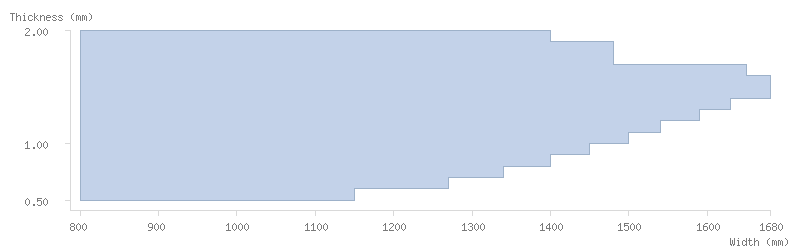

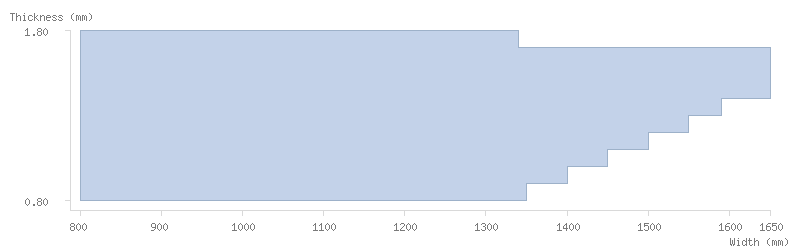

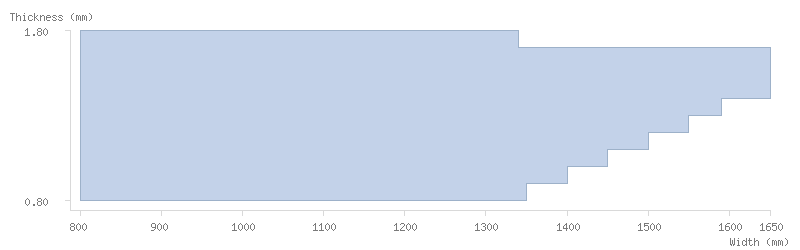

Dimensions

Mechanical properties

Full table

| |

Direction |

Thickness (mm) |

Re (MPa) |

Rm (MPa) |

A80 (%) |

Bending ratio (th) |

| HC260LA EN 10268 |

L |

0.5 - 0.7 |

240 - 310 |

340 - 420 |

≥ 25 |

- |

| 0.7 - 3 |

≥ 27 |

| T |

0.5 - 0.7 |

260 - 330 |

350 - 430 |

≥ 24 |

- |

| 0.7 - 3 |

≥ 26 |

| HC260LA AM FCE |

L |

0.5 - 0.7 |

240 - 310 |

340 - 420 |

≥ 25 |

- |

| 0.7 - 3 |

≥ 27 |

| T |

0.5 - 0.7 |

260 - 330 |

350 - 430 |

≥ 24 |

≥ 0 |

| 0.7 - 3 |

≥ 26 |

| HC300LA EN 10268 |

L |

0.5 - 0.7 |

280 - 360 |

370 - 470 |

≥ 22 |

- |

| 0.7 - 3 |

≥ 24 |

| T |

0.5 - 0.7 |

300 - 380 |

380 - 480 |

≥ 21 |

- |

| 0.7 - 3 |

≥ 23 |

| HC300LA AM FCE |

L |

0.5 - 0.7 |

280 - 360 |

370 - 470 |

≥ 22 |

- |

| 0.7 - 3 |

≥ 24 |

| T |

0.5 - 0.7 |

300 - 380 |

380 - 480 |

≥ 21 |

≥ 0 |

| 0.7 - 3 |

≥ 23 |

| HC340LA EN 10268 |

L |

0.5 - 0.7 |

320 - 410 |

400 - 500 |

≥ 20 |

- |

| 0.7 - 3 |

≥ 22 |

| T |

0.5 - 0.7 |

340 - 420 |

410 - 510 |

≥ 19 |

- |

| 0.7 - 3 |

≥ 21 |

| HC340LA AM FCE |

L |

0.5 - 0.7 |

320 - 410 |

400 - 500 |

≥ 20 |

- |

| 0.7 - 3 |

≥ 22 |

| T |

0.5 - 0.7 |

340 - 420 |

410 - 510 |

≥ 19 |

≥ 0 |

| 0.7 - 3 |

≥ 21 |

| HC380LA EN 10268 |

L |

0.5 - 0.7 |

350 - 450 |

430 - 550 |

≥ 18 |

- |

| 0.7 - 3 |

≥ 20 |

| T |

0.5 - 0.7 |

380 - 480 |

440 - 580 |

≥ 17 |

- |

| 0.7 - 3 |

≥ 19 |

| HC380LA AM FCE |

L |

0.5 - 0.7 |

360 - 450 |

450 - 550 |

≥ 18 |

- |

| 0.7 - 3 |

≥ 20 |

| T |

0.5 - 0.7 |

380 - 480 |

460 - 560 |

≥ 17 |

≥ 0.5 |

| 0.7 - 3 |

≥ 19 |

| HC420LA EN 10268 |

L |

0.5 - 0.7 |

390 - 500 |

460 - 580 |

≥ 16 |

- |

| 0.7 - 3 |

≥ 18 |

| T |

0.5 - 0.7 |

420 - 520 |

470 - 600 |

≥ 15 |

- |

| 0.7 - 3 |

≥ 17 |

| HC420LA AM FCE |

L |

0.5 - 0.7 |

400 - 500 |

470 - 580 |

≥ 16 |

- |

| 0.7 - 3 |

≥ 18 |

| T |

0.5 - 0.7 |

420 - 520 |

480 - 590 |

≥ 15 |

≥ 0.5 |

| 0.7 - 3 |

≥ 17 |

| HC460LA EN 10268 |

T |

0.5 - 0.7 |

460 - 580 |

510 - 660 |

≥ 11 |

- |

| 0.7 - 2 |

≥ 13 |

| HC460LA AM FCE |

T |

0.5 - 0.7 |

460 - 560 |

550 - 650 |

≥ 13 |

- |

| 0.7 - 2 |

≥ 15 |

| HC500LA EN 10268 |

T |

0.5 - 0.7 |

500 - 620 |

550 - 710 |

≥ 10 |

- |

| 0.7 - 2 |

≥ 12 |

| HC500LA AM FCE |

T |

0.5 - 0.7 |

500 - 620 |

570 - 710 |

≥ 12 |

≥ 0.5 |

| 0.7 - 2 |

≥ 14 |

The choice of direction for the mechanical properties should be specified when ordering.

HC260LA EN 10268, HC260LA AM FCE

| |

Direction |

Thickness (mm) |

HC260LA EN 10268 |

HC260LA AM FCE |

| Re (MPa) |

L |

0.5 - 3 |

240 - 310 |

240 - 310 |

| T |

0.5 - 3 |

260 - 330 |

260 - 330 |

| Rm (MPa) |

L |

0.5 - 3 |

340 - 420 |

340 - 420 |

| T |

0.5 - 3 |

350 - 430 |

350 - 430 |

| A80 (%) |

L |

0.5 - 0.7 |

≥ 25 |

≥ 25 |

| 0.7 - 3 |

≥ 27 |

≥ 27 |

| T |

0.5 - 0.7 |

≥ 24 |

≥ 24 |

| 0.7 - 3 |

≥ 26 |

≥ 26 |

| Bending ratio (th) |

T |

0.5 - 3 |

- |

≥ 0 |

HC300LA EN 10268, HC300LA AM FCE

| |

Direction |

Thickness (mm) |

HC300LA EN 10268 |

HC300LA AM FCE |

| Re (MPa) |

L |

0.5 - 3 |

280 - 360 |

280 - 360 |

| T |

0.5 - 3 |

300 - 380 |

300 - 380 |

| Rm (MPa) |

L |

0.5 - 3 |

370 - 470 |

370 - 470 |

| T |

0.5 - 3 |

380 - 480 |

380 - 480 |

| A80 (%) |

L |

0.5 - 0.7 |

≥ 22 |

≥ 22 |

| 0.7 - 3 |

≥ 24 |

≥ 24 |

| T |

0.5 - 0.7 |

≥ 21 |

≥ 21 |

| 0.7 - 3 |

≥ 23 |

≥ 23 |

| Bending ratio (th) |

T |

0.5 - 3 |

- |

≥ 0 |

HC340LA EN 10268, HC340LA AM FCE

| |

Direction |

Thickness (mm) |

HC340LA EN 10268 |

HC340LA AM FCE |

| Re (MPa) |

L |

0.5 - 3 |

320 - 410 |

320 - 410 |

| T |

0.5 - 3 |

340 - 420 |

340 - 420 |

| Rm (MPa) |

L |

0.5 - 3 |

400 - 500 |

400 - 500 |

| T |

0.5 - 3 |

410 - 510 |

410 - 510 |

| A80 (%) |

L |

0.5 - 0.7 |

≥ 20 |

≥ 20 |

| 0.7 - 3 |

≥ 22 |

≥ 22 |

| T |

0.5 - 0.7 |

≥ 19 |

≥ 19 |

| 0.7 - 3 |

≥ 21 |

≥ 21 |

| Bending ratio (th) |

T |

0.5 - 3 |

- |

≥ 0 |

HC380LA EN 10268, HC380LA AM FCE

| |

Direction |

Thickness (mm) |

HC380LA EN 10268 |

HC380LA AM FCE |

| Re (MPa) |

L |

0.5 - 3 |

350 - 450 |

360 - 450 |

| T |

0.5 - 3 |

380 - 480 |

380 - 480 |

| Rm (MPa) |

L |

0.5 - 3 |

430 - 550 |

450 - 550 |

| T |

0.5 - 3 |

440 - 580 |

460 - 560 |

| A80 (%) |

L |

0.5 - 0.7 |

≥ 18 |

≥ 18 |

| 0.7 - 3 |

≥ 20 |

≥ 20 |

| T |

0.5 - 0.7 |

≥ 17 |

≥ 17 |

| 0.7 - 3 |

≥ 19 |

≥ 19 |

| Bending ratio (th) |

T |

0.5 - 3 |

- |

≥ 0.5 |

HC420LA EN 10268, HC420LA AM FCE

| |

Direction |

Thickness (mm) |

HC420LA EN 10268 |

HC420LA AM FCE |

| Re (MPa) |

L |

0.5 - 3 |

390 - 500 |

400 - 500 |

| T |

0.5 - 3 |

420 - 520 |

420 - 520 |

| Rm (MPa) |

L |

0.5 - 3 |

460 - 580 |

470 - 580 |

| T |

0.5 - 3 |

470 - 600 |

480 - 590 |

| A80 (%) |

L |

0.5 - 0.7 |

≥ 16 |

≥ 16 |

| 0.7 - 3 |

≥ 18 |

≥ 18 |

| T |

0.5 - 0.7 |

≥ 15 |

≥ 15 |

| 0.7 - 3 |

≥ 17 |

≥ 17 |

| Bending ratio (th) |

T |

0.5 - 3 |

- |

≥ 0.5 |

HC460LA EN 10268, HC460LA AM FCE

| |

Direction |

Thickness (mm) |

HC460LA EN 10268 |

HC460LA AM FCE |

| Re (MPa) |

T |

0.5 - 2 |

460 - 580 |

460 - 560 |

| Rm (MPa) |

T |

0.5 - 2 |

510 - 660 |

550 - 650 |

| A80 (%) |

T |

0.5 - 0.7 |

≥ 11 |

≥ 13 |

| 0.7 - 2 |

≥ 13 |

≥ 15 |

HC500LA EN 10268, HC500LA AM FCE

| |

Direction |

Thickness (mm) |

HC500LA EN 10268 |

HC500LA AM FCE |

| Re (MPa) |

T |

0.5 - 2 |

500 - 620 |

500 - 620 |

| Rm (MPa) |

T |

0.5 - 2 |

550 - 710 |

570 - 710 |

| A80 (%) |

T |

0.5 - 0.7 |

≥ 10 |

≥ 12 |

| 0.7 - 2 |

≥ 12 |

≥ 14 |

| Bending ratio (th) |

T |

0.5 - 2 |

- |

≥ 0.5 |

Prev grade

Next grade

The choice of direction for the mechanical properties should be specified when ordering.

Chemical composition

Full table

| |

C (%) |

Mn (%) |

P (%) |

S (%) |

Si (%) |

Al (%) |

Nb (%) |

Ti (%) |

Galvanisation |

| HC260LA EN 10268 |

≤ 0.10 |

≤ 1.0 |

≤ 0.030 |

≤ 0.025 |

≤ 0.5 |

≥ 0.015 |

≤ 0.09 |

≤ 0.15 |

- |

| HC260LA AM FCE |

≤ 0.080 |

≤ 0.60 |

≤ 0.025 |

≤ 0.020 |

≤ 0.03 |

≥ 0.015 |

≤ 0.090 |

≤ 0.150 |

Class 1 |

| HC300LA EN 10268 |

≤ 0.12 |

≤ 1.4 |

≤ 0.030 |

≤ 0.025 |

≤ 0.5 |

≥ 0.015 |

≤ 0.09 |

≤ 0.15 |

- |

| HC300LA AM FCE |

≤ 0.090 |

≤ 0.70 |

≤ 0.025 |

≤ 0.020 |

≤ 0.03 |

≥ 0.015 |

≤ 0.090 |

≤ 0.150 |

Class 1 |

| HC340LA EN 10268 |

≤ 0.12 |

≤ 1.5 |

≤ 0.030 |

≤ 0.025 |

≤ 0.5 |

≥ 0.015 |

≤ 0.09 |

≤ 0.15 |

- |

| HC340LA AM FCE |

≤ 0.100 |

≤ 0.90 |

≤ 0.025 |

≤ 0.020 |

≤ 0.03 |

≥ 0.015 |

≤ 0.090 |

≤ 0.150 |

Class 1 |

| HC380LA EN 10268 |

≤ 0.12 |

≤ 1.6 |

≤ 0.030 |

≤ 0.025 |

≤ 0.5 |

≥ 0.015 |

≤ 0.09 |

≤ 0.15 |

- |

| HC380LA AM FCE |

≤ 0.100 |

≤ 1.00 |

≤ 0.025 |

≤ 0.020 |

≤ 0.35 |

≥ 0.015 |

≤ 0.090 |

≤ 0.150 |

No |

| HC420LA EN 10268 |

≤ 0.14 |

≤ 1.6 |

≤ 0.030 |

≤ 0.025 |

≤ 0.5 |

≥ 0.015 |

≤ 0.09 |

≤ 0.15 |

- |

| HC420LA AM FCE |

≤ 0.100 |

≤ 1.20 |

≤ 0.025 |

≤ 0.020 |

≤ 0.15 |

≥ 0.015 |

≤ 0.090 |

≤ 0.150 |

No |

| HC460LA EN 10268 |

≤ 0.14 |

≤ 1.8 |

≤ 0.030 |

≤ 0.025 |

≤ 0.6 |

≥ 0.015 |

≤ 0.09 |

≤ 0.15 |

- |

| HC460LA AM FCE |

≤ 0.100 |

≤ 1.60 |

≤ 0.025 |

≤ 0.020 |

≤ 0.15 |

≥ 0.015 |

≤ 0.090 |

≤ 0.150 |

No |

| HC500LA EN 10268 |

≤ 0.14 |

≤ 1.8 |

≤ 0.030 |

≤ 0.025 |

≤ 0.6 |

≥ 0.015 |

≤ 0.09 |

≤ 0.15 |

- |

| HC500LA AM FCE |

≤ 0.100 |

≤ 1.60 |

≤ 0.025 |

≤ 0.020 |

≤ 0.15 |

≥ 0.015 |

≤ 0.090 |

≤ 0.150 |

No |

V+Nb+Ti ≤ 0.22%

HC260LA EN 10268, HC260LA AM FCE

| |

HC260LA EN 10268 |

HC260LA AM FCE |

| C (%) |

≤ 0.10 |

≤ 0.080 |

| Mn (%) |

≤ 1.0 |

≤ 0.60 |

| P (%) |

≤ 0.030 |

≤ 0.025 |

| S (%) |

≤ 0.025 |

≤ 0.020 |

| Si (%) |

≤ 0.5 |

≤ 0.03 |

| Al (%) |

≥ 0.015 |

≥ 0.015 |

| Nb (%) |

≤ 0.09 |

≤ 0.090 |

| Ti (%) |

≤ 0.15 |

≤ 0.150 |

| Galvanisation |

- |

Class 1 |

HC300LA EN 10268, HC300LA AM FCE

| |

HC300LA EN 10268 |

HC300LA AM FCE |

| C (%) |

≤ 0.12 |

≤ 0.090 |

| Mn (%) |

≤ 1.4 |

≤ 0.70 |

| P (%) |

≤ 0.030 |

≤ 0.025 |

| S (%) |

≤ 0.025 |

≤ 0.020 |

| Si (%) |

≤ 0.5 |

≤ 0.03 |

| Al (%) |

≥ 0.015 |

≥ 0.015 |

| Nb (%) |

≤ 0.09 |

≤ 0.090 |

| Ti (%) |

≤ 0.15 |

≤ 0.150 |

| Galvanisation |

- |

Class 1 |

HC340LA EN 10268, HC340LA AM FCE

| |

HC340LA EN 10268 |

HC340LA AM FCE |

| C (%) |

≤ 0.12 |

≤ 0.100 |

| Mn (%) |

≤ 1.5 |

≤ 0.90 |

| P (%) |

≤ 0.030 |

≤ 0.025 |

| S (%) |

≤ 0.025 |

≤ 0.020 |

| Si (%) |

≤ 0.5 |

≤ 0.03 |

| Al (%) |

≥ 0.015 |

≥ 0.015 |

| Nb (%) |

≤ 0.09 |

≤ 0.090 |

| Ti (%) |

≤ 0.15 |

≤ 0.150 |

| Galvanisation |

- |

Class 1 |

HC380LA EN 10268, HC380LA AM FCE

| |

HC380LA EN 10268 |

HC380LA AM FCE |

| C (%) |

≤ 0.12 |

≤ 0.100 |

| Mn (%) |

≤ 1.6 |

≤ 1.00 |

| P (%) |

≤ 0.030 |

≤ 0.025 |

| S (%) |

≤ 0.025 |

≤ 0.020 |

| Si (%) |

≤ 0.5 |

≤ 0.35 |

| Al (%) |

≥ 0.015 |

≥ 0.015 |

| Nb (%) |

≤ 0.09 |

≤ 0.090 |

| Ti (%) |

≤ 0.15 |

≤ 0.150 |

| Galvanisation |

- |

No |

HC420LA EN 10268, HC420LA AM FCE

| |

HC420LA EN 10268 |

HC420LA AM FCE |

| C (%) |

≤ 0.14 |

≤ 0.100 |

| Mn (%) |

≤ 1.6 |

≤ 1.20 |

| P (%) |

≤ 0.030 |

≤ 0.025 |

| S (%) |

≤ 0.025 |

≤ 0.020 |

| Si (%) |

≤ 0.5 |

≤ 0.15 |

| Al (%) |

≥ 0.015 |

≥ 0.015 |

| Nb (%) |

≤ 0.09 |

≤ 0.090 |

| Ti (%) |

≤ 0.15 |

≤ 0.150 |

| Galvanisation |

- |

No |

HC460LA EN 10268, HC460LA AM FCE

| |

HC460LA EN 10268 |

HC460LA AM FCE |

| C (%) |

≤ 0.14 |

≤ 0.100 |

| Mn (%) |

≤ 1.8 |

≤ 1.60 |

| P (%) |

≤ 0.030 |

≤ 0.025 |

| S (%) |

≤ 0.025 |

≤ 0.020 |

| Si (%) |

≤ 0.6 |

≤ 0.15 |

| Al (%) |

≥ 0.015 |

≥ 0.015 |

| Nb (%) |

≤ 0.09 |

≤ 0.090 |

| Ti (%) |

≤ 0.15 |

≤ 0.150 |

| Galvanisation |

- |

No |

HC500LA EN 10268, HC500LA AM FCE

| |

HC500LA EN 10268 |

HC500LA AM FCE |

| C (%) |

≤ 0.14 |

≤ 0.100 |

| Mn (%) |

≤ 1.8 |

≤ 1.60 |

| P (%) |

≤ 0.030 |

≤ 0.025 |

| S (%) |

≤ 0.025 |

≤ 0.020 |

| Si (%) |

≤ 0.6 |

≤ 0.15 |

| Al (%) |

≥ 0.015 |

≥ 0.015 |

| Nb (%) |

≤ 0.09 |

≤ 0.090 |

| Ti (%) |

≤ 0.15 |

≤ 0.150 |

| Galvanisation |

- |

No |

Prev grade

Next grade

V+Nb+Ti ≤ 0.22%

All details provided in the ArcelorMittal Flat Carbon Europe S.A. catalogue are for information purposes only. ArcelorMittal Flat Carbon Europe S.A. reserves the right to change its product range at any time without prior notice.

Related files on this product in our document centre

- Steel solutions & co-engineering EN

Download

Download