In order to offer you the best possible experience, we suggest that you accept the deposit and reading of cookies and the use of technology necessary for their proper functioning:

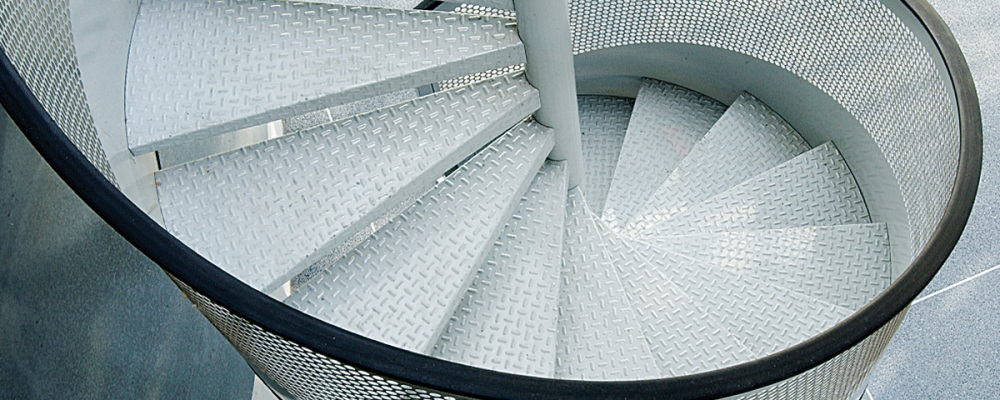

The embossed teardrop pattern gives these stairs excellent anti-slip properties, irrespective of whether the environment is dry, greasy or damp. Moreover, the pattern is almost indestructible.

Floor plates are embossed steels with a chequered or teardrop pattern on the surface.

The steel used is generally structural steel according to the EN 10025 standard.

For floor plates with a chequered pattern, ArcelorMittal has a specific grade, S235DIAMOND, which guarantees only the chemical compositions required for S235JR according to EN 10025-2:2004.

For floor plates with a teardrop pattern, ArcelorMittal also offers other grades, including:

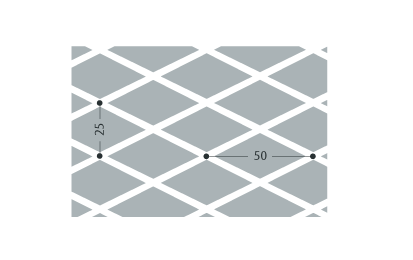

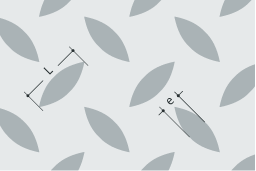

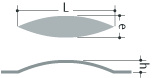

Different patterns are available:

EN 10363 R chequered pattern

The height of the checkerboard pattern is between 1 and 2 mm.

EN 10363 T teardrop pattern

L: approximately 30 mm

e: approximately 10 mm

h: 1 to 2 mm except for core thickness of less than 2.5 mm for which h may vary between 0.5 and 2 mm.

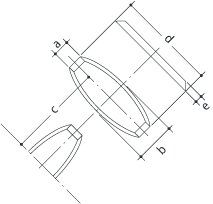

ASTM or EN 10363 A teardrop pattern

a = 3.6 mm

b = 9 mm (- 0 + 1.7)

c = 22.7 mm

d = 23.3 mm (- 0 + 3.8)

e = 1 to 2 mm (depending on core thickness)

The embossed relief gives the floor plate anti-slip properties, irrespective of whether the environment is dry, greasy or damp. Moreover, it is an extremely hardwearing surface that provides excellent resistance to wear due to abrasion, impact and the passage of vehicles, and is also popular with designers for decorative use.

On request, ArcelorMittal's embossed floor plate is also available in Indaten® 355A, which is a weathering grade with good atmospheric corrosion resistance (see data sheet A34).

Floor plates are mainly used for:

Floor plate may be processed in the same way as smooth sheet of the same quality (bending, forming, welding etc).

Indicative typical weight (kg/m2) as a function of core thickness (e.g. thickness ordered) is given in the table below.

| Core thickness (mm) | 2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 |

|---|---|---|---|---|---|---|---|---|---|---|

| Weight for teardrop pattern | 18 | 26 | 34 | 42 | 49 | 65 | 81 | 97 | 120 | 159 |

| Weight for chequered pattern | 20 | 28 | 36 | 44 | 51 | 67 | 83 | 99 | 122 | 161 |

In order to simplify the presentation of this technical data sheet, we refer to the grades as follows:

The three types of each of these grades are available.

| Old brand names | |

|---|---|

| S235J | |

| S275J | |

| S355J | |

| S355MC | |

| S500MC | |

| Lloyds Grade A |

| S235J | |

|---|---|

| S275J | |

|---|---|

| S355J | |

|---|---|

| S355MC | |

|---|---|

| S500MC | |

|---|---|

| Lloyds Grade A | |

|---|---|

ArcelorMittal's floor plates are supplied in as-rolled condition with mill edge. Cut edge (sheared edge) coil can be supplied for certain patterns, grades and dimensions.

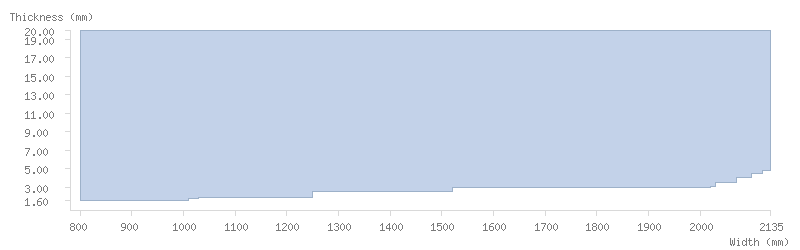

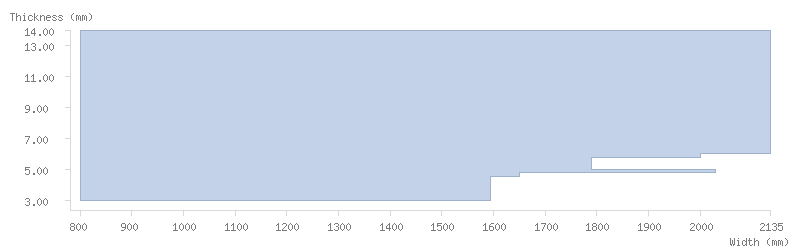

Maximum dimensions for chequered floor plates

| Thickness (mm) | Min width | S235J | S275J | S355J | S355MC | S500MC | Lloyds Grade A |

|---|---|---|---|---|---|---|---|

| Max width | Max width | Max width | Max width | Max width | Max width | ||

| 1.60 ≤ th < 1.80 | 800 | 1010 | - | - | - | - | - |

| 1.80 ≤ th < 1.90 | 1030 | ||||||

| 1.90 ≤ th < 2.00 | 1250 | ||||||

| 2.00 ≤ th < 2.50 | 1250 | 1250 | |||||

| 2.50 ≤ th < 2.95 | 1520 | 1540 | 1540 | ||||

| 2.95 ≤ th < 3.00 | 1880 | ||||||

| 3.00 ≤ th < 3.10 | 2020 | 2020 | 1500 | 1595 | 1345 | 1730 | |

| 3.10 ≤ th < 3.50 | 2030 | 2030 | 1535 | ||||

| 3.50 ≤ th < 4.00 | 2070 | 2070 | 1675 | ||||

| 4.00 ≤ th < 4.50 | 2100 | 2100 | 1845 | 1445 | |||

| 4.50 ≤ th < 4.75 | 2120 | 2120 | 2125 | 1650 | 2130 | ||

| 4.75 ≤ th < 5.00 | 2135 | 2135 | 2030 | 2030 | |||

| 5.00 ≤ th < 5.75 | 2135 | 1790 | |||||

| 5.75 ≤ th < 6.00 | 2000 | ||||||

| 6.00 ≤ th < 12.00 | 2135 | ||||||

| 12.00 ≤ th < 13.00 | - | ||||||

| 13.00 ≤ th < 14.00 | - | ||||||

| 14.00 ≤ th < 15.00 | |||||||

| 15.00 ≤ th < 20.00 |

In view of the specific nature of this range, do not hesitate to contact us to enable us to examine each of your specific requirements.

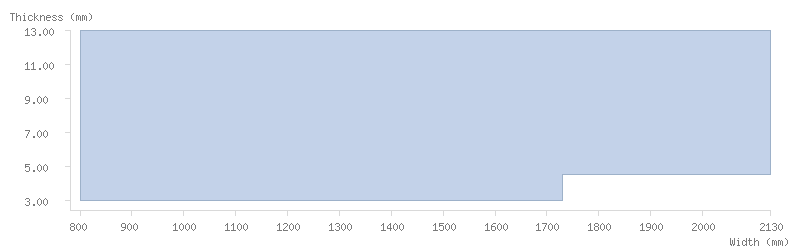

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.60 ≤ th < 1.80 | 800 | 1010 |

| 1.80 ≤ th < 1.90 | 1030 | |

| 1.90 ≤ th < 2.00 | 1250 | |

| 2.00 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.95 | 1520 | |

| 2.95 ≤ th < 3.00 | 1880 | |

| 3.00 ≤ th < 3.10 | 2020 | |

| 3.10 ≤ th < 3.50 | 2030 | |

| 3.50 ≤ th < 4.00 | 2070 | |

| 4.00 ≤ th < 4.50 | 2100 | |

| 4.50 ≤ th < 4.75 | 2120 | |

| 4.75 ≤ th < 5.00 | 2135 | |

| 5.00 ≤ th < 5.75 | ||

| 5.75 ≤ th < 6.00 | ||

| 6.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 20.00 |

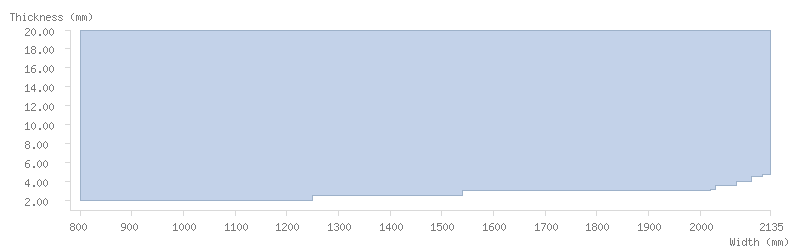

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.60 ≤ th < 1.80 | - | - |

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.50 | 800 | 1250 |

| 2.50 ≤ th < 2.95 | 1540 | |

| 2.95 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.10 | 2020 | |

| 3.10 ≤ th < 3.50 | 2030 | |

| 3.50 ≤ th < 4.00 | 2070 | |

| 4.00 ≤ th < 4.50 | 2100 | |

| 4.50 ≤ th < 4.75 | 2120 | |

| 4.75 ≤ th < 5.00 | 2135 | |

| 5.00 ≤ th < 5.75 | ||

| 5.75 ≤ th < 6.00 | ||

| 6.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 20.00 |

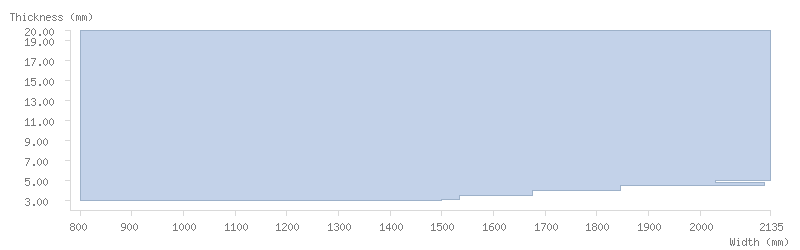

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.60 ≤ th < 1.80 | - | - |

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.95 | 800 | |

| 2.95 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.10 | 1500 | |

| 3.10 ≤ th < 3.50 | 1535 | |

| 3.50 ≤ th < 4.00 | 1675 | |

| 4.00 ≤ th < 4.50 | 1845 | |

| 4.50 ≤ th < 4.75 | 2125 | |

| 4.75 ≤ th < 5.00 | 2030 | |

| 5.00 ≤ th < 5.75 | 2135 | |

| 5.75 ≤ th < 6.00 | ||

| 6.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 20.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.60 ≤ th < 1.80 | - | - |

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.95 | 800 | |

| 2.95 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.10 | 1595 | |

| 3.10 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 4.75 | 1650 | |

| 4.75 ≤ th < 5.00 | 2030 | |

| 5.00 ≤ th < 5.75 | 1790 | |

| 5.75 ≤ th < 6.00 | 2000 | |

| 6.00 ≤ th < 12.00 | 2135 | |

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | - | |

| 15.00 ≤ th < 20.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.60 ≤ th < 1.80 | - | - |

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.95 | ||

| 2.95 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.10 | 800 | 1345 |

| 3.10 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | 1445 | |

| 4.50 ≤ th < 4.75 | ||

| 4.75 ≤ th < 5.00 | ||

| 5.00 ≤ th < 5.75 | ||

| 5.75 ≤ th < 6.00 | ||

| 6.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | - | |

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | - | |

| 15.00 ≤ th < 20.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.60 ≤ th < 1.80 | - | - |

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.50 | 1250 | |

| 2.50 ≤ th < 2.95 | 1540 | |

| 2.95 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.10 | 800 | 1730 |

| 3.10 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 4.75 | 2130 | |

| 4.75 ≤ th < 5.00 | ||

| 5.00 ≤ th < 5.75 | ||

| 5.75 ≤ th < 6.00 | ||

| 6.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | - | |

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 20.00 |

In view of the specific nature of this range, do not hesitate to contact us to enable us to examine each of your specific requirements.

| Galvanisation | |

|---|---|

| S235J | |

| S275J | |

| S355J | |

| S355MC | Class 1 |

| S500MC | Class 1 |

| Lloyds Grade A |

For details about guaranteed values, refer to the corresponding tables in data sheets A20, A30 and H63.

| S235J | |

|---|---|

| Galvanisation | |

| S275J | |

|---|---|

| Galvanisation | |

| S355J | |

|---|---|

| Galvanisation | |

| S355MC | |

|---|---|

| Galvanisation | Class 1 |

| S500MC | |

|---|---|

| Galvanisation | Class 1 |

| Lloyds Grade A | |

|---|---|

| Galvanisation | |

For details about guaranteed values, refer to the corresponding tables in data sheets A20, A30 and H63.

Any questions?

Ask them via our contact form on

https://industry.arcelormittal.com/getintouch

All details provided in the ArcelorMittal Flat Carbon Europe S.A. catalogue are for information purposes only. ArcelorMittal Flat Carbon Europe S.A. reserves the right to change its product range at any time without prior notice.

Download

Download