A62 - Steels for pressure vessels and boilers

The fundamental property of steels for pressure vessels is their ability to withstand high pressure at different temperatures.

Download

Download

Available grades:

Steels for simple pressure vessels (EN 10207:2017)

Steels with specified properties at elevated temperatures (EN 10028-2:2017)

Weldable fine grain steels, normalised (EN 10028-3:2017)

Weldable fine grain steels, thermomechanically rolled (EN 10028-5:2017)

Properties

Steels for pressure vessels and boilers differ from other carbon-manganese structural steels due to their high resistance to pressure at all temperatures (ambient, low or high).

Advantages

The fundamental property of steels for pressure vessels is their ability to withstand high pressure at different temperatures. They have good weldability, as well as excellent toughness, and are suitable for normalisation annealing and stress-relief annealing (both treatments neutralise local hardening caused by welding).

Applications

Steels for pressure vessels are mainly used to manufacture boilers, drums, pressure or steam piping, industrial thermal vessels and heat exchangers. These steels are suitable for mechanical forming and welding.

Brand correspondence

Steels for simple pressure vessels (EN 10207:2017)

Full table

| |

EN 10207:2017 |

EN 10028-3:2017 |

EN 10028-5:2017 |

PN-81/H-92123:1981 |

ASTM |

JIS G3115 |

EN 10028-2:2017 |

Old brand names |

| P235S EN 10207 |

P235S |

|

|

|

|

|

|

|

| P265S EN 10207 |

P265S |

|

|

|

|

|

|

|

| P275SL EN 10207 |

P275SL |

|

|

|

|

|

|

|

P235S EN 10207

| |

P235S EN 10207 |

| EN 10207:2017 |

P235S |

| EN 10028-3:2017 |

|

| EN 10028-5:2017 |

|

| PN-81/H-92123:1981 |

|

| ASTM |

|

| JIS G3115 |

|

| EN 10028-2:2017 |

|

P265S EN 10207

| |

P265S EN 10207 |

| EN 10207:2017 |

P265S |

| EN 10028-3:2017 |

|

| EN 10028-5:2017 |

|

| PN-81/H-92123:1981 |

|

| ASTM |

|

| JIS G3115 |

|

| EN 10028-2:2017 |

|

P275SL EN 10207

| |

P275SL EN 10207 |

| EN 10207:2017 |

P275SL |

| EN 10028-3:2017 |

|

| EN 10028-5:2017 |

|

| PN-81/H-92123:1981 |

|

| ASTM |

|

| JIS G3115 |

|

| EN 10028-2:2017 |

|

Prev grade

Next grade

Steels with specified properties at elevated temperatures (EN 10028-2:2017)

Full table

| |

EN 10207:2017 |

EN 10028-3:2017 |

EN 10028-5:2017 |

PN-81/H-92123:1981 |

ASTM |

JIS G3115 |

EN 10028-2:2017 |

Old brand names |

| P235GH EN 10028-2 |

|

|

|

(St36K) |

A285 gr.C/A414 gr.C |

SPV 24 |

P235GH |

|

| P265GH EN 10028-2 |

|

|

|

(St41K) |

A414 gr.E |

|

P265GH |

|

| P295GH EN 10028-2 |

|

|

|

(St44K) |

A414 gr.F |

|

P295GH |

|

| P355GH EN 10028-2 |

|

|

|

|

A299 gr.A/A414 gr.G |

SPV 36 |

P355GH |

|

| 16Mo3 EN 10028-2 |

|

|

|

|

|

|

16Mo3 |

|

P235GH EN 10028-2

| |

P235GH EN 10028-2 |

| EN 10207:2017 |

|

| EN 10028-3:2017 |

|

| EN 10028-5:2017 |

|

| PN-81/H-92123:1981 |

(St36K) |

| ASTM |

A285 gr.C/A414 gr.C |

| JIS G3115 |

SPV 24 |

| EN 10028-2:2017 |

P235GH |

P265GH EN 10028-2

| |

P265GH EN 10028-2 |

| EN 10207:2017 |

|

| EN 10028-3:2017 |

|

| EN 10028-5:2017 |

|

| PN-81/H-92123:1981 |

(St41K) |

| ASTM |

A414 gr.E |

| JIS G3115 |

|

| EN 10028-2:2017 |

P265GH |

P295GH EN 10028-2

| |

P295GH EN 10028-2 |

| EN 10207:2017 |

|

| EN 10028-3:2017 |

|

| EN 10028-5:2017 |

|

| PN-81/H-92123:1981 |

(St44K) |

| ASTM |

A414 gr.F |

| JIS G3115 |

|

| EN 10028-2:2017 |

P295GH |

P355GH EN 10028-2

| |

P355GH EN 10028-2 |

| EN 10207:2017 |

|

| EN 10028-3:2017 |

|

| EN 10028-5:2017 |

|

| PN-81/H-92123:1981 |

|

| ASTM |

A299 gr.A/A414 gr.G |

| JIS G3115 |

SPV 36 |

| EN 10028-2:2017 |

P355GH |

16Mo3 EN 10028-2

| |

16Mo3 EN 10028-2 |

| EN 10207:2017 |

|

| EN 10028-3:2017 |

|

| EN 10028-5:2017 |

|

| PN-81/H-92123:1981 |

|

| ASTM |

|

| JIS G3115 |

|

| EN 10028-2:2017 |

16Mo3 |

Prev grade

Next grade

Weldable fine grain steels, normalised (EN 10028-3:2017)

Full table

| |

EN 10207:2017 |

EN 10028-3:2017 |

EN 10028-5:2017 |

PN-81/H-92123:1981 |

ASTM |

JIS G3115 |

EN 10028-2:2017 |

Old brand names |

| P275NH EN 10028-3 |

|

P275NH |

|

|

|

|

|

|

| P275NL1 EN 10028-3 |

|

P275NL1 |

|

|

|

|

|

|

| P275NL2 EN 10028-3 |

|

P275NL2 |

|

|

|

|

|

|

| P355N EN 10028-3 |

|

P355N |

|

|

|

|

|

|

| P355NH EN 10028-3 |

|

P355NH |

|

|

|

|

|

|

| P355NL1 EN 10028-3 |

|

P355NL1 |

|

|

|

|

|

|

| P355NL2 EN 10028-3 |

|

P355NL2 |

|

|

|

|

|

|

P275NH EN 10028-3

| |

P275NH EN 10028-3 |

| EN 10207:2017 |

|

| EN 10028-3:2017 |

P275NH |

| EN 10028-5:2017 |

|

| PN-81/H-92123:1981 |

|

| ASTM |

|

| JIS G3115 |

|

| EN 10028-2:2017 |

|

P275NL1 EN 10028-3

| |

P275NL1 EN 10028-3 |

| EN 10207:2017 |

|

| EN 10028-3:2017 |

P275NL1 |

| EN 10028-5:2017 |

|

| PN-81/H-92123:1981 |

|

| ASTM |

|

| JIS G3115 |

|

| EN 10028-2:2017 |

|

P275NL2 EN 10028-3

| |

P275NL2 EN 10028-3 |

| EN 10207:2017 |

|

| EN 10028-3:2017 |

P275NL2 |

| EN 10028-5:2017 |

|

| PN-81/H-92123:1981 |

|

| ASTM |

|

| JIS G3115 |

|

| EN 10028-2:2017 |

|

P355N EN 10028-3

| |

P355N EN 10028-3 |

| EN 10207:2017 |

|

| EN 10028-3:2017 |

P355N |

| EN 10028-5:2017 |

|

| PN-81/H-92123:1981 |

|

| ASTM |

|

| JIS G3115 |

|

| EN 10028-2:2017 |

|

P355NH EN 10028-3

| |

P355NH EN 10028-3 |

| EN 10207:2017 |

|

| EN 10028-3:2017 |

P355NH |

| EN 10028-5:2017 |

|

| PN-81/H-92123:1981 |

|

| ASTM |

|

| JIS G3115 |

|

| EN 10028-2:2017 |

|

P355NL1 EN 10028-3

| |

P355NL1 EN 10028-3 |

| EN 10207:2017 |

|

| EN 10028-3:2017 |

P355NL1 |

| EN 10028-5:2017 |

|

| PN-81/H-92123:1981 |

|

| ASTM |

|

| JIS G3115 |

|

| EN 10028-2:2017 |

|

P355NL2 EN 10028-3

| |

P355NL2 EN 10028-3 |

| EN 10207:2017 |

|

| EN 10028-3:2017 |

P355NL2 |

| EN 10028-5:2017 |

|

| PN-81/H-92123:1981 |

|

| ASTM |

|

| JIS G3115 |

|

| EN 10028-2:2017 |

|

Prev grade

Next grade

Weldable fine grain steels, thermomechanically rolled (EN 10028-5:2017)

Full table

| |

EN 10207:2017 |

EN 10028-3:2017 |

EN 10028-5:2017 |

PN-81/H-92123:1981 |

ASTM |

JIS G3115 |

EN 10028-2:2017 |

Old brand names |

| P420M EN 10028-5 |

|

|

P420M |

|

|

|

|

|

| P420ML1 EN 10028-5 |

|

|

P420ML1 |

|

|

|

|

|

P420M EN 10028-5

| |

P420M EN 10028-5 |

| EN 10207:2017 |

|

| EN 10028-3:2017 |

|

| EN 10028-5:2017 |

P420M |

| PN-81/H-92123:1981 |

|

| ASTM |

|

| JIS G3115 |

|

| EN 10028-2:2017 |

|

P420ML1 EN 10028-5

| |

P420ML1 EN 10028-5 |

| EN 10207:2017 |

|

| EN 10028-3:2017 |

|

| EN 10028-5:2017 |

P420ML1 |

| PN-81/H-92123:1981 |

|

| ASTM |

|

| JIS G3115 |

|

| EN 10028-2:2017 |

|

Prev grade

Next grade

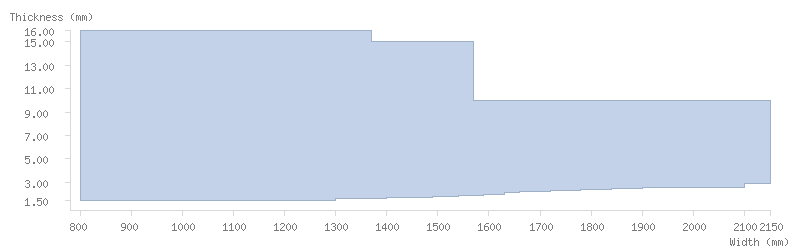

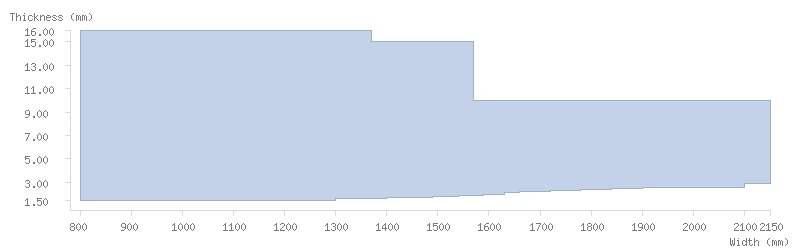

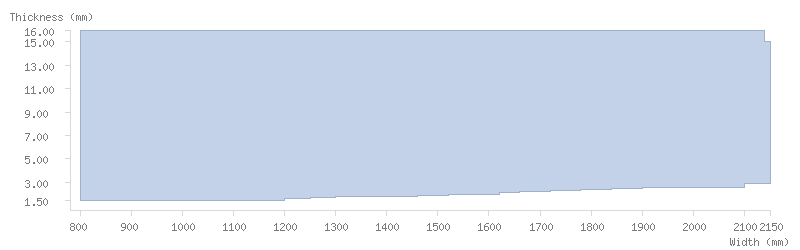

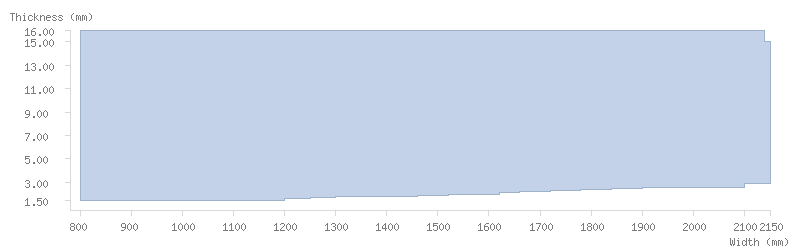

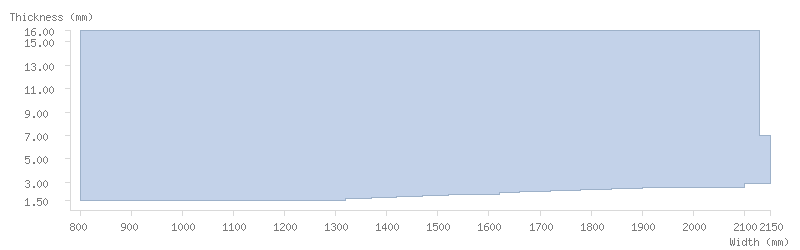

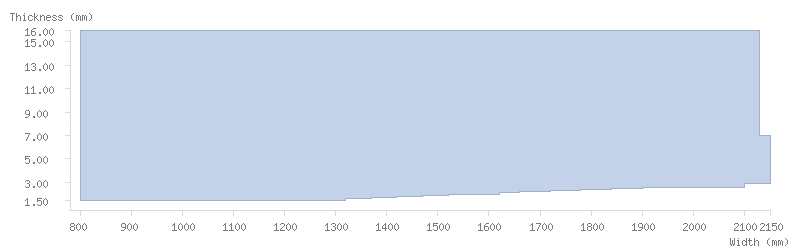

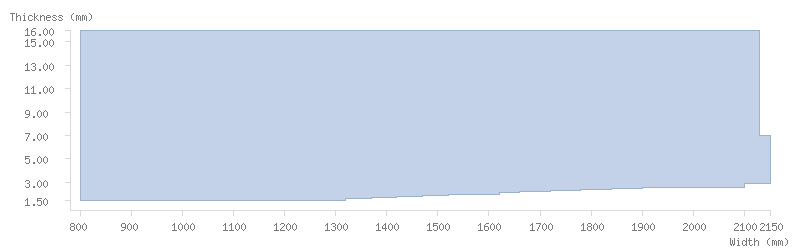

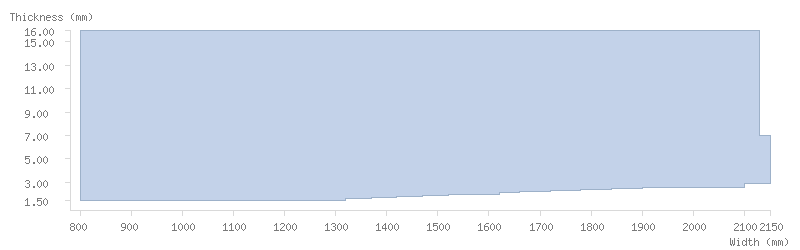

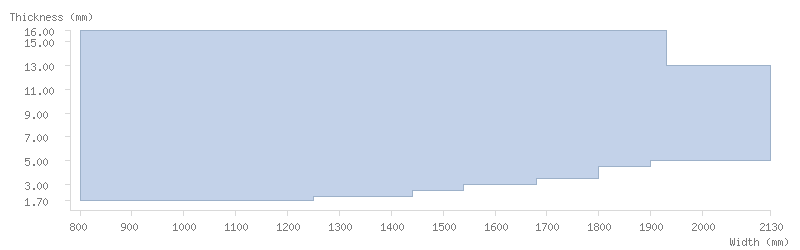

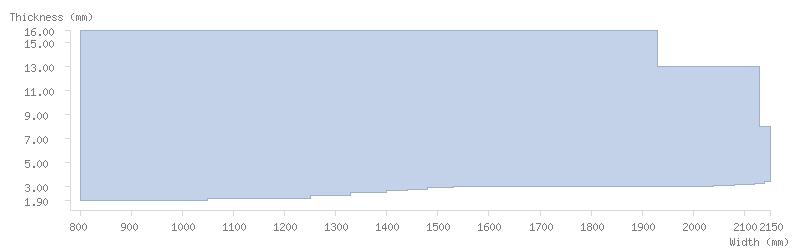

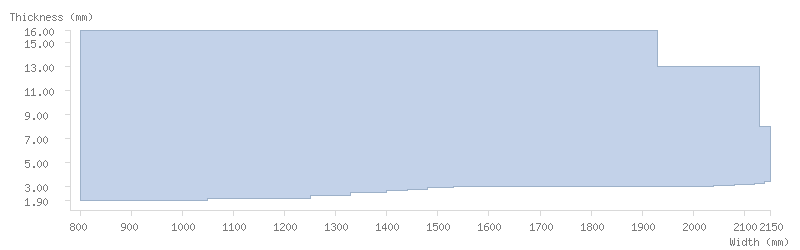

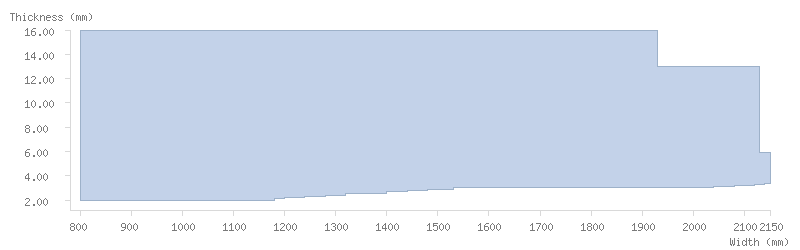

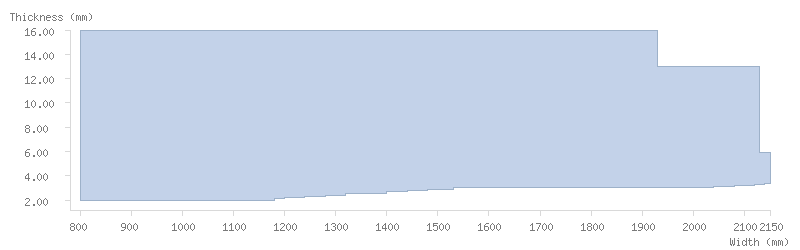

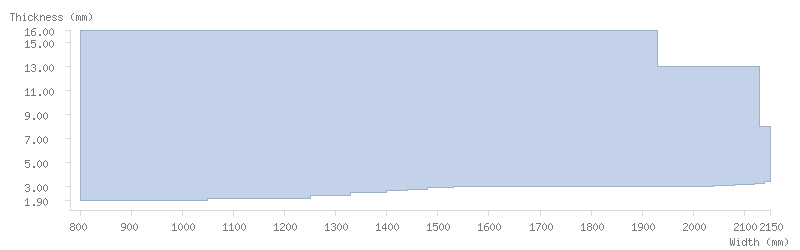

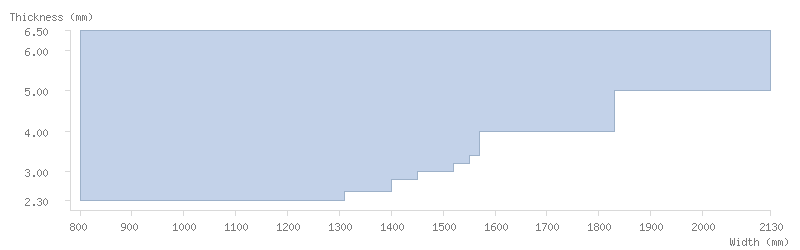

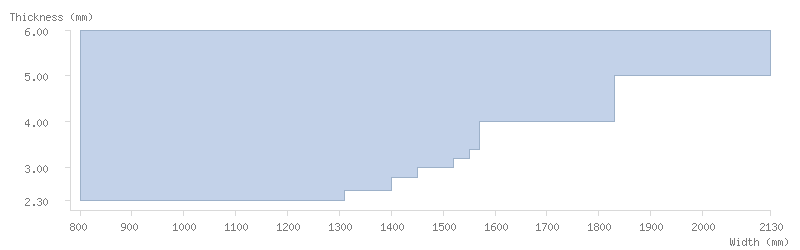

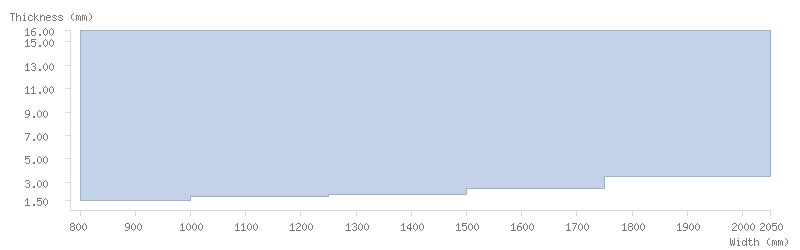

Dimensions

Mechanical properties

The minimum impact energy values specified apply, even if they are not to be verified in the case of product thicknesses < 6 mm. Where minimum impact energy values are specified for several temperatures, verification of the impact energy, unless otherwise agreed, shall be carried out at the temperature for which the value of 27 J is specified. Where the minimum impact energy value specified at the lowest temperature is higher than 27 J, this higher value shall be verified.

Steels for simple pressure vessels (EN 10207:2017)

Full table

| |

Direction |

Thickness (mm) |

Re (MPa) |

Rm (MPa) |

A80 (%) |

A 5.65√So (%) |

KV -20°C (J) |

KV -50°C (J) |

| P235S EN 10207 |

L |

1.5 - 2.5 |

- |

- |

≥ 20 |

- |

- |

- |

| 2.5 - 3 |

≥ 21 |

| 3 - 6 |

- |

≥ 26 |

| 6 - 16 |

≥ 28 |

| T |

1.5 - 2.5 |

≥ 235 |

360 - 480 |

≥ 18 |

- |

- |

- |

| 2.5 - 3 |

≥ 19 |

| 3 - 16 |

- |

≥ 24 |

| P265S EN 10207 |

L |

1.5 - 2.5 |

- |

- |

≥ 17 |

- |

- |

- |

| 2.5 - 3 |

≥ 18 |

| 3 - 6 |

- |

≥ 22 |

| 6 - 16 |

≥ 28 |

| T |

1.5 - 2.5 |

≥ 265 |

410 - 530 |

≥ 15 |

- |

- |

- |

| 2.5 - 3 |

≥ 16 |

| 3 - 16 |

- |

≥ 20 |

| P275SL EN 10207 |

L |

1.5 - 2.5 |

- |

- |

≥ 19 |

- |

- |

- |

| 2.5 - 3 |

≥ 20 |

| 3 - 6 |

- |

≥ 24 |

| 6 - 16 |

≥ 28 |

| T |

1.5 - 2.5 |

≥ 275 |

390 - 510 |

≥ 17 |

- |

- |

- |

| 2.5 - 3 |

≥ 18 |

| 3 - 16 |

- |

≥ 22 |

P235S EN 10207

| |

Direction |

Thickness (mm) |

P235S EN 10207 |

| Re (MPa) |

T |

1.5 - 16 |

≥ 235 |

| Rm (MPa) |

T |

1.5 - 16 |

360 - 480 |

| A80 (%) |

L |

1.5 - 2.5 |

≥ 20 |

| 2.5 - 3 |

≥ 21 |

| T |

1.5 - 2.5 |

≥ 18 |

| 2.5 - 3 |

≥ 19 |

| A 5.65√So (%) |

L |

3 - 16 |

≥ 26 |

| T |

3 - 16 |

≥ 24 |

| KV -20°C (J) |

L |

6 - 16 |

≥ 28 |

P265S EN 10207

| |

Direction |

Thickness (mm) |

P265S EN 10207 |

| Re (MPa) |

T |

1.5 - 16 |

≥ 265 |

| Rm (MPa) |

T |

1.5 - 16 |

410 - 530 |

| A80 (%) |

L |

1.5 - 2.5 |

≥ 17 |

| 2.5 - 3 |

≥ 18 |

| T |

1.5 - 2.5 |

≥ 15 |

| 2.5 - 3 |

≥ 16 |

| A 5.65√So (%) |

L |

3 - 16 |

≥ 22 |

| T |

3 - 16 |

≥ 20 |

| KV -20°C (J) |

L |

6 - 16 |

≥ 28 |

P275SL EN 10207

| |

Direction |

Thickness (mm) |

P275SL EN 10207 |

| Re (MPa) |

T |

1.5 - 16 |

≥ 275 |

| Rm (MPa) |

T |

1.5 - 16 |

390 - 510 |

| A80 (%) |

L |

1.5 - 2.5 |

≥ 19 |

| 2.5 - 3 |

≥ 20 |

| T |

1.5 - 2.5 |

≥ 17 |

| 2.5 - 3 |

≥ 18 |

| A 5.65√So (%) |

L |

3 - 16 |

≥ 24 |

| T |

3 - 16 |

≥ 22 |

| KV -50°C (J) |

L |

6 - 16 |

≥ 28 |

Prev grade

Next grade

Steels with specified properties at elevated temperatures (EN 10028-2:2017)

Full table

| |

Direction |

Thickness (mm) |

Re (MPa) |

Rm (MPa) |

A80 (%) |

A 5.65√So (%) |

KV 20°C (J) |

KV 0°C (J) |

KV -20°C (J) |

| P235GH EN 10028-2 |

T |

1.5 - 3 |

≥ 235 |

360 - 480 |

≥ 19 |

- |

- |

- |

- |

| 3 - 6 |

- |

≥ 24 |

| 6 - 16 |

≥ 40 |

≥ 34 |

≥ 27 |

| P265GH EN 10028-2 |

T |

1.5 - 3 |

≥ 265 |

410 - 530 |

≥ 18 |

- |

- |

- |

- |

| 3 - 6 |

- |

≥ 22 |

| 6 - 16 |

≥ 40 |

≥ 34 |

≥ 27 |

| P295GH EN 10028-2 |

T |

1.5 - 3 |

≥ 295 |

460 - 580 |

≥ 17 |

- |

- |

- |

- |

| 3 - 6 |

- |

≥ 21 |

| 6 - 16 |

≥ 40 |

≥ 34 |

≥ 27 |

| P355GH EN 10028-2 |

T |

2.3 - 3 |

≥ 355 |

510 - 650 |

≥ 16 |

- |

- |

- |

- |

| 3 - 6 |

- |

≥ 20 |

| 6 - 16 |

≥ 40 |

≥ 34 |

≥ 27 |

| 16Mo3 EN 10028-2 |

T |

1.5 - 3 |

≥ 275 |

440 - 590 |

≥ 18 |

- |

- |

- |

- |

| 3 - 6 |

- |

≥ 22 |

| 6 - 16 |

≥ 31 |

P235GH EN 10028-2

| |

Direction |

Thickness (mm) |

P235GH EN 10028-2 |

| Re (MPa) |

T |

1.5 - 16 |

≥ 235 |

| Rm (MPa) |

T |

1.5 - 16 |

360 - 480 |

| A80 (%) |

T |

1.5 - 3 |

≥ 19 |

| A 5.65√So (%) |

T |

3 - 16 |

≥ 24 |

| KV 20°C (J) |

T |

6 - 16 |

≥ 40 |

| KV 0°C (J) |

T |

6 - 16 |

≥ 34 |

| KV -20°C (J) |

T |

6 - 16 |

≥ 27 |

P265GH EN 10028-2

| |

Direction |

Thickness (mm) |

P265GH EN 10028-2 |

| Re (MPa) |

T |

1.5 - 16 |

≥ 265 |

| Rm (MPa) |

T |

1.5 - 16 |

410 - 530 |

| A80 (%) |

T |

1.5 - 3 |

≥ 18 |

| A 5.65√So (%) |

T |

3 - 16 |

≥ 22 |

| KV 20°C (J) |

T |

6 - 16 |

≥ 40 |

| KV 0°C (J) |

T |

6 - 16 |

≥ 34 |

| KV -20°C (J) |

T |

6 - 16 |

≥ 27 |

P295GH EN 10028-2

| |

Direction |

Thickness (mm) |

P295GH EN 10028-2 |

| Re (MPa) |

T |

1.5 - 16 |

≥ 295 |

| Rm (MPa) |

T |

1.5 - 16 |

460 - 580 |

| A80 (%) |

T |

1.5 - 3 |

≥ 17 |

| A 5.65√So (%) |

T |

3 - 16 |

≥ 21 |

| KV 20°C (J) |

T |

6 - 16 |

≥ 40 |

| KV 0°C (J) |

T |

6 - 16 |

≥ 34 |

| KV -20°C (J) |

T |

6 - 16 |

≥ 27 |

P355GH EN 10028-2

| |

Direction |

Thickness (mm) |

P355GH EN 10028-2 |

| Re (MPa) |

T |

2.3 - 16 |

≥ 355 |

| Rm (MPa) |

T |

2.3 - 16 |

510 - 650 |

| A80 (%) |

T |

2.3 - 3 |

≥ 16 |

| A 5.65√So (%) |

T |

3 - 16 |

≥ 20 |

| KV 20°C (J) |

T |

6 - 16 |

≥ 40 |

| KV 0°C (J) |

T |

6 - 16 |

≥ 34 |

| KV -20°C (J) |

T |

6 - 16 |

≥ 27 |

16Mo3 EN 10028-2

| |

Direction |

Thickness (mm) |

16Mo3 EN 10028-2 |

| Re (MPa) |

T |

1.5 - 16 |

≥ 275 |

| Rm (MPa) |

T |

1.5 - 16 |

440 - 590 |

| A80 (%) |

T |

1.5 - 3 |

≥ 18 |

| A 5.65√So (%) |

T |

3 - 16 |

≥ 22 |

| KV 20°C (J) |

T |

6 - 16 |

≥ 31 |

Prev grade

Next grade

Weldable fine grain steels, normalised (EN 10028-3:2017)

Full table

| |

Direction |

Thickness (mm) |

Re (MPa) |

Rm (MPa) |

A80 (%) |

A 5.65√So (%) |

KV 20°C (J) |

KV 0°C (J) |

KV -20°C (J) |

KV -40°C (J) |

KV -50°C (J) |

| P275NH EN 10028-3 |

L |

6 - 16 |

- |

- |

- |

- |

≥ 75 |

≥ 65 |

≥ 45 |

- |

- |

| T |

1.5 - 3 |

≥ 275 |

390 - 510 |

≥ 19 |

- |

- |

- |

- |

- |

- |

| 3 - 6 |

- |

≥ 24 |

| 6 - 16 |

≥ 50 |

≥ 40 |

≥ 30 |

| P275NL1 EN 10028-3 |

L |

6 - 16 |

- |

- |

- |

- |

≥ 80 |

≥ 70 |

≥ 50 |

≥ 40 |

≥ 30 |

| T |

1.5 - 3 |

≥ 275 |

390 - 510 |

≥ 19 |

- |

- |

- |

- |

- |

- |

| 3 - 6 |

- |

≥ 24 |

| 6 - 16 |

≥ 60 |

≥ 50 |

≥ 35 |

≥ 27 |

| P275NL2 EN 10028-3 |

L |

6 - 16 |

- |

- |

- |

- |

≥ 85 |

≥ 75 |

≥ 55 |

≥ 45 |

≥ 42 |

| T |

1.5 - 3 |

≥ 275 |

390 - 510 |

≥ 19 |

- |

- |

- |

- |

- |

- |

| 3 - 6 |

- |

≥ 24 |

| 6 - 16 |

≥ 70 |

≥ 60 |

≥ 40 |

≥ 30 |

≥ 27 |

| P355N EN 10028-3 |

L |

6 - 16 |

- |

- |

- |

- |

≥ 75 |

≥ 65 |

≥ 45 |

- |

- |

| T |

1.7 - 3 |

≥ 355 |

490 - 630 |

≥ 18 |

- |

- |

- |

- |

- |

- |

| 3 - 6 |

- |

≥ 22 |

| 6 - 16 |

≥ 50 |

≥ 40 |

≥ 30 |

| P355NH EN 10028-3 |

L |

6 - 16 |

- |

- |

- |

- |

≥ 75 |

≥ 65 |

≥ 45 |

- |

- |

| T |

1.7 - 3 |

≥ 355 |

490 - 630 |

≥ 18 |

- |

- |

- |

- |

- |

- |

| 3 - 6 |

- |

≥ 22 |

| 6 - 16 |

≥ 50 |

≥ 40 |

≥ 30 |

| P355NL1 EN 10028-3 |

L |

6 - 16 |

- |

- |

- |

- |

≥ 80 |

≥ 70 |

≥ 50 |

≥ 40 |

≥ 30 |

| T |

1.7 - 3 |

≥ 355 |

490 - 630 |

≥ 18 |

- |

- |

- |

- |

- |

- |

| 3 - 6 |

- |

≥ 22 |

| 6 - 16 |

≥ 60 |

≥ 50 |

≥ 35 |

≥ 27 |

| P355NL2 EN 10028-3 |

L |

6 - 16 |

- |

- |

- |

- |

≥ 85 |

≥ 75 |

≥ 55 |

≥ 45 |

≥ 42 |

| T |

1.7 - 3 |

≥ 355 |

490 - 630 |

≥ 18 |

- |

- |

- |

- |

- |

- |

| 3 - 6 |

- |

≥ 22 |

| 6 - 16 |

≥ 70 |

≥ 60 |

≥ 40 |

≥ 30 |

≥ 27 |

P275NH EN 10028-3

| |

Direction |

Thickness (mm) |

P275NH EN 10028-3 |

| Re (MPa) |

T |

1.5 - 16 |

≥ 275 |

| Rm (MPa) |

T |

1.5 - 16 |

390 - 510 |

| A80 (%) |

T |

1.5 - 3 |

≥ 19 |

| A 5.65√So (%) |

T |

3 - 16 |

≥ 24 |

| KV 20°C (J) |

L |

6 - 16 |

≥ 75 |

| T |

6 - 16 |

≥ 50 |

| KV 0°C (J) |

L |

6 - 16 |

≥ 65 |

| T |

6 - 16 |

≥ 40 |

| KV -20°C (J) |

L |

6 - 16 |

≥ 45 |

| T |

6 - 16 |

≥ 30 |

P275NL1 EN 10028-3

| |

Direction |

Thickness (mm) |

P275NL1 EN 10028-3 |

| Re (MPa) |

T |

1.5 - 16 |

≥ 275 |

| Rm (MPa) |

T |

1.5 - 16 |

390 - 510 |

| A80 (%) |

T |

1.5 - 3 |

≥ 19 |

| A 5.65√So (%) |

T |

3 - 16 |

≥ 24 |

| KV 20°C (J) |

L |

6 - 16 |

≥ 80 |

| T |

6 - 16 |

≥ 60 |

| KV 0°C (J) |

L |

6 - 16 |

≥ 70 |

| T |

6 - 16 |

≥ 50 |

| KV -20°C (J) |

L |

6 - 16 |

≥ 50 |

| T |

6 - 16 |

≥ 35 |

| KV -40°C (J) |

L |

6 - 16 |

≥ 40 |

| T |

6 - 16 |

≥ 27 |

| KV -50°C (J) |

L |

6 - 16 |

≥ 30 |

P275NL2 EN 10028-3

| |

Direction |

Thickness (mm) |

P275NL2 EN 10028-3 |

| Re (MPa) |

T |

1.5 - 16 |

≥ 275 |

| Rm (MPa) |

T |

1.5 - 16 |

390 - 510 |

| A80 (%) |

T |

1.5 - 3 |

≥ 19 |

| A 5.65√So (%) |

T |

3 - 16 |

≥ 24 |

| KV 20°C (J) |

L |

6 - 16 |

≥ 85 |

| T |

6 - 16 |

≥ 70 |

| KV 0°C (J) |

L |

6 - 16 |

≥ 75 |

| T |

6 - 16 |

≥ 60 |

| KV -20°C (J) |

L |

6 - 16 |

≥ 55 |

| T |

6 - 16 |

≥ 40 |

| KV -40°C (J) |

L |

6 - 16 |

≥ 45 |

| T |

6 - 16 |

≥ 30 |

| KV -50°C (J) |

L |

6 - 16 |

≥ 42 |

| T |

6 - 16 |

≥ 27 |

P355N EN 10028-3

| |

Direction |

Thickness (mm) |

P355N EN 10028-3 |

| Re (MPa) |

T |

1.7 - 16 |

≥ 355 |

| Rm (MPa) |

T |

1.7 - 16 |

490 - 630 |

| A80 (%) |

T |

1.7 - 3 |

≥ 18 |

| A 5.65√So (%) |

T |

3 - 16 |

≥ 22 |

| KV 20°C (J) |

L |

6 - 16 |

≥ 75 |

| T |

6 - 16 |

≥ 50 |

| KV 0°C (J) |

L |

6 - 16 |

≥ 65 |

| T |

6 - 16 |

≥ 40 |

| KV -20°C (J) |

L |

6 - 16 |

≥ 45 |

| T |

6 - 16 |

≥ 30 |

P355NH EN 10028-3

| |

Direction |

Thickness (mm) |

P355NH EN 10028-3 |

| Re (MPa) |

T |

1.7 - 16 |

≥ 355 |

| Rm (MPa) |

T |

1.7 - 16 |

490 - 630 |

| A80 (%) |

T |

1.7 - 3 |

≥ 18 |

| A 5.65√So (%) |

T |

3 - 16 |

≥ 22 |

| KV 20°C (J) |

L |

6 - 16 |

≥ 75 |

| T |

6 - 16 |

≥ 50 |

| KV 0°C (J) |

L |

6 - 16 |

≥ 65 |

| T |

6 - 16 |

≥ 40 |

| KV -20°C (J) |

L |

6 - 16 |

≥ 45 |

| T |

6 - 16 |

≥ 30 |

P355NL1 EN 10028-3

| |

Direction |

Thickness (mm) |

P355NL1 EN 10028-3 |

| Re (MPa) |

T |

1.7 - 16 |

≥ 355 |

| Rm (MPa) |

T |

1.7 - 16 |

490 - 630 |

| A80 (%) |

T |

1.7 - 3 |

≥ 18 |

| A 5.65√So (%) |

T |

3 - 16 |

≥ 22 |

| KV 20°C (J) |

L |

6 - 16 |

≥ 80 |

| T |

6 - 16 |

≥ 60 |

| KV 0°C (J) |

L |

6 - 16 |

≥ 70 |

| T |

6 - 16 |

≥ 50 |

| KV -20°C (J) |

L |

6 - 16 |

≥ 50 |

| T |

6 - 16 |

≥ 35 |

| KV -40°C (J) |

L |

6 - 16 |

≥ 40 |

| T |

6 - 16 |

≥ 27 |

| KV -50°C (J) |

L |

6 - 16 |

≥ 30 |

P355NL2 EN 10028-3

| |

Direction |

Thickness (mm) |

P355NL2 EN 10028-3 |

| Re (MPa) |

T |

1.7 - 16 |

≥ 355 |

| Rm (MPa) |

T |

1.7 - 16 |

490 - 630 |

| A80 (%) |

T |

1.7 - 3 |

≥ 18 |

| A 5.65√So (%) |

T |

3 - 16 |

≥ 22 |

| KV 20°C (J) |

L |

6 - 16 |

≥ 85 |

| T |

6 - 16 |

≥ 70 |

| KV 0°C (J) |

L |

6 - 16 |

≥ 75 |

| T |

6 - 16 |

≥ 60 |

| KV -20°C (J) |

L |

6 - 16 |

≥ 55 |

| T |

6 - 16 |

≥ 40 |

| KV -40°C (J) |

L |

6 - 16 |

≥ 45 |

| T |

6 - 16 |

≥ 30 |

| KV -50°C (J) |

L |

6 - 16 |

≥ 42 |

| T |

6 - 16 |

≥ 27 |

Prev grade

Next grade

Weldable fine grain steels, thermomechanically rolled (EN 10028-5:2017)

Full table

| |

Direction |

Thickness (mm) |

Re (MPa) |

Rm (MPa) |

A 5.65√So (%) |

KV 20°C (J) |

KV 0°C (J) |

KV -20°C (J) |

KV -40°C (J) |

| P420M EN 10028-5 |

T |

3 - 6 |

≥ 420 |

500 - 660 |

≥ 19 |

≥ 60 |

≥ 40 |

≥ 27 |

- |

| P420ML1 EN 10028-5 |

T |

3 - 6 |

≥ 420 |

500 - 660 |

≥ 19 |

- |

≥ 60 |

≥ 40 |

≥ 27 |

P420M EN 10028-5

| |

Direction |

Thickness (mm) |

P420M EN 10028-5 |

| Re (MPa) |

T |

3 - 6 |

≥ 420 |

| Rm (MPa) |

T |

3 - 6 |

500 - 660 |

| A 5.65√So (%) |

T |

3 - 6 |

≥ 19 |

| KV 20°C (J) |

T |

3 - 6 |

≥ 60 |

| KV 0°C (J) |

T |

3 - 6 |

≥ 40 |

| KV -20°C (J) |

T |

3 - 6 |

≥ 27 |

P420ML1 EN 10028-5

| |

Direction |

Thickness (mm) |

P420ML1 EN 10028-5 |

| Re (MPa) |

T |

3 - 6 |

≥ 420 |

| Rm (MPa) |

T |

3 - 6 |

500 - 660 |

| A 5.65√So (%) |

T |

3 - 6 |

≥ 19 |

| KV 0°C (J) |

T |

3 - 6 |

≥ 60 |

| KV -20°C (J) |

T |

3 - 6 |

≥ 40 |

| KV -40°C (J) |

T |

3 - 6 |

≥ 27 |

Prev grade

Next grade

Min mechanical characteristics at high temperature Re (MPa)

Optional test. The test shall be carried out at 300°C.

Steels for simple pressure vessels (EN 10207:2017)

Full table

| Steel grade |

Thickness (mm) |

50°C |

100°C |

150°C |

200°C |

250°C |

300°C |

350°C |

400°C |

450°C |

500°C |

| P235S EN 10207 |

1.5 < th ≤ 16 |

- |

171 |

162 |

153 |

135 |

117 |

- |

- |

- |

- |

| P265S EN 10207 |

1.5 < th ≤ 16 |

194 |

185 |

176 |

158 |

140 |

| P275SL EN 10207 |

1.5 < th ≤ 16 |

221 |

203 |

159 |

132 |

P235S EN 10207

|

|

Thickness (mm) |

|

| 50°C |

1.5 < th ≤ 16 |

- |

| 100°C |

1.5 < th ≤ 16 |

171 |

| 150°C |

1.5 < th ≤ 16 |

162 |

| 200°C |

1.5 < th ≤ 16 |

153 |

| 250°C |

1.5 < th ≤ 16 |

135 |

| 300°C |

1.5 < th ≤ 16 |

117 |

| 350°C |

1.5 < th ≤ 16 |

- |

| 400°C |

1.5 < th ≤ 16 |

- |

| 450°C |

1.5 < th ≤ 16 |

- |

| 500°C |

1.5 < th ≤ 16 |

- |

P265S EN 10207

|

|

Thickness (mm) |

|

| 50°C |

1.5 < th ≤ 16 |

- |

| 100°C |

1.5 < th ≤ 16 |

194 |

| 150°C |

1.5 < th ≤ 16 |

185 |

| 200°C |

1.5 < th ≤ 16 |

176 |

| 250°C |

1.5 < th ≤ 16 |

158 |

| 300°C |

1.5 < th ≤ 16 |

140 |

| 350°C |

1.5 < th ≤ 16 |

- |

| 400°C |

1.5 < th ≤ 16 |

- |

| 450°C |

1.5 < th ≤ 16 |

- |

| 500°C |

1.5 < th ≤ 16 |

- |

P275SL EN 10207

|

|

Thickness (mm) |

|

| 50°C |

1.5 < th ≤ 16 |

- |

| 100°C |

1.5 < th ≤ 16 |

221 |

| 150°C |

1.5 < th ≤ 16 |

203 |

| 200°C |

1.5 < th ≤ 16 |

176 |

| 250°C |

1.5 < th ≤ 16 |

159 |

| 300°C |

1.5 < th ≤ 16 |

132 |

| 350°C |

1.5 < th ≤ 16 |

- |

| 400°C |

1.5 < th ≤ 16 |

- |

| 450°C |

1.5 < th ≤ 16 |

- |

| 500°C |

1.5 < th ≤ 16 |

- |

Prev grade

Next grade

Steels with specified properties at elevated temperatures (EN 10028-2:2017)

Full table

| Steel grade |

Thickness (mm) |

50°C |

100°C |

150°C |

200°C |

250°C |

300°C |

350°C |

400°C |

450°C |

500°C |

| P235GH EN 10028-2 |

1.5 < th ≤ 16 |

227 |

214 |

198 |

182 |

167 |

153 |

142 |

133 |

- |

- |

| P265GH EN 10028-2 |

1.5 < th ≤ 16 |

256 |

241 |

223 |

205 |

188 |

173 |

160 |

150 |

| P295GH EN 10028-2 |

1.5 < th ≤ 16 |

285 |

268 |

249 |

228 |

209 |

192 |

178 |

167 |

| P355GH EN 10028-2 |

2.3 < th ≤ 16 |

343 |

323 |

299 |

275 |

252 |

232 |

214 |

202 |

| 16Mo3 EN 10028-2 |

1.5 < th ≤ 16 |

273 |

264 |

250 |

233 |

213 |

194 |

175 |

159 |

147 |

141 |

P235GH EN 10028-2

|

|

Thickness (mm) |

|

| 50°C |

1.5 < th ≤ 2.3 |

227 |

| 2.3 < th ≤ 16 |

| 100°C |

1.5 < th ≤ 2.3 |

214 |

| 2.3 < th ≤ 16 |

| 150°C |

1.5 < th ≤ 2.3 |

198 |

| 2.3 < th ≤ 16 |

| 200°C |

1.5 < th ≤ 2.3 |

182 |

| 2.3 < th ≤ 16 |

| 250°C |

1.5 < th ≤ 2.3 |

167 |

| 2.3 < th ≤ 16 |

| 300°C |

1.5 < th ≤ 2.3 |

153 |

| 2.3 < th ≤ 16 |

| 350°C |

1.5 < th ≤ 2.3 |

142 |

| 2.3 < th ≤ 16 |

| 400°C |

1.5 < th ≤ 2.3 |

133 |

| 2.3 < th ≤ 16 |

| 450°C |

1.5 < th ≤ 16 |

- |

| 500°C |

1.5 < th ≤ 16 |

- |

P265GH EN 10028-2

|

|

Thickness (mm) |

|

| 50°C |

1.5 < th ≤ 2.3 |

256 |

| 2.3 < th ≤ 16 |

| 100°C |

1.5 < th ≤ 2.3 |

241 |

| 2.3 < th ≤ 16 |

| 150°C |

1.5 < th ≤ 2.3 |

223 |

| 2.3 < th ≤ 16 |

| 200°C |

1.5 < th ≤ 2.3 |

205 |

| 2.3 < th ≤ 16 |

| 250°C |

1.5 < th ≤ 2.3 |

188 |

| 2.3 < th ≤ 16 |

| 300°C |

1.5 < th ≤ 2.3 |

173 |

| 2.3 < th ≤ 16 |

| 350°C |

1.5 < th ≤ 2.3 |

160 |

| 2.3 < th ≤ 16 |

| 400°C |

1.5 < th ≤ 2.3 |

150 |

| 2.3 < th ≤ 16 |

| 450°C |

1.5 < th ≤ 16 |

- |

| 500°C |

1.5 < th ≤ 16 |

- |

P295GH EN 10028-2

|

|

Thickness (mm) |

|

| 50°C |

1.5 < th ≤ 2.3 |

285 |

| 2.3 < th ≤ 16 |

| 100°C |

1.5 < th ≤ 2.3 |

268 |

| 2.3 < th ≤ 16 |

| 150°C |

1.5 < th ≤ 2.3 |

249 |

| 2.3 < th ≤ 16 |

| 200°C |

1.5 < th ≤ 2.3 |

228 |

| 2.3 < th ≤ 16 |

| 250°C |

1.5 < th ≤ 2.3 |

209 |

| 2.3 < th ≤ 16 |

| 300°C |

1.5 < th ≤ 2.3 |

192 |

| 2.3 < th ≤ 16 |

| 350°C |

1.5 < th ≤ 2.3 |

178 |

| 2.3 < th ≤ 16 |

| 400°C |

1.5 < th ≤ 2.3 |

167 |

| 2.3 < th ≤ 16 |

| 450°C |

1.5 < th ≤ 16 |

- |

| 500°C |

1.5 < th ≤ 16 |

- |

P355GH EN 10028-2

|

|

Thickness (mm) |

|

| 50°C |

1.5 < th ≤ 2.3 |

- |

| 2.3 < th ≤ 16 |

343 |

| 100°C |

1.5 < th ≤ 2.3 |

- |

| 2.3 < th ≤ 16 |

323 |

| 150°C |

1.5 < th ≤ 2.3 |

- |

| 2.3 < th ≤ 16 |

299 |

| 200°C |

1.5 < th ≤ 2.3 |

- |

| 2.3 < th ≤ 16 |

275 |

| 250°C |

1.5 < th ≤ 2.3 |

- |

| 2.3 < th ≤ 16 |

252 |

| 300°C |

1.5 < th ≤ 2.3 |

- |

| 2.3 < th ≤ 16 |

232 |

| 350°C |

1.5 < th ≤ 2.3 |

- |

| 2.3 < th ≤ 16 |

214 |

| 400°C |

1.5 < th ≤ 2.3 |

- |

| 2.3 < th ≤ 16 |

202 |

| 450°C |

1.5 < th ≤ 16 |

- |

| 500°C |

1.5 < th ≤ 16 |

- |

16Mo3 EN 10028-2

|

|

Thickness (mm) |

|

| 50°C |

1.5 < th ≤ 2.3 |

273 |

| 2.3 < th ≤ 16 |

| 100°C |

1.5 < th ≤ 2.3 |

264 |

| 2.3 < th ≤ 16 |

| 150°C |

1.5 < th ≤ 2.3 |

250 |

| 2.3 < th ≤ 16 |

| 200°C |

1.5 < th ≤ 2.3 |

233 |

| 2.3 < th ≤ 16 |

| 250°C |

1.5 < th ≤ 2.3 |

213 |

| 2.3 < th ≤ 16 |

| 300°C |

1.5 < th ≤ 2.3 |

194 |

| 2.3 < th ≤ 16 |

| 350°C |

1.5 < th ≤ 2.3 |

175 |

| 2.3 < th ≤ 16 |

| 400°C |

1.5 < th ≤ 2.3 |

159 |

| 2.3 < th ≤ 16 |

| 450°C |

1.5 < th ≤ 16 |

147 |

| 500°C |

1.5 < th ≤ 16 |

141 |

Prev grade

Next grade

Weldable fine grain steels, normalised (EN 10028-3:2017)

Full table

| Steel grade |

Thickness (mm) |

50°C |

100°C |

150°C |

200°C |

250°C |

300°C |

350°C |

400°C |

450°C |

500°C |

| P275NH EN 10028-3 |

1.5 < th ≤ 16 |

266 |

250 |

232 |

213 |

195 |

179 |

166 |

156 |

- |

- |

| P355NH EN 10028-3 |

1.7 < th ≤ 16 |

343 |

323 |

299 |

275 |

252 |

232 |

214 |

202 |

P275NH EN 10028-3

|

|

Thickness (mm) |

|

| 50°C |

1.5 < th ≤ 1.7 |

266 |

| 1.7 < th ≤ 16 |

| 100°C |

1.5 < th ≤ 1.7 |

250 |

| 1.7 < th ≤ 16 |

| 150°C |

1.5 < th ≤ 1.7 |

232 |

| 1.7 < th ≤ 16 |

| 200°C |

1.5 < th ≤ 1.7 |

213 |

| 1.7 < th ≤ 16 |

| 250°C |

1.5 < th ≤ 1.7 |

195 |

| 1.7 < th ≤ 16 |

| 300°C |

1.5 < th ≤ 1.7 |

179 |

| 1.7 < th ≤ 16 |

| 350°C |

1.5 < th ≤ 1.7 |

166 |

| 1.7 < th ≤ 16 |

| 400°C |

1.5 < th ≤ 1.7 |

156 |

| 1.7 < th ≤ 16 |

| 450°C |

1.5 < th ≤ 16 |

- |

| 500°C |

1.5 < th ≤ 16 |

- |

P275NL1 EN 10028-3

|

|

Thickness (mm) |

|

| 50°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 100°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 150°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 200°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 250°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 300°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 350°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 400°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 450°C |

1.5 < th ≤ 16 |

- |

| 500°C |

1.5 < th ≤ 16 |

- |

P275NL2 EN 10028-3

|

|

Thickness (mm) |

|

| 50°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 100°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 150°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 200°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 250°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 300°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 350°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 400°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 450°C |

1.5 < th ≤ 16 |

- |

| 500°C |

1.5 < th ≤ 16 |

- |

P355N EN 10028-3

|

|

Thickness (mm) |

|

| 50°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 100°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 150°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 200°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 250°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 300°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 350°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 400°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 450°C |

1.5 < th ≤ 16 |

- |

| 500°C |

1.5 < th ≤ 16 |

- |

P355NH EN 10028-3

|

|

Thickness (mm) |

|

| 50°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

343 |

| 100°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

323 |

| 150°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

299 |

| 200°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

275 |

| 250°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

252 |

| 300°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

232 |

| 350°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

214 |

| 400°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

202 |

| 450°C |

1.5 < th ≤ 16 |

- |

| 500°C |

1.5 < th ≤ 16 |

- |

P355NL1 EN 10028-3

|

|

Thickness (mm) |

|

| 50°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 100°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 150°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 200°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 250°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 300°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 350°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 400°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 450°C |

1.5 < th ≤ 16 |

- |

| 500°C |

1.5 < th ≤ 16 |

- |

P355NL2 EN 10028-3

|

|

Thickness (mm) |

|

| 50°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 100°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 150°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 200°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 250°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 300°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 350°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 400°C |

1.5 < th ≤ 1.7 |

- |

| 1.7 < th ≤ 16 |

| 450°C |

1.5 < th ≤ 16 |

- |

| 500°C |

1.5 < th ≤ 16 |

- |

Prev grade

Next grade

Chemical composition

Steels for simple pressure vessels (EN 10207:2017)

Full table

| |

C (%) |

Mn (%) |

P (%) |

S (%) |

Si (%) |

Al (%) |

N (%) |

| P235S EN 10207 |

≤ 0.160 |

0.40 - 1.20 |

≤ 0.025 |

≤ 0.025 |

≤ 0.35 |

≥ 0.020 |

≤ 0.010 |

| P265S EN 10207 |

≤ 0.200 |

0.50 - 1.50 |

≤ 0.025 |

≤ 0.025 |

≤ 0.40 |

≥ 0.020 |

≤ 0.010 |

| P275SL EN 10207 |

≤ 0.160 |

0.50 - 1.50 |

≤ 0.025 |

≤ 0.020 |

≤ 0.40 |

≥ 0.020 |

≤ 0.010 |

P235S EN 10207

| |

Notes |

P235S EN 10207 |

| C (%) |

|

≤ 0.160 |

| Mn (%) |

|

0.40 - 1.20 |

| P (%) |

|

≤ 0.025 |

| S (%) |

|

≤ 0.025 |

| Si (%) |

|

≤ 0.35 |

| Al (%) |

|

≥ 0.020 |

| N (%) |

|

≤ 0.010 |

P265S EN 10207

| |

Notes |

P265S EN 10207 |

| C (%) |

|

≤ 0.200 |

| Mn (%) |

|

0.50 - 1.50 |

| P (%) |

|

≤ 0.025 |

| S (%) |

|

≤ 0.025 |

| Si (%) |

|

≤ 0.40 |

| Al (%) |

|

≥ 0.020 |

| N (%) |

|

≤ 0.010 |

P275SL EN 10207

| |

Notes |

P275SL EN 10207 |

| C (%) |

|

≤ 0.160 |

| Mn (%) |

|

0.50 - 1.50 |

| P (%) |

|

≤ 0.025 |

| S (%) |

|

≤ 0.020 |

| Si (%) |

|

≤ 0.40 |

| Al (%) |

|

≥ 0.020 |

| N (%) |

|

≤ 0.010 |

Prev grade

Next grade

Steels with specified properties at elevated temperatures (EN 10028-2:2017)

Full table

| |

Notes |

C (%) |

Mn (%) |

P (%) |

S (%) |

Si (%) |

Al (%) |

Cu (%) |

Cr (%) |

Ni (%) |

Nb (%) |

V (%) |

Ti (%) |

N (%) |

Ni+Cr+Cu+Mo (%) |

Mo (%) |

| P235GH EN 10028-2 |

1+2 |

≤ 0.16 |

0.60 - 1.20 |

≤ 0.025 |

≤ 0.010 |

≤ 0.35 |

≥ 0.020 |

≤ 0.30 |

≤ 0.30 |

≤ 0.30 |

≤ 0.030 |

≤ 0.02 |

≤ 0.03 |

≤ 0.012 |

≤ 0.70 |

≤ 0.08 |

| P265GH EN 10028-2 |

1+2 |

≤ 0.20 |

0.80 - 1.40 |

≤ 0.025 |

≤ 0.010 |

≤ 0.40 |

≥ 0.020 |

≤ 0.30 |

≤ 0.30 |

≤ 0.30 |

≤ 0.030 |

≤ 0.02 |

≤ 0.03 |

≤ 0.012 |

≤ 0.70 |

≤ 0.08 |

| P295GH EN 10028-2 |

1+2 |

0.08 - 0.20 |

0.90 - 1.50 |

≤ 0.025 |

≤ 0.010 |

≤ 0.40 |

≥ 0.020 |

≤ 0.30 |

≤ 0.30 |

≤ 0.30 |

≤ 0.030 |

≤ 0.02 |

≤ 0.03 |

≤ 0.012 |

≤ 0.70 |

≤ 0.08 |

| P355GH EN 10028-2 |

2 |

0.10 - 0.22 |

1.10 - 1.70 |

≤ 0.025 |

≤ 0.010 |

≤ 0.60 |

≥ 0.020 |

≤ 0.30 |

≤ 0.30 |

≤ 0.30 |

≤ 0.040 |

≤ 0.02 |

≤ 0.03 |

≤ 0.012 |

≤ 0.70 |

≤ 0.08 |

| 16Mo3 EN 10028-2 |

|

0.12 - 0.20 |

0.40 - 0.90 |

≤ 0.025 |

≤ 0.010 |

≤ 0.35 |

- |

≤ 0.30 |

≤ 0.30 |

≤ 0.30 |

- |

- |

- |

≤ 0.012 |

- |

0.25 - 0.35 |

P235GH EN 10028-2

| |

Notes |

P235GH EN 10028-2 |

| C (%) |

1+2 |

≤ 0.16 |

| Mn (%) |

1+2 |

0.60 - 1.20 |

| P (%) |

1+2 |

≤ 0.025 |

| S (%) |

1+2 |

≤ 0.010 |

| Si (%) |

1+2 |

≤ 0.35 |

| Al (%) |

1+2 |

≥ 0.020 |

| Cu (%) |

1+2 |

≤ 0.30 |

| Cr (%) |

1+2 |

≤ 0.30 |

| Ni (%) |

1+2 |

≤ 0.30 |

| Nb (%) |

1+2 |

≤ 0.030 |

| V (%) |

1+2 |

≤ 0.02 |

| Ti (%) |

1+2 |

≤ 0.03 |

| N (%) |

1+2 |

≤ 0.012 |

| Ceq (%) |

1+2 |

- |

| Ni+Cr+Cu+Mo (%) |

1+2 |

≤ 0.70 |

| Mo (%) |

1+2 |

≤ 0.08 |

P265GH EN 10028-2

| |

Notes |

P265GH EN 10028-2 |

| C (%) |

1+2 |

≤ 0.20 |

| Mn (%) |

1+2 |

0.80 - 1.40 |

| P (%) |

1+2 |

≤ 0.025 |

| S (%) |

1+2 |

≤ 0.010 |

| Si (%) |

1+2 |

≤ 0.40 |

| Al (%) |

1+2 |

≥ 0.020 |

| Cu (%) |

1+2 |

≤ 0.30 |

| Cr (%) |

1+2 |

≤ 0.30 |

| Ni (%) |

1+2 |

≤ 0.30 |

| Nb (%) |

1+2 |

≤ 0.030 |

| V (%) |

1+2 |

≤ 0.02 |

| Ti (%) |

1+2 |

≤ 0.03 |

| N (%) |

1+2 |

≤ 0.012 |

| Ceq (%) |

1+2 |

- |

| Ni+Cr+Cu+Mo (%) |

1+2 |

≤ 0.70 |

| Mo (%) |

1+2 |

≤ 0.08 |

P295GH EN 10028-2

| |

Notes |

P295GH EN 10028-2 |

| C (%) |

1+2 |

0.08 - 0.20 |

| Mn (%) |

1+2 |

0.90 - 1.50 |

| P (%) |

1+2 |

≤ 0.025 |

| S (%) |

1+2 |

≤ 0.010 |

| Si (%) |

1+2 |

≤ 0.40 |

| Al (%) |

1+2 |

≥ 0.020 |

| Cu (%) |

1+2 |

≤ 0.30 |

| Cr (%) |

1+2 |

≤ 0.30 |

| Ni (%) |

1+2 |

≤ 0.30 |

| Nb (%) |

1+2 |

≤ 0.030 |

| V (%) |

1+2 |

≤ 0.02 |

| Ti (%) |

1+2 |

≤ 0.03 |

| N (%) |

1+2 |

≤ 0.012 |

| Ceq (%) |

1+2 |

- |

| Ni+Cr+Cu+Mo (%) |

1+2 |

≤ 0.70 |

| Mo (%) |

1+2 |

≤ 0.08 |

P355GH EN 10028-2

| |

Notes |

P355GH EN 10028-2 |

| C (%) |

1 |

0.10 - 0.22 |

| Mn (%) |

1 |

1.10 - 1.70 |

| P (%) |

1 |

≤ 0.025 |

| S (%) |

1 |

≤ 0.010 |

| Si (%) |

1 |

≤ 0.60 |

| Al (%) |

1 |

≥ 0.020 |

| Cu (%) |

1 |

≤ 0.30 |

| Cr (%) |

1 |

≤ 0.30 |

| Ni (%) |

1 |

≤ 0.30 |

| Nb (%) |

1 |

≤ 0.040 |

| V (%) |

1 |

≤ 0.02 |

| Ti (%) |

1 |

≤ 0.03 |

| N (%) |

1 |

≤ 0.012 |

| Ceq (%) |

1 |

- |

| Ni+Cr+Cu+Mo (%) |

1 |

≤ 0.70 |

| Mo (%) |

1 |

≤ 0.08 |

16Mo3 EN 10028-2

| |

Notes |

16Mo3 EN 10028-2 |

| C (%) |

|

0.12 - 0.20 |

| Mn (%) |

|

0.40 - 0.90 |

| P (%) |

|

≤ 0.025 |

| S (%) |

|

≤ 0.010 |

| Si (%) |

|

≤ 0.35 |

| Al (%) |

|

- |

| Cu (%) |

|

≤ 0.30 |

| Cr (%) |

|

≤ 0.30 |

| Ni (%) |

|

≤ 0.30 |

| Nb (%) |

|

- |

| V (%) |

|

- |

| Ti (%) |

|

- |

| N (%) |

|

≤ 0.012 |

| Ceq (%) |

|

- |

| Ni+Cr+Cu+Mo (%) |

|

- |

| Mo (%) |

|

0.25 - 0.35 |

Prev grade

Next grade

Weldable fine grain steels, normalised (EN 10028-3:2017)

Full table

| |

Notes |

C (%) |

Mn (%) |

P (%) |

S (%) |

Si (%) |

Al (%) |

Cu (%) |

Cr (%) |

Ni (%) |

Nb (%) |

V (%) |

Ti (%) |

N (%) |

Mo (%) |

| P275NH EN 10028-3 |

1+2+3+4 |

≤ 0.16 |

0.80 - 1.50 |

≤ 0.025 |

≤ 0.010 |

≤ 0.40 |

≥ 0.020 |

≤ 0.30 |

≤ 0.30 |

≤ 0.50 |

≤ 0.05 |

≤ 0.05 |

≤ 0.03 |

≤ 0.012 |

≤ 0.08 |

| P275NL1 EN 10028-3 |

1+2+3+4 |

≤ 0.16 |

0.80 - 1.50 |

≤ 0.025 |

≤ 0.008 |

≤ 0.40 |

≥ 0.020 |

≤ 0.30 |

≤ 0.30 |

≤ 0.50 |

≤ 0.05 |

≤ 0.05 |

≤ 0.03 |

≤ 0.012 |

≤ 0.08 |

| P275NL2 EN 10028-3 |

2+3+4+1 |

≤ 0.16 |

0.80 - 1.50 |

≤ 0.020 |

≤ 0.005 |

≤ 0.40 |

≥ 0.020 |

≤ 0.30 |

≤ 0.30 |

≤ 0.50 |

≤ 0.05 |

≤ 0.05 |

≤ 0.03 |

≤ 0.012 |

≤ 0.08 |

| P355N EN 10028-3 |

2+3+5 |

≤ 0.18 |

1.10 - 1.70 |

≤ 0.025 |

≤ 0.010 |

≤ 0.50 |

≥ 0.020 |

≤ 0.30 |

≤ 0.30 |

≤ 0.50 |

≤ 0.05 |

≤ 0.05 |

≤ 0.03 |

≤ 0.012 |

≤ 0.08 |

| P355NH EN 10028-3 |

2+3+5 |

≤ 0.18 |

1.10 - 1.70 |

≤ 0.025 |

≤ 0.010 |

≤ 0.50 |

≥ 0.020 |

≤ 0.30 |

≤ 0.30 |

≤ 0.50 |

≤ 0.05 |

≤ 0.05 |

≤ 0.03 |

≤ 0.012 |

≤ 0.08 |

| P355NL1 EN 10028-3 |

2+3+5 |

≤ 0.18 |

1.10 - 1.70 |

≤ 0.025 |

≤ 0.008 |

≤ 0.50 |

≥ 0.020 |

≤ 0.30 |

≤ 0.30 |

≤ 0.50 |

≤ 0.05 |

≤ 0.05 |

≤ 0.03 |

≤ 0.012 |

≤ 0.08 |

| P355NL2 EN 10028-3 |

2+3+5 |

≤ 0.18 |

1.10 - 1.70 |

≤ 0.020 |

≤ 0.005 |

≤ 0.50 |

≥ 0.020 |

≤ 0.30 |

≤ 0.30 |

≤ 0.50 |

≤ 0.05 |

≤ 0.05 |

≤ 0.03 |

≤ 0.012 |

≤ 0.08 |

P275NH EN 10028-3

| |

Notes |

P275NH EN 10028-3 |

| C (%) |

1+2+3+4 |

≤ 0.16 |

| Mn (%) |

1+2+3+4 |

0.80 - 1.50 |

| P (%) |

1+2+3+4 |

≤ 0.025 |

| S (%) |

1+2+3+4 |

≤ 0.010 |

| Si (%) |

1+2+3+4 |

≤ 0.40 |

| Al (%) |

1+2+3+4 |

≥ 0.020 |

| Cu (%) |

1+2+3+4 |

≤ 0.30 |

| Cr (%) |

1+2+3+4 |

≤ 0.30 |

| Ni (%) |

1+2+3+4 |

≤ 0.50 |

| Nb (%) |

1+2+3+4 |

≤ 0.05 |

| V (%) |

1+2+3+4 |

≤ 0.05 |

| Ti (%) |

1+2+3+4 |

≤ 0.03 |

| N (%) |

1+2+3+4 |

≤ 0.012 |

| Ceq (%) |

1+2+3+4 |

- |

| Ni+Cr+Cu+Mo (%) |

1+2+3+4 |

- |

| Mo (%) |

1+2+3+4 |

≤ 0.08 |

P275NL1 EN 10028-3

| |

Notes |

P275NL1 EN 10028-3 |

| C (%) |

1+2+3+4 |

≤ 0.16 |

| Mn (%) |

1+2+3+4 |

0.80 - 1.50 |

| P (%) |

1+2+3+4 |

≤ 0.025 |

| S (%) |

1+2+3+4 |

≤ 0.008 |

| Si (%) |

1+2+3+4 |

≤ 0.40 |

| Al (%) |

1+2+3+4 |

≥ 0.020 |

| Cu (%) |

1+2+3+4 |

≤ 0.30 |

| Cr (%) |

1+2+3+4 |

≤ 0.30 |

| Ni (%) |

1+2+3+4 |

≤ 0.50 |

| Nb (%) |

1+2+3+4 |

≤ 0.05 |

| V (%) |

1+2+3+4 |

≤ 0.05 |

| Ti (%) |

1+2+3+4 |

≤ 0.03 |

| N (%) |

1+2+3+4 |

≤ 0.012 |

| Ceq (%) |

1+2+3+4 |

- |

| Ni+Cr+Cu+Mo (%) |

1+2+3+4 |

- |

| Mo (%) |

1+2+3+4 |

≤ 0.08 |

P275NL2 EN 10028-3

| |

Notes |

P275NL2 EN 10028-3 |

| C (%) |

1+2+3+4 |

≤ 0.16 |

| Mn (%) |

1+2+3+4 |

0.80 - 1.50 |

| P (%) |

1+2+3+4 |

≤ 0.020 |

| S (%) |

1+2+3+4 |

≤ 0.005 |

| Si (%) |

1+2+3+4 |

≤ 0.40 |

| Al (%) |

1+2+3+4 |

≥ 0.020 |

| Cu (%) |

1+2+3+4 |

≤ 0.30 |

| Cr (%) |

1+2+3+4 |

≤ 0.30 |

| Ni (%) |

1+2+3+4 |

≤ 0.50 |

| Nb (%) |

1+2+3+4 |

≤ 0.05 |

| V (%) |

1+2+3+4 |

≤ 0.05 |

| Ti (%) |

1+2+3+4 |

≤ 0.03 |

| N (%) |

1+2+3+4 |

≤ 0.012 |

| Ceq (%) |

1+2+3+4 |

- |

| Ni+Cr+Cu+Mo (%) |

1+2+3+4 |

- |

| Mo (%) |

1+2+3+4 |

≤ 0.08 |

P355N EN 10028-3

| |

Notes |

P355N EN 10028-3 |

| C (%) |

1+2+3 |

≤ 0.18 |

| Mn (%) |

1+2+3 |

1.10 - 1.70 |

| P (%) |

1+2+3 |

≤ 0.025 |

| S (%) |

1+2+3 |

≤ 0.010 |

| Si (%) |

1+2+3 |

≤ 0.50 |

| Al (%) |

1+2+3 |

≥ 0.020 |

| Cu (%) |

1+2+3 |

≤ 0.30 |

| Cr (%) |

1+2+3 |

≤ 0.30 |

| Ni (%) |

1+2+3 |

≤ 0.50 |

| Nb (%) |

1+2+3 |

≤ 0.05 |

| V (%) |

1+2+3 |

≤ 0.05 |

| Ti (%) |

1+2+3 |

≤ 0.03 |

| N (%) |

1+2+3 |

≤ 0.012 |

| Ceq (%) |

1+2+3 |

- |

| Ni+Cr+Cu+Mo (%) |

1+2+3 |

- |

| Mo (%) |

1+2+3 |

≤ 0.08 |

P355NH EN 10028-3

| |

Notes |

P355NH EN 10028-3 |

| C (%) |

1+2+3 |

≤ 0.18 |

| Mn (%) |

1+2+3 |

1.10 - 1.70 |

| P (%) |

1+2+3 |

≤ 0.025 |

| S (%) |

1+2+3 |

≤ 0.010 |

| Si (%) |

1+2+3 |

≤ 0.50 |

| Al (%) |

1+2+3 |

≥ 0.020 |

| Cu (%) |

1+2+3 |

≤ 0.30 |

| Cr (%) |

1+2+3 |

≤ 0.30 |

| Ni (%) |

1+2+3 |

≤ 0.50 |

| Nb (%) |

1+2+3 |

≤ 0.05 |

| V (%) |

1+2+3 |

≤ 0.05 |

| Ti (%) |

1+2+3 |

≤ 0.03 |

| N (%) |

1+2+3 |

≤ 0.012 |

| Ceq (%) |

1+2+3 |

- |

| Ni+Cr+Cu+Mo (%) |

1+2+3 |

- |

| Mo (%) |

1+2+3 |

≤ 0.08 |

P355NL1 EN 10028-3

| |

Notes |

P355NL1 EN 10028-3 |

| C (%) |

1+2+3 |

≤ 0.18 |

| Mn (%) |

1+2+3 |

1.10 - 1.70 |

| P (%) |

1+2+3 |

≤ 0.025 |

| S (%) |

1+2+3 |

≤ 0.008 |

| Si (%) |

1+2+3 |

≤ 0.50 |

| Al (%) |

1+2+3 |

≥ 0.020 |

| Cu (%) |

1+2+3 |

≤ 0.30 |

| Cr (%) |

1+2+3 |

≤ 0.30 |

| Ni (%) |

1+2+3 |

≤ 0.50 |

| Nb (%) |

1+2+3 |

≤ 0.05 |

| V (%) |

1+2+3 |

≤ 0.05 |

| Ti (%) |

1+2+3 |

≤ 0.03 |

| N (%) |

1+2+3 |

≤ 0.012 |

| Ceq (%) |

1+2+3 |

- |

| Ni+Cr+Cu+Mo (%) |

1+2+3 |

- |

| Mo (%) |

1+2+3 |

≤ 0.08 |

P355NL2 EN 10028-3

| |

Notes |

P355NL2 EN 10028-3 |

| C (%) |

1+2+3 |

≤ 0.18 |

| Mn (%) |

1+2+3 |

1.10 - 1.70 |

| P (%) |

1+2+3 |

≤ 0.020 |

| S (%) |

1+2+3 |

≤ 0.005 |

| Si (%) |

1+2+3 |

≤ 0.50 |

| Al (%) |

1+2+3 |

≥ 0.020 |

| Cu (%) |

1+2+3 |

≤ 0.30 |

| Cr (%) |

1+2+3 |

≤ 0.30 |

| Ni (%) |

1+2+3 |

≤ 0.50 |

| Nb (%) |

1+2+3 |

≤ 0.05 |

| V (%) |

1+2+3 |

≤ 0.05 |

| Ti (%) |

1+2+3 |

≤ 0.03 |

| N (%) |

1+2+3 |

≤ 0.012 |

| Ceq (%) |

1+2+3 |

- |

| Ni+Cr+Cu+Mo (%) |

1+2+3 |

- |

| Mo (%) |

1+2+3 |

≤ 0.08 |

Prev grade

Next grade

Weldable fine grain steels, thermomechanically rolled (EN 10028-5:2017)

Full table

| |

Notes |

C (%) |

Mn (%) |

P (%) |

S (%) |

Si (%) |

Al (%) |

Ni (%) |

Nb (%) |

V (%) |

Ti (%) |

N (%) |

Mo (%) |

| P420M EN 10028-5 |

1+2 |

≤ 0.16 |

≤ 1.70 |

≤ 0.025 |

≤ 0.010 |

≤ 0.50 |

≥ 0.020 |

≤ 0.50 |

≤ 0.05 |

≤ 0.10 |

≤ 0.05 |

≤ 0.020 |

≤ 0.20 |

| P420ML1 EN 10028-5 |

1+2 |

≤ 0.16 |

≤ 1.70 |

≤ 0.020 |

≤ 0.008 |

≤ 0.50 |

≥ 0.020 |

≤ 0.50 |

≤ 0.05 |

≤ 0.10 |

≤ 0.05 |

≤ 0.020 |

≤ 0.20 |

P420M EN 10028-5

| |

Notes |

P420M EN 10028-5 |

| C (%) |

1+2 |

≤ 0.16 |

| Mn (%) |

1+2 |

≤ 1.70 |

| P (%) |

1+2 |

≤ 0.025 |

| S (%) |

1+2 |

≤ 0.010 |

| Si (%) |

1+2 |

≤ 0.50 |

| Al (%) |

1+2 |

≥ 0.020 |

| Cu (%) |

1+2 |

- |

| Cr (%) |

1+2 |

- |

| Ni (%) |

1+2 |

≤ 0.50 |

| Nb (%) |

1+2 |

≤ 0.05 |

| V (%) |

1+2 |

≤ 0.10 |

| Ti (%) |

1+2 |

≤ 0.05 |

| N (%) |

1+2 |

≤ 0.020 |

| Ceq (%) |

1+2 |

- |

| Ni+Cr+Cu+Mo (%) |

1+2 |

- |

| Mo (%) |

1+2 |

≤ 0.20 |

P420ML1 EN 10028-5

| |

Notes |

P420ML1 EN 10028-5 |

| C (%) |

1+2 |

≤ 0.16 |

| Mn (%) |

1+2 |

≤ 1.70 |

| P (%) |

1+2 |

≤ 0.020 |

| S (%) |

1+2 |

≤ 0.008 |

| Si (%) |

1+2 |

≤ 0.50 |

| Al (%) |

1+2 |

≥ 0.020 |

| Cu (%) |

1+2 |

- |

| Cr (%) |

1+2 |

- |

| Ni (%) |

1+2 |

≤ 0.50 |

| Nb (%) |

1+2 |

≤ 0.05 |

| V (%) |

1+2 |

≤ 0.10 |

| Ti (%) |

1+2 |

≤ 0.05 |

| N (%) |

1+2 |

≤ 0.020 |

| Ceq (%) |

1+2 |

- |

| Ni+Cr+Cu+Mo (%) |

1+2 |

- |

| Mo (%) |

1+2 |

≤ 0.20 |

Prev grade

Next grade

All details provided in the ArcelorMittal Flat Carbon Europe S.A. catalogue are for information purposes only. ArcelorMittal Flat Carbon Europe S.A. reserves the right to change its product range at any time without prior notice.

For more information on our products, visit the document centre.

Download

Download