In order to offer you the best possible experience, we suggest that you accept the deposit and reading of cookies and the use of technology necessary for their proper functioning:

These grades may be used as semi-finished products for re-rolling or heat treatment in order to obtain specific properties.

Steels with a specific chemical composition are in compliance with SAE J403:2009. For high carbon steel grades, from 1035 to 1095, please refer to data sheet A52 for the AM FCE range designed to meet similar requirements.

These grades cover different fields, ranging from deep drawing and construction to high carbon steel applications.

These products are used in a very wide range of applications. In addition to meeting the requirements of the American standards, they also comply with many of the analytical specifications laid down in the European standards. They may be used as semi-finished products for re-rolling or heat treatment in order to obtain specific properties.

| SAE J403:2009 | Old brand names | |

|---|---|---|

| 1006 SAE J 403 | 1006 | |

| 1008 SAE J 403 | 1008 | |

| 1010 SAE J 403 | 1010 | |

| 1015 SAE J 403 | 1015 |

| 1006 SAE J 403 | |

|---|---|

| SAE J403:2009 | 1006 |

| 1008 SAE J 403 | |

|---|---|

| SAE J403:2009 | 1008 |

| 1010 SAE J 403 | |

|---|---|

| SAE J403:2009 | 1010 |

| 1015 SAE J 403 | |

|---|---|

| SAE J403:2009 | 1015 |

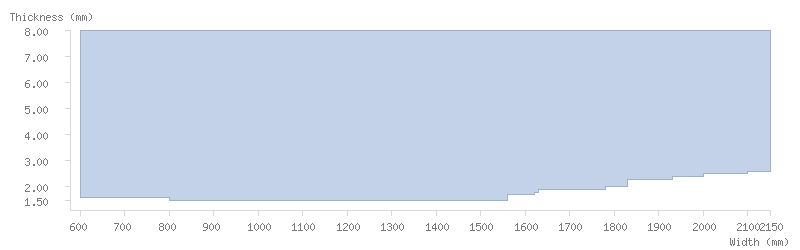

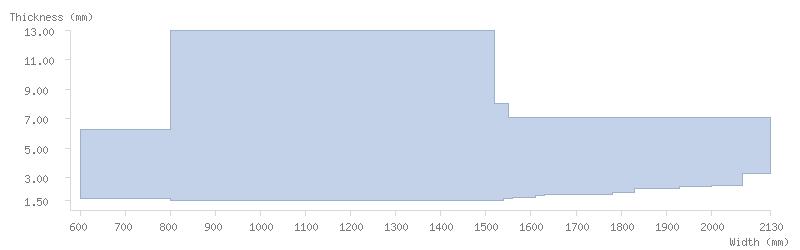

| Thickness (mm) | 1006 SAE J 403 | 1008 SAE J 403 | 1010 SAE J 403 | 1015 SAE J 403 | ||||

|---|---|---|---|---|---|---|---|---|

| Min width | Max width | Min width | Max width | Min width | Max width | Min width | Max width | |

| 1.50 ≤ th < 1.60 | 800 | 1560 | 800 | 1560 | 800 | 1250 | 800 | 1320 |

| 1.60 ≤ th < 1.70 | 600 | 600 | 600 | 1400 | ||||

| 1.70 ≤ th < 1.80 | 1620 | 1490 | ||||||

| 1.80 ≤ th < 1.90 | 1630 | 1620 | 1460 | 1540 | ||||

| 1.90 ≤ th < 2.00 | 1780 | 1780 | 1520 | 1590 | ||||

| 2.00 ≤ th < 2.10 | 1830 | 1830 | 1620 | 1630 | ||||

| 2.10 ≤ th < 2.20 | 1660 | 1660 | ||||||

| 2.20 ≤ th < 2.30 | 1720 | 1720 | ||||||

| 2.30 ≤ th < 2.40 | 1930 | 1780 | 1780 | |||||

| 2.40 ≤ th < 2.50 | 2000 | 2000 | 1840 | 1840 | ||||

| 2.50 ≤ th < 2.60 | 2100 | 1900 | 1900 | |||||

| 2.60 ≤ th < 2.90 | 2150 | 2150 | 2100 | 2100 | ||||

| 2.90 ≤ th < 8.00 | 2150 | 2150 | ||||||

| 8.00 ≤ th < 16.00 | - | 2140 | ||||||

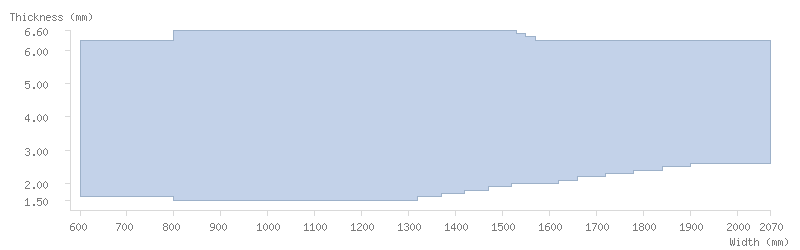

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1560 |

| 1.60 ≤ th < 1.70 | 600 | |

| 1.70 ≤ th < 1.80 | 1620 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.10 | 1830 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1930 | |

| 2.40 ≤ th < 2.50 | 2000 | |

| 2.50 ≤ th < 2.60 | 2100 | |

| 2.60 ≤ th < 2.90 | 2150 | |

| 2.90 ≤ th < 8.00 | ||

| 8.00 ≤ th < 16.00 | - | |

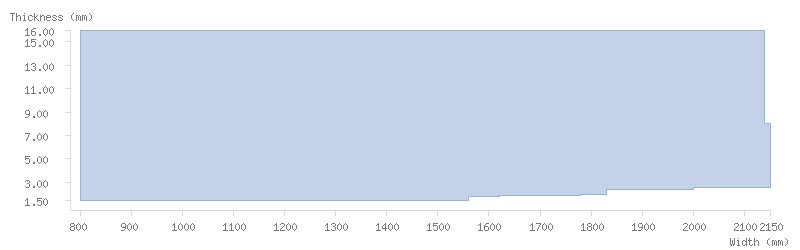

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1560 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | 1620 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.10 | 1830 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 2000 | |

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 2.90 | 2150 | |

| 2.90 ≤ th < 8.00 | ||

| 8.00 ≤ th < 16.00 | 2140 | |

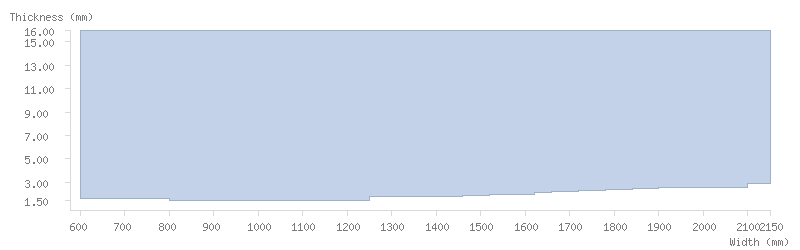

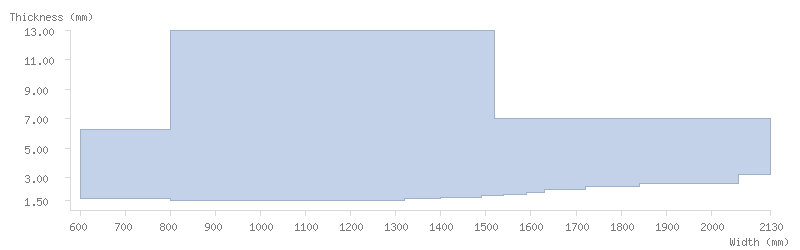

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1250 |

| 1.60 ≤ th < 1.70 | 600 | |

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | 1460 | |

| 1.90 ≤ th < 2.00 | 1520 | |

| 2.00 ≤ th < 2.10 | 1620 | |

| 2.10 ≤ th < 2.20 | 1660 | |

| 2.20 ≤ th < 2.30 | 1720 | |

| 2.30 ≤ th < 2.40 | 1780 | |

| 2.40 ≤ th < 2.50 | 1840 | |

| 2.50 ≤ th < 2.60 | 1900 | |

| 2.60 ≤ th < 2.90 | 2100 | |

| 2.90 ≤ th < 8.00 | 2150 | |

| 8.00 ≤ th < 16.00 | ||

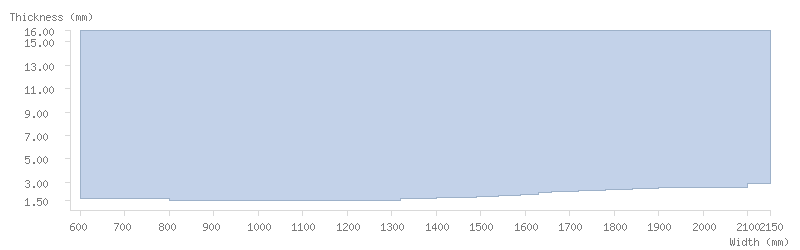

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1320 |

| 1.60 ≤ th < 1.70 | 600 | 1400 |

| 1.70 ≤ th < 1.80 | 1490 | |

| 1.80 ≤ th < 1.90 | 1540 | |

| 1.90 ≤ th < 2.00 | 1590 | |

| 2.00 ≤ th < 2.10 | 1630 | |

| 2.10 ≤ th < 2.20 | 1660 | |

| 2.20 ≤ th < 2.30 | 1720 | |

| 2.30 ≤ th < 2.40 | 1780 | |

| 2.40 ≤ th < 2.50 | 1840 | |

| 2.50 ≤ th < 2.60 | 1900 | |

| 2.60 ≤ th < 2.90 | 2100 | |

| 2.90 ≤ th < 8.00 | 2150 | |

| 8.00 ≤ th < 16.00 | ||

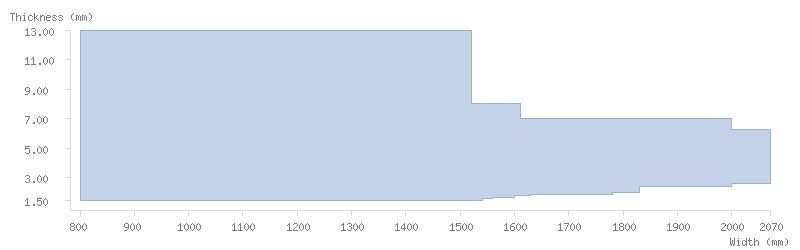

| Thickness (mm) | 1006 SAE J 403 | 1008 SAE J 403 | 1010 SAE J 403 | 1015 SAE J 403 | ||||

|---|---|---|---|---|---|---|---|---|

| Min width | Max width | Min width | Max width | Min width | Max width | Min width | Max width | |

| 1.50 ≤ th < 1.60 | 800 | 1540 | 800 | 1540 | 800 | 1320 | 800 | 1320 |

| 1.60 ≤ th < 1.70 | 600 | 1560 | 1560 | 600 | 1370 | 600 | 1400 | |

| 1.70 ≤ th < 1.80 | 1610 | 1600 | 1420 | 1490 | ||||

| 1.80 ≤ th < 1.90 | 1630 | 1630 | 1470 | 1540 | ||||

| 1.90 ≤ th < 2.00 | 1780 | 1780 | 1520 | 1590 | ||||

| 2.00 ≤ th < 2.10 | 1830 | 1830 | 1620 | 1630 | ||||

| 2.10 ≤ th < 2.20 | 1660 | |||||||

| 2.20 ≤ th < 2.30 | 1720 | 1720 | ||||||

| 2.30 ≤ th < 2.40 | 1930 | 1780 | ||||||

| 2.40 ≤ th < 2.50 | 2000 | 2000 | 1840 | 1840 | ||||

| 2.50 ≤ th < 2.60 | 2070 | 1900 | ||||||

| 2.60 ≤ th < 3.20 | 2070 | 2070 | 2060 | |||||

| 3.20 ≤ th < 3.30 | 2130 | |||||||

| 3.30 ≤ th < 6.30 | 2130 | |||||||

| 6.30 ≤ th < 6.40 | 800 | 2000 | 800 | 1570 | 800 | |||

| 6.40 ≤ th < 6.50 | 1550 | |||||||

| 6.50 ≤ th < 6.60 | 1530 | |||||||

| 6.60 ≤ th < 7.00 | - | |||||||

| 7.00 ≤ th < 7.10 | 1610 | - | 1520 | |||||

| 7.10 ≤ th < 8.00 | 1550 | |||||||

| 8.00 ≤ th < 13.00 | 1520 | 1520 | ||||||

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | 600 | 1560 |

| 1.70 ≤ th < 1.80 | 1610 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.10 | 1830 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1930 | |

| 2.40 ≤ th < 2.50 | 2000 | |

| 2.50 ≤ th < 2.60 | 2070 | |

| 2.60 ≤ th < 3.20 | ||

| 3.20 ≤ th < 3.30 | ||

| 3.30 ≤ th < 6.30 | 2130 | |

| 6.30 ≤ th < 6.40 | 800 | |

| 6.40 ≤ th < 6.50 | ||

| 6.50 ≤ th < 6.60 | ||

| 6.60 ≤ th < 7.00 | ||

| 7.00 ≤ th < 7.10 | ||

| 7.10 ≤ th < 8.00 | 1550 | |

| 8.00 ≤ th < 13.00 | 1520 | |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | 1560 | |

| 1.70 ≤ th < 1.80 | 1600 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.10 | 1830 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 2000 | |

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 3.20 | 2070 | |

| 3.20 ≤ th < 3.30 | ||

| 3.30 ≤ th < 6.30 | ||

| 6.30 ≤ th < 6.40 | 2000 | |

| 6.40 ≤ th < 6.50 | ||

| 6.50 ≤ th < 6.60 | ||

| 6.60 ≤ th < 7.00 | ||

| 7.00 ≤ th < 7.10 | 1610 | |

| 7.10 ≤ th < 8.00 | ||

| 8.00 ≤ th < 13.00 | 1520 | |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1320 |

| 1.60 ≤ th < 1.70 | 600 | 1370 |

| 1.70 ≤ th < 1.80 | 1420 | |

| 1.80 ≤ th < 1.90 | 1470 | |

| 1.90 ≤ th < 2.00 | 1520 | |

| 2.00 ≤ th < 2.10 | 1620 | |

| 2.10 ≤ th < 2.20 | 1660 | |

| 2.20 ≤ th < 2.30 | 1720 | |

| 2.30 ≤ th < 2.40 | 1780 | |

| 2.40 ≤ th < 2.50 | 1840 | |

| 2.50 ≤ th < 2.60 | 1900 | |

| 2.60 ≤ th < 3.20 | 2070 | |

| 3.20 ≤ th < 3.30 | ||

| 3.30 ≤ th < 6.30 | ||

| 6.30 ≤ th < 6.40 | 800 | 1570 |

| 6.40 ≤ th < 6.50 | 1550 | |

| 6.50 ≤ th < 6.60 | 1530 | |

| 6.60 ≤ th < 7.00 | - | |

| 7.00 ≤ th < 7.10 | - | |

| 7.10 ≤ th < 8.00 | ||

| 8.00 ≤ th < 13.00 | ||

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1320 |

| 1.60 ≤ th < 1.70 | 600 | 1400 |

| 1.70 ≤ th < 1.80 | 1490 | |

| 1.80 ≤ th < 1.90 | 1540 | |

| 1.90 ≤ th < 2.00 | 1590 | |

| 2.00 ≤ th < 2.10 | 1630 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | 1720 | |

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1840 | |

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 3.20 | 2060 | |

| 3.20 ≤ th < 3.30 | 2130 | |

| 3.30 ≤ th < 6.30 | ||

| 6.30 ≤ th < 6.40 | 800 | |

| 6.40 ≤ th < 6.50 | ||

| 6.50 ≤ th < 6.60 | ||

| 6.60 ≤ th < 7.00 | ||

| 7.00 ≤ th < 7.10 | 1520 | |

| 7.10 ≤ th < 8.00 | ||

| 8.00 ≤ th < 13.00 | ||

| C (%) | Mn (%) | P (%) | S (%) | |

|---|---|---|---|---|

| 1006 SAE J 403 | ≤ 0.080 | ≤ 0.45 | ≤ 0.030 | ≤ 0.035 |

| 1008 SAE J 403 | ≤ 0.100 | ≤ 0.50 | ≤ 0.030 | ≤ 0.035 |

| 1010 SAE J 403 | 0.080 - 0.130 | 0.30 - 0.60 | ≤ 0.030 | ≤ 0.035 |

| 1015 SAE J 403 | 0.130 - 0.170 | 0.30 - 0.60 | ≤ 0.030 | ≤ 0.035 |

On request, maximum levels of residual elements (Ni, Cr, Cu, Mo) can be set as per option A in Table 1 of SAE J403 (Cu ≤ 0.20%, Ni ≤ 0.20%, Cr ≤ 0.15%, Mo ≤ 0.08%).

| 1006 SAE J 403 | |

|---|---|

| C (%) | ≤ 0.080 |

| Mn (%) | ≤ 0.45 |

| P (%) | ≤ 0.030 |

| S (%) | ≤ 0.035 |

| 1008 SAE J 403 | |

|---|---|

| C (%) | ≤ 0.100 |

| Mn (%) | ≤ 0.50 |

| P (%) | ≤ 0.030 |

| S (%) | ≤ 0.035 |

| 1010 SAE J 403 | |

|---|---|

| C (%) | 0.080 - 0.130 |

| Mn (%) | 0.30 - 0.60 |

| P (%) | ≤ 0.030 |

| S (%) | ≤ 0.035 |

| 1015 SAE J 403 | |

|---|---|

| C (%) | 0.130 - 0.170 |

| Mn (%) | 0.30 - 0.60 |

| P (%) | ≤ 0.030 |

| S (%) | ≤ 0.035 |

On request, maximum levels of residual elements (Ni, Cr, Cu, Mo) can be set as per option A in Table 1 of SAE J403 (Cu ≤ 0.20%, Ni ≤ 0.20%, Cr ≤ 0.15%, Mo ≤ 0.08%).

Any questions?

Ask them via our contact form on

https://industry.arcelormittal.com/getintouch

All details provided in the ArcelorMittal Flat Carbon Europe S.A. catalogue are for information purposes only. ArcelorMittal Flat Carbon Europe S.A. reserves the right to change its product range at any time without prior notice.

Download

Download