In order to offer you the best possible experience, we suggest that you accept the deposit and reading of cookies and the use of technology necessary for their proper functioning:

When used uncoated and exposed to bad weather, a protective oxide layer develops on the steel surface. That is why this steel is often called “the weathering steel”.

Indaten® 355 is a range of steels with improved resistance to atmospheric corrosion that meet the requirements of the EN 10025-5:2004 standard. These grades are fine-grain, high-strength structural steels that have been optimised to give improved processing and in-service performance.

The grades as per EN 10025-5 can be supplied:

Furthermore, option 11c of EN 10025-5 is also available (sheet, plate, strip, wide flats and flats (width < 150 mm) with a nominal thickness ≤ 20 mm shall be suitable for flanging without cracking).

With their characteristic colour, Indaten® 355 steels are used in architectural projects either to harmonise with the environment or to create a pleasing contrast with other materials, such as stainless steel. When used uncoated and exposed to bad weather, an oxide layer develops on the steel surface, forming a purplish-brown, finely grained patina that bonds very strongly to the steel and protects it. If the patina is damaged, the steel re-oxidises, thus repairing the patina and maintaining the protective barrier. Indaten® 355 can also be coated (paint, metallic coatings etc). In the case of coated parts, the protective layer prevents rust propagation under the paint layer.

Experience has shown that the adhesion of organic coatings on Indaten® 355 is superior to bonding on other carbon steel grades.

Indaten® 355 has a wide range of applications: architecture, sculpture, engineering structures, smokestacks, freight wagons, silos, containers and pylons. When used uncoated, no maintenance is required and the material will not deteriorate through corrosion.

The effectiveness of the corrosion protection largely depends on the speed of patina formation. For optimum patina formation, Indaten® 355 can be used in a non-confined environment, even in the presence of sulphuric fumes. However, it is strongly recommended not to expose Indaten® 355 to condensation or repeated soiling, particularly in environments containing free chlorine.

Since 1 July 2013, the Construction Products Regulation (Regulation (EU) No. 305/2011 – CPR) has required that CE marking be affixed to all products delivered in accordance with a harmonised standard (e.g. EN 10025). This CE marking guarantees, for the uses defined in the standard, the properties described in the declaration of performance submitted by the manufacturer.

All of the steels in this data sheet comply with this Regulation.

The corresponding declarations of performance are available on our website at:

Indaten® 355 has excellent weldability with all the usual welding processes thanks to its low carbon content and fine-grained structure.

Shielded metal arc welding (process no. 111, SMAW)

| Supplier | Reference | EN ISO | AWS |

|---|---|---|---|

| Esab | OK 73.08* | 2560-A / E 46 5 Z B 32 | A5.5 / E8018-G |

| OK 48.08* | 2560-A / E 42 4 B 32 H5 | A5.1 / E7018 | |

| Lincoln Electric | Conarc 55CT SRP* | 499 / E 46 5 Mn1Ni B 32 H5 | A5.5 / E8018-W2-H4R |

| Conarc 60G** | 757 / E 55 4 Z B 32 H5 | A5.5 / E9018M-H4 | |

| Conarc 70G** | 757 / E 55 4 1NiMo B 32 H5 | A5.5 / E9018-G-H4 | |

| S.A.F. Air Liquide | Safer CU 56** | 499 / E 464 Z B 32 H5 | A5.5 / E8018-G |

| Safer NF 52** | 499 / E 424 B 54 H5 | A5.5 / E7028 | |

| 499 / E 423 B 74 H5 | |||

| Safer NF 510** | 499 / E 423 B 32 H5 | A5.5 / E7018 | |

| Thyssen | SH Patinax KB** | 499 / E 38 3 Z 1 NiCu B 42 | A5.5 / E7015-G |

* Specific electrode

** Specially adapted electrode

Submerged arc welding (process no. 21, SAW)

The filler materials to be used are the same as those recommended for welding steels with the same mechanical properties. As SAW involves strong inherent dilution, the welds will develop a patina.

The mechanical properties obtained in fusion zones meet the normal mechanical property requirements for the base metal.

| Supplier | Reference | EN ISO | AWS |

|---|---|---|---|

| Esab | Fil Autrod 13.36* | 756 / S2Ni1Cu | A5.23 / EG |

| OK Flux 10.71 and 10.81 to 10.83* | |||

| Lincoln Electric | Fil LNS 163* | ||

| Flux P230* | 760 / S A AB 1 67 AC H5 | ||

| Fil L60** | 756 / S1 | A5.17 / EL12 | |

| Flux 780** | 760 / S A AR/AB 1 78 AC H5 | ||

| Fil L61** | S2Si | A5.17 / EM12K | |

| Flux 860** | 760 / S A AB 1 56 AC H5 | ||

| S.A.F. Air Liquide | Fil AS 26** | 756 / S1 | A5.17 / EL12 |

| Flux AS 50** | 756 / SF 35 0 MS 1 S 1 | A5.17 / F6-A0-EL12 | |

| Fil AS 35** | 756 / S2 | A5.17 / EM12K | |

| Flux AS 50** | 756 / SF 38 0 MS 1 S 2 | A5.17 / F7-A0-EM12K | |

| Thyssen | Union Patinax U* | 756 / S 42 2 FB S0 | A5.23 / F7A2-EG-G |

| Flux UV 420 TT / UV 420 TT-LH* | 760 / SA FB 1 65 DC / SA FB 1 65 DC H5 |

* Specific welding wire/flux couple

** Specially adapted welding wire/flux couple

Gas metal-arc welding (process no. 135, GMAW)

The thin wires used for equivalent carbon steel grades can also be used for Indaten® 355 steels; copper-plated wires deposit more copper on the surface of the welded zone, which contributes to the development of a patina on the welds. The cored wires to be used are also the same as those used for the equivalent carbon-manganese steel grades.

| Supplier | Reference | EN ISO | AWS |

|---|---|---|---|

| Esab | OK Autrod 12.51** | 440 / G3Si1 | A5.18 / ER70S-6 |

| OK AristoRod 13.29** | 12534 / GMn3Ni1CrMo | A5.28 / ER110S-G | |

| Lincoln Electric | LNM 28* | 12070 / G465MG3Ni1 | A5.28 / ER80S-G |

| LNM Ni1** | A5.28 / ER80S-Ni1 | ||

| S.A.F. Air Liquide | Nertalic 70 A** | 440 / G3Si1 | A5.18 / ER70S-6 |

| Thyssen | Union Patinax* | 440 / G423CGO | A5.18 / ER70S-G |

* Specific welding wire

** Specially adapted welding wire

Flux-cored arc welding (process no. 136, FCAW)

The process is suitable for the assembly of thin products with the same welding parameters recommended for equivalent carbon-manganese steel grades. If a filler wire is used, it must be of the same type as the base metal.

| Supplier | Reference | EN ISO | AWS |

|---|---|---|---|

| Esab | OK Tubrod 14.01* | 17632-A / T 42 2 Z M M 2 H10 | A5.18 / E70C-GM |

| OK Tubrod 15.00** | 758 / T 42 3 B M 2 H5 | A5.20 / E71T-5H4 | |

| 758 / T 42 3 B C 2 H5 | A5.20 / E71T-5MH4 | ||

| OK Tubrod 15.17** | 758 / T 46 4 1Ni P M 2 H5 | A5.29 / E81T1-Ni1M | |

| 758 / T 46 3 1Ni P C 2 H5 | |||

| Lincoln Electric | Outershield 500CT-H* | 758 / T 50 5 Z P M 2 H5 | A5.29 / E81T1-G-H4 |

| S.A.F. Air Liquide | Safdual 31* | 758 / T 42 4 B M 2 H5 | A5.20 / E71T5 |

| Safdual 248* | 758 / T 46 A Z MM 1 H5 | A5.29 / E81T1G-W2M |

* Specific welding wire

** Specially adapted welding wire

Appearance of the patina

Outdoor use: the patina forms naturally in the open air (over a period of three to four years). Variations in appearance will be observed, depending on the water condensation, evacuation and evaporation conditions. After a few years, the patina will stabilise, even in an industrial, sulphur-containing or rural environment. To ensure optimum patina formation and limit the formation of rust streaks, the oxidation process can be accelerated artificially by first descaling the surface (by sandblasting or shotblasting) and then subjecting it to alternate periods of dry and humid conditions.

Indoor use: to preserve the natural appearance of the material and at the same time avoid powdery oxide deposits that may cause staining, the following three steps are recommended:

Use painted: as the surface has a high reactivity, it is recommended that the first coat of paint be applied on a clean surface immediately after pickling or sandblasting.

The presence of copper in the oxide layer contributes to the formation of a strongly bonded, elastic and compact patina on the surface of Indaten® 355 in the course of the corrosion process. The chromium and nickel contribute to the formation of insoluble alkaline sulphates, which will seal the pores of the oxide layer, thereby protecting the metal from water and oxygen. Silicon, and to a lesser extent phosphorus, also has a favourable effect on corrosion resistance.

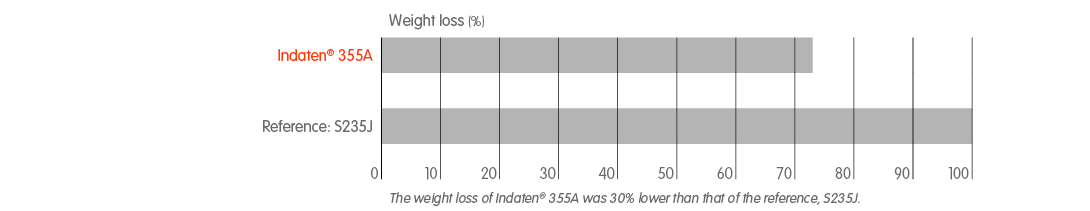

Corrosion in a salt spray atmosphere (according to ASTM B117)

Tests were conducted in a chamber at a temperature of 35°C, in a humid atmosphere with a 5% concentration of NaCl. Weight loss was measured after 1000 hours. The sample was weighed before and after the test, and the rust was removed with an acid solution.

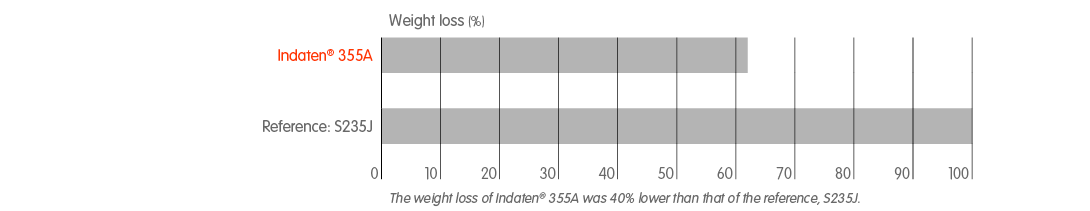

Atmospheric corrosion

The samples were exposed to an industrial, marine atmosphere for 12 months.

| EN 10155:1993 | JIS G3114 | ASTM | EN 10025-5:2004 | Old brand names | |

|---|---|---|---|---|---|

| S235J0W EN 10025-5 | S235J0W | ||||

| S235J2W EN 10025-5 | S235J2W | ||||

| S355J0W EN 10025-5 | S355J0W | ||||

| S355J0WP EN 10025-5 | S355J0WP | ||||

| Indaten® 355A | S355J0WP | SMA 50AW | A242 Grade A/A606 T2/A606 T4 | S355J0WP | Ensacor® A |

| S355J2W EN 10025-5 | S355J2W | ||||

| Indaten® 355D | S355J2W | S355J2W | Ensacor® D | ||

| S355J2WP EN 10025-5 | S355J2WP |

| S235J0W EN 10025-5 | |

|---|---|

| EN 10155:1993 | |

| JIS G3114 | |

| ASTM | |

| EN 10025-5:2004 | S235J0W |

| Old brand names | |

| S235J2W EN 10025-5 | |

|---|---|

| EN 10155:1993 | |

| JIS G3114 | |

| ASTM | |

| EN 10025-5:2004 | S235J2W |

| Old brand names | |

| S355J0W EN 10025-5 | |

|---|---|

| EN 10155:1993 | |

| JIS G3114 | |

| ASTM | |

| EN 10025-5:2004 | S355J0W |

| Old brand names | |

| S355J0WP EN 10025-5 | |

|---|---|

| EN 10155:1993 | |

| JIS G3114 | |

| ASTM | |

| EN 10025-5:2004 | S355J0WP |

| Old brand names | |

| Indaten® 355A | |

|---|---|

| EN 10155:1993 | S355J0WP |

| JIS G3114 | SMA 50AW |

| ASTM | A242 Grade A/A606 T2/A606 T4 |

| EN 10025-5:2004 | S355J0WP |

| Old brand names | Ensacor® A |

| S355J2W EN 10025-5 | |

|---|---|

| EN 10155:1993 | |

| JIS G3114 | |

| ASTM | |

| EN 10025-5:2004 | S355J2W |

| Old brand names | |

| Indaten® 355D | |

|---|---|

| EN 10155:1993 | S355J2W |

| JIS G3114 | |

| ASTM | |

| EN 10025-5:2004 | S355J2W |

| Old brand names | Ensacor® D |

| S355J2WP EN 10025-5 | |

|---|---|

| EN 10155:1993 | |

| JIS G3114 | |

| ASTM | |

| EN 10025-5:2004 | S355J2WP |

| Old brand names | |

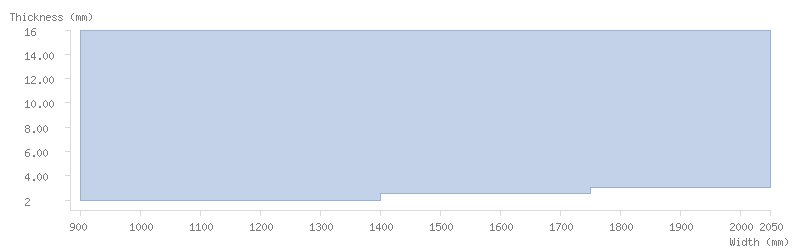

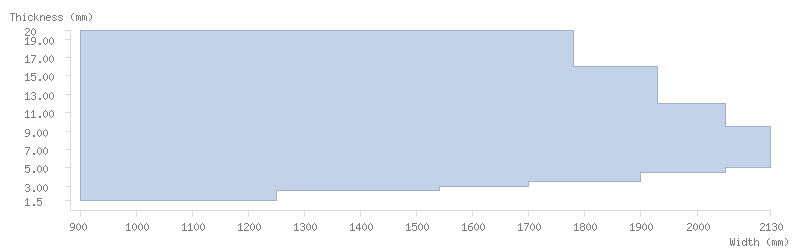

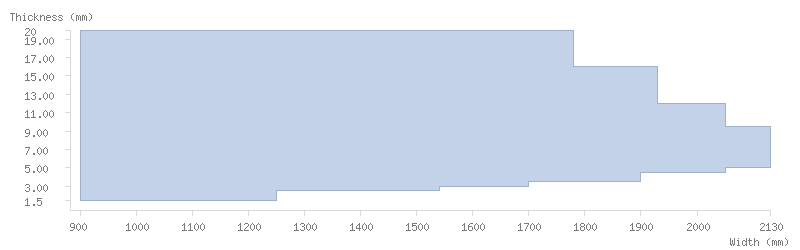

| Thickness (mm) | Min width | S235J0W EN 10025-5, S235J2W EN 10025-5 | S355J0W EN 10025-5, S355J2W EN 10025-5, Indaten® 355D | S355J0WP EN 10025-5, Indaten® 355A, S355J2WP EN 10025-5 |

|---|---|---|---|---|

| Max width | Max width | Max width | ||

| 1.50 ≤ th < 2.00 | 900 | - | 1250 | 1250 |

| 2.00 ≤ th < 2.50 | 1400 | 1400 | ||

| 2.50 ≤ th < 3.00 | 1750 | 1540 | 1540 | |

| 3.00 ≤ th < 3.50 | 2050 | 1700 | 1700 | |

| 3.50 ≤ th < 4.50 | 1900 | 1780 | ||

| 4.50 ≤ th < 5.00 | 2050 | 1900 | ||

| 5.00 ≤ th < 5.50 | 2130 | 1990 | ||

| 5.50 ≤ th < 9.50 | 2130 | |||

| 9.50 ≤ th < 10.00 | 2050 | |||

| 10.00 ≤ th < 12.00 | 2030 | |||

| 12.00 ≤ th < 13.00 | 1930 | |||

| 13.00 ≤ th < 16.00 | 1930 | |||

| 16.00 ≤ th < 20.00 | - | 1780 | 1780 |

Product can also be supplied pickled on request.

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 2.00 | - | - |

| 2.00 ≤ th < 2.50 | 900 | 1400 |

| 2.50 ≤ th < 3.00 | 1750 | |

| 3.00 ≤ th < 3.50 | 2050 | |

| 3.50 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 5.50 | ||

| 5.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 16.00 | ||

| 16.00 ≤ th < 20.00 | - | - |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 2.00 | - | - |

| 2.00 ≤ th < 2.50 | 900 | 1400 |

| 2.50 ≤ th < 3.00 | 1750 | |

| 3.00 ≤ th < 3.50 | 2050 | |

| 3.50 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 5.50 | ||

| 5.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 16.00 | ||

| 16.00 ≤ th < 20.00 | - | - |

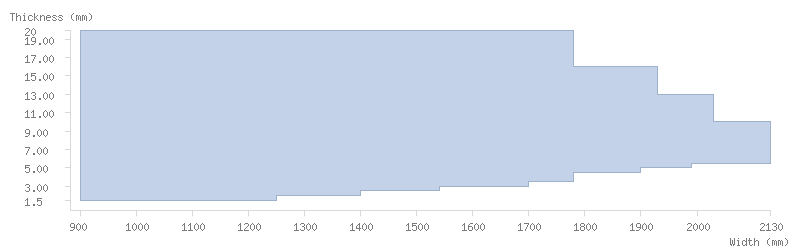

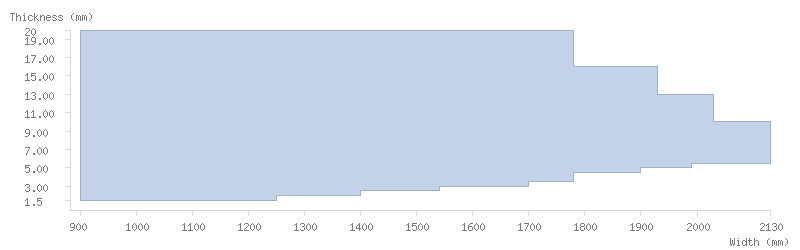

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 2.00 | 900 | 1250 |

| 2.00 ≤ th < 2.50 | ||

| 2.50 ≤ th < 3.00 | 1540 | |

| 3.00 ≤ th < 3.50 | 1700 | |

| 3.50 ≤ th < 4.50 | 1900 | |

| 4.50 ≤ th < 5.00 | 2050 | |

| 5.00 ≤ th < 5.50 | 2130 | |

| 5.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | 2050 | |

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | 1930 | |

| 13.00 ≤ th < 16.00 | ||

| 16.00 ≤ th < 20.00 | 1780 |

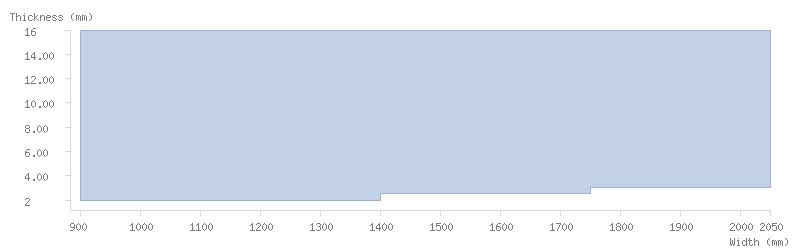

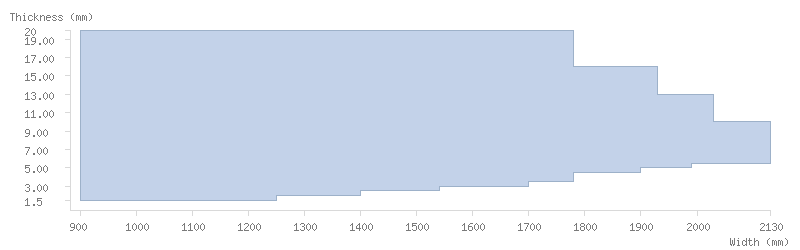

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 2.00 | 900 | 1250 |

| 2.00 ≤ th < 2.50 | 1400 | |

| 2.50 ≤ th < 3.00 | 1540 | |

| 3.00 ≤ th < 3.50 | 1700 | |

| 3.50 ≤ th < 4.50 | 1780 | |

| 4.50 ≤ th < 5.00 | 1900 | |

| 5.00 ≤ th < 5.50 | 1990 | |

| 5.50 ≤ th < 9.50 | 2130 | |

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | 2030 | |

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 16.00 | 1930 | |

| 16.00 ≤ th < 20.00 | 1780 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 2.00 | 900 | 1250 |

| 2.00 ≤ th < 2.50 | 1400 | |

| 2.50 ≤ th < 3.00 | 1540 | |

| 3.00 ≤ th < 3.50 | 1700 | |

| 3.50 ≤ th < 4.50 | 1780 | |

| 4.50 ≤ th < 5.00 | 1900 | |

| 5.00 ≤ th < 5.50 | 1990 | |

| 5.50 ≤ th < 9.50 | 2130 | |

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | 2030 | |

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 16.00 | 1930 | |

| 16.00 ≤ th < 20.00 | 1780 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 2.00 | 900 | 1250 |

| 2.00 ≤ th < 2.50 | ||

| 2.50 ≤ th < 3.00 | 1540 | |

| 3.00 ≤ th < 3.50 | 1700 | |

| 3.50 ≤ th < 4.50 | 1900 | |

| 4.50 ≤ th < 5.00 | 2050 | |

| 5.00 ≤ th < 5.50 | 2130 | |

| 5.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | 2050 | |

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | 1930 | |

| 13.00 ≤ th < 16.00 | ||

| 16.00 ≤ th < 20.00 | 1780 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 2.00 | 900 | 1250 |

| 2.00 ≤ th < 2.50 | ||

| 2.50 ≤ th < 3.00 | 1540 | |

| 3.00 ≤ th < 3.50 | 1700 | |

| 3.50 ≤ th < 4.50 | 1900 | |

| 4.50 ≤ th < 5.00 | 2050 | |

| 5.00 ≤ th < 5.50 | 2130 | |

| 5.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | 2050 | |

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | 1930 | |

| 13.00 ≤ th < 16.00 | ||

| 16.00 ≤ th < 20.00 | 1780 |

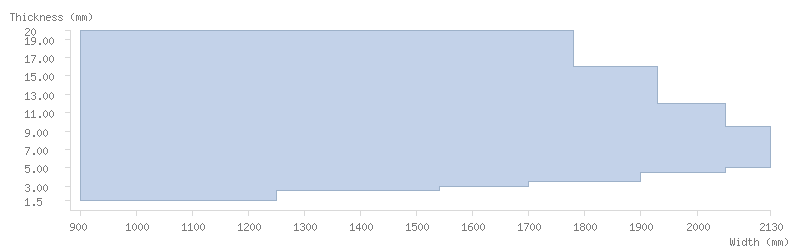

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 2.00 | 900 | 1250 |

| 2.00 ≤ th < 2.50 | 1400 | |

| 2.50 ≤ th < 3.00 | 1540 | |

| 3.00 ≤ th < 3.50 | 1700 | |

| 3.50 ≤ th < 4.50 | 1780 | |

| 4.50 ≤ th < 5.00 | 1900 | |

| 5.00 ≤ th < 5.50 | 1990 | |

| 5.50 ≤ th < 9.50 | 2130 | |

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | 2030 | |

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 16.00 | 1930 | |

| 16.00 ≤ th < 20.00 | 1780 |

Product can also be supplied pickled on request.

| Notes | Direction | Thickness (mm) | Re (MPa) | Rm (MPa) | A80 (%) | A 5.65√So (%) | Bending ratio (th) | KV 0°C (J) | KV -20°C (J) | |

|---|---|---|---|---|---|---|---|---|---|---|

| S235J0W EN 10025-5 | L | 6 - 25 | - | - | - | - | - | ≥ 27 | - | |

| T | 1.5 - 2 | ≥ 235 | 360 - 510 | ≥ 17 | - | - | - | - | ||

| 2 - 2.5 | ≥ 18 | |||||||||

| 2.5 - 3 | ≥ 19 | |||||||||

| 3 - 16 | - | ≥ 24 | ||||||||

| 16 - 25 | ≥ 225 | |||||||||

| S235J2W EN 10025-5 | L | 6 - 25 | - | - | - | - | - | - | ≥ 27 | |

| T | 1.5 - 2 | ≥ 235 | 360 - 510 | ≥ 17 | - | - | - | - | ||

| 2 - 2.5 | ≥ 18 | |||||||||

| 2.5 - 3 | ≥ 19 | |||||||||

| 3 - 16 | - | ≥ 24 | ||||||||

| 16 - 25 | ≥ 225 | |||||||||

| S355J0W EN 10025-5 | L | 6 - 20 | - | - | - | - | - | ≥ 27 | - | |

| T | 1.5 - 2 | ≥ 355 | 510 - 680 | ≥ 14 | - | - | - | - | ||

| 2 - 2.5 | ≥ 15 | |||||||||

| 2.5 - 3 | ≥ 16 | |||||||||

| 3 - 16 | 470 - 630 | - | ≥ 20 | |||||||

| 16 - 20 | ≥ 345 | |||||||||

| S355J0WP EN 10025-5 | L | 6 - 12 | - | - | - | - | - | ≥ 27 | - | |

| T | 1.5 - 2 | ≥ 355 | 510 - 680 | ≥ 14 | - | - | - | - | ||

| 2 - 2.5 | ≥ 15 | |||||||||

| 2.5 - 3 | ≥ 16 | |||||||||

| 3 - 12 | 470 - 630 | - | ≥ 20 | |||||||

| Indaten® 355A | 1 | L | 6 - 16 | - | - | - | - | - | ≥ 27 | - |

| T | 1.7 - 3 | ≥ 355 | 510 - 680 | ≥ 18 | - | ≥ 1.5 | - | - | ||

| 3 - 10 | 490 - 630 | - | ≥ 22 | ≥ 2 | ||||||

| 10 - 16 | ≥ 3 | |||||||||

| S355J2W EN 10025-5 | L | 6 - 20 | - | - | - | - | - | - | ≥ 27 | |

| T | 1.5 - 2 | ≥ 355 | 510 - 680 | ≥ 14 | - | - | - | - | ||

| 2 - 2.5 | ≥ 15 | |||||||||

| 2.5 - 3 | ≥ 16 | |||||||||

| 3 - 16 | 470 - 630 | - | ≥ 20 | |||||||

| 16 - 20 | ≥ 345 | |||||||||

| Indaten® 355D | L | 5 - 12.7 | - | - | - | - | - | - | ≥ 27 | |

| T | 1.8 - 2 | ≥ 355 | 510 - 680 | ≥ 14 | - | - | - | - | ||

| 2 - 2.5 | ≥ 15 | |||||||||

| 2.5 - 3 | ≥ 16 | |||||||||

| 3 - 12.7 | 470 - 630 | - | ≥ 20 | |||||||

| S355J2WP EN 10025-5 | L | 6 - 12 | - | - | - | - | - | - | ≥ 27 | |

| T | 1.5 - 2 | ≥ 355 | 510 - 680 | ≥ 14 | - | - | - | - | ||

| 2 - 2.5 | ≥ 15 | |||||||||

| 2.5 - 3 | ≥ 16 | |||||||||

| 3 - 12 | 470 - 630 | - | ≥ 20 |

Values in bold: tighter than the standard

1. For impact resistance at lower temperatures, please check with ArcelorMittal technical representative.

| Direction | Thickness (mm) | S235J0W EN 10025-5 | |

|---|---|---|---|

| Re (MPa) | T | 1.5 - 16 | ≥ 235 |

| 16 - 25 | ≥ 225 | ||

| Rm (MPa) | T | 1.5 - 25 | 360 - 510 |

| A80 (%) | T | 1.5 - 2 | ≥ 17 |

| 2 - 2.5 | ≥ 18 | ||

| 2.5 - 3 | ≥ 19 | ||

| A 5.65√So (%) | T | 3 - 25 | ≥ 24 |

| KV 0°C (J) | L | 6 - 25 | ≥ 27 |

| Direction | Thickness (mm) | S235J2W EN 10025-5 | |

|---|---|---|---|

| Re (MPa) | T | 1.5 - 16 | ≥ 235 |

| 16 - 25 | ≥ 225 | ||

| Rm (MPa) | T | 1.5 - 25 | 360 - 510 |

| A80 (%) | T | 1.5 - 2 | ≥ 17 |

| 2 - 2.5 | ≥ 18 | ||

| 2.5 - 3 | ≥ 19 | ||

| A 5.65√So (%) | T | 3 - 25 | ≥ 24 |

| KV -20°C (J) | L | 6 - 25 | ≥ 27 |

| Direction | Thickness (mm) | S355J0W EN 10025-5 | |

|---|---|---|---|

| Re (MPa) | T | 1.5 - 16 | ≥ 355 |

| 16 - 20 | ≥ 345 | ||

| Rm (MPa) | T | 1.5 - 3 | 510 - 680 |

| 3 - 20 | 470 - 630 | ||

| A80 (%) | T | 1.5 - 2 | ≥ 14 |

| 2 - 2.5 | ≥ 15 | ||

| 2.5 - 3 | ≥ 16 | ||

| A 5.65√So (%) | T | 3 - 20 | ≥ 20 |

| KV 0°C (J) | L | 6 - 20 | ≥ 27 |

| Direction | Thickness (mm) | S355J0WP EN 10025-5 | |

|---|---|---|---|

| Re (MPa) | T | 1.5 - 12 | ≥ 355 |

| Rm (MPa) | T | 1.5 - 3 | 510 - 680 |

| 3 - 12 | 470 - 630 | ||

| A80 (%) | T | 1.5 - 2 | ≥ 14 |

| 2 - 2.5 | ≥ 15 | ||

| 2.5 - 3 | ≥ 16 | ||

| A 5.65√So (%) | T | 3 - 12 | ≥ 20 |

| KV 0°C (J) | L | 6 - 12 | ≥ 27 |

| Notes | Direction | Thickness (mm) | Indaten® 355A | |

|---|---|---|---|---|

| Re (MPa) | 1 | T | 1.7 - 16 | ≥ 355 |

| Rm (MPa) | T | 1.7 - 3 | 510 - 680 | |

| 3 - 16 | 490 - 630 | |||

| A80 (%) | T | 1.7 - 3 | ≥ 18 | |

| A 5.65√So (%) | T | 3 - 16 | ≥ 22 | |

| Bending ratio (th) | T | 1.7 - 3 | ≥ 1.5 | |

| 3 - 10 | ≥ 2 | |||

| 10 - 16 | ≥ 3 | |||

| KV 0°C (J) | L | 6 - 16 | ≥ 27 |

Values in bold: tighter than the standard

1. For impact resistance at lower temperatures, please check with ArcelorMittal technical representative.

| Direction | Thickness (mm) | S355J2W EN 10025-5 | |

|---|---|---|---|

| Re (MPa) | T | 1.5 - 16 | ≥ 355 |

| 16 - 20 | ≥ 345 | ||

| Rm (MPa) | T | 1.5 - 3 | 510 - 680 |

| 3 - 20 | 470 - 630 | ||

| A80 (%) | T | 1.5 - 2 | ≥ 14 |

| 2 - 2.5 | ≥ 15 | ||

| 2.5 - 3 | ≥ 16 | ||

| A 5.65√So (%) | T | 3 - 20 | ≥ 20 |

| KV -20°C (J) | L | 6 - 20 | ≥ 27 |

| Direction | Thickness (mm) | Indaten® 355D | |

|---|---|---|---|

| Re (MPa) | T | 1.8 - 12.7 | ≥ 355 |

| Rm (MPa) | T | 1.8 - 3 | 510 - 680 |

| 3 - 12.7 | 470 - 630 | ||

| A80 (%) | T | 1.8 - 2 | ≥ 14 |

| 2 - 2.5 | ≥ 15 | ||

| 2.5 - 3 | ≥ 16 | ||

| A 5.65√So (%) | T | 3 - 12.7 | ≥ 20 |

| KV -20°C (J) | L | 5 - 12.7 | ≥ 27 |

| Direction | Thickness (mm) | S355J2WP EN 10025-5 | |

|---|---|---|---|

| Re (MPa) | T | 1.5 - 12 | ≥ 355 |

| Rm (MPa) | T | 1.5 - 3 | 510 - 680 |

| 3 - 12 | 470 - 630 | ||

| A80 (%) | T | 1.5 - 2 | ≥ 14 |

| 2 - 2.5 | ≥ 15 | ||

| 2.5 - 3 | ≥ 16 | ||

| A 5.65√So (%) | T | 3 - 12 | ≥ 20 |

| KV -20°C (J) | L | 6 - 12 | ≥ 27 |

Values in bold: tighter than the standard

1. For impact resistance at lower temperatures, please check with ArcelorMittal technical representative.

| C (%) | Mn (%) | P (%) | S (%) | Si (%) | Al (%) | Cu (%) | Cr (%) | Ni (%) | Ceq (%) | Mo (%) | N (%) | Galvanisation | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S235J0W EN 10025-5 | ≤ 0.130 | 0.20 - 0.60 | ≤ 0.035 | ≤ 0.035 | ≤ 0.40 | ≥ 0.020 | 0.25 - 0.55 | 0.40 - 0.80 | ≤ 0.65 | ≤ 0.44 | - | ≤ 0.009 | No |

| S235J2W EN 10025-5 | ≤ 0.130 | 0.20 - 0.60 | ≤ 0.035 | ≤ 0.030 | ≤ 0.40 | ≥ 0.020 | 0.25 - 0.55 | 0.40 - 0.80 | ≤ 0.65 | ≤ 0.44 | - | ≤ 0.009 | No |

| S355J0W EN 10025-5 | ≤ 0.160 | 0.50 - 1.50 | ≤ 0.035 | ≤ 0.035 | ≤ 0.50 | ≥ 0.020 | 0.25 - 0.55 | 0.40 - 0.80 | ≤ 0.65 | ≤ 0.52 | ≤ 0.30 | ≤ 0.009 | No |

| S355J0WP EN 10025-5 | ≤ 0.120 | ≤ 1.00 | 0.060 - 0.150 | ≤ 0.035 | ≤ 0.75 | ≥ 0.020 | 0.25 - 0.55 | 0.30 - 1.25 | ≤ 0.65 | ≤ 0.52 | - | ≤ 0.009 | No |

| Indaten® 355A | ≤ 0.120 | ≤ 1.00 | 0.060 - 0.150 | ≤ 0.015 | 0.20 - 0.50 | ≥ 0.020 | 0.25 - 0.55 | 0.30 - 0.80 | ≤ 0.30 | ≤ 0.45 | - | ≤ 0.009 | No |

| S355J2W EN 10025-5 | ≤ 0.160 | 0.50 - 1.50 | ≤ 0.030 | ≤ 0.030 | ≤ 0.50 | ≥ 0.020 | 0.25 - 0.55 | 0.40 - 0.80 | ≤ 0.65 | ≤ 0.52 | ≤ 0.30 | ≤ 0.009 | No |

| Indaten® 355D | ≤ 0.160 | 0.50 - 1.50 | ≤ 0.030 | ≤ 0.030 | ≤ 0.50 | ≥ 0.020 | 0.25 - 0.55 | 0.40 - 0.80 | ≤ 0.65 | ≤ 0.52 | ≤ 0.30 | ≤ 0.009 | No |

| S355J2WP EN 10025-5 | ≤ 0.120 | ≤ 1.00 | 0.060 - 0.150 | ≤ 0.030 | ≤ 0.75 | ≥ 0.020 | 0.25 - 0.55 | 0.30 - 1.25 | ≤ 0.65 | ≤ 0.52 | - | ≤ 0.009 | No |

Values in bold: tighter than the standard

The chemical properties given are based on cast analysis data.

For Indaten® 355D, Zr ≤ 0.15%

| S235J0W EN 10025-5 | |

|---|---|

| C (%) | ≤ 0.130 |

| Mn (%) | 0.20 - 0.60 |

| P (%) | ≤ 0.035 |

| S (%) | ≤ 0.035 |

| Si (%) | ≤ 0.40 |

| Al (%) | ≥ 0.020 |

| Cu (%) | 0.25 - 0.55 |

| Cr (%) | 0.40 - 0.80 |

| Ni (%) | ≤ 0.65 |

| Ceq (%) | ≤ 0.44 |

| Mo (%) | - |

| N (%) | ≤ 0.009 |

| Galvanisation | No |

| S235J2W EN 10025-5 | |

|---|---|

| C (%) | ≤ 0.130 |

| Mn (%) | 0.20 - 0.60 |

| P (%) | ≤ 0.035 |

| S (%) | ≤ 0.030 |

| Si (%) | ≤ 0.40 |

| Al (%) | ≥ 0.020 |

| Cu (%) | 0.25 - 0.55 |

| Cr (%) | 0.40 - 0.80 |

| Ni (%) | ≤ 0.65 |

| Ceq (%) | ≤ 0.44 |

| Mo (%) | - |

| N (%) | ≤ 0.009 |

| Galvanisation | No |

| S355J0W EN 10025-5 | |

|---|---|

| C (%) | ≤ 0.160 |

| Mn (%) | 0.50 - 1.50 |

| P (%) | ≤ 0.035 |

| S (%) | ≤ 0.035 |

| Si (%) | ≤ 0.50 |

| Al (%) | ≥ 0.020 |

| Cu (%) | 0.25 - 0.55 |

| Cr (%) | 0.40 - 0.80 |

| Ni (%) | ≤ 0.65 |

| Ceq (%) | ≤ 0.52 |

| Mo (%) | ≤ 0.30 |

| N (%) | ≤ 0.009 |

| Galvanisation | No |

| S355J0WP EN 10025-5 | |

|---|---|

| C (%) | ≤ 0.120 |

| Mn (%) | ≤ 1.00 |

| P (%) | 0.060 - 0.150 |

| S (%) | ≤ 0.035 |

| Si (%) | ≤ 0.75 |

| Al (%) | ≥ 0.020 |

| Cu (%) | 0.25 - 0.55 |

| Cr (%) | 0.30 - 1.25 |

| Ni (%) | ≤ 0.65 |

| Ceq (%) | ≤ 0.52 |

| Mo (%) | - |

| N (%) | ≤ 0.009 |

| Galvanisation | No |

| Indaten® 355A | |

|---|---|

| C (%) | ≤ 0.120 |

| Mn (%) | ≤ 1.00 |

| P (%) | 0.060 - 0.150 |

| S (%) | ≤ 0.015 |

| Si (%) | 0.20 - 0.50 |

| Al (%) | ≥ 0.020 |

| Cu (%) | 0.25 - 0.55 |

| Cr (%) | 0.30 - 0.80 |

| Ni (%) | ≤ 0.30 |

| Ceq (%) | ≤ 0.45 |

| Mo (%) | - |

| N (%) | ≤ 0.009 |

| Galvanisation | No |

Values in bold: tighter than the standard

| S355J2W EN 10025-5 | |

|---|---|

| C (%) | ≤ 0.160 |

| Mn (%) | 0.50 - 1.50 |

| P (%) | ≤ 0.030 |

| S (%) | ≤ 0.030 |

| Si (%) | ≤ 0.50 |

| Al (%) | ≥ 0.020 |

| Cu (%) | 0.25 - 0.55 |

| Cr (%) | 0.40 - 0.80 |

| Ni (%) | ≤ 0.65 |

| Ceq (%) | ≤ 0.52 |

| Mo (%) | ≤ 0.30 |

| N (%) | ≤ 0.009 |

| Galvanisation | No |

| Indaten® 355D | |

|---|---|

| C (%) | ≤ 0.160 |

| Mn (%) | 0.50 - 1.50 |

| P (%) | ≤ 0.030 |

| S (%) | ≤ 0.030 |

| Si (%) | ≤ 0.50 |

| Al (%) | ≥ 0.020 |

| Cu (%) | 0.25 - 0.55 |

| Cr (%) | 0.40 - 0.80 |

| Ni (%) | ≤ 0.65 |

| Ceq (%) | ≤ 0.52 |

| Mo (%) | ≤ 0.30 |

| N (%) | ≤ 0.009 |

| Galvanisation | No |

| S355J2WP EN 10025-5 | |

|---|---|

| C (%) | ≤ 0.120 |

| Mn (%) | ≤ 1.00 |

| P (%) | 0.060 - 0.150 |

| S (%) | ≤ 0.030 |

| Si (%) | ≤ 0.75 |

| Al (%) | ≥ 0.020 |

| Cu (%) | 0.25 - 0.55 |

| Cr (%) | 0.30 - 1.25 |

| Ni (%) | ≤ 0.65 |

| Ceq (%) | ≤ 0.52 |

| Mo (%) | - |

| N (%) | ≤ 0.009 |

| Galvanisation | No |

Values in bold: tighter than the standard

The chemical properties given are based on cast analysis data.

For Indaten® 355D, Zr ≤ 0.15%

Any questions?

Ask them via our contact form on

https://industry.arcelormittal.com/getintouch

All details provided in the ArcelorMittal Flat Carbon Europe S.A. catalogue are for information purposes only. ArcelorMittal Flat Carbon Europe S.A. reserves the right to change its product range at any time without prior notice.

Download

Download