In order to offer you the best possible experience, we suggest that you accept the deposit and reading of cookies and the use of technology necessary for their proper functioning:

Quenchable boron steels are used in applications requiring good wear resistant properties.

Quenchable boron steels represent a breakthrough in heat treatment technology. These steels use boron as a hardening agent. The melting and refining process, together with thermomechanical treatment by controlled hot rolling, allow ArcelorMittal quenchable boron steel to attain a remarkable degree of hardness and a very uniform microstructure, resulting in excellent mechanical loading performance after heat treatment of the finished part.

After heat treatment

Their extreme hardness after heat treatment makes these grades particularly suitable for applications requiring high wear/abrasion resistance. Their use allows significant weight saving (up to 50% compared with an HSLA grade) in structural and automotive components. The specific advantage of ArcelorMittal quenchable boron steels is their suitability for water quenching, making the process more environmentally friendly (less effluent treatment) than that used for conventional carbon steels. Their hardening performance is excellent with both liquid and gas quenching.

ArcelorMittal offers the following quenchable boron grades: Durabor® 20MnB5, Durabor® 22MnB5, Durabor® 28MnB5, Durabor® 30MnB5, Durabor® 33MnCrB5 and Durabor® 38MnB5 and equivalent EN ISO 683-2:2018 grades. Please contact us for other grades which are under development.

Properties can be tailored to specific requirements. Additional grades may be available on request. Contact our commercial teams for further information.

The choice of grade will depend on:

All the grades in the Durabor® boron steel range can be hot or cold formed.

As supplied

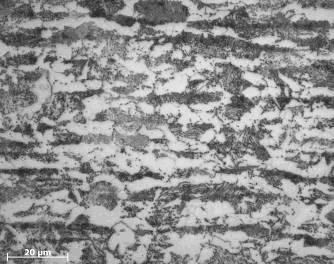

In spite of their moderate hardness and mechanical properties, boron grades exhibit remarkably good abrasion resistance in their delivery condition, thanks to their composite microstructure consisting of a hard pearlite phase embedded in ferrite. They are therefore very cost-effective solutions for applications requiring good abrasion resistance.

Durabor® 30MnB5

Ferrite-pearlite structure

Quenchable boron steels are used in applications requiring good wear resistant properties. The main applications for these steel grades after heat treatment are agricultural machinery (discs, plough shares), machinery for public works and mining, cutting equipment, tubes for automotive safety parts etc. A popular application for untreated steel is concrete mixer drums.

TRC characterisation of Durabor® 22MnB5

The recommended austenitising temperature is 880°C. The temperature at the beginning of the quenching process (i.e. at the maximum cooling rate) is 750°C. Ac3 temperature is 860°C, for a heating rate of 5°C/s. Ac1 temperature is 750°C, and Ms (Martensitic Start) starting temperature is 400°C.

In a tensile test, after austenitisation for 5 minutes at 850°C followed by water quenching, the structure of the sample obtained is entirely of the martensite type. In the same test performed at 840°C, a few islands of residual ferrite can be observed, regularly distributed.

TRC characterisation of Durabor® 30MnB5

The recommended austenitising temperature is 830°C to 850°C. The temperature at the beginning of the quenching process (i.e. at the maximum cooling rate) is 730°C. The TRC diagrams are available on request.

Forming

Durabor® 20MnB5, Durabor® 22MnB5, Durabor® 28MnB5, Durabor® 30MnB5, Durabor® 33MnCrB5 and Durabor® 38MnB5 can be hot or cold formed.

Typical mechanical properties of a 6 mm specimen in the rolling direction before and after quenching are indicated below.

| Delivery condition | Quenched | ||||||

| Grade | Re (MPa) | Rm (MPa) | A (%) | Hardness HRC | Re (MPa) | Rm (MPa) | A (%) |

| Durabor® 20MnB5 and EN ISO 683-2:2018 | 350 | 520 | 27 | 45 | 1100 | 1450 | 11 |

| Durabor® 22MnB5 | 1500 | 10 | |||||

| Durabor® 28MnB5 | 420 | 620 | 26 | 49 | 1200 | 1650 | 9 |

| Durabor® 30MnB5 and EN ISO 683-2:2018 | 440 | 660 | 25 | 50 | 1700 | 8 | |

| Durabor® 33MnCrB5 and EN ISO 683-2:2018 | 495 | 750 | 20 | 54 | 1300 | 2000 | 7 |

| Durabor® 38MnB5 | 480 | 760 | 18 | 55 | |||

Changing up from grade Durabor® 30MnB5 to Durabor® 38MnB5 makes it possible to increase hardness by about 10% on the quenched parts. Abrasion tests show that this translates into a dramatic improvement of 40% of the wear resistance.

The boron grades are available in A unexposed surface quality only.

Fatigue resistance is determined after heat treatment and quenching. Durabor® 22MnB5 steel 2.65 mm thick has been fatigue-tested by cyclical tensile loading with a load ratio of Rs = 0.1 after different heat treatments. Specimens were austenitised at 950°C for 5 minutes.

| Specimen heated for 5 minutes at 950°C followed by: | Endurance limit sD (MPa) | Spread (sigma) (MPa) | Maximum stress sD (MPa) |

|---|---|---|---|

| Water quenching | 253 | 5 | 562 |

| Oil quenching | 260 | 6 | 578 |

| Water quenching + heat treatment at 200°C for 20 minutes | 293 | 26 | 651 |

sD = (smax - smin)/2

Remark:

The fatigue resistance of ArcelorMittal's boron quenchable steels is between 40 and 60% higher than S355MC AM FCE low alloy grade. It can be reduced by over 30% if total decarburisation is carried out.

| EN 10083-3:2006 | NF A 36102 | DIN 1654 Teil 4 | BS970 Part 1 | UNI 3756 | UNE 36034 | J1268 | UNS | Old brand names | |

|---|---|---|---|---|---|---|---|---|---|

| 20MnB5 EN ISO 683-2:2018 | 20MnB5 | 20MnB5RR | 20B2 | 174H20 | |||||

| Durabor® 20MnB5 | 20MnB5 | 20MnB5RR | 20B2 | 174H20 | |||||

| Durabor® 22MnB5 | 20MnB5 | 20MnB5RR | 22B2 | 174H20 | 21B3 | 21B3/20MnB5 | 10B21/15B21 | H15211 | |

| Durabor® 28MnB5 | 28MnB5 | 28MnB5RR | 28B2 | ||||||

| 30MnB5 EN ISO 683-2:2018 | 30MnB5 | 30MnB5RR | 28B2 | 15B30 | H15301 | ||||

| Durabor® 30MnB5 | 30MnB5 | 30MnB5RR | 28B2 | 15B30 | H15301 | ||||

| 33MnCrB5 EN ISO 683-2:2018 | 33MnCrB5 | ||||||||

| Durabor® 33MnCrB5 | 33MnCrB5 | ||||||||

| 39MnB5 EN ISO 683-2:2018 | 38MnB5 | ||||||||

| Durabor® 38MnB5 | 38MnB5 |

Grades in italics: not included in the standard

| 20MnB5 EN ISO 683-2:2018 | |

|---|---|

| EN 10083-3:2006 | 20MnB5 |

| NF A 36102 | 20MnB5RR |

| DIN 1654 Teil 4 | 20B2 |

| BS970 Part 1 | 174H20 |

| UNI 3756 | |

| UNE 36034 | |

| J1268 | |

| UNS | |

| Durabor® 20MnB5 | |

|---|---|

| EN 10083-3:2006 | 20MnB5 |

| NF A 36102 | 20MnB5RR |

| DIN 1654 Teil 4 | 20B2 |

| BS970 Part 1 | 174H20 |

| UNI 3756 | |

| UNE 36034 | |

| J1268 | |

| UNS | |

Grades in italics: not included in the standard

| Durabor® 22MnB5 | |

|---|---|

| EN 10083-3:2006 | 20MnB5 |

| NF A 36102 | 20MnB5RR |

| DIN 1654 Teil 4 | 22B2 |

| BS970 Part 1 | 174H20 |

| UNI 3756 | 21B3 |

| UNE 36034 | 21B3/20MnB5 |

| J1268 | 10B21/15B21 |

| UNS | H15211 |

Grades in italics: not included in the standard

| Durabor® 28MnB5 | |

|---|---|

| EN 10083-3:2006 | 28MnB5 |

| NF A 36102 | 28MnB5RR |

| DIN 1654 Teil 4 | 28B2 |

| BS970 Part 1 | |

| UNI 3756 | |

| UNE 36034 | |

| J1268 | |

| UNS | |

Grades in italics: not included in the standard

| 30MnB5 EN ISO 683-2:2018 | |

|---|---|

| EN 10083-3:2006 | 30MnB5 |

| NF A 36102 | 30MnB5RR |

| DIN 1654 Teil 4 | 28B2 |

| BS970 Part 1 | |

| UNI 3756 | |

| UNE 36034 | |

| J1268 | 15B30 |

| UNS | H15301 |

| Durabor® 30MnB5 | |

|---|---|

| EN 10083-3:2006 | 30MnB5 |

| NF A 36102 | 30MnB5RR |

| DIN 1654 Teil 4 | 28B2 |

| BS970 Part 1 | |

| UNI 3756 | |

| UNE 36034 | |

| J1268 | 15B30 |

| UNS | H15301 |

Grades in italics: not included in the standard

| 33MnCrB5 EN ISO 683-2:2018 | |

|---|---|

| EN 10083-3:2006 | 33MnCrB5 |

| NF A 36102 | |

| DIN 1654 Teil 4 | |

| BS970 Part 1 | |

| UNI 3756 | |

| UNE 36034 | |

| J1268 | |

| UNS | |

| Durabor® 33MnCrB5 | |

|---|---|

| EN 10083-3:2006 | 33MnCrB5 |

| NF A 36102 | |

| DIN 1654 Teil 4 | |

| BS970 Part 1 | |

| UNI 3756 | |

| UNE 36034 | |

| J1268 | |

| UNS | |

Grades in italics: not included in the standard

| 39MnB5 EN ISO 683-2:2018 | |

|---|---|

| EN 10083-3:2006 | 38MnB5 |

| NF A 36102 | |

| DIN 1654 Teil 4 | |

| BS970 Part 1 | |

| UNI 3756 | |

| UNE 36034 | |

| J1268 | |

| UNS | |

| Durabor® 38MnB5 | |

|---|---|

| EN 10083-3:2006 | 38MnB5 |

| NF A 36102 | |

| DIN 1654 Teil 4 | |

| BS970 Part 1 | |

| UNI 3756 | |

| UNE 36034 | |

| J1268 | |

| UNS | |

Grades in italics: not included in the standard

Grades in italics: not included in the standard

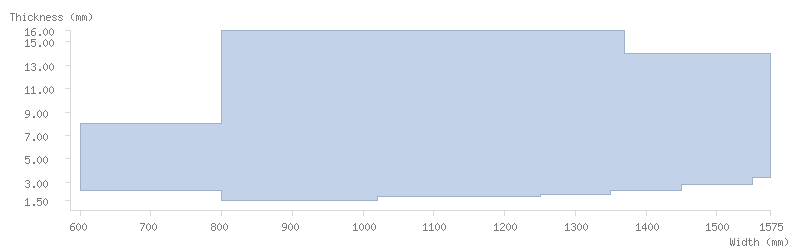

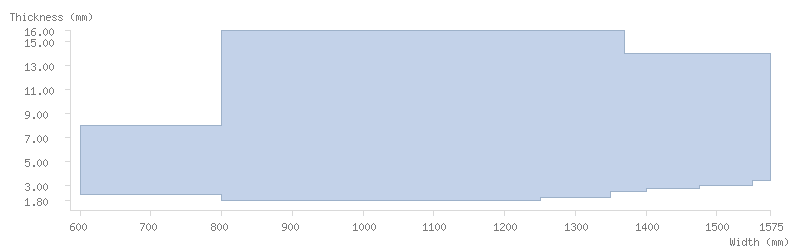

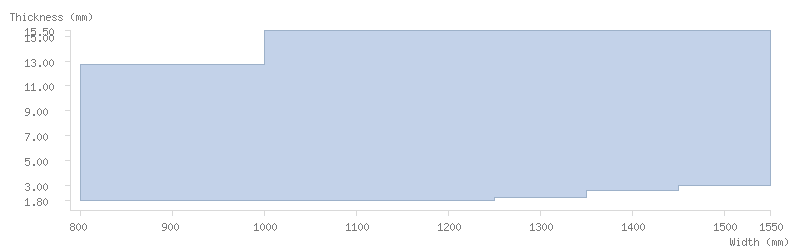

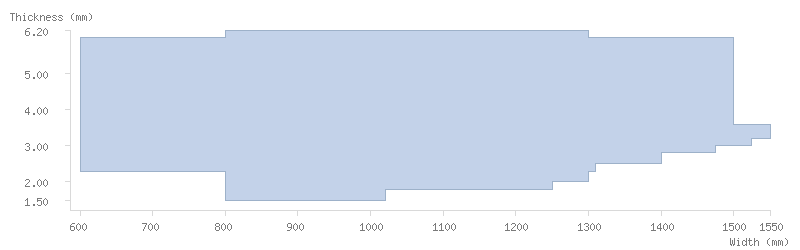

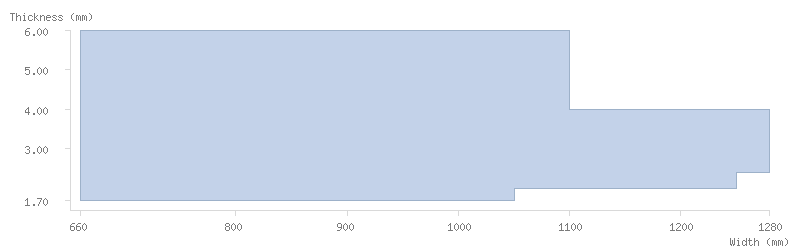

| Thickness (mm) | 20MnB5 EN ISO 683-2:2018, Durabor® 20MnB5 | Durabor® 22MnB5 | Durabor® 28MnB5 | 30MnB5 EN ISO 683-2:2018, Durabor® 30MnB5 | 33MnCrB5 EN ISO 683-2:2018, Durabor® 33MnCrB5 | 39MnB5 EN ISO 683-2:2018, Durabor® 38MnB5 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min width | Max width | Min width | Max width | Min width | Max width | Min width | Max width | Min width | Max width | Min width | Max width | |

| 1.50 ≤ th < 1.70 | 800 | 1020 | - | - | - | - | - | - | - | - | - | - |

| 1.70 ≤ th < 1.80 | 685 | 1015 | 685 | 1065 | ||||||||

| 1.80 ≤ th < 2.00 | 1250 | 800 | 1250 | 800 | 1250 | |||||||

| 2.00 ≤ th < 2.30 | 1350 | 1265 | 1350 | 1265 | 1350 | |||||||

| 2.30 ≤ th < 2.40 | 600 | 1450 | 600 | 600 | 600 | 1250 | ||||||

| 2.40 ≤ th < 2.50 | 1460 | 1460 | 1370 | |||||||||

| 2.50 ≤ th < 2.60 | 1400 | |||||||||||

| 2.60 ≤ th < 2.80 | 1450 | |||||||||||

| 2.80 ≤ th < 3.00 | 1550 | 1475 | ||||||||||

| 3.00 ≤ th < 3.40 | 1650 | 1550 | 1650 | 1550 | 1575 | |||||||

| 3.40 ≤ th < 4.00 | 1575 | 1575 | ||||||||||

| 4.00 ≤ th < 4.50 | 1850 | 1850 | ||||||||||

| 4.50 ≤ th < 5.00 | 1950 | 1950 | ||||||||||

| 5.00 ≤ th < 8.00 | 2150 | 2150 | ||||||||||

| 8.00 ≤ th < 12.70 | 800 | 800 | 685 | 800 | ||||||||

| 12.70 ≤ th < 14.00 | 1000 | |||||||||||

| 14.00 ≤ th < 15.00 | 1370 | 1370 | 1370 | |||||||||

| 15.00 ≤ th < 15.50 | - | - | 800 | 1370 | ||||||||

| 15.50 ≤ th < 16.00 | - | - | ||||||||||

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | 800 | 1020 |

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 2.00 | 1250 | |

| 2.00 ≤ th < 2.30 | 1350 | |

| 2.30 ≤ th < 2.40 | 600 | 1450 |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | 1550 | |

| 3.00 ≤ th < 3.40 | ||

| 3.40 ≤ th < 4.00 | 1575 | |

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 8.00 | ||

| 8.00 ≤ th < 12.70 | 800 | |

| 12.70 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | 1370 | |

| 15.00 ≤ th < 15.50 | ||

| 15.50 ≤ th < 16.00 |

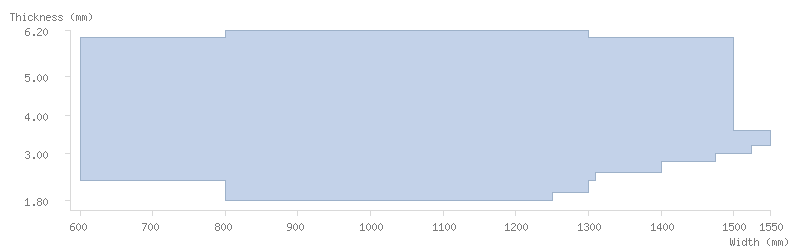

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | 800 | 1020 |

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 2.00 | 1250 | |

| 2.00 ≤ th < 2.30 | 1350 | |

| 2.30 ≤ th < 2.40 | 600 | 1450 |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | 1550 | |

| 3.00 ≤ th < 3.40 | ||

| 3.40 ≤ th < 4.00 | 1575 | |

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 8.00 | ||

| 8.00 ≤ th < 12.70 | 800 | |

| 12.70 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | 1370 | |

| 15.00 ≤ th < 15.50 | ||

| 15.50 ≤ th < 16.00 |

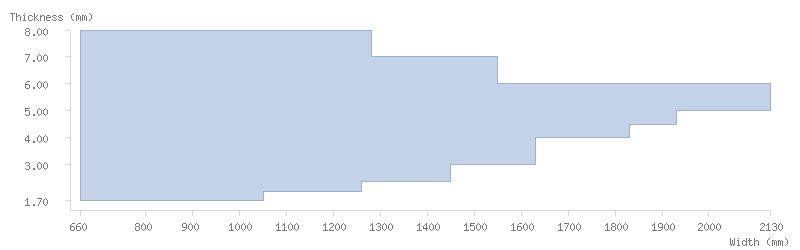

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | 685 | 1015 |

| 1.80 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.30 | 1265 | |

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1460 | |

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.40 | 1650 | |

| 3.40 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | 1850 | |

| 4.50 ≤ th < 5.00 | 1950 | |

| 5.00 ≤ th < 8.00 | 2150 | |

| 8.00 ≤ th < 12.70 | ||

| 12.70 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 15.50 | - | - |

| 15.50 ≤ th < 16.00 |

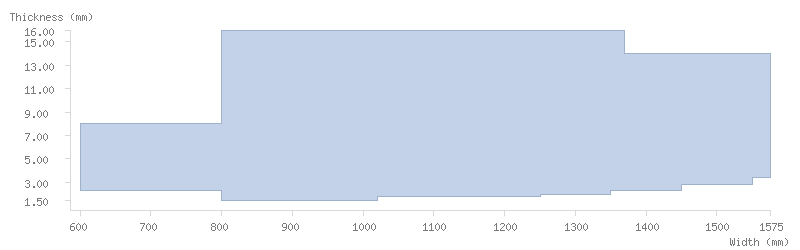

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 2.00 | 800 | 1250 |

| 2.00 ≤ th < 2.30 | 1350 | |

| 2.30 ≤ th < 2.40 | 600 | |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | 1400 | |

| 2.60 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | 1475 | |

| 3.00 ≤ th < 3.40 | 1550 | |

| 3.40 ≤ th < 4.00 | 1575 | |

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 8.00 | ||

| 8.00 ≤ th < 12.70 | 800 | |

| 12.70 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | 1370 | |

| 15.00 ≤ th < 15.50 | ||

| 15.50 ≤ th < 16.00 |

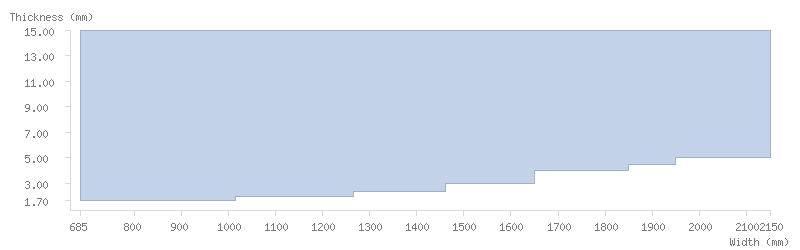

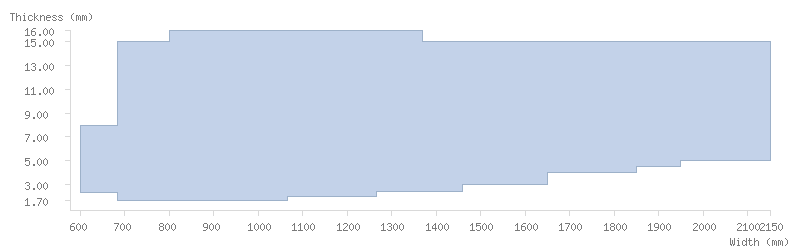

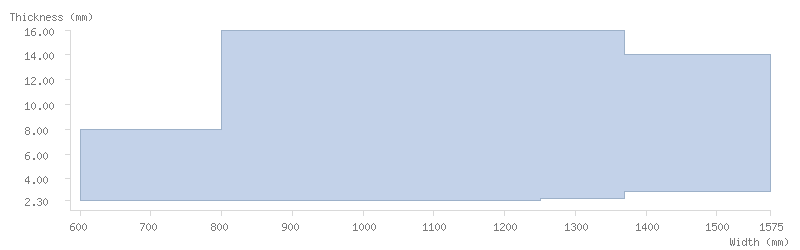

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | 685 | 1065 |

| 1.80 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.30 | 1265 | |

| 2.30 ≤ th < 2.40 | 600 | |

| 2.40 ≤ th < 2.50 | 1460 | |

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.40 | 1650 | |

| 3.40 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | 1850 | |

| 4.50 ≤ th < 5.00 | 1950 | |

| 5.00 ≤ th < 8.00 | 2150 | |

| 8.00 ≤ th < 12.70 | 685 | |

| 12.70 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 15.50 | 800 | 1370 |

| 15.50 ≤ th < 16.00 |

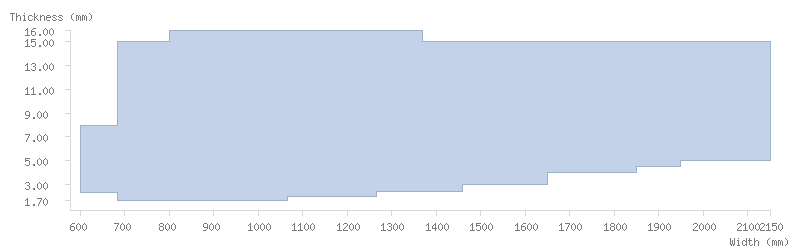

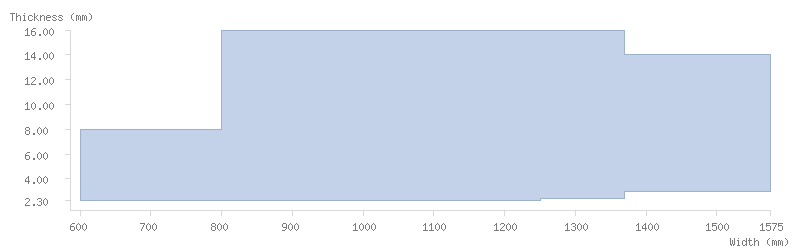

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | 685 | 1065 |

| 1.80 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.30 | 1265 | |

| 2.30 ≤ th < 2.40 | 600 | |

| 2.40 ≤ th < 2.50 | 1460 | |

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.40 | 1650 | |

| 3.40 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | 1850 | |

| 4.50 ≤ th < 5.00 | 1950 | |

| 5.00 ≤ th < 8.00 | 2150 | |

| 8.00 ≤ th < 12.70 | 685 | |

| 12.70 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 15.50 | 800 | 1370 |

| 15.50 ≤ th < 16.00 |

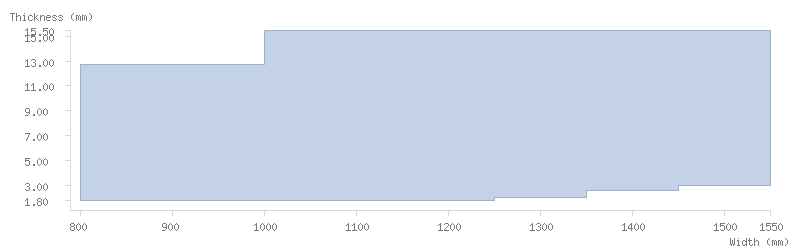

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 2.00 | 800 | 1250 |

| 2.00 ≤ th < 2.30 | 1350 | |

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 2.80 | 1450 | |

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.40 | 1550 | |

| 3.40 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 8.00 | ||

| 8.00 ≤ th < 12.70 | ||

| 12.70 ≤ th < 14.00 | 1000 | |

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 15.50 | ||

| 15.50 ≤ th < 16.00 | - | - |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 2.00 | 800 | 1250 |

| 2.00 ≤ th < 2.30 | 1350 | |

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 2.80 | 1450 | |

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.40 | 1550 | |

| 3.40 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 8.00 | ||

| 8.00 ≤ th < 12.70 | ||

| 12.70 ≤ th < 14.00 | 1000 | |

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 15.50 | ||

| 15.50 ≤ th < 16.00 | - | - |

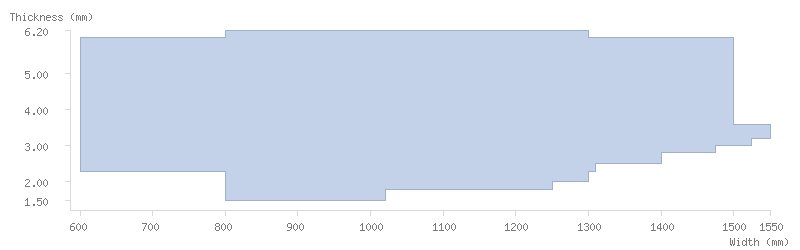

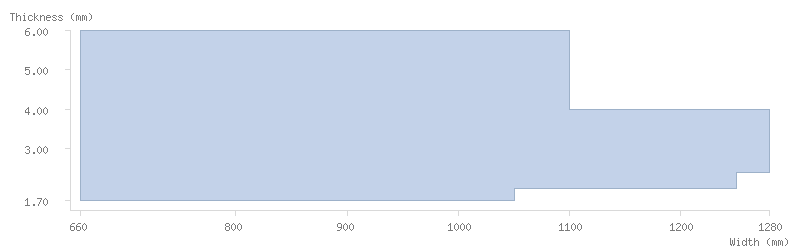

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 600 | 1250 |

| 2.40 ≤ th < 2.50 | 1370 | |

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.40 | 1575 | |

| 3.40 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 8.00 | ||

| 8.00 ≤ th < 12.70 | 800 | |

| 12.70 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | 1370 | |

| 15.00 ≤ th < 15.50 | ||

| 15.50 ≤ th < 16.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 600 | 1250 |

| 2.40 ≤ th < 2.50 | 1370 | |

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.40 | 1575 | |

| 3.40 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 8.00 | ||

| 8.00 ≤ th < 12.70 | 800 | |

| 12.70 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | 1370 | |

| 15.00 ≤ th < 15.50 | ||

| 15.50 ≤ th < 16.00 |

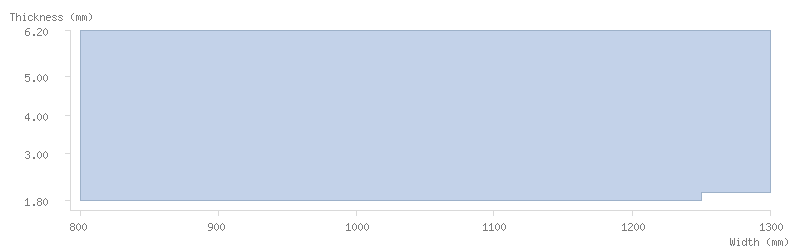

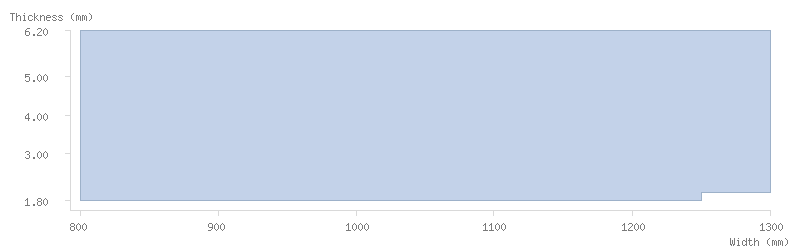

| Thickness (mm) | 20MnB5 EN ISO 683-2:2018, Durabor® 20MnB5 | Durabor® 22MnB5 | Durabor® 28MnB5 | 30MnB5 EN ISO 683-2:2018, Durabor® 30MnB5 | 33MnCrB5 EN ISO 683-2:2018, Durabor® 33MnCrB5 | 39MnB5 EN ISO 683-2:2018, Durabor® 38MnB5 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min width | Max width | Min width | Max width | Min width | Max width | Min width | Max width | Min width | Max width | Min width | Max width | |

| 1.50 ≤ th < 1.70 | 800 | 1020 | - | - | - | - | - | - | - | - | - | - |

| 1.70 ≤ th < 1.80 | 660 | 1050 | 660 | 1050 | ||||||||

| 1.80 ≤ th < 2.00 | 1250 | 800 | 1250 | 800 | 1250 | |||||||

| 2.00 ≤ th < 2.30 | 1300 | 1260 | 1300 | 1250 | 1300 | |||||||

| 2.30 ≤ th < 2.40 | 600 | 1310 | 600 | 1310 | ||||||||

| 2.40 ≤ th < 2.50 | 1450 | 1280 | ||||||||||

| 2.50 ≤ th < 2.80 | 1400 | 1400 | ||||||||||

| 2.80 ≤ th < 3.00 | 1475 | 1475 | ||||||||||

| 3.00 ≤ th < 3.20 | 1525 | 1630 | 1525 | |||||||||

| 3.20 ≤ th < 3.60 | 1550 | 1550 | ||||||||||

| 3.60 ≤ th < 4.00 | 1500 | 1500 | ||||||||||

| 4.00 ≤ th < 4.50 | 1830 | 1100 | ||||||||||

| 4.50 ≤ th < 5.00 | 1930 | |||||||||||

| 5.00 ≤ th < 6.00 | 2130 | |||||||||||

| 6.00 ≤ th < 6.20 | 800 | 1300 | 1550 | 800 | 1300 | - | ||||||

| 6.20 ≤ th < 7.00 | - | - | - | - | - | - | ||||||

| 7.00 ≤ th < 8.00 | 1280 | |||||||||||

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | 800 | 1020 |

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 2.00 | 1250 | |

| 2.00 ≤ th < 2.30 | 1300 | |

| 2.30 ≤ th < 2.40 | 600 | 1310 |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.80 | 1400 | |

| 2.80 ≤ th < 3.00 | 1475 | |

| 3.00 ≤ th < 3.20 | 1525 | |

| 3.20 ≤ th < 3.60 | 1550 | |

| 3.60 ≤ th < 4.00 | 1500 | |

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.20 | 800 | 1300 |

| 6.20 ≤ th < 7.00 | - | - |

| 7.00 ≤ th < 8.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | 800 | 1020 |

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 2.00 | 1250 | |

| 2.00 ≤ th < 2.30 | 1300 | |

| 2.30 ≤ th < 2.40 | 600 | 1310 |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.80 | 1400 | |

| 2.80 ≤ th < 3.00 | 1475 | |

| 3.00 ≤ th < 3.20 | 1525 | |

| 3.20 ≤ th < 3.60 | 1550 | |

| 3.60 ≤ th < 4.00 | 1500 | |

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.20 | 800 | 1300 |

| 6.20 ≤ th < 7.00 | - | - |

| 7.00 ≤ th < 8.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | 660 | 1050 |

| 1.80 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.30 | 1260 | |

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1450 | |

| 2.50 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.20 | 1630 | |

| 3.20 ≤ th < 3.60 | ||

| 3.60 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | 1830 | |

| 4.50 ≤ th < 5.00 | 1930 | |

| 5.00 ≤ th < 6.00 | 2130 | |

| 6.00 ≤ th < 6.20 | 1550 | |

| 6.20 ≤ th < 7.00 | ||

| 7.00 ≤ th < 8.00 | 1280 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 2.00 | 800 | 1250 |

| 2.00 ≤ th < 2.30 | 1300 | |

| 2.30 ≤ th < 2.40 | 600 | 1310 |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.80 | 1400 | |

| 2.80 ≤ th < 3.00 | 1475 | |

| 3.00 ≤ th < 3.20 | 1525 | |

| 3.20 ≤ th < 3.60 | 1550 | |

| 3.60 ≤ th < 4.00 | 1500 | |

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.20 | 800 | 1300 |

| 6.20 ≤ th < 7.00 | - | - |

| 7.00 ≤ th < 8.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | 660 | 1050 |

| 1.80 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.30 | 1250 | |

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1280 | |

| 2.50 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.20 | ||

| 3.20 ≤ th < 3.60 | ||

| 3.60 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | 1100 | |

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.20 | - | |

| 6.20 ≤ th < 7.00 | ||

| 7.00 ≤ th < 8.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | 660 | 1050 |

| 1.80 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.30 | 1250 | |

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1280 | |

| 2.50 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.20 | ||

| 3.20 ≤ th < 3.60 | ||

| 3.60 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | 1100 | |

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.20 | - | |

| 6.20 ≤ th < 7.00 | ||

| 7.00 ≤ th < 8.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 2.00 | 800 | 1250 |

| 2.00 ≤ th < 2.30 | 1300 | |

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.20 | ||

| 3.20 ≤ th < 3.60 | ||

| 3.60 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.20 | ||

| 6.20 ≤ th < 7.00 | - | - |

| 7.00 ≤ th < 8.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 2.00 | 800 | 1250 |

| 2.00 ≤ th < 2.30 | 1300 | |

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.20 | ||

| 3.20 ≤ th < 3.60 | ||

| 3.60 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.20 | ||

| 6.20 ≤ th < 7.00 | - | - |

| 7.00 ≤ th < 8.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.20 | ||

| 3.20 ≤ th < 3.60 | ||

| 3.60 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.20 | ||

| 6.20 ≤ th < 7.00 | ||

| 7.00 ≤ th < 8.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.70 | - | - |

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.20 | ||

| 3.20 ≤ th < 3.60 | ||

| 3.60 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.00 | ||

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.20 | ||

| 6.20 ≤ th < 7.00 | ||

| 7.00 ≤ th < 8.00 |

These grades receive a globularisation treatment of the manganese sulphides. The efficiency of boron is ensured by the addition of elements that bind nitrogen.

| C (%) | Mn (%) | P (%) | S (%) | Si (%) | Al (%) | Ti (%) | B (%) | Cr (%) | |

|---|---|---|---|---|---|---|---|---|---|

| 20MnB5 EN ISO 683-2:2018 | 0.170 - 0.230 | 1.10 - 1.40 | ≤ 0.025 | ≤ 0.035 | ≤ 0.40 | - | - | 0.0008 - 0.0050 | - |

| Durabor® 20MnB5 | 0.190 - 0.230 | 1.15 - 1.35 | ≤ 0.020 | ≤ 0.005 | 0.15 - 0.35 | ≥ 0.020 | 0.020 - 0.050 | 0.0015 - 0.0045 | - |

| Durabor® 22MnB5 | 0.200 - 0.250 | 1.10 - 1.40 | ≤ 0.025 | ≤ 0.008 | 0.15 - 0.35 | ≥ 0.020 | 0.020 - 0.060 | 0.0020 - 0.0050 | - |

| Durabor® 28MnB5 | 0.260 - 0.300 | 1.20 - 1.40 | ≤ 0.020 | ≤ 0.005 | 0.20 - 0.30 | ≥ 0.015 | 0.020 - 0.050 | 0.0020 - 0.0050 | - |

| 30MnB5 EN ISO 683-2:2018 | 0.270 - 0.330 | 1.15 - 1.45 | ≤ 0.025 | ≤ 0.035 | ≤ 0.40 | - | - | 0.0008 - 0.0050 | - |

| Durabor® 30MnB5 | 0.270 - 0.330 | 1.15 - 1.45 | ≤ 0.025 | ≤ 0.004 | 0.20 - 0.30 | ≥ 0.020 | 0.020 - 0.050 | 0.0010 - 0.0040 | - |

| 33MnCrB5 EN ISO 683-2:2018 | 0.300 - 0.360 | 1.20 - 1.50 | ≤ 0.025 | ≤ 0.035 | ≤ 0.40 | - | - | 0.0008 - 0.0050 | 0.30 - 0.60 |

| Durabor® 33MnCrB5 | 0.300 - 0.380 | 1.20 - 1.45 | ≤ 0.020 | ≤ 0.030 | ≤ 0.35 | ≥ 0.015 | 0.020 - 0.050 | 0.0010 - 0.0040 | 0.40 - 0.50 |

| 39MnB5 EN ISO 683-2:2018 | 0.360 - 0.420 | 1.15 - 1.45 | ≤ 0.025 | ≤ 0.035 | ≤ 0.40 | - | - | 0.0008 - 0.0050 | - |

| Durabor® 38MnB5 | 0.360 - 0.400 | 1.20 - 1.40 | ≤ 0.020 | ≤ 0.005 | 0.20 - 0.35 | ≥ 0.020 | 0.020 - 0.050 | 0.0020 - 0.0050 | - |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

| 20MnB5 EN ISO 683-2:2018 | |

|---|---|

| C (%) | 0.170 - 0.230 |

| Mn (%) | 1.10 - 1.40 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.035 |

| Si (%) | ≤ 0.40 |

| Al (%) | - |

| Ti (%) | - |

| B (%) | 0.0008 - 0.0050 |

| Cr (%) | - |

| Durabor® 20MnB5 | |

|---|---|

| C (%) | 0.190 - 0.230 |

| Mn (%) | 1.15 - 1.35 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.005 |

| Si (%) | 0.15 - 0.35 |

| Al (%) | ≥ 0.020 |

| Ti (%) | 0.020 - 0.050 |

| B (%) | 0.0015 - 0.0045 |

| Cr (%) | - |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

| Durabor® 22MnB5 | |

|---|---|

| C (%) | 0.200 - 0.250 |

| Mn (%) | 1.10 - 1.40 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.008 |

| Si (%) | 0.15 - 0.35 |

| Al (%) | ≥ 0.020 |

| Ti (%) | 0.020 - 0.060 |

| B (%) | 0.0020 - 0.0050 |

| Cr (%) | - |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

| Durabor® 28MnB5 | |

|---|---|

| C (%) | 0.260 - 0.300 |

| Mn (%) | 1.20 - 1.40 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.005 |

| Si (%) | 0.20 - 0.30 |

| Al (%) | ≥ 0.015 |

| Ti (%) | 0.020 - 0.050 |

| B (%) | 0.0020 - 0.0050 |

| Cr (%) | - |

Grades in italics: not included in the standard

| 30MnB5 EN ISO 683-2:2018 | |

|---|---|

| C (%) | 0.270 - 0.330 |

| Mn (%) | 1.15 - 1.45 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.035 |

| Si (%) | ≤ 0.40 |

| Al (%) | - |

| Ti (%) | - |

| B (%) | 0.0008 - 0.0050 |

| Cr (%) | - |

| Durabor® 30MnB5 | |

|---|---|

| C (%) | 0.270 - 0.330 |

| Mn (%) | 1.15 - 1.45 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.004 |

| Si (%) | 0.20 - 0.30 |

| Al (%) | ≥ 0.020 |

| Ti (%) | 0.020 - 0.050 |

| B (%) | 0.0010 - 0.0040 |

| Cr (%) | - |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

| 33MnCrB5 EN ISO 683-2:2018 | |

|---|---|

| C (%) | 0.300 - 0.360 |

| Mn (%) | 1.20 - 1.50 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.035 |

| Si (%) | ≤ 0.40 |

| Al (%) | - |

| Ti (%) | - |

| B (%) | 0.0008 - 0.0050 |

| Cr (%) | 0.30 - 0.60 |

| Durabor® 33MnCrB5 | |

|---|---|

| C (%) | 0.300 - 0.380 |

| Mn (%) | 1.20 - 1.45 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.030 |

| Si (%) | ≤ 0.35 |

| Al (%) | ≥ 0.015 |

| Ti (%) | 0.020 - 0.050 |

| B (%) | 0.0010 - 0.0040 |

| Cr (%) | 0.40 - 0.50 |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

| 39MnB5 EN ISO 683-2:2018 | |

|---|---|

| C (%) | 0.360 - 0.420 |

| Mn (%) | 1.15 - 1.45 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.035 |

| Si (%) | ≤ 0.40 |

| Al (%) | - |

| Ti (%) | - |

| B (%) | 0.0008 - 0.0050 |

| Cr (%) | - |

| Durabor® 38MnB5 | |

|---|---|

| C (%) | 0.360 - 0.400 |

| Mn (%) | 1.20 - 1.40 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.005 |

| Si (%) | 0.20 - 0.35 |

| Al (%) | ≥ 0.020 |

| Ti (%) | 0.020 - 0.050 |

| B (%) | 0.0020 - 0.0050 |

| Cr (%) | - |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

Grades in italics: not included in the standard

Values in bold: tighter than the standard

Any questions?

Ask them via our contact form on

https://industry.arcelormittal.com/getintouch

All details provided in the ArcelorMittal Flat Carbon Europe S.A. catalogue are for information purposes only. ArcelorMittal Flat Carbon Europe S.A. reserves the right to change its product range at any time without prior notice.

Download

Download