A30 - Structural steels

Structural steels can be used in the building industry, for example for light steel-frame construction.

Last update: 2019-06-14

Available grades:

Properties

Structural steels are carbon-manganese steels with a guaranteed minimum yield strength and tensile strength, and satisfactory ductility. These steels are suitable for most common applications and are readily available from distributors and Steel Service Centres in the most common forms and dimensions.

Various grades can be supplied:

Without any special rolling and/or heat treatment requirements. The abbreviated designation of this delivery condition is +AR.

Following a rolling process in which final forming is carried out within a certain temperature range, producing a material in a condition equivalent to that obtained after normalisation, with the result that the specified mechanical properties values are conserved even after normalisation treatment. The abbreviated designation of this delivery condition is +N.

Advantages

Structural steels offer good weldability with conventional welding processes. In most cases, pre- or post-heat treatment is not necessary with welding. In addition to their good mechanical properties, structural steels also have very acceptable toughness values.

Applications

Structural steels are mainly used in the building industry and in mechanical engineering. Applications include building components, containers, storage tanks and roll formed profiles.

Since 1 July 2013, the Construction Products Regulation (Regulation (EU) No. 305/2011 – CPR) has required that CE marking be affixed to all products delivered in accordance with a harmonised standard (e.g. EN 10025). This CE marking guarantees, for the uses defined in the standard, the properties described in the declaration of performance submitted by the manufacturer.

All of the steels in this data sheet comply with this Regulation.

The corresponding declarations of performance are available on our website at:

http://dop.arcelormittal.net/index.php

Recommendations for use

Options available (after prior agreement):

Suitability for galvanising: + CL1 or + CL3

Suitability for cold forming: + C

Copper addition: + Cu

Brand correspondence

Full table

EN 10025-2:2004

DIN 17100:1983

UNE 36080:1990

EN 10025-2:1993

NF A 35-501

PN-88/H-84020:1988

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

UN 7070

BS 4360:1996

SS

ASTM A1011-01a

JIS G 3101

Old brand names

S185 EN 10025-2

S185

St33

A310-0

S185

A33

Fe 320

13 00-00

S235JR EN 10025-2

S235JR

RSt37-2

AE235 B

S235JRG2

(E24-2)

St3S

(Fe 360 B)

40 B

13 12-00

SS Grade 36

SS 330

S235JR-CL1 AM FCE (S235JR-Galva1) (RSt37-2) (AE235 B) (S235JRG2) (E24-2) St3S 11375 (Fe 360 B) (40 B) (13 12-00) (SS Grade 36) (SS 330)

S235J0 EN 10025-2

S235J0

St37-3 U

AE235 C

S235J0

E24-3

Fe 360 C

40 C

S235J0 AM FCE

S235J0

St37-3 U

AE235 C

S235J0

E24-3

(St3V)

11378

Fe 360 C

40 C

SS Grade 36

SS 330

S235J2 EN 10025-2

S235J2

S235J2G4

S235J2 AM FCE

S235J2

S235J2G4

St3SAL

11378

40 D

SS 330

S235J2+N EN 10025-2

S235J2+N

St37-3 N

AE235 D

S235J2G3

E24-4

11378

Fe 360D

S235J2+N AM FCE

S235J2+N

St37-3 N

AE235 D

S235J2G3

E24-4

(St3W)

11378

Fe 360 D

SS 330

S275JR EN 10025-2

S275JR

St44-2

AE275 B

S275JR

E28-2

Fe 430 B

43 B

S275JR AM FCE

S275JR

St44-2

AE275 B

S275JR

E28-2

St4S

11443

Fe 430 B

43 B

14 12-00

SS Grade 40

SS 400

S275J0 EN 10025-2

S275J0

St44-3 U

AE275 C

S275J0

E28-3

Fe 430 C

43 C

S275J0 AM FCE

S275J0

St44-3 U

AE275 C

S275J0

E28-3

(St4V)

11448

Fe 430 C

43 C

SS Grade 40

SS 400

S275J2 EN 10025-2

S275J2

S275J2G4

14 14-01

S275J2 AM FCE

S275J2

S275J2G4

St4SAL

11448

14 14-01

SS Grade 40

SS 400

S275J2+N EN 10025-2

S275J2+N

St44-3 N

AE275 D

S275J2G3

E28-4

11448

Fe 430 D

43 D

14 14-00

SS 400

S275J2+N AM FCE

S275J2+N

St44-3 N

AE275 D

S275J2G3

E28-4

(St4W)

11448

Fe 430 D

43 D

14 14-00

SS 400

S355JR EN 10025-2

S355JR

AE355 B

S355JR

E36-2

Fe 510 B

50 B

S355JR AM FCE

S355JR

AE355 B

S355JR

E36-2

(18G2)

11523

Fe 510 B

50 B

SS Grade 50

S355J0 EN 10025-2

S355J0

St52-3 U

AE355 C

S355J0

E36-3

Fe 510 C

50 C

S355J0 AM FCE

S355J0

St52-3 U

AE355 C

S355J0

E36-3

11523

Fe 510 C

50 C

SS Grade 50

S355J2 EN 10025-2

S355J2

S355J2G4

S355J2 AM FCE

S355J2

S355J2G4

11523

SS Grade 50

S355J2+N EN 10025-2

S355J2+N

St52-3 N

AE355 D

S355J2G3

E36-4

Fe 510 D

50 D

S355J2+N AM FCE

S355J2+N

St52-3 N

AE355 D

S355J2G3

E36-4

18G2A

11523

Fe 510 D

50 D

S355K2 EN 10025-2

S355K2

S355K2G4

S355K2+N EN 10025-2

S355K2+N

S355K2G3

50 DD

S355K2+N AM FCE

S355K2+N

S355K2G3

50 DD

S185 EN 10025-2

S185 EN 10025-2

EN 10025-2:2004

S185

DIN 17100:1983

St33

UNE 36080:1990

A310-0

EN 10025-2:1993

S185

NF A 35-501

A33

PN-88/H-84020:1988

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

UN 7070

Fe 320

BS 4360:1996

SS

13 00-00

ASTM A1011-01a

JIS G 3101

S235JR EN 10025-2

S235JR EN 10025-2

EN 10025-2:2004

S235JR

DIN 17100:1983

RSt37-2

UNE 36080:1990

AE235 B

EN 10025-2:1993

S235JRG2

NF A 35-501

(E24-2)

PN-88/H-84020:1988

St3S

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

UN 7070

(Fe 360 B)

BS 4360:1996

40 B

SS

13 12-00

ASTM A1011-01a

SS Grade 36

JIS G 3101

SS 330

S235JR-CL1 AM FCE

S235JR-CL1 AM FCE

EN 10025-2:2004

(S235JR-Galva1)

DIN 17100:1983

(RSt37-2)

UNE 36080:1990

(AE235 B)

EN 10025-2:1993

(S235JRG2)

NF A 35-501

(E24-2)

PN-88/H-84020:1988

St3S

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

11375

UN 7070

(Fe 360 B)

BS 4360:1996

(40 B)

SS

(13 12-00)

ASTM A1011-01a

(SS Grade 36)

JIS G 3101

(SS 330)

S235J0 EN 10025-2, S235J0 AM FCE

S235J0 EN 10025-2

S235J0 AM FCE

EN 10025-2:2004

S235J0

S235J0

DIN 17100:1983

St37-3 U

St37-3 U

UNE 36080:1990

AE235 C

AE235 C

EN 10025-2:1993

S235J0

S235J0

NF A 35-501

E24-3

E24-3

PN-88/H-84020:1988

(St3V)

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

11378

UN 7070

Fe 360 C

Fe 360 C

BS 4360:1996

40 C

40 C

SS

ASTM A1011-01a

SS Grade 36

JIS G 3101

SS 330

S235J2 EN 10025-2, S235J2 AM FCE

S235J2 EN 10025-2

S235J2 AM FCE

EN 10025-2:2004

S235J2

S235J2

DIN 17100:1983

UNE 36080:1990

EN 10025-2:1993

S235J2G4

S235J2G4

NF A 35-501

PN-88/H-84020:1988

PN-86/H-84018:1986

ZN-96/0632-07:1996

St3SAL

CSN

11378

UN 7070

BS 4360:1996

40 D

SS

ASTM A1011-01a

JIS G 3101

SS 330

S235J2+N EN 10025-2

S235J2+N EN 10025-2

EN 10025-2:2004

S235J2+N

DIN 17100:1983

St37-3 N

UNE 36080:1990

AE235 D

EN 10025-2:1993

S235J2G3

NF A 35-501

E24-4

PN-88/H-84020:1988

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

11378

UN 7070

Fe 360D

BS 4360:1996

SS

ASTM A1011-01a

JIS G 3101

S235J2+N AM FCE

S235J2+N AM FCE

EN 10025-2:2004

S235J2+N

DIN 17100:1983

St37-3 N

UNE 36080:1990

AE235 D

EN 10025-2:1993

S235J2G3

NF A 35-501

E24-4

PN-88/H-84020:1988

(St3W)

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

11378

UN 7070

Fe 360 D

BS 4360:1996

SS

ASTM A1011-01a

JIS G 3101

SS 330

S275JR EN 10025-2, S275JR AM FCE

S275JR EN 10025-2

S275JR AM FCE

EN 10025-2:2004

S275JR

S275JR

DIN 17100:1983

St44-2

St44-2

UNE 36080:1990

AE275 B

AE275 B

EN 10025-2:1993

S275JR

S275JR

NF A 35-501

E28-2

E28-2

PN-88/H-84020:1988

St4S

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

11443

UN 7070

Fe 430 B

Fe 430 B

BS 4360:1996

43 B

43 B

SS

14 12-00

ASTM A1011-01a

SS Grade 40

JIS G 3101

SS 400

S275J0 EN 10025-2, S275J0 AM FCE

S275J0 EN 10025-2

S275J0 AM FCE

EN 10025-2:2004

S275J0

S275J0

DIN 17100:1983

St44-3 U

St44-3 U

UNE 36080:1990

AE275 C

AE275 C

EN 10025-2:1993

S275J0

S275J0

NF A 35-501

E28-3

E28-3

PN-88/H-84020:1988

(St4V)

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

11448

UN 7070

Fe 430 C

Fe 430 C

BS 4360:1996

43 C

43 C

SS

ASTM A1011-01a

SS Grade 40

JIS G 3101

SS 400

S275J2 EN 10025-2, S275J2 AM FCE

S275J2 EN 10025-2

S275J2 AM FCE

EN 10025-2:2004

S275J2

S275J2

DIN 17100:1983

UNE 36080:1990

EN 10025-2:1993

S275J2G4

S275J2G4

NF A 35-501

PN-88/H-84020:1988

PN-86/H-84018:1986

ZN-96/0632-07:1996

St4SAL

CSN

11448

UN 7070

BS 4360:1996

SS

14 14-01

14 14-01

ASTM A1011-01a

SS Grade 40

JIS G 3101

SS 400

S275J2+N EN 10025-2

S275J2+N EN 10025-2

EN 10025-2:2004

S275J2+N

DIN 17100:1983

St44-3 N

UNE 36080:1990

AE275 D

EN 10025-2:1993

S275J2G3

NF A 35-501

E28-4

PN-88/H-84020:1988

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

11448

UN 7070

Fe 430 D

BS 4360:1996

43 D

SS

14 14-00

ASTM A1011-01a

JIS G 3101

SS 400

S275J2+N AM FCE

S275J2+N AM FCE

EN 10025-2:2004

S275J2+N

DIN 17100:1983

St44-3 N

UNE 36080:1990

AE275 D

EN 10025-2:1993

S275J2G3

NF A 35-501

E28-4

PN-88/H-84020:1988

(St4W)

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

11448

UN 7070

Fe 430 D

BS 4360:1996

43 D

SS

14 14-00

ASTM A1011-01a

JIS G 3101

SS 400

S355JR EN 10025-2, S355JR AM FCE

S355JR EN 10025-2

S355JR AM FCE

EN 10025-2:2004

S355JR

S355JR

DIN 17100:1983

UNE 36080:1990

AE355 B

AE355 B

EN 10025-2:1993

S355JR

S355JR

NF A 35-501

E36-2

E36-2

PN-88/H-84020:1988

PN-86/H-84018:1986

(18G2)

ZN-96/0632-07:1996

CSN

11523

UN 7070

Fe 510 B

Fe 510 B

BS 4360:1996

50 B

50 B

SS

ASTM A1011-01a

SS Grade 50

JIS G 3101

S355J0 EN 10025-2, S355J0 AM FCE

S355J0 EN 10025-2

S355J0 AM FCE

EN 10025-2:2004

S355J0

S355J0

DIN 17100:1983

St52-3 U

St52-3 U

UNE 36080:1990

AE355 C

AE355 C

EN 10025-2:1993

S355J0

S355J0

NF A 35-501

E36-3

E36-3

PN-88/H-84020:1988

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

11523

UN 7070

Fe 510 C

Fe 510 C

BS 4360:1996

50 C

50 C

SS

ASTM A1011-01a

SS Grade 50

JIS G 3101

S355J2 EN 10025-2, S355J2 AM FCE

S355J2 EN 10025-2

S355J2 AM FCE

EN 10025-2:2004

S355J2

S355J2

DIN 17100:1983

UNE 36080:1990

EN 10025-2:1993

S355J2G4

S355J2G4

NF A 35-501

PN-88/H-84020:1988

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

11523

UN 7070

BS 4360:1996

SS

ASTM A1011-01a

SS Grade 50

JIS G 3101

S355J2+N EN 10025-2

S355J2+N EN 10025-2

EN 10025-2:2004

S355J2+N

DIN 17100:1983

St52-3 N

UNE 36080:1990

AE355 D

EN 10025-2:1993

S355J2G3

NF A 35-501

E36-4

PN-88/H-84020:1988

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

UN 7070

Fe 510 D

BS 4360:1996

50 D

SS

ASTM A1011-01a

JIS G 3101

S355J2+N AM FCE

S355J2+N AM FCE

EN 10025-2:2004

S355J2+N

DIN 17100:1983

St52-3 N

UNE 36080:1990

AE355 D

EN 10025-2:1993

S355J2G3

NF A 35-501

E36-4

PN-88/H-84020:1988

PN-86/H-84018:1986

18G2A

ZN-96/0632-07:1996

CSN

11523

UN 7070

Fe 510 D

BS 4360:1996

50 D

SS

ASTM A1011-01a

JIS G 3101

S355K2 EN 10025-2

S355K2 EN 10025-2

EN 10025-2:2004

S355K2

DIN 17100:1983

UNE 36080:1990

EN 10025-2:1993

S355K2G4

NF A 35-501

PN-88/H-84020:1988

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

UN 7070

BS 4360:1996

SS

ASTM A1011-01a

JIS G 3101

S355K2+N EN 10025-2

S355K2+N EN 10025-2

EN 10025-2:2004

S355K2+N

DIN 17100:1983

UNE 36080:1990

EN 10025-2:1993

S355K2G3

NF A 35-501

PN-88/H-84020:1988

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

UN 7070

BS 4360:1996

50 DD

SS

ASTM A1011-01a

JIS G 3101

S355K2+N AM FCE

S355K2+N AM FCE

EN 10025-2:2004

S355K2+N

DIN 17100:1983

UNE 36080:1990

EN 10025-2:1993

S355K2G3

NF A 35-501

PN-88/H-84020:1988

PN-86/H-84018:1986

ZN-96/0632-07:1996

CSN

UN 7070

BS 4360:1996

50 DD

SS

ASTM A1011-01a

JIS G 3101

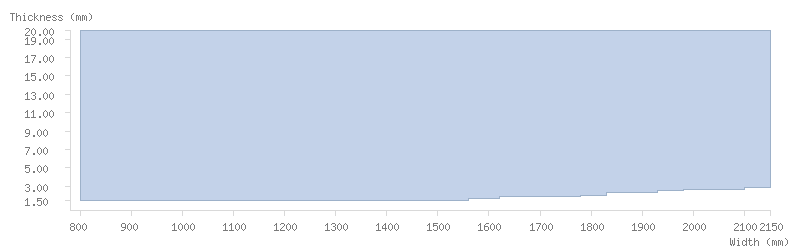

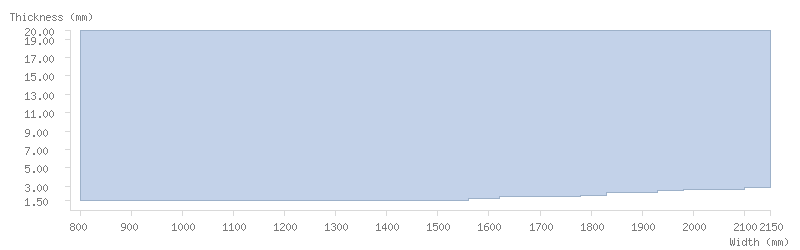

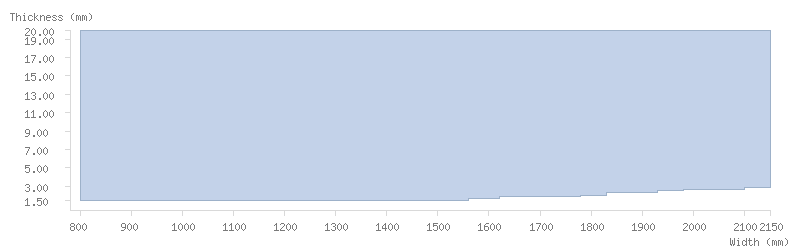

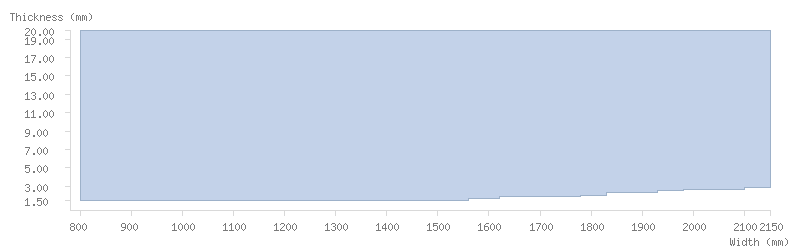

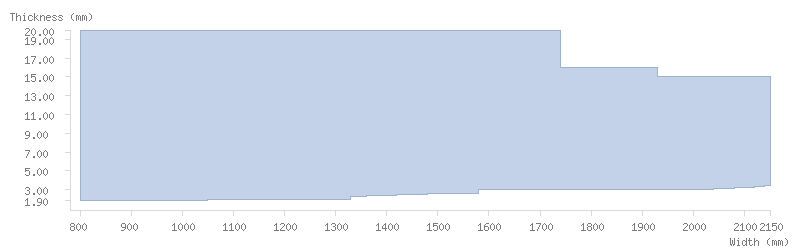

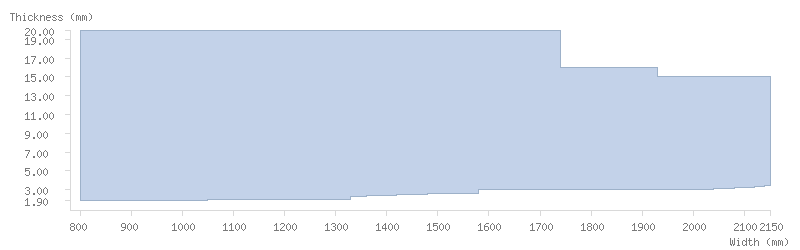

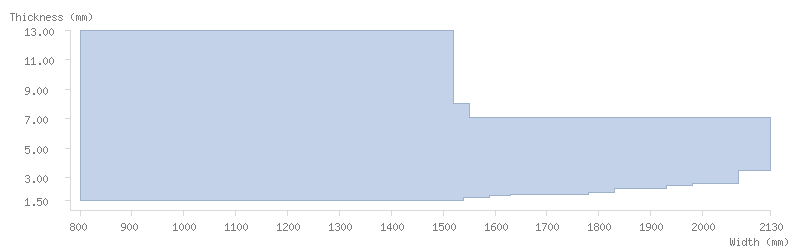

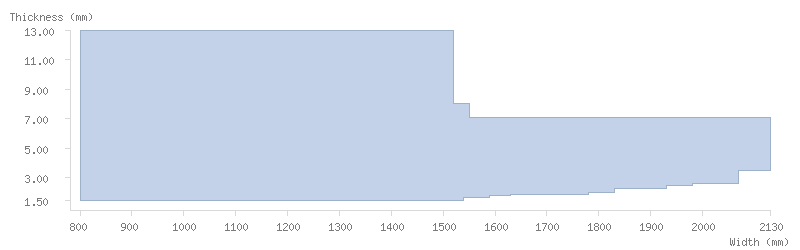

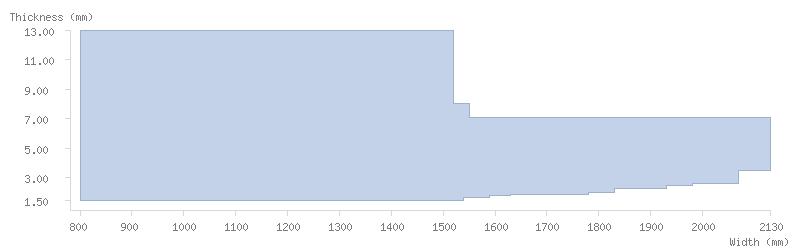

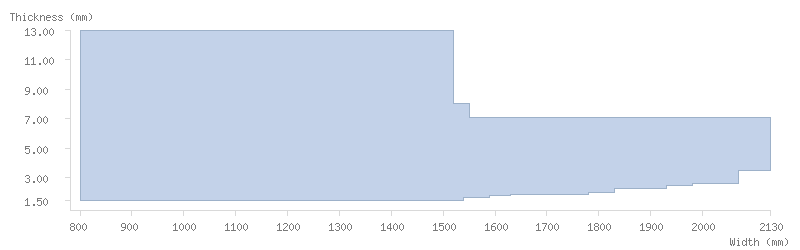

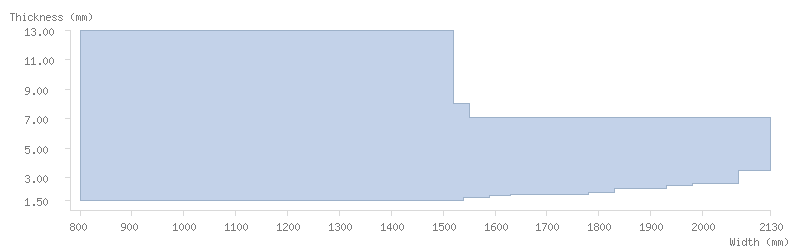

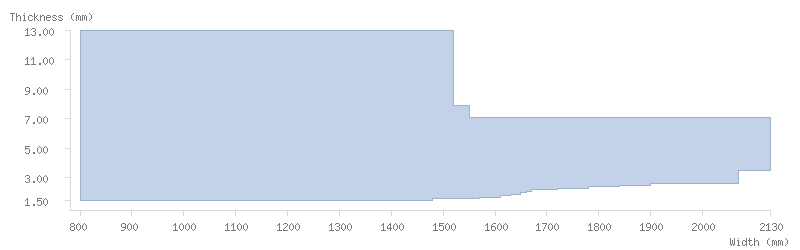

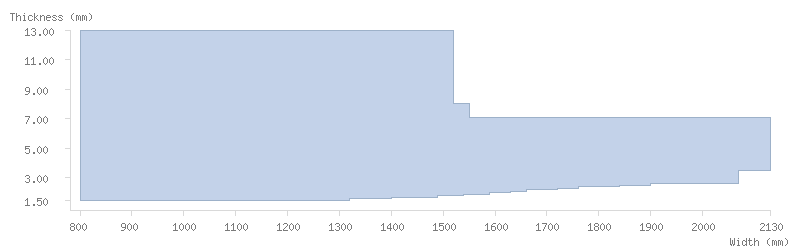

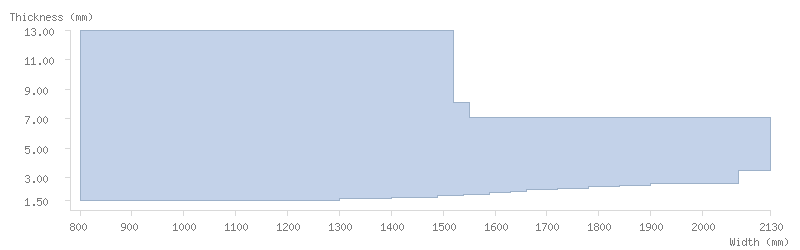

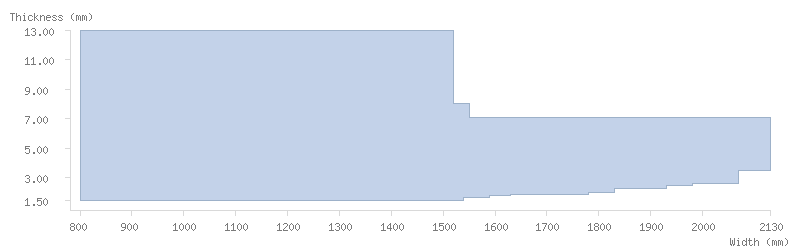

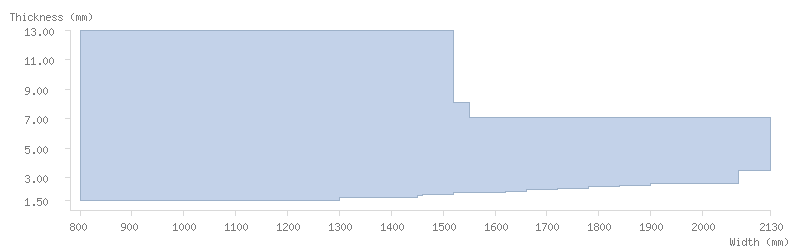

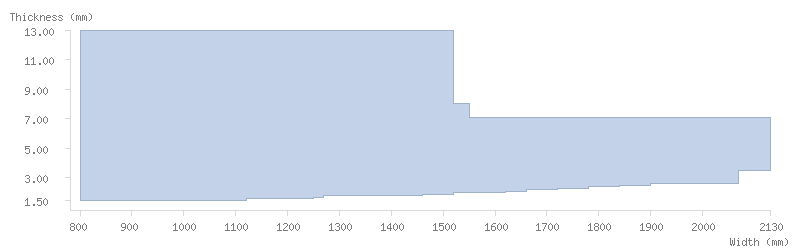

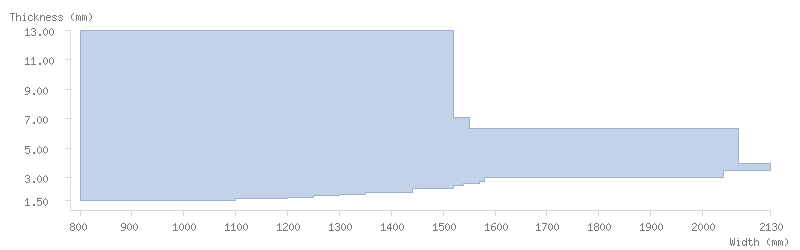

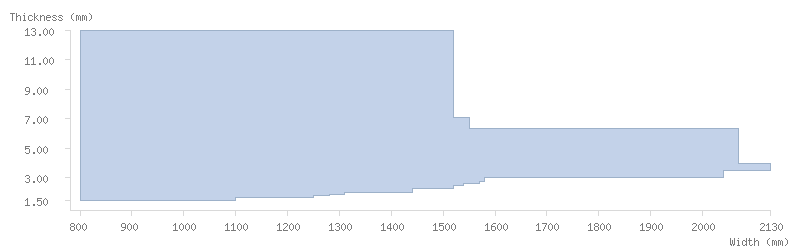

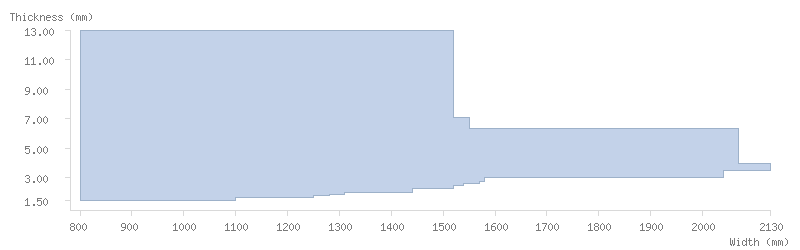

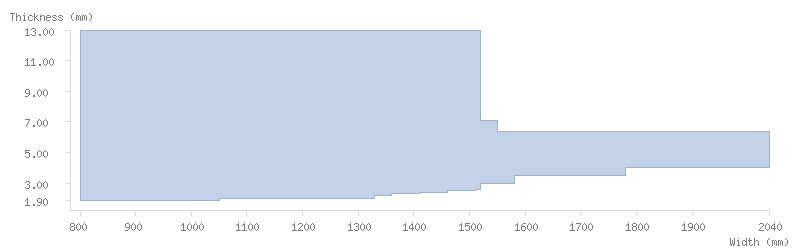

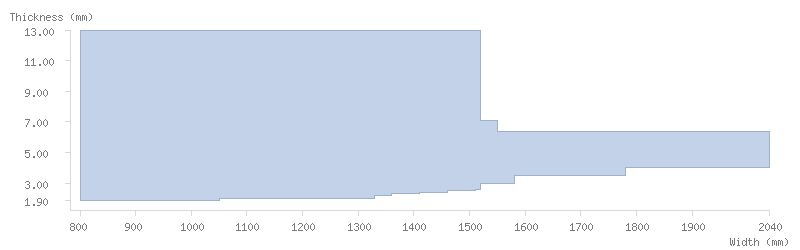

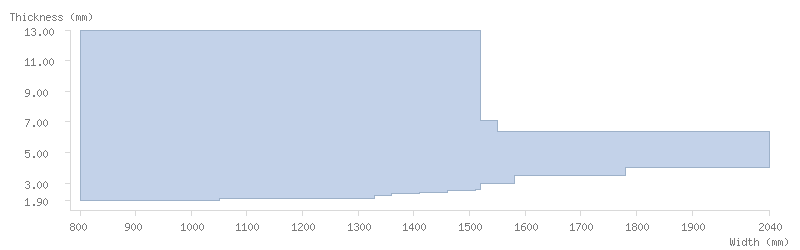

Dimensions

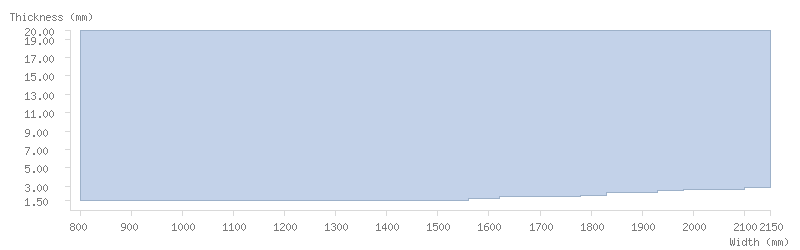

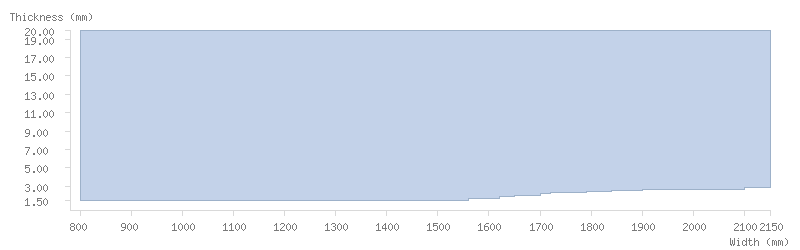

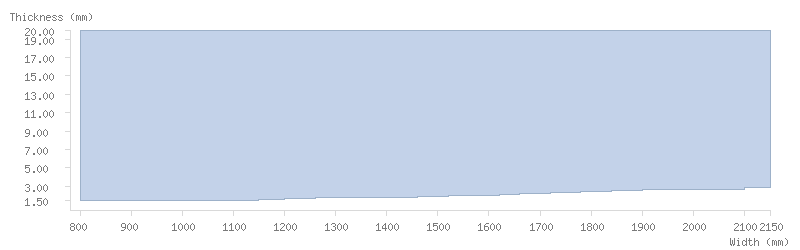

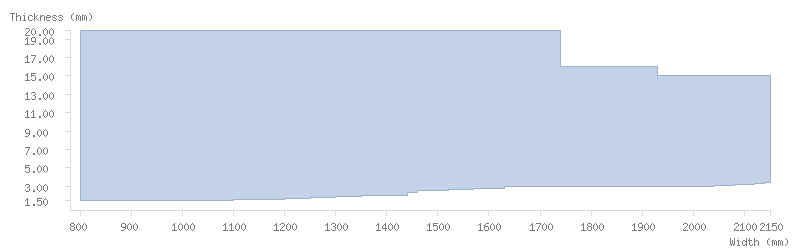

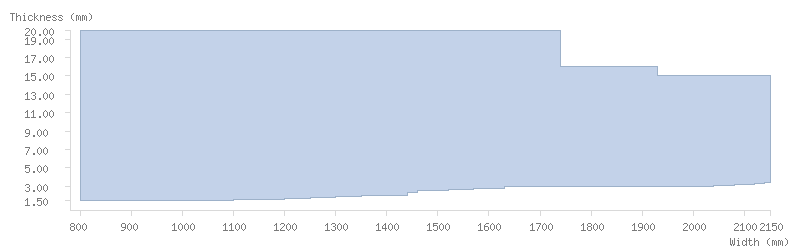

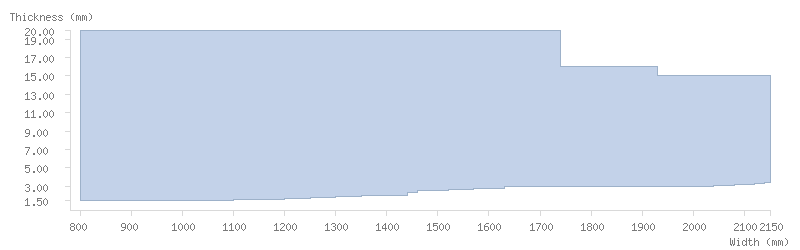

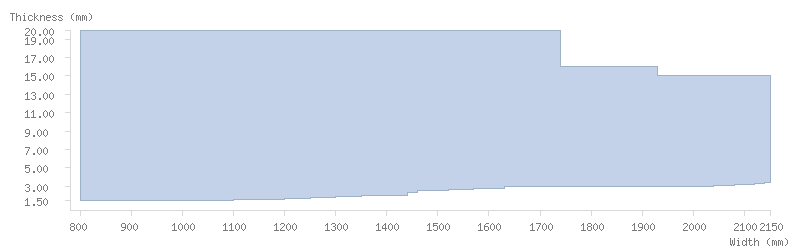

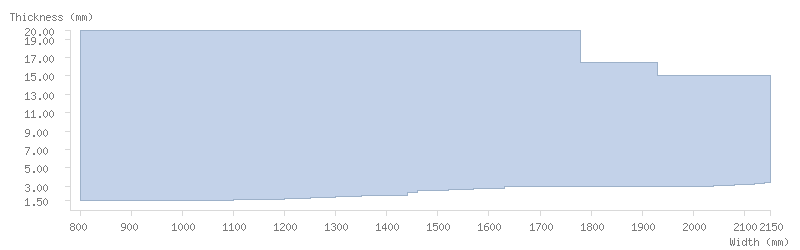

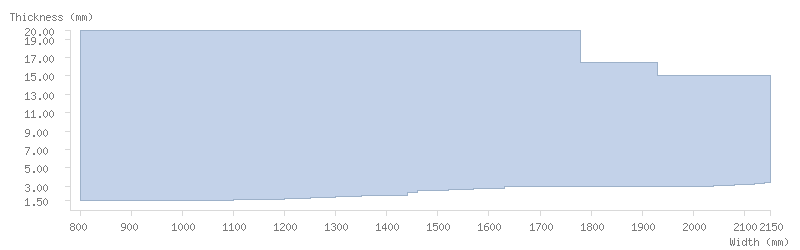

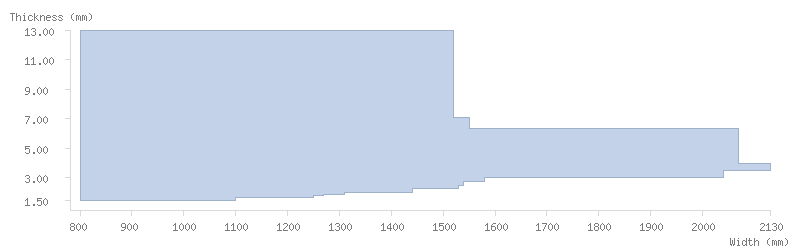

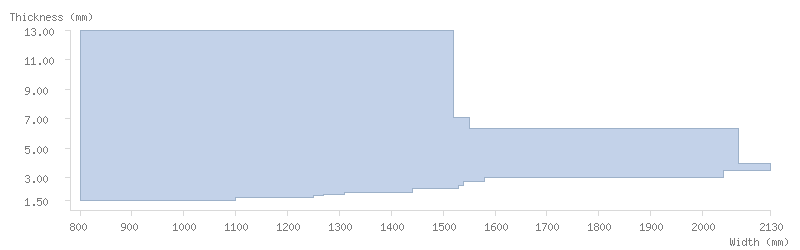

Mill finish

Full table

Thickness (mm)

Min width

S185 EN 10025-2, S235JR EN 10025-2, S235JR-CL1 AM FCE, S235J0 EN 10025-2, S235J0 AM FCE

S235J2 EN 10025-2, S235J2 AM FCE

S235J2+N EN 10025-2, S235J2+N AM FCE

S275JR EN 10025-2, S275JR AM FCE, S275J0 EN 10025-2, S275J0 AM FCE

S275J2 EN 10025-2, S275J2 AM FCE

S275J2+N EN 10025-2, S275J2+N AM FCE

S355JR EN 10025-2, S355JR AM FCE, S355J0 EN 10025-2, S355J0 AM FCE

S355J2 EN 10025-2, S355J2 AM FCE

S355J2+N EN 10025-2, S355J2+N AM FCE, S355K2 EN 10025-2, S355K2+N EN 10025-2, S355K2+N AM FCE

Max width

Max width

Max width

Max width

Max width

Max width

Max width

Max width

Max width

1.50 ≤ th < 1.60

800

1560

1560

1320

1300

1300

1150

1100

1100

-

1.60 ≤ th < 1.70

1400

1400

1200

1200

1200

1.70 ≤ th < 1.80

1620

1620

1490

1490

1450

1260

1250

1250

1.80 ≤ th < 1.90

1540

1540

1460

1460

1300

1300

1.90 ≤ th < 2.00

1780

1650

1590

1590

1520

1520

1350

1350

1050

2.00 ≤ th < 2.10

1830

1700

1630

1630

1620

1620

1440

1440

1330

2.10 ≤ th < 2.20

1660

1660

1660

1660

2.20 ≤ th < 2.30

1720

1720

1720

1720

1720

2.30 ≤ th < 2.40

1930

1790

1780

1780

1780

1780

1460

1460

1360

2.40 ≤ th < 2.50

1840

2140

1840

1840

1840

1420

2.50 ≤ th < 2.60

1980

1900

1900

1900

1900

1900

1520

1520

1480

2.60 ≤ th < 2.70

2100

2100

2100

2100

2100

2100

1570

1570

1580

2.70 ≤ th < 2.80

1590

1590

2.80 ≤ th < 2.90

1630

1630

2.90 ≤ th < 3.00

2150

2150

2150

2150

2150

2150

3.00 ≤ th < 3.10

2040

2040

2040

3.10 ≤ th < 3.20

2080

2080

2080

3.20 ≤ th < 3.30

2120

2120

2120

3.30 ≤ th < 3.40

2140

2140

2140

3.40 ≤ th < 15.00

2150

2150

2150

15.00 ≤ th < 16.00

1930

1930

1930

16.00 ≤ th < 16.10

1740

1740

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

1780

19.00 ≤ th < 20.00

Coils in thicknesses greater than 20 mm can also be produced. Please contact us.

S185 EN 10025-2

S185 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1560

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1620

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1780

2.00 ≤ th < 2.10

1830

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1930

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1980

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S235JR EN 10025-2

S235JR EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1560

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1620

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1780

2.00 ≤ th < 2.10

1830

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1930

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1980

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S235JR-CL1 AM FCE

S235JR-CL1 AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1560

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1620

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1780

2.00 ≤ th < 2.10

1830

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1930

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1980

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S235J0 EN 10025-2

S235J0 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1560

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1620

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1780

2.00 ≤ th < 2.10

1830

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1930

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1980

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S235J0 AM FCE

S235J0 AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1560

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1620

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1780

2.00 ≤ th < 2.10

1830

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1930

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1980

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S235J2 EN 10025-2

S235J2 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1560

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1620

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1650

2.00 ≤ th < 2.10

1700

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1790

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S235J2 AM FCE

S235J2 AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1560

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1620

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1650

2.00 ≤ th < 2.10

1700

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1790

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S235J2+N EN 10025-2

S235J2+N EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1320

1.60 ≤ th < 1.70

1400

1.70 ≤ th < 1.80

1490

1.80 ≤ th < 1.90

1540

1.90 ≤ th < 2.00

1590

2.00 ≤ th < 2.10

1630

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

2140

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S235J2+N AM FCE

S235J2+N AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1320

1.60 ≤ th < 1.70

1400

1.70 ≤ th < 1.80

1490

1.80 ≤ th < 1.90

1540

1.90 ≤ th < 2.00

1590

2.00 ≤ th < 2.10

1630

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

2140

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S275JR EN 10025-2

S275JR EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1300

1.60 ≤ th < 1.70

1400

1.70 ≤ th < 1.80

1490

1.80 ≤ th < 1.90

1540

1.90 ≤ th < 2.00

1590

2.00 ≤ th < 2.10

1630

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S275JR AM FCE

S275JR AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1300

1.60 ≤ th < 1.70

1400

1.70 ≤ th < 1.80

1490

1.80 ≤ th < 1.90

1540

1.90 ≤ th < 2.00

1590

2.00 ≤ th < 2.10

1630

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S275J0 EN 10025-2

S275J0 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1300

1.60 ≤ th < 1.70

1400

1.70 ≤ th < 1.80

1490

1.80 ≤ th < 1.90

1540

1.90 ≤ th < 2.00

1590

2.00 ≤ th < 2.10

1630

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S275J0 AM FCE

S275J0 AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1300

1.60 ≤ th < 1.70

1400

1.70 ≤ th < 1.80

1490

1.80 ≤ th < 1.90

1540

1.90 ≤ th < 2.00

1590

2.00 ≤ th < 2.10

1630

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S275J2 EN 10025-2

S275J2 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1300

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1450

1.80 ≤ th < 1.90

1460

1.90 ≤ th < 2.00

1520

2.00 ≤ th < 2.10

1620

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S275J2 AM FCE

S275J2 AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1300

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1450

1.80 ≤ th < 1.90

1460

1.90 ≤ th < 2.00

1520

2.00 ≤ th < 2.10

1620

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S275J2+N EN 10025-2

S275J2+N EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1150

1.60 ≤ th < 1.70

1200

1.70 ≤ th < 1.80

1260

1.80 ≤ th < 1.90

1460

1.90 ≤ th < 2.00

1520

2.00 ≤ th < 2.10

1620

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S275J2+N AM FCE

S275J2+N AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1150

1.60 ≤ th < 1.70

1200

1.70 ≤ th < 1.80

1260

1.80 ≤ th < 1.90

1460

1.90 ≤ th < 2.00

1520

2.00 ≤ th < 2.10

1620

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.70

2100

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

2150

3.00 ≤ th < 3.10

3.10 ≤ th < 3.20

3.20 ≤ th < 3.30

3.30 ≤ th < 3.40

3.40 ≤ th < 15.00

15.00 ≤ th < 16.00

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S355JR EN 10025-2

S355JR EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1100

1.60 ≤ th < 1.70

1200

1.70 ≤ th < 1.80

1250

1.80 ≤ th < 1.90

1300

1.90 ≤ th < 2.00

1350

2.00 ≤ th < 2.10

1440

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1460

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1520

2.60 ≤ th < 2.70

1570

2.70 ≤ th < 2.80

1590

2.80 ≤ th < 2.90

1630

2.90 ≤ th < 3.00

3.00 ≤ th < 3.10

2040

3.10 ≤ th < 3.20

2080

3.20 ≤ th < 3.30

2120

3.30 ≤ th < 3.40

2140

3.40 ≤ th < 15.00

2150

15.00 ≤ th < 16.00

1930

16.00 ≤ th < 16.10

1740

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S355JR AM FCE

S355JR AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1100

1.60 ≤ th < 1.70

1200

1.70 ≤ th < 1.80

1250

1.80 ≤ th < 1.90

1300

1.90 ≤ th < 2.00

1350

2.00 ≤ th < 2.10

1440

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1460

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1520

2.60 ≤ th < 2.70

1570

2.70 ≤ th < 2.80

1590

2.80 ≤ th < 2.90

1630

2.90 ≤ th < 3.00

3.00 ≤ th < 3.10

2040

3.10 ≤ th < 3.20

2080

3.20 ≤ th < 3.30

2120

3.30 ≤ th < 3.40

2140

3.40 ≤ th < 15.00

2150

15.00 ≤ th < 16.00

1930

16.00 ≤ th < 16.10

1740

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S355J0 EN 10025-2

S355J0 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1100

1.60 ≤ th < 1.70

1200

1.70 ≤ th < 1.80

1250

1.80 ≤ th < 1.90

1300

1.90 ≤ th < 2.00

1350

2.00 ≤ th < 2.10

1440

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1460

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1520

2.60 ≤ th < 2.70

1570

2.70 ≤ th < 2.80

1590

2.80 ≤ th < 2.90

1630

2.90 ≤ th < 3.00

3.00 ≤ th < 3.10

2040

3.10 ≤ th < 3.20

2080

3.20 ≤ th < 3.30

2120

3.30 ≤ th < 3.40

2140

3.40 ≤ th < 15.00

2150

15.00 ≤ th < 16.00

1930

16.00 ≤ th < 16.10

1740

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S355J0 AM FCE

S355J0 AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1100

1.60 ≤ th < 1.70

1200

1.70 ≤ th < 1.80

1250

1.80 ≤ th < 1.90

1300

1.90 ≤ th < 2.00

1350

2.00 ≤ th < 2.10

1440

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1460

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1520

2.60 ≤ th < 2.70

1570

2.70 ≤ th < 2.80

1590

2.80 ≤ th < 2.90

1630

2.90 ≤ th < 3.00

3.00 ≤ th < 3.10

2040

3.10 ≤ th < 3.20

2080

3.20 ≤ th < 3.30

2120

3.30 ≤ th < 3.40

2140

3.40 ≤ th < 15.00

2150

15.00 ≤ th < 16.00

1930

16.00 ≤ th < 16.10

1740

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S355J2 EN 10025-2

S355J2 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1100

1.60 ≤ th < 1.70

1200

1.70 ≤ th < 1.80

1250

1.80 ≤ th < 1.90

1300

1.90 ≤ th < 2.00

1350

2.00 ≤ th < 2.10

1440

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1460

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1520

2.60 ≤ th < 2.70

1570

2.70 ≤ th < 2.80

1590

2.80 ≤ th < 2.90

1630

2.90 ≤ th < 3.00

3.00 ≤ th < 3.10

2040

3.10 ≤ th < 3.20

2080

3.20 ≤ th < 3.30

2120

3.30 ≤ th < 3.40

2140

3.40 ≤ th < 15.00

2150

15.00 ≤ th < 16.00

1930

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

1780

19.00 ≤ th < 20.00

S355J2 AM FCE

S355J2 AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1100

1.60 ≤ th < 1.70

1200

1.70 ≤ th < 1.80

1250

1.80 ≤ th < 1.90

1300

1.90 ≤ th < 2.00

1350

2.00 ≤ th < 2.10

1440

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1460

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1520

2.60 ≤ th < 2.70

1570

2.70 ≤ th < 2.80

1590

2.80 ≤ th < 2.90

1630

2.90 ≤ th < 3.00

3.00 ≤ th < 3.10

2040

3.10 ≤ th < 3.20

2080

3.20 ≤ th < 3.30

2120

3.30 ≤ th < 3.40

2140

3.40 ≤ th < 15.00

2150

15.00 ≤ th < 16.00

1930

16.00 ≤ th < 16.10

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

1780

19.00 ≤ th < 20.00

S355J2+N EN 10025-2

S355J2+N EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

-

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1050

2.00 ≤ th < 2.10

1330

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1360

2.40 ≤ th < 2.50

1420

2.50 ≤ th < 2.60

1480

2.60 ≤ th < 2.70

1580

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

3.00 ≤ th < 3.10

2040

3.10 ≤ th < 3.20

2080

3.20 ≤ th < 3.30

2120

3.30 ≤ th < 3.40

2140

3.40 ≤ th < 15.00

2150

15.00 ≤ th < 16.00

1930

16.00 ≤ th < 16.10

1740

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S355J2+N AM FCE

S355J2+N AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

-

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1050

2.00 ≤ th < 2.10

1330

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1360

2.40 ≤ th < 2.50

1420

2.50 ≤ th < 2.60

1480

2.60 ≤ th < 2.70

1580

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

3.00 ≤ th < 3.10

2040

3.10 ≤ th < 3.20

2080

3.20 ≤ th < 3.30

2120

3.30 ≤ th < 3.40

2140

3.40 ≤ th < 15.00

2150

15.00 ≤ th < 16.00

1930

16.00 ≤ th < 16.10

1740

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S355K2 EN 10025-2

S355K2 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

-

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1050

2.00 ≤ th < 2.10

1330

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1360

2.40 ≤ th < 2.50

1420

2.50 ≤ th < 2.60

1480

2.60 ≤ th < 2.70

1580

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

3.00 ≤ th < 3.10

2040

3.10 ≤ th < 3.20

2080

3.20 ≤ th < 3.30

2120

3.30 ≤ th < 3.40

2140

3.40 ≤ th < 15.00

2150

15.00 ≤ th < 16.00

1930

16.00 ≤ th < 16.10

1740

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S355K2+N EN 10025-2

S355K2+N EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

-

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1050

2.00 ≤ th < 2.10

1330

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1360

2.40 ≤ th < 2.50

1420

2.50 ≤ th < 2.60

1480

2.60 ≤ th < 2.70

1580

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

3.00 ≤ th < 3.10

2040

3.10 ≤ th < 3.20

2080

3.20 ≤ th < 3.30

2120

3.30 ≤ th < 3.40

2140

3.40 ≤ th < 15.00

2150

15.00 ≤ th < 16.00

1930

16.00 ≤ th < 16.10

1740

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

S355K2+N AM FCE

S355K2+N AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

-

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1050

2.00 ≤ th < 2.10

1330

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1360

2.40 ≤ th < 2.50

1420

2.50 ≤ th < 2.60

1480

2.60 ≤ th < 2.70

1580

2.70 ≤ th < 2.80

2.80 ≤ th < 2.90

2.90 ≤ th < 3.00

3.00 ≤ th < 3.10

2040

3.10 ≤ th < 3.20

2080

3.20 ≤ th < 3.30

2120

3.30 ≤ th < 3.40

2140

3.40 ≤ th < 15.00

2150

15.00 ≤ th < 16.00

1930

16.00 ≤ th < 16.10

1740

16.10 ≤ th < 16.50

16.50 ≤ th < 19.00

19.00 ≤ th < 20.00

Coils in thicknesses greater than 20 mm can also be produced. Please contact us.

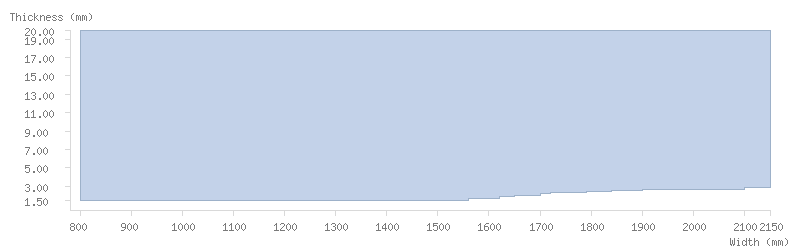

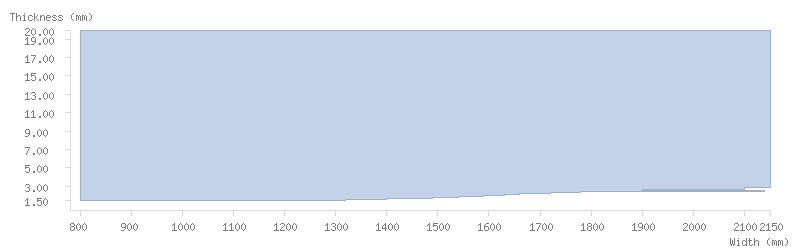

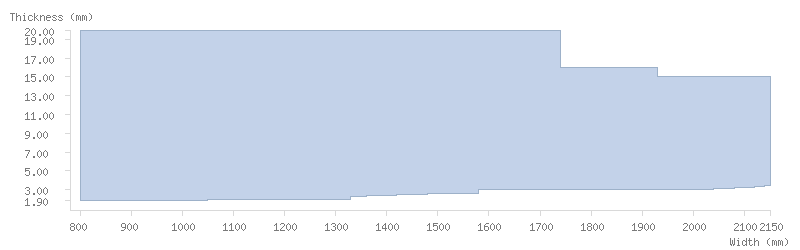

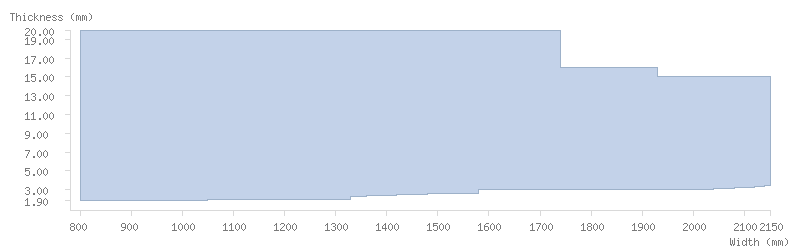

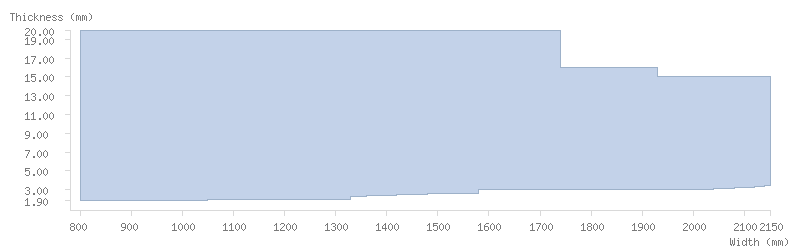

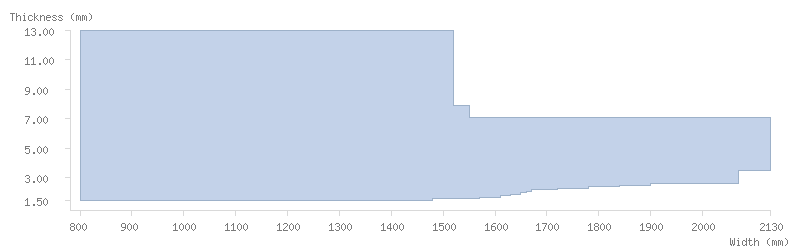

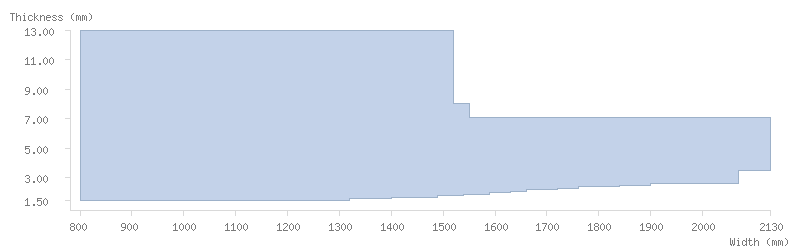

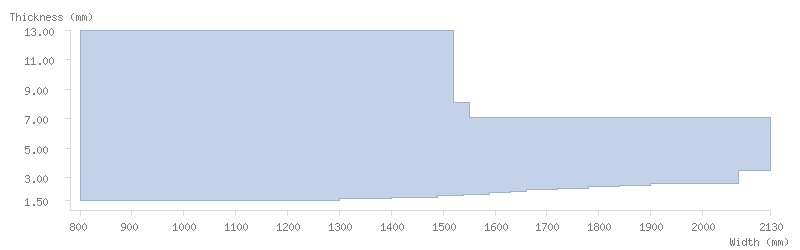

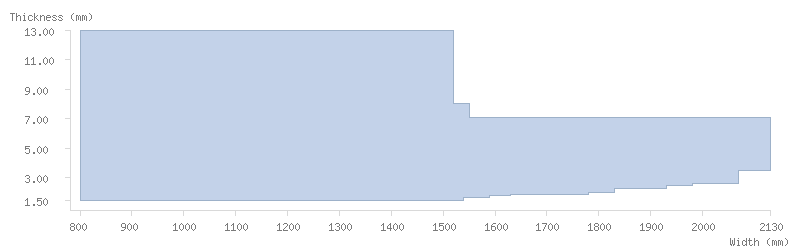

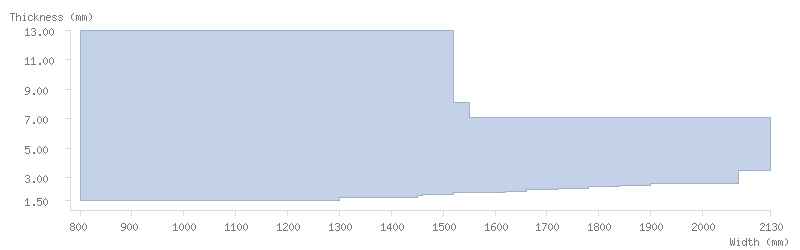

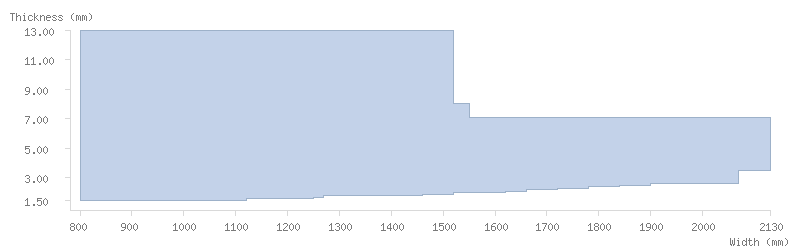

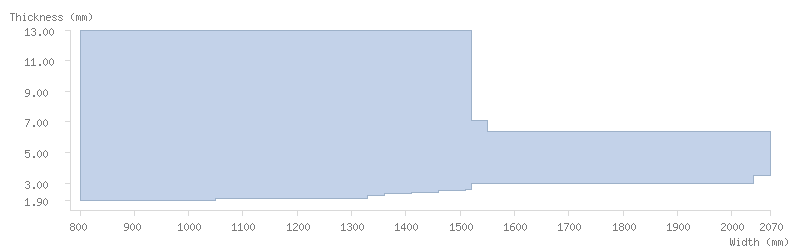

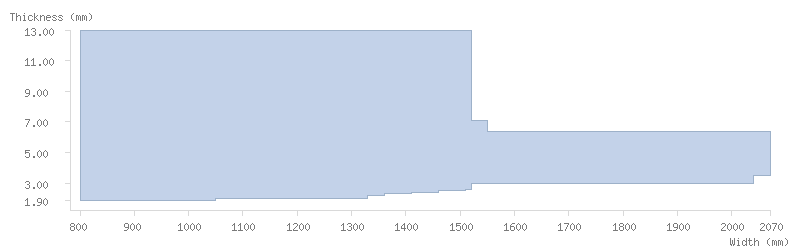

Pickled

Full table

Thickness (mm)

Min width

S185 EN 10025-2, S235JR EN 10025-2, S235JR-CL1 AM FCE, S235J0 EN 10025-2, S235J0 AM FCE, S275J0 EN 10025-2, S275J0 AM FCE

S235J2 EN 10025-2, S235J2 AM FCE

S235J2+N EN 10025-2, S235J2+N AM FCE

S275JR EN 10025-2, S275JR AM FCE

S275J2 EN 10025-2, S275J2 AM FCE

S275J2+N EN 10025-2, S275J2+N AM FCE

S355JR EN 10025-2, S355JR AM FCE

S355J0 EN 10025-2, S355J0 AM FCE

S355J2 EN 10025-2, S355J2 AM FCE

S355J2+N EN 10025-2, S355J2+N AM FCE

S355K2 EN 10025-2, S355K2+N EN 10025-2, S355K2+N AM FCE

Max width

Max width

Max width

Max width

Max width

Max width

Max width

Max width

Max width

Max width

Max width

1.50 ≤ th < 1.60

800

1540

1480

1320

1300

1300

1120

1100

1100

1100

-

-

1.60 ≤ th < 1.70

1570

1400

1400

1250

1200

1.70 ≤ th < 1.80

1590

1610

1490

1490

1450

1270

1250

1250

1250

1.80 ≤ th < 1.90

1630

1630

1540

1540

1460

1460

1300

1280

1270

1.90 ≤ th < 2.00

1780

1650

1590

1590

1520

1520

1350

1310

1310

1050

1050

2.00 ≤ th < 2.10

1830

1660

1630

1630

1620

1620

1440

1440

1440

1330

1330

2.10 ≤ th < 2.20

1670

1660

1660

1660

1660

2.20 ≤ th < 2.30

1720

1720

1720

1720

1720

1360

1360

2.30 ≤ th < 2.40

1930

1780

1760

1780

1780

1780

1520

1520

1530

1410

1410

2.40 ≤ th < 2.50

1840

1840

1840

1840

1840

1460

1460

2.50 ≤ th < 2.60

1980

1900

1900

1900

1900

1900

1540

1540

1540

1510

1510

2.60 ≤ th < 2.75

2070

2070

2070

2070

2070

2070

1570

1570

1520

1520

2.75 ≤ th < 3.00

1580

1580

1580

3.00 ≤ th < 3.50

2040

2040

2040

2040

1580

3.50 ≤ th < 4.00

2130

2130

2130

2130

2130

2130

2130

2130

2130

2070

1780

4.00 ≤ th < 6.35

2070

2070

2070

2040

6.35 ≤ th < 7.10

1550

1550

1550

1550

1550

7.10 ≤ th < 7.90

1550

1550

1550

1550

1550

1550

1520

1520

1520

1520

1520

7.90 ≤ th < 8.00

1520

8.00 ≤ th < 8.10

1520

1520

1520

8.10 ≤ th < 13.00

1520

1520

S185 EN 10025-2

S185 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1540

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1590

1.80 ≤ th < 1.90

1630

1.90 ≤ th < 2.00

1780

2.00 ≤ th < 2.10

1830

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1930

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1980

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

1520

8.10 ≤ th < 13.00

S235JR EN 10025-2

S235JR EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1540

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1590

1.80 ≤ th < 1.90

1630

1.90 ≤ th < 2.00

1780

2.00 ≤ th < 2.10

1830

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1930

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1980

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

1520

8.10 ≤ th < 13.00

S235JR-CL1 AM FCE

S235JR-CL1 AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1540

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1590

1.80 ≤ th < 1.90

1630

1.90 ≤ th < 2.00

1780

2.00 ≤ th < 2.10

1830

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1930

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1980

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

1520

8.10 ≤ th < 13.00

S235J0 EN 10025-2

S235J0 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1540

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1590

1.80 ≤ th < 1.90

1630

1.90 ≤ th < 2.00

1780

2.00 ≤ th < 2.10

1830

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1930

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1980

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

1520

8.10 ≤ th < 13.00

S235J0 AM FCE

S235J0 AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1540

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1590

1.80 ≤ th < 1.90

1630

1.90 ≤ th < 2.00

1780

2.00 ≤ th < 2.10

1830

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1930

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1980

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

1520

8.10 ≤ th < 13.00

S235J2 EN 10025-2

S235J2 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1480

1.60 ≤ th < 1.70

1570

1.70 ≤ th < 1.80

1610

1.80 ≤ th < 1.90

1630

1.90 ≤ th < 2.00

1650

2.00 ≤ th < 2.10

1660

2.10 ≤ th < 2.20

1670

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

1520

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

S235J2 AM FCE

S235J2 AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1480

1.60 ≤ th < 1.70

1570

1.70 ≤ th < 1.80

1610

1.80 ≤ th < 1.90

1630

1.90 ≤ th < 2.00

1650

2.00 ≤ th < 2.10

1660

2.10 ≤ th < 2.20

1670

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

1520

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

S235J2+N EN 10025-2

S235J2+N EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1320

1.60 ≤ th < 1.70

1400

1.70 ≤ th < 1.80

1490

1.80 ≤ th < 1.90

1540

1.90 ≤ th < 2.00

1590

2.00 ≤ th < 2.10

1630

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1760

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

1520

8.10 ≤ th < 13.00

S235J2+N AM FCE

S235J2+N AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1320

1.60 ≤ th < 1.70

1400

1.70 ≤ th < 1.80

1490

1.80 ≤ th < 1.90

1540

1.90 ≤ th < 2.00

1590

2.00 ≤ th < 2.10

1630

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1760

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

1520

8.10 ≤ th < 13.00

S275JR EN 10025-2

S275JR EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1300

1.60 ≤ th < 1.70

1400

1.70 ≤ th < 1.80

1490

1.80 ≤ th < 1.90

1540

1.90 ≤ th < 2.00

1590

2.00 ≤ th < 2.10

1630

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

1520

S275JR AM FCE

S275JR AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1300

1.60 ≤ th < 1.70

1400

1.70 ≤ th < 1.80

1490

1.80 ≤ th < 1.90

1540

1.90 ≤ th < 2.00

1590

2.00 ≤ th < 2.10

1630

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

1520

S275J0 EN 10025-2

S275J0 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1540

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1590

1.80 ≤ th < 1.90

1630

1.90 ≤ th < 2.00

1780

2.00 ≤ th < 2.10

1830

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1930

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1980

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

1520

8.10 ≤ th < 13.00

S275J0 AM FCE

S275J0 AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1540

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1590

1.80 ≤ th < 1.90

1630

1.90 ≤ th < 2.00

1780

2.00 ≤ th < 2.10

1830

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1930

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1980

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

1520

8.10 ≤ th < 13.00

S275J2 EN 10025-2

S275J2 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1300

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1450

1.80 ≤ th < 1.90

1460

1.90 ≤ th < 2.00

1520

2.00 ≤ th < 2.10

1620

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

1520

S275J2 AM FCE

S275J2 AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1300

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1450

1.80 ≤ th < 1.90

1460

1.90 ≤ th < 2.00

1520

2.00 ≤ th < 2.10

1620

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

1520

S275J2+N EN 10025-2

S275J2+N EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1120

1.60 ≤ th < 1.70

1250

1.70 ≤ th < 1.80

1270

1.80 ≤ th < 1.90

1460

1.90 ≤ th < 2.00

1520

2.00 ≤ th < 2.10

1620

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

1520

8.10 ≤ th < 13.00

S275J2+N AM FCE

S275J2+N AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1120

1.60 ≤ th < 1.70

1250

1.70 ≤ th < 1.80

1270

1.80 ≤ th < 1.90

1460

1.90 ≤ th < 2.00

1520

2.00 ≤ th < 2.10

1620

2.10 ≤ th < 2.20

1660

2.20 ≤ th < 2.30

1720

2.30 ≤ th < 2.40

1780

2.40 ≤ th < 2.50

1840

2.50 ≤ th < 2.60

1900

2.60 ≤ th < 2.75

2070

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

7.10 ≤ th < 7.90

1550

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

1520

8.10 ≤ th < 13.00

S355JR EN 10025-2

S355JR EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1100

1.60 ≤ th < 1.70

1200

1.70 ≤ th < 1.80

1250

1.80 ≤ th < 1.90

1300

1.90 ≤ th < 2.00

1350

2.00 ≤ th < 2.10

1440

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1520

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1540

2.60 ≤ th < 2.75

1570

2.75 ≤ th < 3.00

1580

3.00 ≤ th < 3.50

2040

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

2070

6.35 ≤ th < 7.10

1550

7.10 ≤ th < 7.90

1520

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

S355JR AM FCE

S355JR AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1100

1.60 ≤ th < 1.70

1200

1.70 ≤ th < 1.80

1250

1.80 ≤ th < 1.90

1300

1.90 ≤ th < 2.00

1350

2.00 ≤ th < 2.10

1440

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1520

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1540

2.60 ≤ th < 2.75

1570

2.75 ≤ th < 3.00

1580

3.00 ≤ th < 3.50

2040

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

2070

6.35 ≤ th < 7.10

1550

7.10 ≤ th < 7.90

1520

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

S355J0 EN 10025-2

S355J0 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1100

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1250

1.80 ≤ th < 1.90

1280

1.90 ≤ th < 2.00

1310

2.00 ≤ th < 2.10

1440

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1520

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1540

2.60 ≤ th < 2.75

1570

2.75 ≤ th < 3.00

1580

3.00 ≤ th < 3.50

2040

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

2070

6.35 ≤ th < 7.10

1550

7.10 ≤ th < 7.90

1520

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

S355J0 AM FCE

S355J0 AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1100

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1250

1.80 ≤ th < 1.90

1280

1.90 ≤ th < 2.00

1310

2.00 ≤ th < 2.10

1440

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1520

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1540

2.60 ≤ th < 2.75

1570

2.75 ≤ th < 3.00

1580

3.00 ≤ th < 3.50

2040

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

2070

6.35 ≤ th < 7.10

1550

7.10 ≤ th < 7.90

1520

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

S355J2 EN 10025-2

S355J2 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1100

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1250

1.80 ≤ th < 1.90

1270

1.90 ≤ th < 2.00

1310

2.00 ≤ th < 2.10

1440

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1530

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1540

2.60 ≤ th < 2.75

2.75 ≤ th < 3.00

1580

3.00 ≤ th < 3.50

2040

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

2070

6.35 ≤ th < 7.10

1550

7.10 ≤ th < 7.90

1520

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

S355J2 AM FCE

S355J2 AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

1100

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1250

1.80 ≤ th < 1.90

1270

1.90 ≤ th < 2.00

1310

2.00 ≤ th < 2.10

1440

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

2.30 ≤ th < 2.40

1530

2.40 ≤ th < 2.50

2.50 ≤ th < 2.60

1540

2.60 ≤ th < 2.75

2.75 ≤ th < 3.00

1580

3.00 ≤ th < 3.50

2040

3.50 ≤ th < 4.00

2130

4.00 ≤ th < 6.35

2070

6.35 ≤ th < 7.10

1550

7.10 ≤ th < 7.90

1520

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

S355J2+N EN 10025-2

S355J2+N EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

-

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1050

2.00 ≤ th < 2.10

1330

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

1360

2.30 ≤ th < 2.40

1410

2.40 ≤ th < 2.50

1460

2.50 ≤ th < 2.60

1510

2.60 ≤ th < 2.75

1520

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

2040

3.50 ≤ th < 4.00

2070

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

1550

7.10 ≤ th < 7.90

1520

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

S355J2+N AM FCE

S355J2+N AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

-

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1050

2.00 ≤ th < 2.10

1330

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

1360

2.30 ≤ th < 2.40

1410

2.40 ≤ th < 2.50

1460

2.50 ≤ th < 2.60

1510

2.60 ≤ th < 2.75

1520

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

2040

3.50 ≤ th < 4.00

2070

4.00 ≤ th < 6.35

6.35 ≤ th < 7.10

1550

7.10 ≤ th < 7.90

1520

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

S355K2 EN 10025-2

S355K2 EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

-

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1050

2.00 ≤ th < 2.10

1330

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

1360

2.30 ≤ th < 2.40

1410

2.40 ≤ th < 2.50

1460

2.50 ≤ th < 2.60

1510

2.60 ≤ th < 2.75

1520

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

1580

3.50 ≤ th < 4.00

1780

4.00 ≤ th < 6.35

2040

6.35 ≤ th < 7.10

1550

7.10 ≤ th < 7.90

1520

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

S355K2+N EN 10025-2

S355K2+N EN 10025-2

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

-

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1050

2.00 ≤ th < 2.10

1330

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

1360

2.30 ≤ th < 2.40

1410

2.40 ≤ th < 2.50

1460

2.50 ≤ th < 2.60

1510

2.60 ≤ th < 2.75

1520

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

1580

3.50 ≤ th < 4.00

1780

4.00 ≤ th < 6.35

2040

6.35 ≤ th < 7.10

1550

7.10 ≤ th < 7.90

1520

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

S355K2+N AM FCE

S355K2+N AM FCE

Thickness (mm)

Min width

Max width

1.50 ≤ th < 1.60

800

-

1.60 ≤ th < 1.70

1.70 ≤ th < 1.80

1.80 ≤ th < 1.90

1.90 ≤ th < 2.00

1050

2.00 ≤ th < 2.10

1330

2.10 ≤ th < 2.20

2.20 ≤ th < 2.30

1360

2.30 ≤ th < 2.40

1410

2.40 ≤ th < 2.50

1460

2.50 ≤ th < 2.60

1510

2.60 ≤ th < 2.75

1520

2.75 ≤ th < 3.00

3.00 ≤ th < 3.50

1580

3.50 ≤ th < 4.00

1780

4.00 ≤ th < 6.35

2040

6.35 ≤ th < 7.10

1550

7.10 ≤ th < 7.90

1520

7.90 ≤ th < 8.00

8.00 ≤ th < 8.10

8.10 ≤ th < 13.00

Mechanical properties

Full table

Direction

Thickness (mm)

Re (MPa)

Rm (MPa)

A80 (%)

A 5.65√So (%)

KV 20°C (J)

KV 0°C (J)

KV -20°C (J)

S185 EN 10025-2

T

1.5 - 2

≥ 185

310 - 540

≥ 10

-

-

-

-

2 - 2.5

≥ 11

2.5 - 3

≥ 12

3 - 16

290 - 510

-

≥ 16

16 - 20

≥ 175

S235JR EN 10025-2

L

6 - 20

-

-

-

-

≥ 27

-

-

T

1.5 - 2

≥ 235

360 - 510

≥ 17

-

-

-

-

2 - 2.5

≥ 18

2.5 - 3

≥ 19

3 - 16

-

≥ 24

16 - 20

≥ 225

S235JR-CL1 AM FCE L

6 - 20

-

-

-

-

≥ 27

-

-

T

1.5 - 2

≥ 235

360 - 510

≥ 17

-

-

-

-

2 - 2.5

≥ 18

2.5 - 3

≥ 19

3 - 16

-

≥ 24

16 - 20

≥ 225

S235J0 EN 10025-2

L

6 - 20

-

-

-

-

-

≥ 27

-

T

1.5 - 2

≥ 235

360 - 510

≥ 17

-

-

-

-

2 - 2.5

≥ 18

2.5 - 3

≥ 19

3 - 16

-

≥ 24

16 - 20

≥ 225

S235J0 AM FCE

L

6 - 20

-

-

-

-

-

≥ 27

-

T

1.5 - 2

≥ 235

360 - 510

≥ 17

-

-

-

-

2 - 2.5

≥ 18

2.5 - 3

≥ 19

3 - 16

-

≥ 24

16 - 20

≥ 225

S235J2 EN 10025-2

L

6 - 20

-

-

-

-

-

-

≥ 27

T

1.5 - 2

≥ 235

360 - 510

≥ 17

-

-

-

-

2 - 2.5

≥ 18

2.5 - 3

≥ 19

3 - 16

-

≥ 24

16 - 20

≥ 225

S235J2 AM FCE

L

6 - 20

-

-

-

-

-

-

≥ 27

T

1.5 - 2

≥ 235

360 - 510

≥ 17

-

-

-

-

2 - 2.5

≥ 18

2.5 - 3

≥ 19

3 - 16

-

≥ 24

16 - 20

≥ 225

S235J2+N EN 10025-2

L

6 - 20

-

-

-

-

-

-

≥ 27

T

1.5 - 2

≥ 235

360 - 510

≥ 17

-

-

-

-

2 - 2.5

≥ 18

2.5 - 3

≥ 19

3 - 16

-

≥ 24

16 - 20

≥ 225

S235J2+N AM FCE

L

6 - 20

-

-

-

-

-

-

≥ 27

T

1.5 - 2

≥ 235

360 - 510

≥ 17

-

-

-

-

2 - 2.5

≥ 18

2.5 - 3

≥ 19

3 - 16

-

≥ 24

16 - 20

≥ 225

S275JR EN 10025-2

L

6 - 20

-

-

-

-

≥ 27

-

-

T

1.5 - 2

≥ 275

430 - 580

≥ 15

-

-

-

-

2 - 2.5

≥ 16

2.5 - 3

≥ 17

3 - 16

410 - 560

-

≥ 21

16 - 20

≥ 265

S275JR AM FCE

L

6 - 20

-

-

-

-

≥ 27

-

-

T

1.5 - 2

≥ 275

430 - 580

≥ 15

-

-

-

-

2 - 2.5

≥ 16

2.5 - 3

≥ 17

3 - 16

410 - 560

-

≥ 21

16 - 20

≥ 265

S275J0 EN 10025-2

L

6 - 20

-

-

-

-

-

≥ 27

-

T

1.5 - 2

≥ 275

430 - 580

≥ 15

-

-

-

-

2 - 2.5

≥ 16

2.5 - 3

≥ 17

3 - 16

410 - 560

-

≥ 21

16 - 20

≥ 265

S275J0 AM FCE

L

6 - 20

-

-

-

-

-

≥ 27

-

T

1.5 - 2

≥ 275

430 - 580

≥ 15

-

-

-

-

2 - 2.5

≥ 16

2.5 - 3

≥ 17

3 - 16

410 - 560

-

≥ 21

16 - 20

≥ 265

S275J2 EN 10025-2

L

6 - 20

-

-

-

-

-

-

≥ 27

T

1.5 - 2

≥ 275

430 - 580

≥ 15

-

-

-

-

2 - 2.5

≥ 16

2.5 - 3

≥ 17

3 - 16

410 - 560

-

≥ 21

16 - 20

≥ 265

S275J2 AM FCE

L

6 - 20

-

-

-

-

-

-

≥ 27

T

1.5 - 2

≥ 275

430 - 580

≥ 15

-

-

-

-

2 - 2.5

≥ 16

2.5 - 3

≥ 17

3 - 16

410 - 560

-

≥ 21

16 - 20

≥ 265

S275J2+N EN 10025-2

L

6 - 20

-

-

-

-

-

-

≥ 27

T

1.5 - 2

≥ 275

430 - 580

≥ 15

-

-

-

-

2 - 2.5

≥ 16

2.5 - 3

≥ 17

3 - 16

410 - 560

-

≥ 21

16 - 20

≥ 265

S275J2+N AM FCE

L

6 - 20

-

-

-

-

-

-

≥ 27

T

1.5 - 2

≥ 275

430 - 580

≥ 15

-

-

-

-

2 - 2.5

≥ 16

2.5 - 3

≥ 17

3 - 16

410 - 560

-

≥ 21

16 - 20

≥ 265

S355JR EN 10025-2

L

6 - 20

-

-

-

-

≥ 27

-

-

T

1.5 - 2

≥ 355

510 - 680

≥ 14

-

-

-

-

2 - 2.5

≥ 15

2.5 - 3

≥ 16

3 - 16

470 - 630

-

≥ 20

16 - 20

≥ 345

S355JR AM FCE

L

6 - 20

-

-

-

-

≥ 27

-

-

T

1.5 - 2

≥ 355

510 - 680

≥ 14

-

-

-

-

2 - 2.5

≥ 15

2.5 - 3

≥ 16

3 - 16

470 - 630

-

≥ 20

16 - 20

≥ 345

S355J0 EN 10025-2

L

6 - 20

-

-

-

-

-

≥ 27

-

T

1.5 - 2

≥ 355

510 - 680

≥ 14

-

-

-

-

2 - 2.5

≥ 15

2.5 - 3

≥ 16

3 - 16

470 - 630

-

≥ 20

16 - 20

≥ 345

S355J0 AM FCE

L

6 - 20

-

-

-

-

-

≥ 27

-

T

1.5 - 2

≥ 355

510 - 680

≥ 14

-

-

-

-

2 - 2.5

≥ 15

2.5 - 3

≥ 16

3 - 16

470 - 630

-

≥ 20

16 - 20

≥ 345

S355J2 EN 10025-2

L

6 - 20

-

-

-

-

-

-

≥ 27

T

1.5 - 2

≥ 355

510 - 680

≥ 14

-

-

-

-

2 - 2.5

≥ 15

2.5 - 3

≥ 16

3 - 16

470 - 630

-

≥ 20

16 - 20

≥ 345

S355J2 AM FCE

L

6 - 20

-

-

-

-

-

-

≥ 27

T

1.5 - 2

≥ 355

510 - 680

≥ 14

-

-

-

-

2 - 2.5

≥ 15

2.5 - 3

≥ 16

3 - 16

470 - 630

-

≥ 20

16 - 20

≥ 345

S355J2+N EN 10025-2

L

6 - 20

-

-

-

-

-

-

≥ 27

T

1.5 - 2

≥ 355

510 - 680

≥ 14

-

-

-

-

2 - 2.5

≥ 15

2.5 - 3

≥ 16

3 - 16

470 - 630

-

≥ 20

16 - 20

≥ 345

S355J2+N AM FCE

L

6 - 20

-

-

-

-

-

-

≥ 27

T

1.5 - 2

≥ 355

510 - 680

≥ 14

-

-

-

-

2 - 2.5

≥ 15

2.5 - 3

≥ 16

3 - 16

470 - 630

-

≥ 20

16 - 20

≥ 345

S355K2 EN 10025-2

L

6 - 20

-

-

-

-

-

-

≥ 40

T

2 - 2.5

≥ 355

510 - 680

≥ 15

-

-

-

-

2.5 - 3

≥ 16

3 - 16

470 - 630

-

≥ 20

16 - 20

≥ 345

S355K2+N EN 10025-2

L

6 - 20

-

-

-

-

-

-

≥ 40

T

2 - 2.5

≥ 355

510 - 680

≥ 15

-

-

-

-

2.5 - 3

≥ 16

3 - 16

470 - 630

-

≥ 20

16 - 20

≥ 345

S355K2+N AM FCE

L

6 - 20

-

-

-

-

-

-

≥ 40

T

2 - 2.5

≥ 355

510 - 680

≥ 15

-

-

-

-

2.5 - 3

≥ 16

3 - 16

470 - 630

-

≥ 20

16 - 20

≥ 345

S185 EN 10025-2

Direction

Thickness (mm)

S185 EN 10025-2

Re (MPa)

T

1.5 - 16

≥ 185

16 - 20

≥ 175

Rm (MPa)

T

1.5 - 3

310 - 540

3 - 20

290 - 510

A80 (%)

T

1.5 - 2

≥ 10

2 - 2.5

≥ 11

2.5 - 3

≥ 12

A 5.65√So (%)

T

3 - 20

≥ 16

S235JR EN 10025-2

Direction

Thickness (mm)

S235JR EN 10025-2

Re (MPa)

T

1.5 - 16

≥ 235

16 - 20

≥ 225

Rm (MPa)

T

1.5 - 20

360 - 510

A80 (%)

T

1.5 - 2

≥ 17

2 - 2.5

≥ 18

2.5 - 3

≥ 19

A 5.65√So (%)

T

3 - 20

≥ 24

KV 20°C (J)

L

6 - 20

≥ 27

S235JR-CL1 AM FCE

Direction

Thickness (mm)

S235JR-CL1 AM FCE

Re (MPa)

T

1.5 - 16

≥ 235

16 - 20

≥ 225

Rm (MPa)

T

1.5 - 20

360 - 510

A80 (%)

T

1.5 - 2

≥ 17

2 - 2.5

≥ 18

2.5 - 3

≥ 19

A 5.65√So (%)

T

3 - 20

≥ 24

KV 20°C (J)

L

6 - 20

≥ 27

S235J0 EN 10025-2, S235J0 AM FCE

Direction

Thickness (mm)

S235J0 EN 10025-2

S235J0 AM FCE

Re (MPa)

T

1.5 - 16

≥ 235

≥ 235

16 - 20

≥ 225

≥ 225

Rm (MPa)

T

1.5 - 20

360 - 510

360 - 510

A80 (%)

T

1.5 - 2

≥ 17

≥ 17

2 - 2.5

≥ 18

≥ 18

2.5 - 3

≥ 19

≥ 19

A 5.65√So (%)

T

3 - 20

≥ 24

≥ 24

KV 0°C (J)

L

6 - 20

≥ 27

≥ 27

S235J2 EN 10025-2, S235J2 AM FCE

Direction

Thickness (mm)

S235J2 EN 10025-2

S235J2 AM FCE

Re (MPa)

T

1.5 - 16

≥ 235

≥ 235

16 - 20

≥ 225

≥ 225

Rm (MPa)

T

1.5 - 20

360 - 510

360 - 510

A80 (%)

T

1.5 - 2

≥ 17

≥ 17

2 - 2.5

≥ 18

≥ 18

2.5 - 3

≥ 19

≥ 19

A 5.65√So (%)

T

3 - 20

≥ 24

≥ 24

KV -20°C (J)

L

6 - 20

≥ 27

≥ 27

S235J2+N EN 10025-2

Direction

Thickness (mm)

S235J2+N EN 10025-2

Re (MPa)

T

1.5 - 16

≥ 235

16 - 20