In order to offer you the best possible experience, we suggest that you accept the deposit and reading of cookies and the use of technology necessary for their proper functioning:

These steels are recommended when high reproducibility of processing performance is required.

ArcelorMittal's structural forming grades offer superior strength compared with standard deep drawing grades. Furthermore, their mechanical properties meet very narrow tolerance limits.

S200 AM FCE is the basic grade in the range and corresponds to DD11 (EN 10111:2008).

S200D AM FCE, which corresponds to DD14 (EN 10111:2008), is recommended for extreme deep drawing operations.

S240D AM FCE offers mechanical properties equivalent to those of DD11 (EN 10111:2008), and a strength corresponding to S235JR (EN 10025-2:2004).

Structural forming grades are well suited to applications requiring high reproducibility of processing performance (especially control of springback). That is why the S200D AM FCE grade is especially suitable for applications such as compressor casings. The S240D AM FCE grade is popular with Steel Service Centres, since it allows them to rationalise their supplies of deep drawable and structural steel. This grade is a versatile material for numerous applications in industry markets.

| EN 10111:2008 | EN 10025-2:2004 | WT.76.01:2001 | Old brand names | |

|---|---|---|---|---|

| S200 AM FCE | DD11 | |||

| S200D AM FCE | DD14 | |||

| S240D AM FCE | DD11 | S235JR | (ZG240C) |

Grades in italics: not included in the standard

() Closest grade as no fully equivalent grade exists.

| S200 AM FCE | |

|---|---|

| EN 10111:2008 | DD11 |

| EN 10025-2:2004 | |

| WT.76.01:2001 | |

Grades in italics: not included in the standard

| S200D AM FCE | |

|---|---|

| EN 10111:2008 | DD14 |

| EN 10025-2:2004 | |

| WT.76.01:2001 | |

Grades in italics: not included in the standard

| S240D AM FCE | |

|---|---|

| EN 10111:2008 | DD11 |

| EN 10025-2:2004 | S235JR |

| WT.76.01:2001 | (ZG240C) |

Grades in italics: not included in the standard

() Closest grade as no fully equivalent grade exists.

Grades in italics: not included in the standard

() Closest grade as no fully equivalent grade exists.

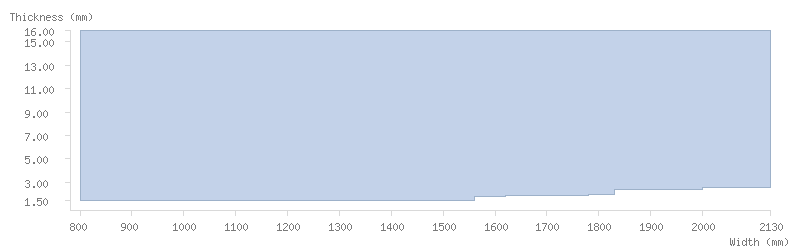

| Thickness (mm) | Min width | S200 AM FCE, S240D AM FCE | S200D AM FCE |

|---|---|---|---|

| Max width | Max width | ||

| 1.50 ≤ th < 1.60 | 800 | 1560 | 1350 |

| 1.60 ≤ th < 1.80 | 1450 | ||

| 1.80 ≤ th < 1.90 | 1620 | ||

| 1.90 ≤ th < 2.00 | 1780 | ||

| 2.00 ≤ th < 2.40 | 1830 | 1600 | |

| 2.40 ≤ th < 2.60 | 2000 | 1930 | |

| 2.60 ≤ th < 2.80 | 2130 | 1980 | |

| 2.80 ≤ th < 3.00 | 2030 | ||

| 3.00 ≤ th < 3.30 | |||

| 3.30 ≤ th < 7.00 | 2130 | ||

| 7.00 ≤ th < 16.00 | - |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1560 |

| 1.60 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | 1620 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.40 | 1830 | |

| 2.40 ≤ th < 2.60 | 2000 | |

| 2.60 ≤ th < 2.80 | 2130 | |

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 7.00 | ||

| 7.00 ≤ th < 16.00 |

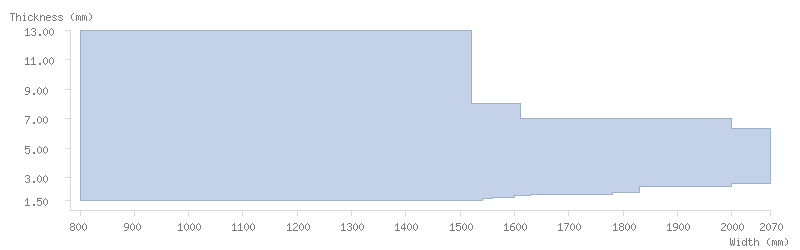

| Thickness (mm) | Min width | S200 AM FCE, S240D AM FCE | S200D AM FCE |

|---|---|---|---|

| Max width | Max width | ||

| 1.50 ≤ th < 1.60 | 800 | 1540 | - |

| 1.60 ≤ th < 1.70 | 1560 | 1440 | |

| 1.70 ≤ th < 1.80 | 1600 | 1470 | |

| 1.80 ≤ th < 1.90 | 1630 | 1500 | |

| 1.90 ≤ th < 2.00 | 1780 | 1620 | |

| 2.00 ≤ th < 2.20 | 1830 | ||

| 2.20 ≤ th < 2.40 | 1640 | ||

| 2.40 ≤ th < 2.60 | 2000 | 1930 | |

| 2.60 ≤ th < 3.20 | 2070 | 1980 | |

| 3.20 ≤ th < 6.00 | 2000 | ||

| 6.00 ≤ th < 6.35 | - | ||

| 6.35 ≤ th < 7.00 | 2000 | ||

| 7.00 ≤ th < 8.00 | 1610 | ||

| 8.00 ≤ th < 13.00 | 1520 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | 1560 | |

| 1.70 ≤ th < 1.80 | 1600 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.20 | 1830 | |

| 2.20 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.60 | 2000 | |

| 2.60 ≤ th < 3.20 | 2070 | |

| 3.20 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.35 | ||

| 6.35 ≤ th < 7.00 | 2000 | |

| 7.00 ≤ th < 8.00 | 1610 | |

| 8.00 ≤ th < 13.00 | 1520 |

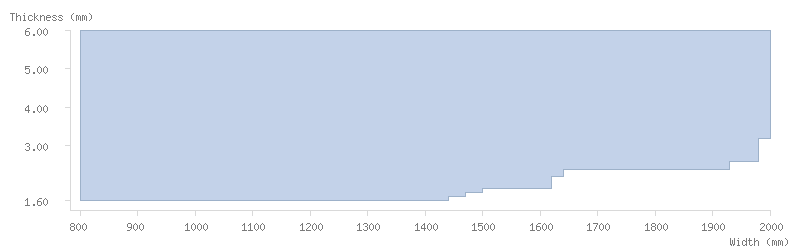

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | 1440 | |

| 1.70 ≤ th < 1.80 | 1470 | |

| 1.80 ≤ th < 1.90 | 1500 | |

| 1.90 ≤ th < 2.00 | 1620 | |

| 2.00 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.40 | 1640 | |

| 2.40 ≤ th < 2.60 | 1930 | |

| 2.60 ≤ th < 3.20 | 1980 | |

| 3.20 ≤ th < 6.00 | 2000 | |

| 6.00 ≤ th < 6.35 | - | |

| 6.35 ≤ th < 7.00 | ||

| 7.00 ≤ th < 8.00 | ||

| 8.00 ≤ th < 13.00 |

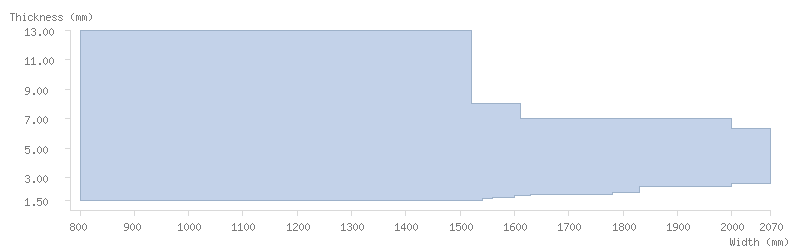

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | 1560 | |

| 1.70 ≤ th < 1.80 | 1600 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.20 | 1830 | |

| 2.20 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.60 | 2000 | |

| 2.60 ≤ th < 3.20 | 2070 | |

| 3.20 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.35 | ||

| 6.35 ≤ th < 7.00 | 2000 | |

| 7.00 ≤ th < 8.00 | 1610 | |

| 8.00 ≤ th < 13.00 | 1520 |

| Direction | Thickness (mm) | Re (MPa) | Rm (MPa) | A80 (%) | A 5.65√So (%) | Bending ratio (th) | MP guarantees (Months) | KV 20°C (J) | |

|---|---|---|---|---|---|---|---|---|---|

| S200 AM FCE | L | 1.5 - 16 | - | - | - | - | - | ≥ 1 | - |

| T | 1.5 - 2 | 200 - 360 | 270 - 440 | ≥ 23 | - | ≥ 1 | ≥ 1 | - | |

| 2 - 3 | 200 - 340 | ≥ 24 | |||||||

| 3 - 16 | - | ≥ 28 | |||||||

| S200D AM FCE | L | 1.8 - 13 | - | - | - | - | - | ≥ 6 | - |

| T | 1.8 - 2 | 200 - 310 | 300 - 380 | ≥ 32 | - | - | ≥ 6 | - | |

| 2 - 3 | 200 - 290 | ≥ 33 | |||||||

| 3 - 6 | - | ≥ 37 | |||||||

| 6 - 13 | - | - | |||||||

| S240D AM FCE | L | 1.5 - 20 | - | - | - | - | - | ≥ 6 | ≥ 27 |

| T | 1.5 - 2 | 240 - 360 | 360 - 430 | ≥ 23 | - | - | ≥ 6 | - | |

| 2 - 3 | 240 - 340 | ≥ 24 | |||||||

| 3 - 20 | - | ≥ 28 |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

| Direction | Thickness (mm) | S200 AM FCE | |

|---|---|---|---|

| Re (MPa) | T | 1.5 - 2 | 200 - 360 |

| 2 - 16 | 200 - 340 | ||

| Rm (MPa) | T | 1.5 - 16 | 270 - 440 |

| A80 (%) | T | 1.5 - 2 | ≥ 23 |

| 2 - 3 | ≥ 24 | ||

| A 5.65√So (%) | T | 3 - 16 | ≥ 28 |

| Bending ratio (th) | T | 1.5 - 16 | ≥ 1 |

Grades in italics: not included in the standard

| Direction | Thickness (mm) | S200D AM FCE | |

|---|---|---|---|

| Re (MPa) | T | 1.8 - 2 | 200 - 310 |

| 2 - 6 | 200 - 290 | ||

| Rm (MPa) | T | 1.8 - 6 | 300 - 380 |

| A80 (%) | T | 1.8 - 2 | ≥ 32 |

| 2 - 3 | ≥ 33 | ||

| A 5.65√So (%) | T | 3 - 13 | ≥ 37 |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

| Direction | Thickness (mm) | S240D AM FCE | |

|---|---|---|---|

| Re (MPa) | T | 1.5 - 2 | 240 - 360 |

| 2 - 20 | 240 - 340 | ||

| Rm (MPa) | T | 1.5 - 20 | 360 - 430 |

| A80 (%) | T | 1.5 - 2 | ≥ 23 |

| 2 - 3 | ≥ 24 | ||

| A 5.65√So (%) | T | 3 - 20 | ≥ 28 |

| KV 20°C (J) | L | 1.5 - 20 | ≥ 27 |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

Grades in italics: not included in the standard

Values in bold: tighter than the standard

| C (%) | Mn (%) | P (%) | S (%) | Si (%) | Al (%) | B (%) | Ceq (%) | Galvanisation | |

|---|---|---|---|---|---|---|---|---|---|

| S200 AM FCE | 0.020 - 0.100 | 0.15 - 0.50 | ≤ 0.030 | ≤ 0.030 | ≤ 0.03 | - | - | - | Class 1 |

| S200D AM FCE | 0.020 - 0.080 | ≤ 0.35 | ≤ 0.025 | ≤ 0.020 | ≤ 0.03 | ≥ 0.020 | 0.0020 - 0.0050 | ≤ 0.15 | Class 1 |

| S240D AM FCE | 0.020 - 0.120 | ≤ 0.60 | ≤ 0.030 | ≤ 0.030 | ≤ 0.03 | ≥ 0.010 | - | ≤ 0.18 | Class 1 |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

The chemical properties given are based on cast analysis data.

| S200 AM FCE | |

|---|---|

| C (%) | 0.020 - 0.100 |

| Mn (%) | 0.15 - 0.50 |

| P (%) | ≤ 0.030 |

| S (%) | ≤ 0.030 |

| Si (%) | ≤ 0.03 |

| Al (%) | - |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

| S200D AM FCE | |

|---|---|

| C (%) | 0.020 - 0.080 |

| Mn (%) | ≤ 0.35 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.020 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.020 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

| S240D AM FCE | |

|---|---|

| C (%) | 0.020 - 0.120 |

| Mn (%) | ≤ 0.60 |

| P (%) | ≤ 0.030 |

| S (%) | ≤ 0.030 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.010 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

Grades in italics: not included in the standard

Values in bold: tighter than the standard

The chemical properties given are based on cast analysis data.

Any questions?

Ask them via our contact form on

https://industry.arcelormittal.com/getintouch

All details provided in the ArcelorMittal Flat Carbon Europe S.A. catalogue are for information purposes only. ArcelorMittal Flat Carbon Europe S.A. reserves the right to change its product range at any time without prior notice.

Download

Download