ArcelorMittal Europe – Flat Products

ArcelorMittal Europe – Flat Products

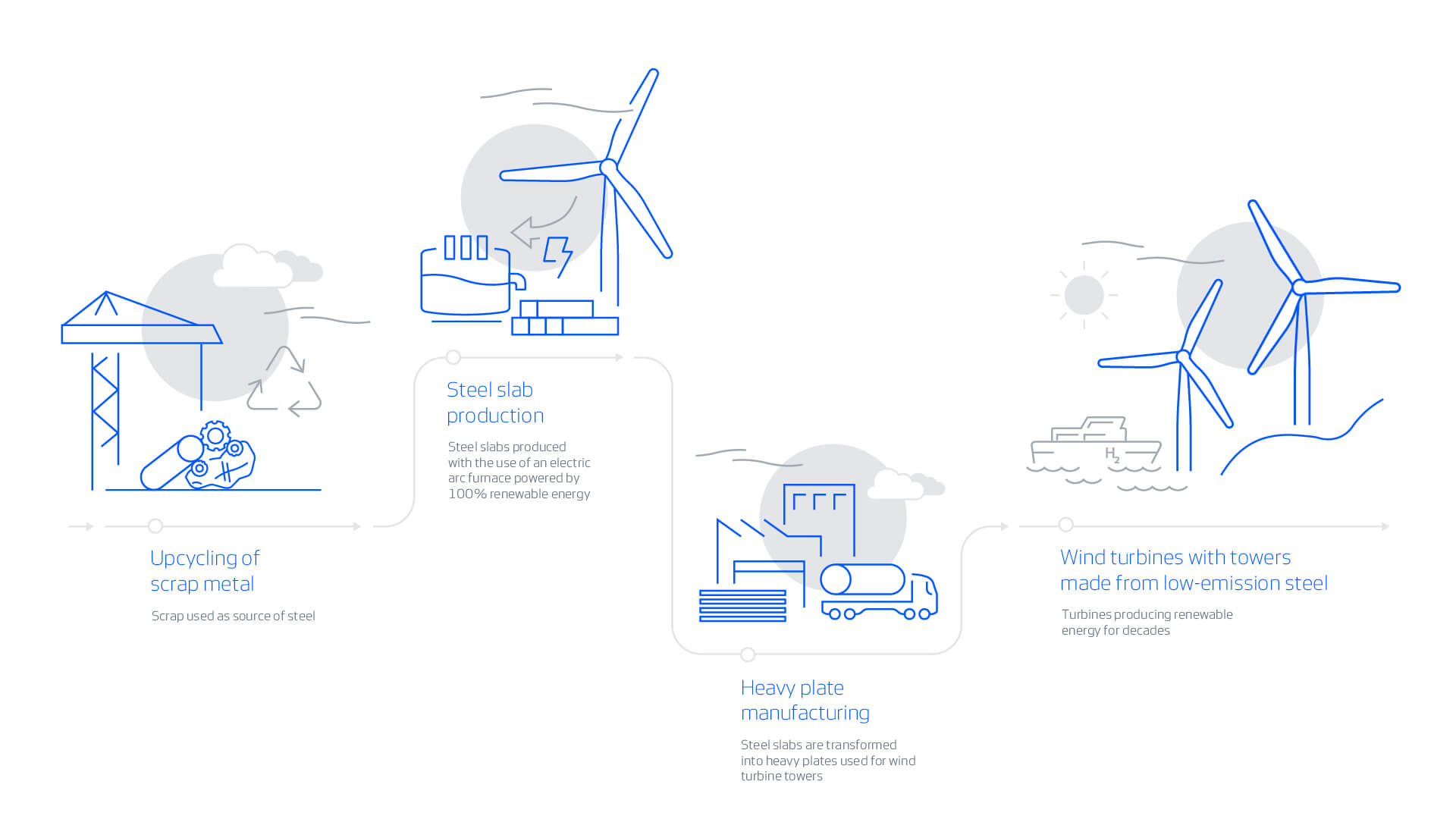

A 66-percent reduction in CO2 emission intensity per kilogram of heavy plate is achieved using recycled steel and renewable electricity.

“It was a pleasure to meet Henrik Andersen to discuss our partnership with Vestas. This cooperation illustrates the power of partnerships that span the whole supply chain: they accelerate change and move us closer to the large-scale use of low carbon-emissions steel to build the infrastructure of the future”, notes Geert Van Poelvoorde, CEO of ArcelorMittal Europe.

From left to right: Geert Van Poelvoorde, CEO ArcelorMittal Europe and Henrik Andersen, CEO Vestas.

Dieter Dehoorne, Head of Global Procurement at Vestas.

The 1.2 GW Baltic Power wind farm will consist of 76, V236-15.0 MW offshore wind turbines which will supply power to around 1.5 million homes in Poland. Fifty-two of the towers will utilise the low carbon-emissions steel. “Heavy plates for towers are one of the biggest contributors to Vestas’ Scope 3 emissions,” notes Dieter Dehoorne, Head of Global Procurement at Vestas. “So they are a key focus of our sustainability transformation as a company and this announcement is a massive leap towards tackling this challenge. We expect the interest in low carbon-emissions plates to grow in the coming years.”

To read the full article, please

Click here