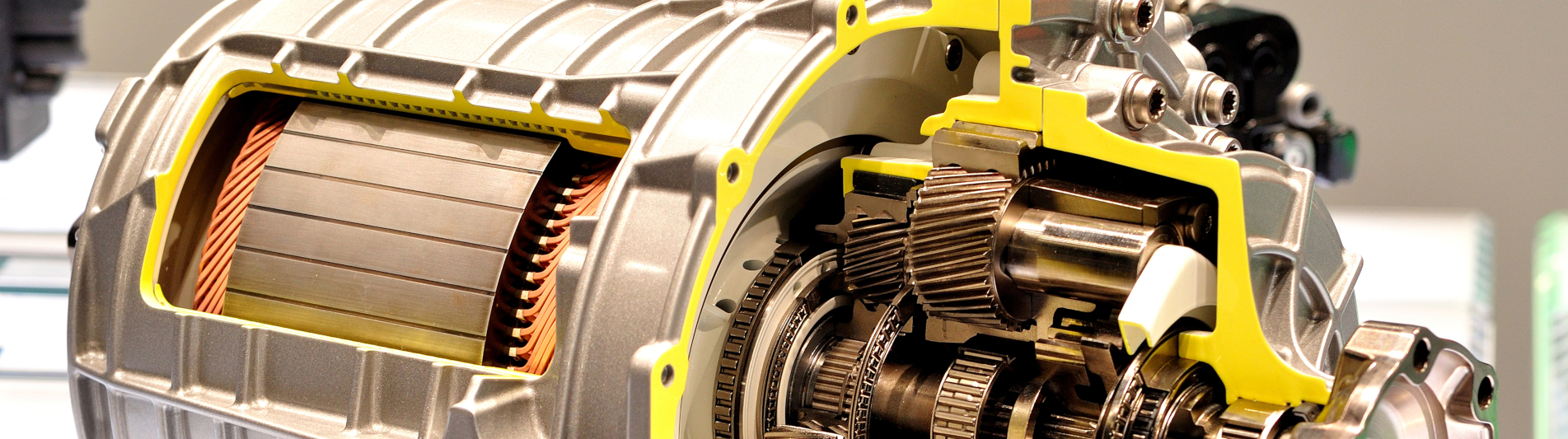

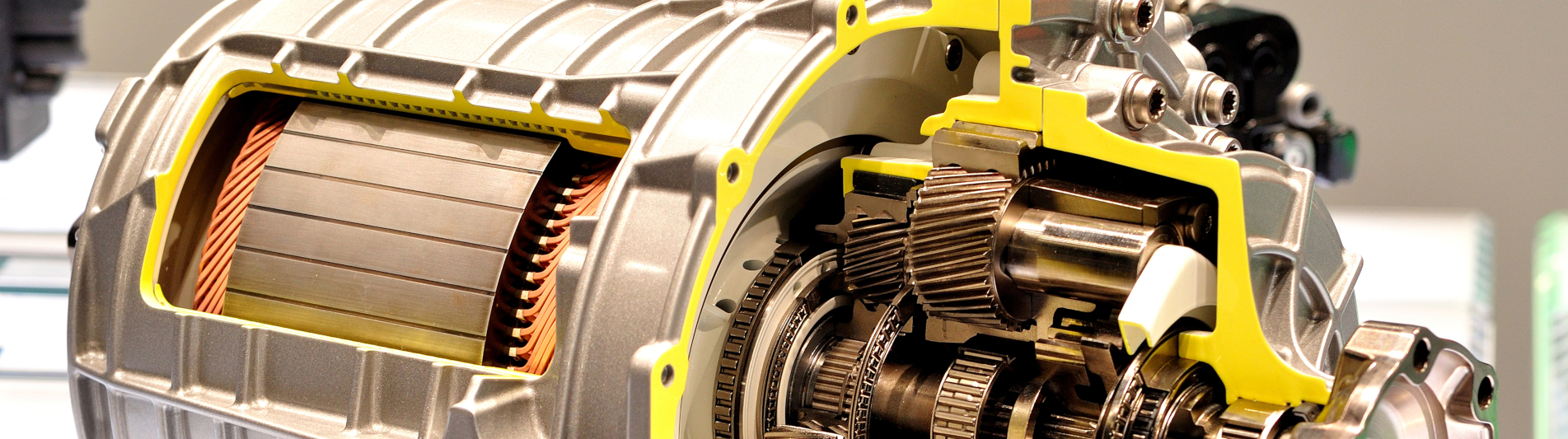

ArcelorMittal’s non-oriented electrical steel (NOES) products are recognised by our customers for their quality and sustainability, namely in the sector of power generation. NOES will be even more at the forefront of the “Green Deal” changes such as the automotive electrification transition for which ArcelorMittal is demonstrating the value creation of its smart solutions thanks to its specific iCARe® e-steels offer.

ArcelorMittal’s NOES respond more to the most advanced requirements needed by our customers, with grades going beyond the requisites of Euronorm, such as:

On top of its product offer, ArcelorMittal offers a wide range of services, from technical support and co-engineering, to logistics and supply chain solutions.

ArcelorMittal's product range contains a very broad spectrum of steel grades with specific magnetic properties, including:

Non-oriented fully processed electrical steels

Advantages

Applications

Non-oriented semi-processed electrical steels

The semi-processed grades still need an additional annealing treatment step after the client’s punching process. ArcelorMittal offers semi-processed standard grades and semi-processed high permeability grades. The overall average of polarisation in all directions of the high permeability steel sheet plane is therefore much higher than for the standard products.

Advantages

The semi-processed high permeability grades allow core weight reduction and increased efficiency of motors and transformers. The improved efficiency achieved reduces machine operating costs and at the same time makes them more environmentally friendly.

Applications

Pole sheet electrical steels

Hot and cold rolled pole sheet grades are classified according to their yield strength (EN 10265:1995). As well as guaranteed mechanical properties, they have guaranteed magnetic properties, but unlike other electrical steel grades, their magnetic characterisation is determined under direct current (DC) conditions.

Advantages

Applications

All our varnishes are environmentally friendly, hydrosoluble and chromium-free.

Each varnish for non-oriented grades (C3, C5, C6) has its own specific properties, such as insulation level, punchability effect, corrosion protection, temperature resistance and weldability.

Listen and discover how your business can benefit from ArcelorMittal’s extensive electrical steels offer and expertise.

For manufacturers and automakers who wish to exploit the full potential of ArcelorMittal’s electrical steels, we can offer advanced technical support in many areas including modelling, prototyping and material handling.