When ADGAS wanted to renew the jacketing of their gas installation on Das Island in the Persian Gulf, they turned to the same steel solution they used more than 20 years ago: a special steel grade known as Aluminized Type 2. And they asked their long-term partner ADCC to manufacture the jackets which protect the pipes, vessels, tanks, and other infrastructure in the harsh local environment.

The new jackets will insulate, weatherproof, and enhance the fire resistance of the Abu Dhabi Gas Liquefaction Company Limited (ADGAS) infrastructure on Das Island. That includes all equipment used in cold, cryogenic, cyclic, and elevated temperature operations. The new jackets also had to meet strict local safety specifications.

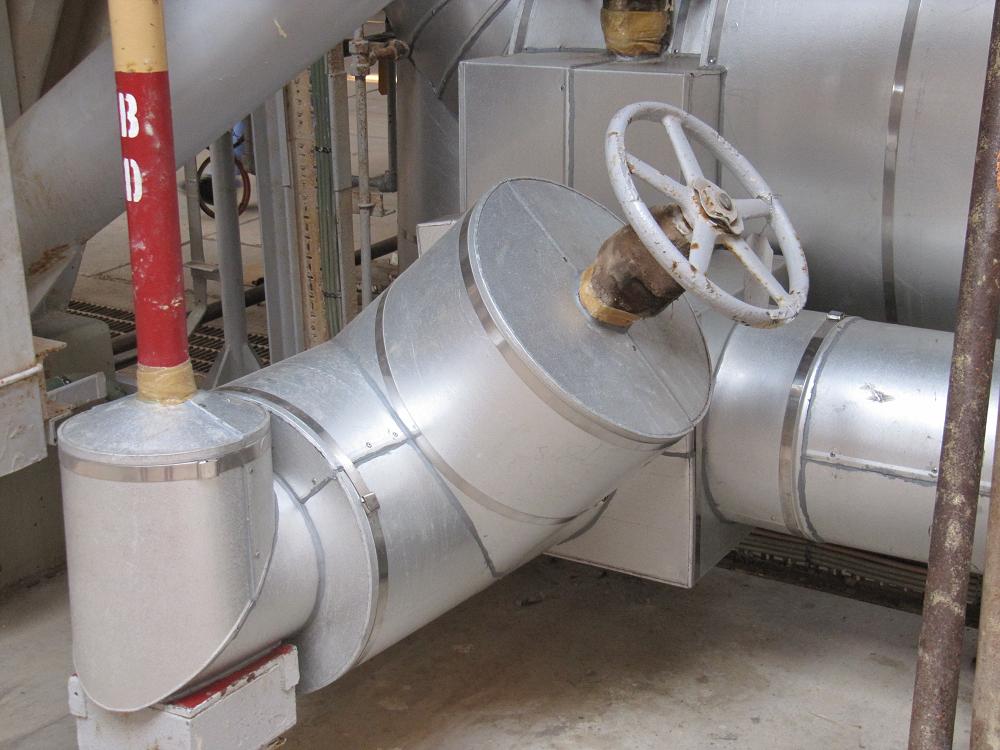

“It’s not just pipes that get jackets,” notes Husam Mahmoud Al Alkhateeb, general manager of the Abu Dhabi Construction Company (ADCC). “They are also used to protect vessels, tanks, pumps, and compressors. And they can be very large – one of the biggest vessels is 70-metres high, and we had to jacket a tank with a diameter of 25 metres.”

Best value for money

But when it came to choosing a material for the jackets, there was only one obvious choice – Aluminized Type 2 (T2) from ArcelorMittal. “This was the same material ADGAS used in 1992-93 when they installed the existing jackets,” says Mr Al Alkhateeb. “Aluminized T2 has a proven track record with oil and gas companies and it is widely utilised as a result. It offers the best value for money.”

Alternative materials used in this application include stainless steel and glass-reinforced plastic (GRP) notes Mr Al Alkhateeb: “The biggest disadvantage of stainless is its cost. GRP is more cost-effective but it isn’t practical. It turns into a solid block. To maintain a valve, you must break the GRP off and then replace it once the maintenance operation is completed. It also changes colour as it ages, becoming dark brown and spotty in the harsh sunlight of the Gulf. It looks unattractive and unsafe.”

Cost and efficiency advantages

While there have been lots of attempts to introduce alternative products such as GRP into the oil and gas industry, ADCC actively lobbies for the continued use of Aluminized T2. “Aluminized T2 is the best material available for jacketing applications in the oil and gas sector,” says Mr Al Alkhateeb. “It has both cost and efficiency advantages. ArcelorMittal has also been producing this grade for decades, so ADCC and ADGAS know it is a good quality product from a reputable supplier.”

Mr Al Alkhateeb believes that ADCC has a responsibility to insist on the use of top-quality materials such as Aluminized T2: “Clients sometimes ask us to use cheaper, inferior products, but cheap is cheap. It will not provide long-term service and that doesn’t go with our ethics. We do something right, or we don’t do it at all. We’ve been in this business for 50 years, we want to be doing it for at least another 50.”

ADCC offers a six-year warranty for jackets made with Aluminized T2. “In fact, it lasts much longer,” explains Mr Al Alkhateeb. “The jackets we are replacing were originally installed in 1992 and 1993, and they have been in continuous use ever since.

As you can imagine, the environment is very hot and humid, and there are traces of corrosive gases. Aluminized T2 does age slightly over time in this environment. Some parts have been replaced over the years, but this is very easy to do compared to other materials.”

Hardcore support from ArcelorMittal

Mr Al Alkhateeb is also pleased with the direct support ADCC receives from ArcelorMittal: “We are well supported by our local partner AK Steel, but hardcore support always comes from the manufacturer. A customer recently asked us to utilise a jacketing material which they believed mimicked the performance of Aluminized T2. ArcelorMittal’s R&D team did a very detailed analysis that showed the material had a different chemical composition to Aluminized T2. The analysis enabled us to explain the exact differences to our client. Clients can’t do this level of analysis themselves. With a partner like ArcelorMittal, ADCC is able to scientifically show our clients why these cheaper materials are inferior.”

And will Mr Al Alkhateeb recommend Aluminized T2 to ADCC in another 20 years: “I think so – ArcelorMittal’s Aluminized Type 2 has stood the test of time and we know it won’t fail. We will continue to use this product in the future. It is definitely here to stay!”

From 1 May 2017, ArcelorMittal Projects Oil & Gas has become the main distributor of ArcelorMittal’s Aluminized Type 2 offer around the world.

ArcelorMittal Projects Oil & Gas is uniquely positioned to provide the strong global supply chain and international project follow-up required by insulation companies and other contractors in the oil and gas sector.

Coils of Aluminized Type 2 are shipped directly from the ArcelorMittal Projects warehouses in the Netherlands and the United Arab Emirates to customers anywhere in the world.

Download our brochure on steel and solutions for the oil and gas industry

Find out everything on our steels in our

Product document centre