In order to offer you the best possible experience, we suggest that you accept the deposit and reading of cookies and the use of technology necessary for their proper functioning:

Some parts need very high resistance even if they seem simple, which is why they are made out of this type of steel.

These grades are characterised by their hardness after heat treatment. They can offer high strength ratings, including fatigue resistance.

High carbon and alloy steels are designed for the production of parts for intensive use.

They can be cold rolled and subjected to heat treatment (quenching and annealing), depending on their intended application, and are used to make mechanical parts, such as clutches, springs, segments, saw blades, measuring tape etc.

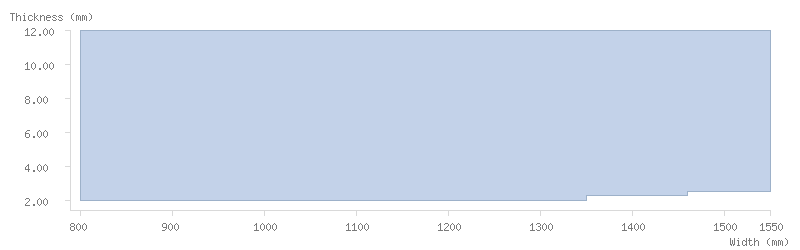

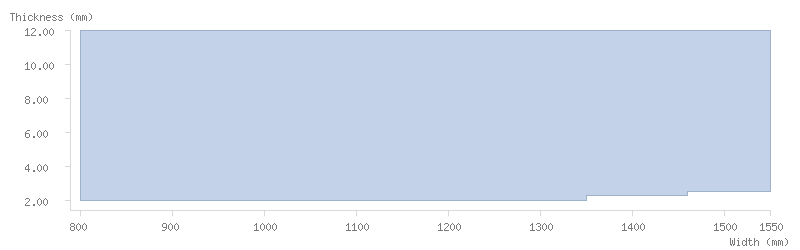

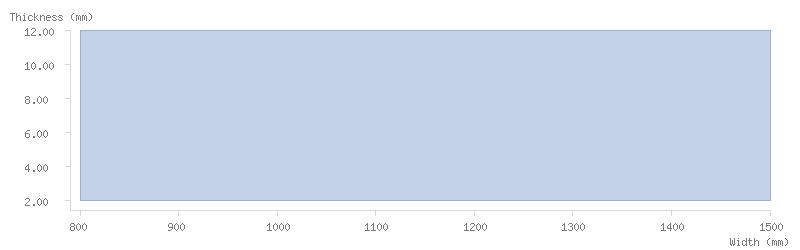

Thickness tolerance

In view of the tolerance values required for finished products made from narrow strip, ArcelorMittal normally offers a tighter tolerance range for these grades (half the tolerance range required by the EN 10051:2010 standard).

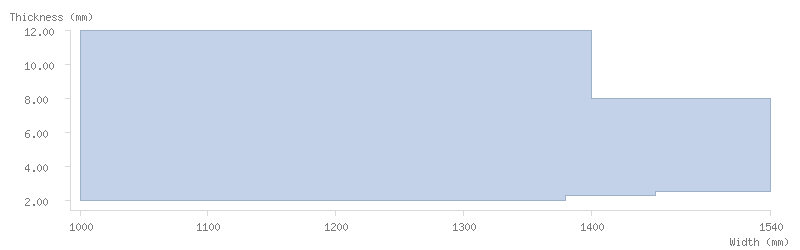

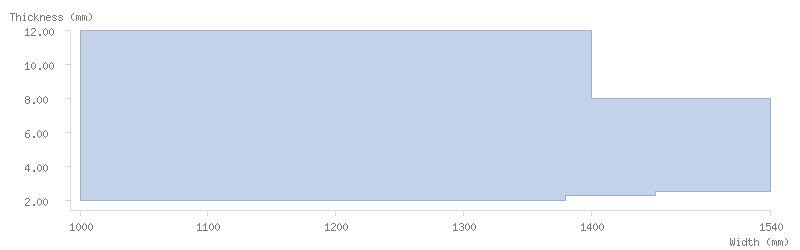

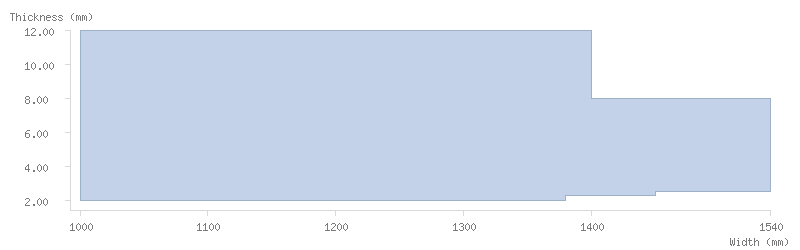

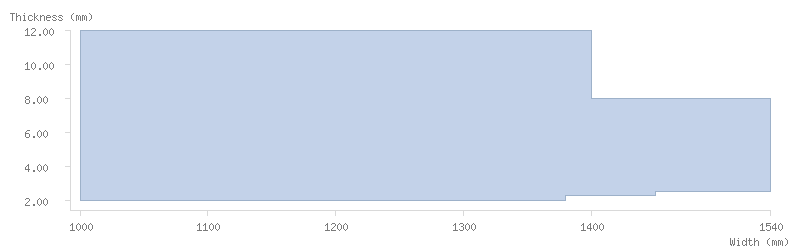

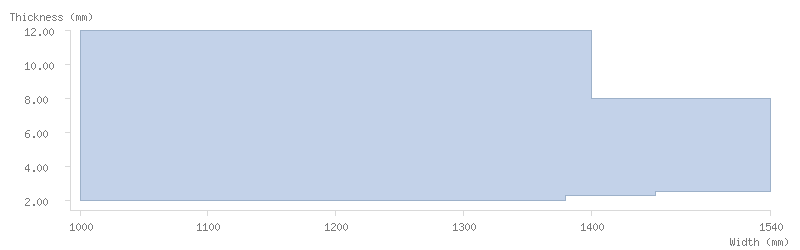

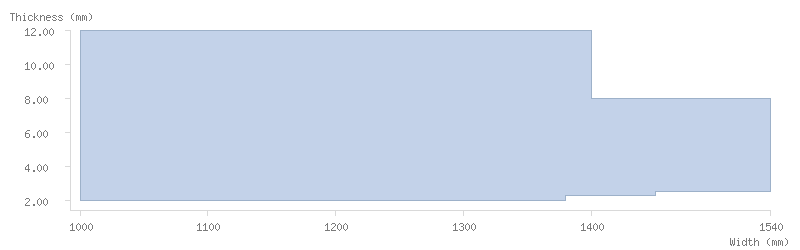

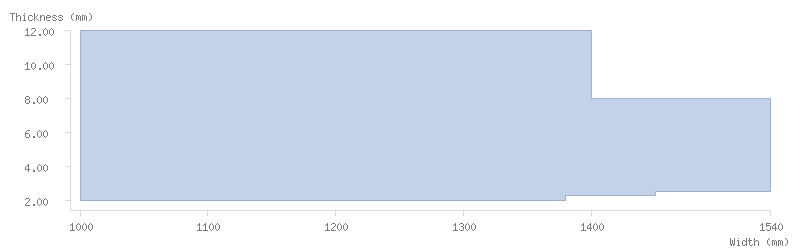

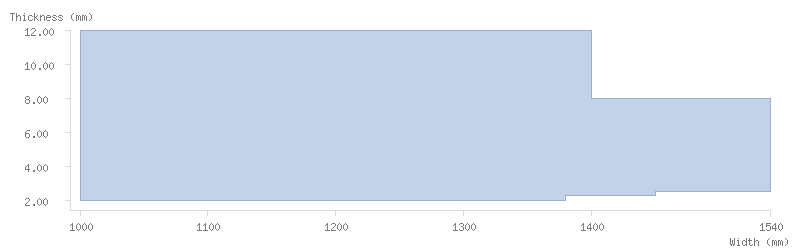

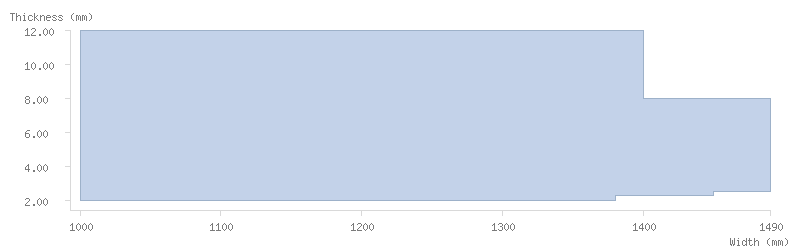

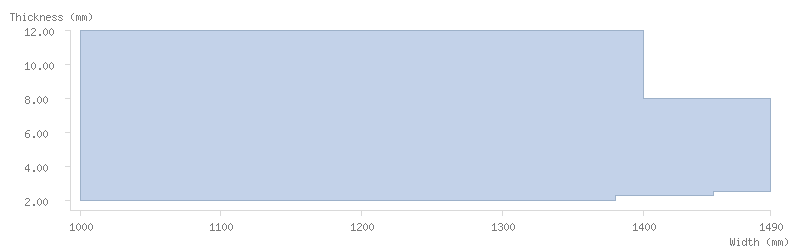

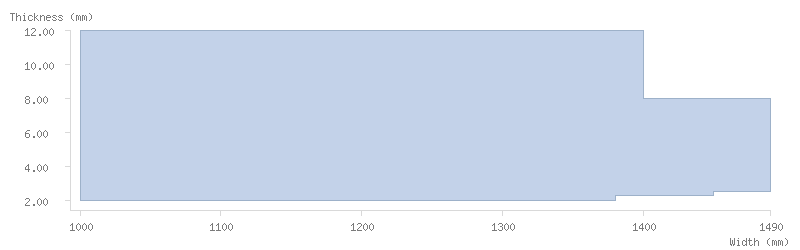

Transverse coil profile

As these products are frequently re-rolled after slitting, ArcelorMittal can supply coils with an extra flat profile (to order), which can guarantee a hot-rolled strip crown lower than 60 µm for coil thicknesses ranging from 2 to 6 mm.

Do not hesitate to contact us.

Internal purity

Our steels have the degree of internal purity corresponding to the steel grade specified. It is possible to agree on the required degree of purity at the time of enquiry and order.

Decarburisation

The guaranteed maximum decarburisation is 1% per side.

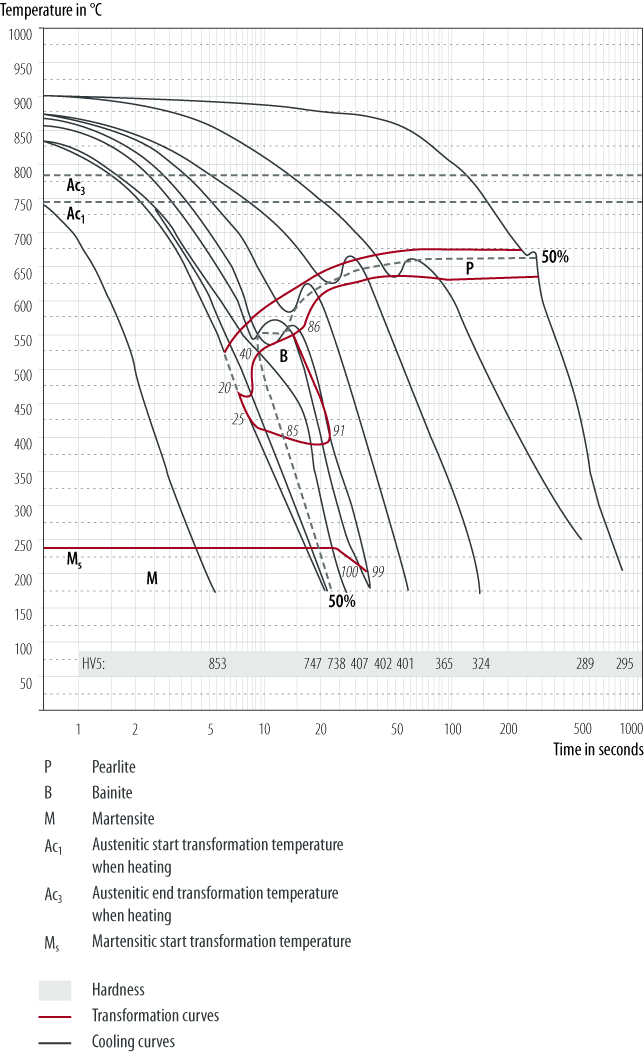

As these steel grades generally undergo heat treatment, a number of diagrams showing typical behaviour are available on request, such as:

As an example, here is a CCT diagram for the C75S AM FCE grade.

| C | Mn | P | S | Si | Al | Ni | Cr | Cu | N2 |

|---|---|---|---|---|---|---|---|---|---|

| 742 | 636 | 9 | 2.9 | 213 | 18 | 245 | 5 | 4.2 | |

| Grade C75 | Austenitised at 900°C for 15' | ||||||||

| EN 10083-2:2006 | EN 10084:2008 | EN 10132-4:2000 | DIN 17200 | BS 970 - BS 5867 | Old brand names | |

|---|---|---|---|---|---|---|

| 16MnCr5 EN 10084 | 16MnCr5 | |||||

| 16MnCr5 AM FCE | 16MnCr5 | |||||

| C22E EN 10083-2 | C22E | |||||

| C35E EN 10083-2 | C35E | |||||

| C35E AM FCE | C35E | |||||

| C40E EN 10083-2 | C40E | |||||

| C40E AM FCE | C40E | Ck40 | 080M40 | |||

| C45E EN 10083-2 | C45E | |||||

| C45E AM FCE | C45E | Ck45 | 080M46 | |||

| C50E EN 10083-2 | C50E | |||||

| C50E AM FCE | C50E | Ck50 | 080M50 | |||

| C55E EN 10083-2 | C55E | |||||

| C60E EN 10083-2 | C60E | |||||

| C60E AM FCE | C60E | Ck60 | 070M60 | |||

| C67S AM FCE | C67S | Ck67 | CS70 | |||

| C75S AM FCE | C75S | Ck75 | CS80 |

| 16MnCr5 EN 10084 | 16MnCr5 AM FCE | |

|---|---|---|

| EN 10083-2:2006 | ||

| EN 10084:2008 | 16MnCr5 | 16MnCr5 |

| EN 10132-4:2000 | ||

| DIN 17200 | ||

| BS 970 - BS 5867 | ||

| C22E EN 10083-2 | |

|---|---|

| EN 10083-2:2006 | C22E |

| EN 10084:2008 | |

| EN 10132-4:2000 | |

| DIN 17200 | |

| BS 970 - BS 5867 | |

| C35E EN 10083-2 | C35E AM FCE | |

|---|---|---|

| EN 10083-2:2006 | C35E | C35E |

| EN 10084:2008 | ||

| EN 10132-4:2000 | ||

| DIN 17200 | ||

| BS 970 - BS 5867 | ||

| C40E EN 10083-2 | C40E AM FCE | |

|---|---|---|

| EN 10083-2:2006 | C40E | C40E |

| EN 10084:2008 | ||

| EN 10132-4:2000 | ||

| DIN 17200 | Ck40 | |

| BS 970 - BS 5867 | 080M40 | |

| C45E EN 10083-2 | C45E AM FCE | |

|---|---|---|

| EN 10083-2:2006 | C45E | C45E |

| EN 10084:2008 | ||

| EN 10132-4:2000 | ||

| DIN 17200 | Ck45 | |

| BS 970 - BS 5867 | 080M46 | |

| C50E EN 10083-2 | C50E AM FCE | |

|---|---|---|

| EN 10083-2:2006 | C50E | C50E |

| EN 10084:2008 | ||

| EN 10132-4:2000 | ||

| DIN 17200 | Ck50 | |

| BS 970 - BS 5867 | 080M50 | |

| C55E EN 10083-2 | |

|---|---|

| EN 10083-2:2006 | C55E |

| EN 10084:2008 | |

| EN 10132-4:2000 | |

| DIN 17200 | |

| BS 970 - BS 5867 | |

| C60E EN 10083-2 | C60E AM FCE | |

|---|---|---|

| EN 10083-2:2006 | C60E | C60E |

| EN 10084:2008 | ||

| EN 10132-4:2000 | ||

| DIN 17200 | Ck60 | |

| BS 970 - BS 5867 | 070M60 | |

| C67S AM FCE | |

|---|---|

| EN 10083-2:2006 | |

| EN 10084:2008 | |

| EN 10132-4:2000 | C67S |

| DIN 17200 | Ck67 |

| BS 970 - BS 5867 | CS70 |

| C75S AM FCE | |

|---|---|

| EN 10083-2:2006 | |

| EN 10084:2008 | |

| EN 10132-4:2000 | C75S |

| DIN 17200 | Ck75 |

| BS 970 - BS 5867 | CS80 |

Other dimensions may be available after prior agreement.

| Thickness (mm) | 16MnCr5 EN 10084, 16MnCr5 AM FCE | C22E EN 10083-2 | C35E EN 10083-2, C35E AM FCE, C40E EN 10083-2, C40E AM FCE, C45E EN 10083-2, C45E AM FCE, C50E EN 10083-2, C50E AM FCE | C55E EN 10083-2, C60E EN 10083-2, C60E AM FCE, C67S AM FCE | C75S AM FCE | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Min width | Max width | Min width | Max width | Min width | Max width | Min width | Max width | Min width | Max width | |

| 2.00 ≤ th < 2.25 | 800 | 1350 | 800 | 1500 | 1000 | 1380 | 1000 | 1380 | 1000 | 1350 |

| 2.25 ≤ th < 2.50 | 1460 | 1450 | 1450 | 1450 | ||||||

| 2.50 ≤ th < 8.00 | 1550 | 1540 | 1490 | 1490 | ||||||

| 8.00 ≤ th < 12.00 | 1400 | 1400 | - | - | ||||||

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 2.00 ≤ th < 2.25 | 800 | 1350 |

| 2.25 ≤ th < 2.50 | 1460 | |

| 2.50 ≤ th < 8.00 | 1550 | |

| 8.00 ≤ th < 12.00 | ||

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 2.00 ≤ th < 2.25 | 800 | 1350 |

| 2.25 ≤ th < 2.50 | 1460 | |

| 2.50 ≤ th < 8.00 | 1550 | |

| 8.00 ≤ th < 12.00 | ||

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 2.00 ≤ th < 2.25 | 800 | 1500 |

| 2.25 ≤ th < 2.50 | ||

| 2.50 ≤ th < 8.00 | ||

| 8.00 ≤ th < 12.00 | ||

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 2.00 ≤ th < 2.25 | 1000 | 1380 |

| 2.25 ≤ th < 2.50 | 1450 | |

| 2.50 ≤ th < 8.00 | 1540 | |

| 8.00 ≤ th < 12.00 | 1400 | |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 2.00 ≤ th < 2.25 | 1000 | 1380 |

| 2.25 ≤ th < 2.50 | 1450 | |

| 2.50 ≤ th < 8.00 | 1540 | |

| 8.00 ≤ th < 12.00 | 1400 | |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 2.00 ≤ th < 2.25 | 1000 | 1380 |

| 2.25 ≤ th < 2.50 | 1450 | |

| 2.50 ≤ th < 8.00 | 1540 | |

| 8.00 ≤ th < 12.00 | 1400 | |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 2.00 ≤ th < 2.25 | 1000 | 1380 |

| 2.25 ≤ th < 2.50 | 1450 | |

| 2.50 ≤ th < 8.00 | 1540 | |

| 8.00 ≤ th < 12.00 | 1400 | |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 2.00 ≤ th < 2.25 | 1000 | 1380 |

| 2.25 ≤ th < 2.50 | 1450 | |

| 2.50 ≤ th < 8.00 | 1540 | |

| 8.00 ≤ th < 12.00 | 1400 | |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 2.00 ≤ th < 2.25 | 1000 | 1380 |

| 2.25 ≤ th < 2.50 | 1450 | |

| 2.50 ≤ th < 8.00 | 1540 | |

| 8.00 ≤ th < 12.00 | 1400 | |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 2.00 ≤ th < 2.25 | 1000 | 1380 |

| 2.25 ≤ th < 2.50 | 1450 | |

| 2.50 ≤ th < 8.00 | 1540 | |

| 8.00 ≤ th < 12.00 | 1400 | |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 2.00 ≤ th < 2.25 | 1000 | 1380 |

| 2.25 ≤ th < 2.50 | 1450 | |

| 2.50 ≤ th < 8.00 | 1540 | |

| 8.00 ≤ th < 12.00 | 1400 | |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 2.00 ≤ th < 2.25 | 1000 | 1380 |

| 2.25 ≤ th < 2.50 | 1450 | |

| 2.50 ≤ th < 8.00 | 1490 | |

| 8.00 ≤ th < 12.00 | 1400 | |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 2.00 ≤ th < 2.25 | 1000 | 1380 |

| 2.25 ≤ th < 2.50 | 1450 | |

| 2.50 ≤ th < 8.00 | 1490 | |

| 8.00 ≤ th < 12.00 | 1400 | |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 2.00 ≤ th < 2.25 | 1000 | 1380 |

| 2.25 ≤ th < 2.50 | 1450 | |

| 2.50 ≤ th < 8.00 | 1490 | |

| 8.00 ≤ th < 12.00 | 1400 | |

Since these grades will undergo re-rolling or heat treatment, we cannot guarantee their mechanical properties when delivered. Please contact us for further information on this subject.

| Notes | C (%) | Mn (%) | P (%) | S (%) | Si (%) | Al (%) | Cr (%) | Ni (%) | Mo (%) | N (%) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 16MnCr5 EN 10084 | 0.14 - 0.19 | 1.00 - 1.30 | ≤ 0.025 | ≤ 0.035 | ≤ 0.40 | - | 0.80 - 1.10 | - | - | - | |

| 16MnCr5 AM FCE | 0.140 - 0.170 | 1.00 - 1.15 | ≤ 0.020 | ≤ 0.005 | ≤ 0.10 | 0.020 - 0.045 | 0.85 - 0.95 | ≤ 0.10 | ≤ 0.020 | 0.004 - 0.008 | |

| C22E EN 10083-2 | 1 | 0.170 - 0.240 | 0.40 - 0.70 | ≤ 0.030 | ≤ 0.035 | ≤ 0.40 | - | ≤ 0.40 | ≤ 0.40 | ≤ 0.10 | - |

| C35E EN 10083-2 | 1 | 0.32 - 0.39 | 0.50 - 0.80 | ≤ 0.030 | ≤ 0.035 | ≤ 0.40 | - | ≤ 0.40 | ≤ 0.40 | ≤ 0.10 | - |

| C35E AM FCE | 1 | 0.340 - 0.390 | 0.60 - 0.80 | ≤ 0.025 | ≤ 0.005 | 0.15 - 0.35 | 0.010 - 0.030 | 0.20 - 0.35 | ≤ 0.10 | ≤ 0.08 | - |

| C40E EN 10083-2 | 1 | 0.37 - 0.44 | 0.50 - 0.80 | ≤ 0.030 | ≤ 0.035 | ≤ 0.40 | - | ≤ 0.40 | ≤ 0.40 | ≤ 0.10 | - |

| C40E AM FCE | 1 | 0.370 - 0.420 | 0.60 - 0.75 | ≤ 0.025 | ≤ 0.005 | 0.15 - 0.25 | 0.010 - 0.030 | 0.20 - 0.35 | ≤ 0.10 | ≤ 0.08 | - |

| C45E EN 10083-2 | 1 | 0.42 - 0.50 | 0.50 - 0.80 | ≤ 0.030 | ≤ 0.035 | ≤ 0.40 | - | ≤ 0.40 | ≤ 0.40 | ≤ 0.10 | - |

| C45E AM FCE | 1 | 0.420 - 0.480 | 0.60 - 0.75 | ≤ 0.025 | ≤ 0.005 | 0.15 - 0.25 | 0.010 - 0.030 | 0.20 - 0.30 | ≤ 0.10 | ≤ 0.08 | - |

| C50E EN 10083-2 | 1 | 0.47 - 0.55 | 0.60 - 0.90 | ≤ 0.030 | ≤ 0.035 | ≤ 0.40 | - | ≤ 0.40 | ≤ 0.40 | ≤ 0.10 | - |

| C50E AM FCE | 1 | 0.470 - 0.520 | 0.60 - 0.75 | ≤ 0.025 | ≤ 0.005 | 0.15 - 0.25 | 0.010 - 0.030 | 0.20 - 0.30 | ≤ 0.10 | ≤ 0.08 | - |

| C55E EN 10083-2 | 1 | 0.52 - 0.60 | 0.60 - 0.90 | ≤ 0.030 | ≤ 0.035 | ≤ 0.40 | - | ≤ 0.40 | ≤ 0.40 | ≤ 0.10 | - |

| C60E EN 10083-2 | 1 | 0.57 - 0.65 | 0.60 - 0.90 | ≤ 0.030 | ≤ 0.035 | ≤ 0.40 | - | ≤ 0.40 | ≤ 0.40 | ≤ 0.10 | - |

| C60E AM FCE | 1 | 0.570 - 0.650 | 0.60 - 0.75 | ≤ 0.025 | ≤ 0.005 | 0.15 - 0.25 | 0.010 - 0.030 | 0.20 - 0.30 | ≤ 0.10 | ≤ 0.08 | - |

| C67S AM FCE | 0.650 - 0.730 | 0.60 - 0.75 | ≤ 0.025 | ≤ 0.005 | 0.15 - 0.25 | 0.010 - 0.030 | 0.20 - 0.30 | ≤ 0.10 | ≤ 0.08 | - | |

| C75S AM FCE | 0.700 - 0.800 | 0.60 - 0.75 | ≤ 0.025 | ≤ 0.005 | 0.15 - 0.25 | ≤ 0.010 | 0.20 - 0.30 | ≤ 0.10 | ≤ 0.08 | - |

Values in bold: tighter than the standard

1. The sum of the percentages by mass of the three elements chromium, nickel and molybdenum shall not exceed 0.63%.

| Notes | 16MnCr5 EN 10084 | 16MnCr5 AM FCE | |

|---|---|---|---|

| C (%) | 0.14 - 0.19 | 0.140 - 0.170 | |

| Mn (%) | 1.00 - 1.30 | 1.00 - 1.15 | |

| P (%) | ≤ 0.025 | ≤ 0.020 | |

| S (%) | ≤ 0.035 | ≤ 0.005 | |

| Si (%) | ≤ 0.40 | ≤ 0.10 | |

| Al (%) | - | 0.020 - 0.045 | |

| Cr (%) | 0.80 - 1.10 | 0.85 - 0.95 | |

| Ni (%) | - | ≤ 0.10 | |

| Mo (%) | - | ≤ 0.020 | |

| N (%) | - | 0.004 - 0.008 | |

Values in bold: tighter than the standard

| Notes | C22E EN 10083-2 | |

|---|---|---|

| C (%) | 1 | 0.170 - 0.240 |

| Mn (%) | 1 | 0.40 - 0.70 |

| P (%) | 1 | ≤ 0.030 |

| S (%) | 1 | ≤ 0.035 |

| Si (%) | 1 | ≤ 0.40 |

| Al (%) | 1 | - |

| Cr (%) | 1 | ≤ 0.40 |

| Ni (%) | 1 | ≤ 0.40 |

| Mo (%) | 1 | ≤ 0.10 |

| N (%) | 1 | - |

1. The sum of the percentages by mass of the three elements chromium, nickel and molybdenum shall not exceed 0.63%.

| Notes | C35E EN 10083-2 | C35E AM FCE | |

|---|---|---|---|

| C (%) | 1 | 0.32 - 0.39 | 0.340 - 0.390 |

| Mn (%) | 1 | 0.50 - 0.80 | 0.60 - 0.80 |

| P (%) | 1 | ≤ 0.030 | ≤ 0.025 |

| S (%) | 1 | ≤ 0.035 | ≤ 0.005 |

| Si (%) | 1 | ≤ 0.40 | 0.15 - 0.35 |

| Al (%) | 1 | - | 0.010 - 0.030 |

| Cr (%) | 1 | ≤ 0.40 | 0.20 - 0.35 |

| Ni (%) | 1 | ≤ 0.40 | ≤ 0.10 |

| Mo (%) | 1 | ≤ 0.10 | ≤ 0.08 |

| N (%) | 1 | - | - |

Values in bold: tighter than the standard

1. The sum of the percentages by mass of the three elements chromium, nickel and molybdenum shall not exceed 0.63%.

| Notes | C40E EN 10083-2 | C40E AM FCE | |

|---|---|---|---|

| C (%) | 1 | 0.37 - 0.44 | 0.370 - 0.420 |

| Mn (%) | 1 | 0.50 - 0.80 | 0.60 - 0.75 |

| P (%) | 1 | ≤ 0.030 | ≤ 0.025 |

| S (%) | 1 | ≤ 0.035 | ≤ 0.005 |

| Si (%) | 1 | ≤ 0.40 | 0.15 - 0.25 |

| Al (%) | 1 | - | 0.010 - 0.030 |

| Cr (%) | 1 | ≤ 0.40 | 0.20 - 0.35 |

| Ni (%) | 1 | ≤ 0.40 | ≤ 0.10 |

| Mo (%) | 1 | ≤ 0.10 | ≤ 0.08 |

| N (%) | 1 | - | - |

Values in bold: tighter than the standard

1. The sum of the percentages by mass of the three elements chromium, nickel and molybdenum shall not exceed 0.63%.

| Notes | C45E EN 10083-2 | C45E AM FCE | |

|---|---|---|---|

| C (%) | 1 | 0.42 - 0.50 | 0.420 - 0.480 |

| Mn (%) | 1 | 0.50 - 0.80 | 0.60 - 0.75 |

| P (%) | 1 | ≤ 0.030 | ≤ 0.025 |

| S (%) | 1 | ≤ 0.035 | ≤ 0.005 |

| Si (%) | 1 | ≤ 0.40 | 0.15 - 0.25 |

| Al (%) | 1 | - | 0.010 - 0.030 |

| Cr (%) | 1 | ≤ 0.40 | 0.20 - 0.30 |

| Ni (%) | 1 | ≤ 0.40 | ≤ 0.10 |

| Mo (%) | 1 | ≤ 0.10 | ≤ 0.08 |

| N (%) | 1 | - | - |

Values in bold: tighter than the standard

1. The sum of the percentages by mass of the three elements chromium, nickel and molybdenum shall not exceed 0.63%.

| Notes | C50E EN 10083-2 | C50E AM FCE | |

|---|---|---|---|

| C (%) | 1 | 0.47 - 0.55 | 0.470 - 0.520 |

| Mn (%) | 1 | 0.60 - 0.90 | 0.60 - 0.75 |

| P (%) | 1 | ≤ 0.030 | ≤ 0.025 |

| S (%) | 1 | ≤ 0.035 | ≤ 0.005 |

| Si (%) | 1 | ≤ 0.40 | 0.15 - 0.25 |

| Al (%) | 1 | - | 0.010 - 0.030 |

| Cr (%) | 1 | ≤ 0.40 | 0.20 - 0.30 |

| Ni (%) | 1 | ≤ 0.40 | ≤ 0.10 |

| Mo (%) | 1 | ≤ 0.10 | ≤ 0.08 |

| N (%) | 1 | - | - |

Values in bold: tighter than the standard

1. The sum of the percentages by mass of the three elements chromium, nickel and molybdenum shall not exceed 0.63%.

| Notes | C55E EN 10083-2 | |

|---|---|---|

| C (%) | 1 | 0.52 - 0.60 |

| Mn (%) | 1 | 0.60 - 0.90 |

| P (%) | 1 | ≤ 0.030 |

| S (%) | 1 | ≤ 0.035 |

| Si (%) | 1 | ≤ 0.40 |

| Al (%) | 1 | - |

| Cr (%) | 1 | ≤ 0.40 |

| Ni (%) | 1 | ≤ 0.40 |

| Mo (%) | 1 | ≤ 0.10 |

| N (%) | 1 | - |

1. The sum of the percentages by mass of the three elements chromium, nickel and molybdenum shall not exceed 0.63%.

| Notes | C60E EN 10083-2 | C60E AM FCE | |

|---|---|---|---|

| C (%) | 1 | 0.57 - 0.65 | 0.570 - 0.650 |

| Mn (%) | 1 | 0.60 - 0.90 | 0.60 - 0.75 |

| P (%) | 1 | ≤ 0.030 | ≤ 0.025 |

| S (%) | 1 | ≤ 0.035 | ≤ 0.005 |

| Si (%) | 1 | ≤ 0.40 | 0.15 - 0.25 |

| Al (%) | 1 | - | 0.010 - 0.030 |

| Cr (%) | 1 | ≤ 0.40 | 0.20 - 0.30 |

| Ni (%) | 1 | ≤ 0.40 | ≤ 0.10 |

| Mo (%) | 1 | ≤ 0.10 | ≤ 0.08 |

| N (%) | 1 | - | - |

Values in bold: tighter than the standard

1. The sum of the percentages by mass of the three elements chromium, nickel and molybdenum shall not exceed 0.63%.

| Notes | C67S AM FCE | |

|---|---|---|

| C (%) | 0.650 - 0.730 | |

| Mn (%) | 0.60 - 0.75 | |

| P (%) | ≤ 0.025 | |

| S (%) | ≤ 0.005 | |

| Si (%) | 0.15 - 0.25 | |

| Al (%) | 0.010 - 0.030 | |

| Cr (%) | 0.20 - 0.30 | |

| Ni (%) | ≤ 0.10 | |

| Mo (%) | ≤ 0.08 | |

| N (%) | - | |

Values in bold: tighter than the standard

| Notes | C75S AM FCE | |

|---|---|---|

| C (%) | 0.700 - 0.800 | |

| Mn (%) | 0.60 - 0.75 | |

| P (%) | ≤ 0.025 | |

| S (%) | ≤ 0.005 | |

| Si (%) | 0.15 - 0.25 | |

| Al (%) | ≤ 0.010 | |

| Cr (%) | 0.20 - 0.30 | |

| Ni (%) | ≤ 0.10 | |

| Mo (%) | ≤ 0.08 | |

| N (%) | - | |

Values in bold: tighter than the standard

Values in bold: tighter than the standard

1. The sum of the percentages by mass of the three elements chromium, nickel and molybdenum shall not exceed 0.63%.

Any questions?

Ask them via our contact form on

https://industry.arcelormittal.com/getintouch

All details provided in the ArcelorMittal Flat Carbon Europe S.A. catalogue are for information purposes only. ArcelorMittal Flat Carbon Europe S.A. reserves the right to change its product range at any time without prior notice.

Download

Download