In order to offer you the best possible experience, we suggest that you accept the deposit and reading of cookies and the use of technology necessary for their proper functioning:

These sheets are particularly suitable for manufacturing complex parts or for improving productivity when parts are to be produced on a small scale.

The Amstrong® Laser sheet range comprises hot rolled steel grades developed for applications using computer-controlled thermal and mechanical cutting equipment (laser, plasma etc). The sheets are cut to length from ArcelorMittal coils for laser applications on certified lines that are able to reduce internal stresses and improve flatness before, during and after cutting.

All these grades are designed to:

Amstrong® Laser sheets are virtually free of internal stresses and can therefore be used to produce sheets with guaranteed flatness before, during and after cutting.

These sheets are particularly suitable for manufacturing complex parts or for improving productivity.

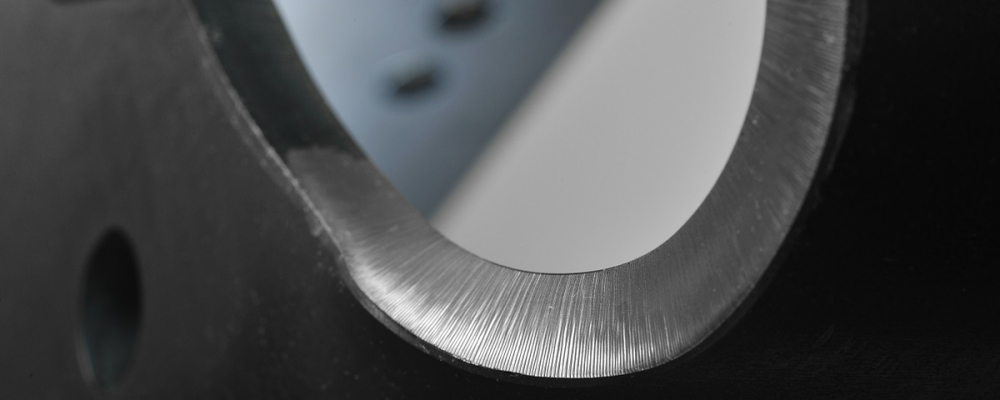

Laser cutting speed largely depends on surface homogeneity and reflectivity. To improve productivity for our clients, ArcelorMittal has developed several surface finishes compatible with laser cutting:

With the ArcelorMittal steels used to produce these sheets for laser cutting applications, excellent weldability is expected.

These sheets may be delivered from coils produced in the different grades shown below.

| Coils for laser cutting applications | EN 10025-2:2004 | EN 10149-2:2013 | EN 10111:2008 | Old brand names | |

|---|---|---|---|---|---|

| Amstrong® 320MC Laser | Amstrong® 320MC CLAS AM FCE | S315MC | |||

| Amstrong® 360MC Laser | Amstrong® 360MC CLAS AM FCE | S355MC | |||

| Amstrong® 420MC Laser | Amstrong® 420MC CLAS AM FCE | S420MC | |||

| Amstrong® 500MC Laser | Amstrong® 500MC CLAS AM FCE | S500MC |

| Amstrong® 320MC Laser | |

|---|---|

| Coils for laser cutting applications | Amstrong® 320MC CLAS AM FCE |

| EN 10025-2:2004 | |

| EN 10149-2:2013 | S315MC |

| EN 10111:2008 | |

| Amstrong® 360MC Laser | |

|---|---|

| Coils for laser cutting applications | Amstrong® 360MC CLAS AM FCE |

| EN 10025-2:2004 | |

| EN 10149-2:2013 | S355MC |

| EN 10111:2008 | |

| Amstrong® 420MC Laser | |

|---|---|

| Coils for laser cutting applications | Amstrong® 420MC CLAS AM FCE |

| EN 10025-2:2004 | |

| EN 10149-2:2013 | S420MC |

| EN 10111:2008 | |

| Amstrong® 500MC Laser | |

|---|---|

| Coils for laser cutting applications | Amstrong® 500MC CLAS AM FCE |

| EN 10025-2:2004 | |

| EN 10149-2:2013 | S500MC |

| EN 10111:2008 | |

| Coils for laser cutting applications | EN 10025-2:2004 | EN 10149-2:2013 | EN 10111:2008 | Old brand names | |

|---|---|---|---|---|---|

| S200 Laser | S200 CLAS AM FCE | DD12 | |||

| S240 Laser | S240 CLAS AM FCE | S235JR/J0 | |||

| S275 Laser | S275 CLAS AM FCE | S275JR/J0 | |||

| S355 Laser | S355 CLAS AM FCE | S355JR/J0 |

| S200 Laser | |

|---|---|

| Coils for laser cutting applications | S200 CLAS AM FCE |

| EN 10025-2:2004 | |

| EN 10149-2:2013 | |

| EN 10111:2008 | DD12 |

| S240 Laser | |

|---|---|

| Coils for laser cutting applications | S240 CLAS AM FCE |

| EN 10025-2:2004 | S235JR/J0 |

| EN 10149-2:2013 | |

| EN 10111:2008 | |

| S275 Laser | |

|---|---|

| Coils for laser cutting applications | S275 CLAS AM FCE |

| EN 10025-2:2004 | S275JR/J0 |

| EN 10149-2:2013 | |

| EN 10111:2008 | |

| S355 Laser | |

|---|---|

| Coils for laser cutting applications | S355 CLAS AM FCE |

| EN 10025-2:2004 | S355JR/J0 |

| EN 10149-2:2013 | |

| EN 10111:2008 | |

Thickness tolerance

The consistent thickness and reduced internal stresses make it possible to operate laser cutting machines continuously by lowering the breakdown risk and the frequency of laser cutting head breakage. This allows the use of fully automated loading and discharging systems.

The following thickness tolerances (EN 10051:2010) are available: 1/2 or 1/3 for both mill finish and pickled steels.

Flatness tolerance

Two products are available, depending on the level of guarantee required:

All the types of guarantee available are summarised in the following table:

| Laser Classic | Laser Premium | |

|---|---|---|

| For sheets | Maximum deviation: the minimum value, depending on the circumstances, between 4 mm/m or 8 mm/2 m or 12 mm/3 m and the special tolerances in EN 10051:2010 | Maximum deviation: the minimum value, depending on the circumstances, between 3 mm/m or 6 mm/2 m or 9 mm/3 m and the special tolerances in EN 10051:2010 |

| On cut parts | Maximum deviation of 5 mm over a length of 1 m | Maximum deviation of 3 mm over a length of 1 m |

Dimension tables

Cut-to-length sheets will be produced from coils of steels for laser cutting applications (see data sheet A40) and/or from steels in the Amstrong® range (see data sheets A20 – A22). Since the dimensions available are linked to the cutting line, contact our commercial teams for further information on the sheets produced on the line in question.

See guarantees on coils in A20 – A22 – A40 data sheets

See guarantees on coils in A20 – A22 – A40 data sheets

Any questions?

Ask them via our contact form on

https://industry.arcelormittal.com/getintouch

All details provided in the ArcelorMittal Flat Carbon Europe S.A. catalogue are for information purposes only. ArcelorMittal Flat Carbon Europe S.A. reserves the right to change its product range at any time without prior notice.

Download

Download