In order to offer you the best possible experience, we suggest that you accept the deposit and reading of cookies and the use of technology necessary for their proper functioning:

A significant weight reduction can be achieved by using Amstrong® steels.

The lighter the trailer, the heavier the payload that can be transported.

Amstrong® steels are characterised by high ductility, controlled internal purity, fine grain structure and low carbon content.

On request, Amstrong® may be delivered with an improved surface finish on black hot-rolled product called MASC (Micro Adhesive Scale). Contact our commercial teams for further information.

Amstrong® steels combine:

With their high strength, they are an excellent choice when weight-saving is a priority, and are frequently used to replace structural steels.

High strength Amstrong® steels are used in a wide range of applications in transport (earth movers, trailers, agricultural and railroad machinery etc), profiling (racks etc) and building (cranes, safety barriers, light poles etc). Significant weight reductions can be achieved by using Amstrong® steels, especially for cranes and heavy vehicle trailers, thus allowing a larger payload.

| EN 10149-2:2013 | SEW 092:1990 | UNE 36090 | NF A 36-231:1992 | BS 1449/1 | ASTM A1011-12 | Old brand names | |

|---|---|---|---|---|---|---|---|

| Amstrong® 240MC | |||||||

| Amstrong® 280MC | QstE300TM | AE275HC | HR40 F30 | Soldur 280/Profilar 300/BSK 30 | |||

| S315MC EN 10149-2 | S315MC | ||||||

| Amstrong® 315MC | S315MC | QstE340TM | E315D | HSLAS-F Grade 45 class 2 | Soldur 320/Profilar 340/BSK 34/SPXE 340 | ||

| S355MC EN 10149-2 | S355MC | ||||||

| Amstrong® 355MC | S355MC | QstE380TM | AE340HC | E355D | HR43 F35 | HSLAS-F Grade 50 class 2 | Soldur 360/Profilar 380/BSK 38/SPXE 380 |

| Amstrong® 390MC | QstE420TM | AE390HC | HR46 F40 | Profilar 420/BSK 42/SPXE 420 | |||

| S420MC EN 10149-2 | S420MC | ||||||

| Amstrong® 420MC | S420MC | QstE460TM | AE440HC | E420D | HR50 F45 | HSLAS-F Grade 60 class 2 | Soldur 420/Profilar 460/BSK 46 |

| S460MC EN 10149-2 | S460MC | ||||||

| Amstrong® 460MC | S460MC | QstE500TM | AE490HC | HSLAS-F Grade 65 class 2 | Soldur 460/Profilar 500/BSK 50/SPXE 480 | ||

| S500MC EN 10149-2 | S500MC | ||||||

| Amstrong® 500MC | S500MC | QstE550TM | E490D | HSLAS-F Grade 70 class 2 | Soldur 500/Profilar 550/BSK 55/SPXE 530 | ||

| S550MC EN 10149-2 | S550MC | ||||||

| Amstrong® 550MC | S550MC | (QstE600TM) | E560D | HR60 F55 | HSLAS-F Grade 80 class 2 | Soldur 550 | |

| S600MC EN 10149-2 | S600MC | (QstE650TM) | |||||

| Amstrong® 600MC | S600MC | (QstE650TM) |

Grades in italics: not included in the standard

() Closest grade as no fully equivalent grade exists.

| Amstrong® 240MC | |

|---|---|

| EN 10149-2:2013 | |

| SEW 092:1990 | |

| UNE 36090 | |

| NF A 36-231:1992 | |

| BS 1449/1 | |

| ASTM A1011-12 | |

| Old brand names | |

Grades in italics: not included in the standard

| Amstrong® 280MC | |

|---|---|

| EN 10149-2:2013 | |

| SEW 092:1990 | QstE300TM |

| UNE 36090 | AE275HC |

| NF A 36-231:1992 | |

| BS 1449/1 | HR40 F30 |

| ASTM A1011-12 | |

| Old brand names | Soldur 280/Profilar 300/BSK 30 |

Grades in italics: not included in the standard

| S315MC EN 10149-2 | |

|---|---|

| EN 10149-2:2013 | S315MC |

| SEW 092:1990 | |

| UNE 36090 | |

| NF A 36-231:1992 | |

| BS 1449/1 | |

| ASTM A1011-12 | |

| Old brand names | |

| Amstrong® 315MC | |

|---|---|

| EN 10149-2:2013 | S315MC |

| SEW 092:1990 | QstE340TM |

| UNE 36090 | |

| NF A 36-231:1992 | E315D |

| BS 1449/1 | |

| ASTM A1011-12 | HSLAS-F Grade 45 class 2 |

| Old brand names | Soldur 320/Profilar 340/BSK 34/SPXE 340 |

| S355MC EN 10149-2 | |

|---|---|

| EN 10149-2:2013 | S355MC |

| SEW 092:1990 | |

| UNE 36090 | |

| NF A 36-231:1992 | |

| BS 1449/1 | |

| ASTM A1011-12 | |

| Old brand names | |

| Amstrong® 355MC | |

|---|---|

| EN 10149-2:2013 | S355MC |

| SEW 092:1990 | QstE380TM |

| UNE 36090 | AE340HC |

| NF A 36-231:1992 | E355D |

| BS 1449/1 | HR43 F35 |

| ASTM A1011-12 | HSLAS-F Grade 50 class 2 |

| Old brand names | Soldur 360/Profilar 380/BSK 38/SPXE 380 |

| Amstrong® 390MC | |

|---|---|

| EN 10149-2:2013 | |

| SEW 092:1990 | QstE420TM |

| UNE 36090 | AE390HC |

| NF A 36-231:1992 | |

| BS 1449/1 | HR46 F40 |

| ASTM A1011-12 | |

| Old brand names | Profilar 420/BSK 42/SPXE 420 |

Grades in italics: not included in the standard

| S420MC EN 10149-2 | |

|---|---|

| EN 10149-2:2013 | S420MC |

| SEW 092:1990 | |

| UNE 36090 | |

| NF A 36-231:1992 | |

| BS 1449/1 | |

| ASTM A1011-12 | |

| Old brand names | |

| Amstrong® 420MC | |

|---|---|

| EN 10149-2:2013 | S420MC |

| SEW 092:1990 | QstE460TM |

| UNE 36090 | AE440HC |

| NF A 36-231:1992 | E420D |

| BS 1449/1 | HR50 F45 |

| ASTM A1011-12 | HSLAS-F Grade 60 class 2 |

| Old brand names | Soldur 420/Profilar 460/BSK 46 |

| S460MC EN 10149-2 | |

|---|---|

| EN 10149-2:2013 | S460MC |

| SEW 092:1990 | |

| UNE 36090 | |

| NF A 36-231:1992 | |

| BS 1449/1 | |

| ASTM A1011-12 | |

| Old brand names | |

| Amstrong® 460MC | |

|---|---|

| EN 10149-2:2013 | S460MC |

| SEW 092:1990 | QstE500TM |

| UNE 36090 | AE490HC |

| NF A 36-231:1992 | |

| BS 1449/1 | |

| ASTM A1011-12 | HSLAS-F Grade 65 class 2 |

| Old brand names | Soldur 460/Profilar 500/BSK 50/SPXE 480 |

| S500MC EN 10149-2 | |

|---|---|

| EN 10149-2:2013 | S500MC |

| SEW 092:1990 | |

| UNE 36090 | |

| NF A 36-231:1992 | |

| BS 1449/1 | |

| ASTM A1011-12 | |

| Old brand names | |

| Amstrong® 500MC | |

|---|---|

| EN 10149-2:2013 | S500MC |

| SEW 092:1990 | QstE550TM |

| UNE 36090 | |

| NF A 36-231:1992 | E490D |

| BS 1449/1 | |

| ASTM A1011-12 | HSLAS-F Grade 70 class 2 |

| Old brand names | Soldur 500/Profilar 550/BSK 55/SPXE 530 |

| S550MC EN 10149-2 | |

|---|---|

| EN 10149-2:2013 | S550MC |

| SEW 092:1990 | |

| UNE 36090 | |

| NF A 36-231:1992 | |

| BS 1449/1 | |

| ASTM A1011-12 | |

| Old brand names | |

| Amstrong® 550MC | |

|---|---|

| EN 10149-2:2013 | S550MC |

| SEW 092:1990 | (QstE600TM) |

| UNE 36090 | |

| NF A 36-231:1992 | E560D |

| BS 1449/1 | HR60 F55 |

| ASTM A1011-12 | HSLAS-F Grade 80 class 2 |

| Old brand names | Soldur 550 |

() Closest grade as no fully equivalent grade exists.

| S600MC EN 10149-2 | |

|---|---|

| EN 10149-2:2013 | S600MC |

| SEW 092:1990 | (QstE650TM) |

| UNE 36090 | |

| NF A 36-231:1992 | |

| BS 1449/1 | |

| ASTM A1011-12 | |

| Old brand names | |

() Closest grade as no fully equivalent grade exists.

| Amstrong® 600MC | |

|---|---|

| EN 10149-2:2013 | S600MC |

| SEW 092:1990 | (QstE650TM) |

| UNE 36090 | |

| NF A 36-231:1992 | |

| BS 1449/1 | |

| ASTM A1011-12 | |

| Old brand names | |

() Closest grade as no fully equivalent grade exists.

Grades in italics: not included in the standard

() Closest grade as no fully equivalent grade exists.

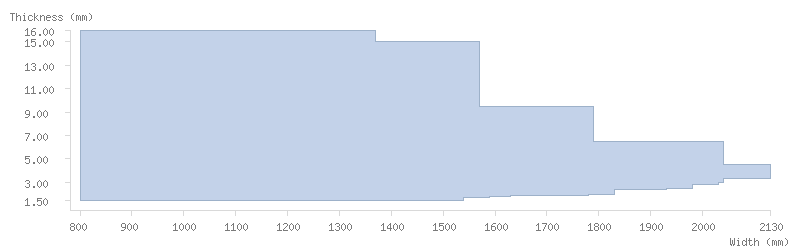

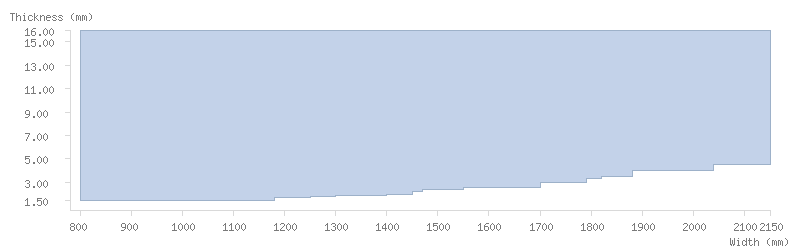

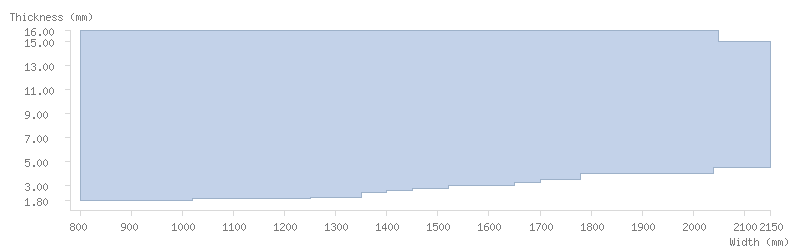

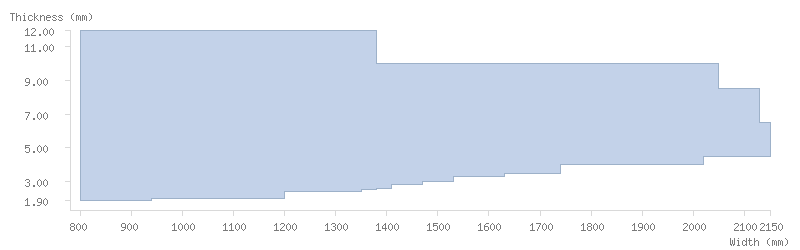

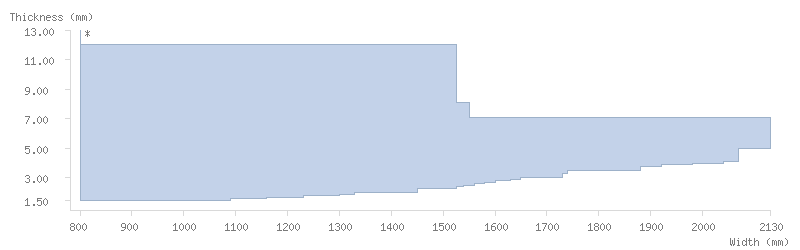

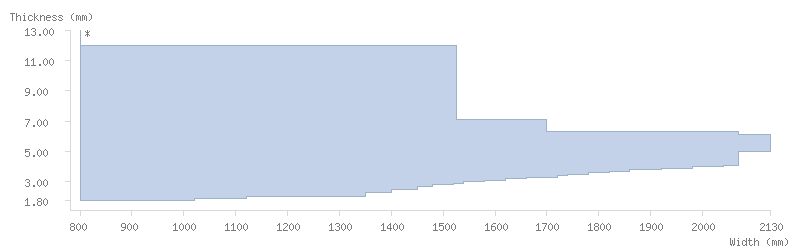

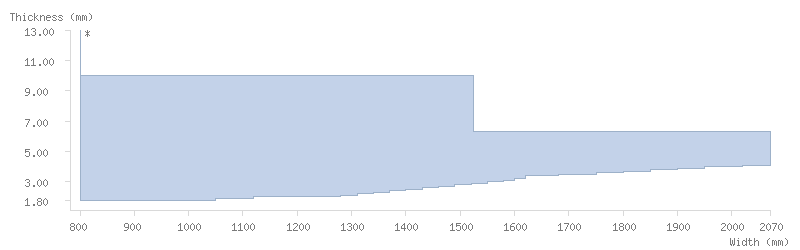

| Thickness (mm) | Min width | Amstrong® 240MC | Amstrong® 280MC | S315MC EN 10149-2, Amstrong® 315MC | S355MC EN 10149-2, Amstrong® 355MC | Amstrong® 390MC |

|---|---|---|---|---|---|---|

| Max width | Max width | Max width | Max width | Max width | ||

| 1.50 ≤ th < 1.60 | 800 | 1540 | 1350 | 1300 | 1180 | - |

| 1.60 ≤ th < 1.70 | ||||||

| 1.70 ≤ th < 1.80 | 1590 | 1450 | 1450 | 1250 | 1020 | |

| 1.80 ≤ th < 1.90 | 1630 | 1300 | 1200 | |||

| 1.90 ≤ th < 2.00 | 1780 | 1500 | 1540 | 1400 | 1250 | |

| 2.00 ≤ th < 2.20 | 1830 | 1600 | 1600 | 1450 | 1350 | |

| 2.20 ≤ th < 2.40 | 1680 | 1470 | 1400 | |||

| 2.40 ≤ th < 2.50 | 1930 | 1800 | 1680 | 1550 | ||

| 2.50 ≤ th < 2.60 | 1980 | 1850 | 1740 | 1450 | ||

| 2.60 ≤ th < 2.80 | 1880 | 1700 | ||||

| 2.80 ≤ th < 3.00 | 2030 | 1820 | 1530 | |||

| 3.00 ≤ th < 3.30 | 2040 | 2030 | 2000 | 1790 | 1600 | |

| 3.30 ≤ th < 3.50 | 2130 | 2130 | 2030 | 1820 | 1650 | |

| 3.50 ≤ th < 4.00 | 2130 | 1880 | 1750 | |||

| 4.00 ≤ th < 4.50 | 2040 | 2040 | ||||

| 4.50 ≤ th < 5.50 | 2040 | 2150 | 2150 | |||

| 5.50 ≤ th < 6.00 | ||||||

| 6.00 ≤ th < 6.50 | 2030 | |||||

| 6.50 ≤ th < 8.50 | 1790 | |||||

| 8.50 ≤ th < 9.50 | ||||||

| 9.50 ≤ th < 10.00 | 1570 | |||||

| 10.00 ≤ th < 12.00 | 1700 | |||||

| 12.00 ≤ th < 13.00 | 1570 | |||||

| 13.00 ≤ th < 14.00 | ||||||

| 14.00 ≤ th < 15.00 | ||||||

| 15.00 ≤ th < 16.00 | 1370 | 1370 | 2050 | 1370 |

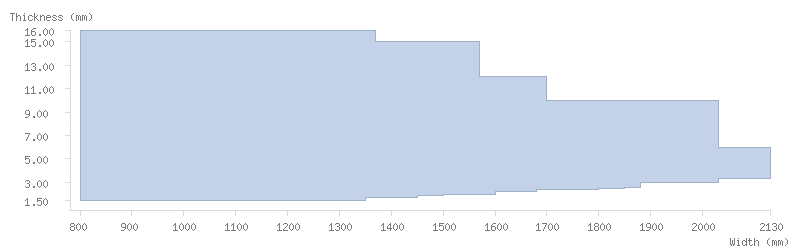

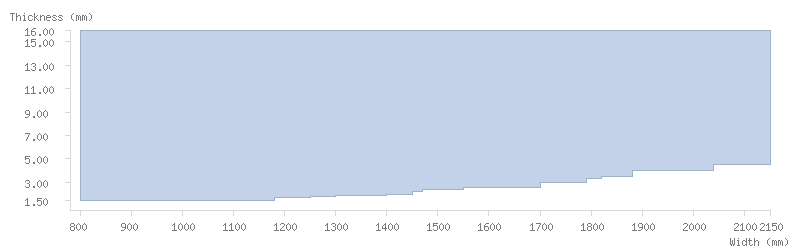

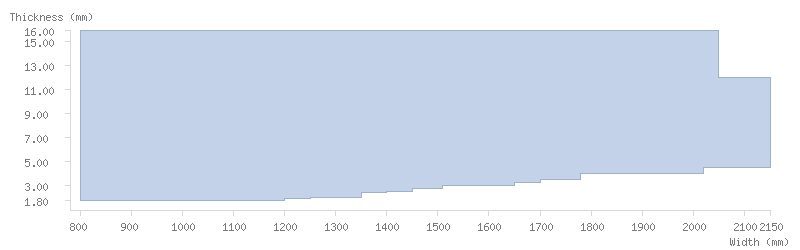

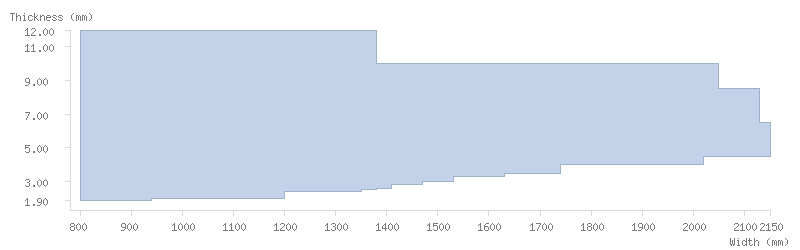

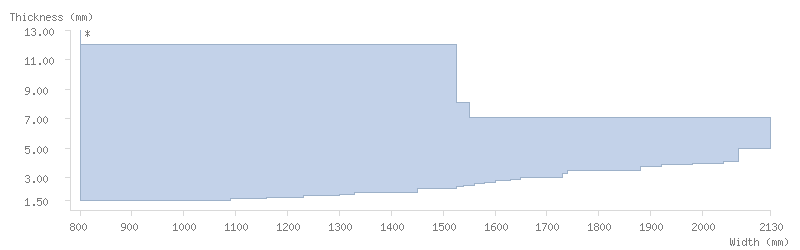

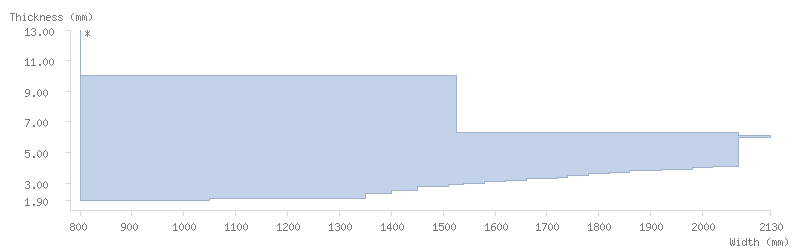

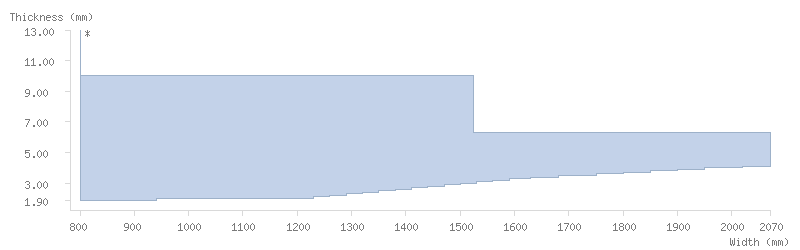

| Thickness (mm) | Min width | S420MC EN 10149-2, Amstrong® 420MC | S460MC EN 10149-2, Amstrong® 460MC | S500MC EN 10149-2, Amstrong® 500MC | S550MC EN 10149-2, Amstrong® 550MC | S600MC EN 10149-2, Amstrong® 600MC |

|---|---|---|---|---|---|---|

| Max width | Max width | Max width | Max width | Max width | ||

| 1.50 ≤ th < 1.60 | 800 | - | - | - | - | - |

| 1.60 ≤ th < 1.70 | ||||||

| 1.70 ≤ th < 1.80 | ||||||

| 1.80 ≤ th < 1.90 | 1020 | 1200 | 1050 | |||

| 1.90 ≤ th < 2.00 | 1250 | 1250 | 1120 | 940 | ||

| 2.00 ≤ th < 2.20 | 1350 | 1350 | 1280 | 1200 | 1100 | |

| 2.20 ≤ th < 2.40 | 1320 | 1170 | ||||

| 2.40 ≤ th < 2.50 | 1400 | 1400 | 1380 | 1350 | 1200 | |

| 2.50 ≤ th < 2.60 | 1450 | 1420 | 1380 | 1250 | ||

| 2.60 ≤ th < 2.80 | 1450 | 1460 | 1410 | 1340 | ||

| 2.80 ≤ th < 3.00 | 1520 | 1510 | 1520 | 1470 | ||

| 3.00 ≤ th < 3.30 | 1650 | 1650 | 1570 | 1530 | ||

| 3.30 ≤ th < 3.50 | 1700 | 1700 | 1650 | 1630 | ||

| 3.50 ≤ th < 4.00 | 1780 | 1780 | 1740 | 1740 | 1440 | |

| 4.00 ≤ th < 4.50 | 2040 | 2020 | 2020 | 2020 | 1540 | |

| 4.50 ≤ th < 5.50 | 2150 | 2150 | 2150 | 2150 | 1630 | |

| 5.50 ≤ th < 6.00 | 1830 | |||||

| 6.00 ≤ th < 6.50 | 2135 | |||||

| 6.50 ≤ th < 8.50 | 2130 | |||||

| 8.50 ≤ th < 9.50 | 2050 | 1980 | ||||

| 9.50 ≤ th < 10.00 | 1930 | |||||

| 10.00 ≤ th < 12.00 | 2130 | 1380 | - | |||

| 12.00 ≤ th < 13.00 | 2050 | - | ||||

| 13.00 ≤ th < 14.00 | - | |||||

| 14.00 ≤ th < 15.00 | ||||||

| 15.00 ≤ th < 16.00 | 2050 |

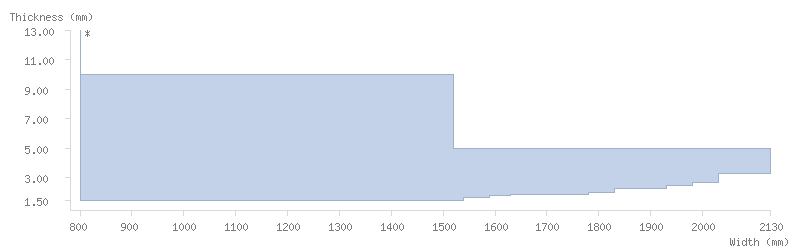

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1590 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.20 | 1830 | |

| 2.20 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1930 | |

| 2.50 ≤ th < 2.60 | 1980 | |

| 2.60 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | 2030 | |

| 3.00 ≤ th < 3.30 | 2040 | |

| 3.30 ≤ th < 3.50 | 2130 | |

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.50 | 2040 | |

| 5.50 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.50 | ||

| 6.50 ≤ th < 8.50 | 1790 | |

| 8.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | 1570 | |

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 | 1370 |

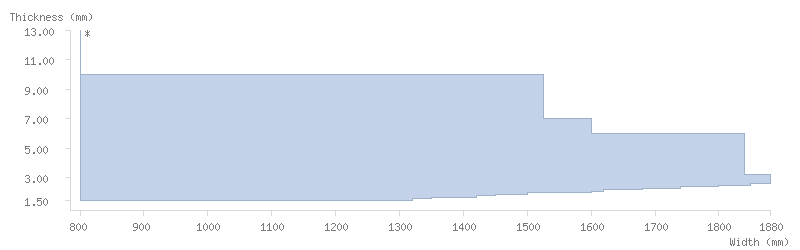

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1350 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1450 | |

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | 1500 | |

| 2.00 ≤ th < 2.20 | 1600 | |

| 2.20 ≤ th < 2.40 | 1680 | |

| 2.40 ≤ th < 2.50 | 1800 | |

| 2.50 ≤ th < 2.60 | 1850 | |

| 2.60 ≤ th < 2.80 | 1880 | |

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | 2030 | |

| 3.30 ≤ th < 3.50 | 2130 | |

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.50 | ||

| 5.50 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.50 | 2030 | |

| 6.50 ≤ th < 8.50 | ||

| 8.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | 1700 | |

| 12.00 ≤ th < 13.00 | 1570 | |

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 | 1370 |

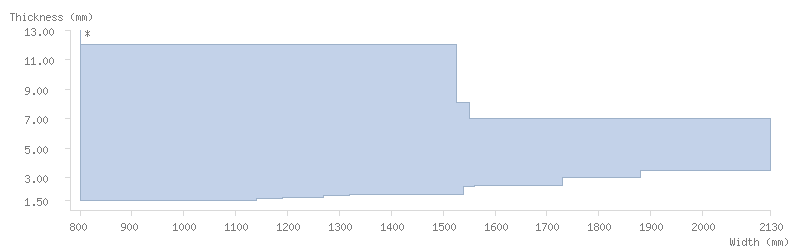

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1300 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1450 | |

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | 1540 | |

| 2.00 ≤ th < 2.20 | 1600 | |

| 2.20 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1680 | |

| 2.50 ≤ th < 2.60 | 1740 | |

| 2.60 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | 1820 | |

| 3.00 ≤ th < 3.30 | 2000 | |

| 3.30 ≤ th < 3.50 | 2030 | |

| 3.50 ≤ th < 4.00 | 2130 | |

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.50 | ||

| 5.50 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.50 | ||

| 6.50 ≤ th < 8.50 | ||

| 8.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 | 2050 |

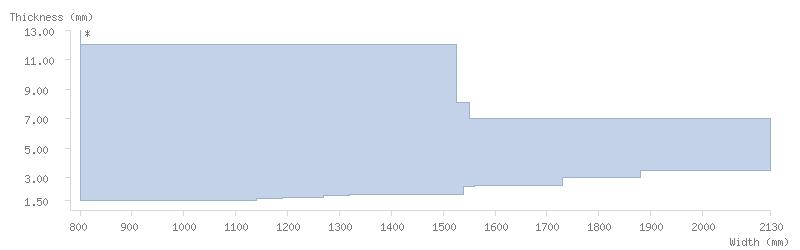

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1300 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1450 | |

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | 1540 | |

| 2.00 ≤ th < 2.20 | 1600 | |

| 2.20 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1680 | |

| 2.50 ≤ th < 2.60 | 1740 | |

| 2.60 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | 1820 | |

| 3.00 ≤ th < 3.30 | 2000 | |

| 3.30 ≤ th < 3.50 | 2030 | |

| 3.50 ≤ th < 4.00 | 2130 | |

| 4.00 ≤ th < 4.50 | ||

| 4.50 ≤ th < 5.50 | ||

| 5.50 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.50 | ||

| 6.50 ≤ th < 8.50 | ||

| 8.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 | 2050 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1180 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1250 | |

| 1.80 ≤ th < 1.90 | 1300 | |

| 1.90 ≤ th < 2.00 | 1400 | |

| 2.00 ≤ th < 2.20 | 1450 | |

| 2.20 ≤ th < 2.40 | 1470 | |

| 2.40 ≤ th < 2.50 | 1550 | |

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 2.80 | 1700 | |

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | 1790 | |

| 3.30 ≤ th < 3.50 | 1820 | |

| 3.50 ≤ th < 4.00 | 1880 | |

| 4.00 ≤ th < 4.50 | 2040 | |

| 4.50 ≤ th < 5.50 | 2150 | |

| 5.50 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.50 | ||

| 6.50 ≤ th < 8.50 | ||

| 8.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1180 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1250 | |

| 1.80 ≤ th < 1.90 | 1300 | |

| 1.90 ≤ th < 2.00 | 1400 | |

| 2.00 ≤ th < 2.20 | 1450 | |

| 2.20 ≤ th < 2.40 | 1470 | |

| 2.40 ≤ th < 2.50 | 1550 | |

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 2.80 | 1700 | |

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | 1790 | |

| 3.30 ≤ th < 3.50 | 1820 | |

| 3.50 ≤ th < 4.00 | 1880 | |

| 4.00 ≤ th < 4.50 | 2040 | |

| 4.50 ≤ th < 5.50 | 2150 | |

| 5.50 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.50 | ||

| 6.50 ≤ th < 8.50 | ||

| 8.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1020 | |

| 1.80 ≤ th < 1.90 | 1200 | |

| 1.90 ≤ th < 2.00 | 1250 | |

| 2.00 ≤ th < 2.20 | 1350 | |

| 2.20 ≤ th < 2.40 | 1400 | |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | 1450 | |

| 2.60 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | 1530 | |

| 3.00 ≤ th < 3.30 | 1600 | |

| 3.30 ≤ th < 3.50 | 1650 | |

| 3.50 ≤ th < 4.00 | 1750 | |

| 4.00 ≤ th < 4.50 | 2040 | |

| 4.50 ≤ th < 5.50 | 2150 | |

| 5.50 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.50 | ||

| 6.50 ≤ th < 8.50 | ||

| 8.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 | 1370 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | 1020 | |

| 1.90 ≤ th < 2.00 | 1250 | |

| 2.00 ≤ th < 2.20 | 1350 | |

| 2.20 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1400 | |

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 2.80 | 1450 | |

| 2.80 ≤ th < 3.00 | 1520 | |

| 3.00 ≤ th < 3.30 | 1650 | |

| 3.30 ≤ th < 3.50 | 1700 | |

| 3.50 ≤ th < 4.00 | 1780 | |

| 4.00 ≤ th < 4.50 | 2040 | |

| 4.50 ≤ th < 5.50 | 2150 | |

| 5.50 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.50 | ||

| 6.50 ≤ th < 8.50 | ||

| 8.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 | 2050 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | 1020 | |

| 1.90 ≤ th < 2.00 | 1250 | |

| 2.00 ≤ th < 2.20 | 1350 | |

| 2.20 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1400 | |

| 2.50 ≤ th < 2.60 | ||

| 2.60 ≤ th < 2.80 | 1450 | |

| 2.80 ≤ th < 3.00 | 1520 | |

| 3.00 ≤ th < 3.30 | 1650 | |

| 3.30 ≤ th < 3.50 | 1700 | |

| 3.50 ≤ th < 4.00 | 1780 | |

| 4.00 ≤ th < 4.50 | 2040 | |

| 4.50 ≤ th < 5.50 | 2150 | |

| 5.50 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.50 | ||

| 6.50 ≤ th < 8.50 | ||

| 8.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 | 2050 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | 1200 | |

| 1.90 ≤ th < 2.00 | 1250 | |

| 2.00 ≤ th < 2.20 | 1350 | |

| 2.20 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1400 | |

| 2.50 ≤ th < 2.60 | 1450 | |

| 2.60 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | 1510 | |

| 3.00 ≤ th < 3.30 | 1650 | |

| 3.30 ≤ th < 3.50 | 1700 | |

| 3.50 ≤ th < 4.00 | 1780 | |

| 4.00 ≤ th < 4.50 | 2020 | |

| 4.50 ≤ th < 5.50 | 2150 | |

| 5.50 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.50 | ||

| 6.50 ≤ th < 8.50 | ||

| 8.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | 2050 | |

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | 1200 | |

| 1.90 ≤ th < 2.00 | 1250 | |

| 2.00 ≤ th < 2.20 | 1350 | |

| 2.20 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1400 | |

| 2.50 ≤ th < 2.60 | 1450 | |

| 2.60 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | 1510 | |

| 3.00 ≤ th < 3.30 | 1650 | |

| 3.30 ≤ th < 3.50 | 1700 | |

| 3.50 ≤ th < 4.00 | 1780 | |

| 4.00 ≤ th < 4.50 | 2020 | |

| 4.50 ≤ th < 5.50 | 2150 | |

| 5.50 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.50 | ||

| 6.50 ≤ th < 8.50 | ||

| 8.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | 2050 | |

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | 1050 | |

| 1.90 ≤ th < 2.00 | 1120 | |

| 2.00 ≤ th < 2.20 | 1280 | |

| 2.20 ≤ th < 2.40 | 1320 | |

| 2.40 ≤ th < 2.50 | 1380 | |

| 2.50 ≤ th < 2.60 | 1420 | |

| 2.60 ≤ th < 2.80 | 1460 | |

| 2.80 ≤ th < 3.00 | 1520 | |

| 3.00 ≤ th < 3.30 | 1570 | |

| 3.30 ≤ th < 3.50 | 1650 | |

| 3.50 ≤ th < 4.00 | 1740 | |

| 4.00 ≤ th < 4.50 | 2020 | |

| 4.50 ≤ th < 5.50 | 2150 | |

| 5.50 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.50 | ||

| 6.50 ≤ th < 8.50 | ||

| 8.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | 2130 | |

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | - | |

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | 1050 | |

| 1.90 ≤ th < 2.00 | 1120 | |

| 2.00 ≤ th < 2.20 | 1280 | |

| 2.20 ≤ th < 2.40 | 1320 | |

| 2.40 ≤ th < 2.50 | 1380 | |

| 2.50 ≤ th < 2.60 | 1420 | |

| 2.60 ≤ th < 2.80 | 1460 | |

| 2.80 ≤ th < 3.00 | 1520 | |

| 3.00 ≤ th < 3.30 | 1570 | |

| 3.30 ≤ th < 3.50 | 1650 | |

| 3.50 ≤ th < 4.00 | 1740 | |

| 4.00 ≤ th < 4.50 | 2020 | |

| 4.50 ≤ th < 5.50 | 2150 | |

| 5.50 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.50 | ||

| 6.50 ≤ th < 8.50 | ||

| 8.50 ≤ th < 9.50 | ||

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | 2130 | |

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | - | |

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | 940 | |

| 2.00 ≤ th < 2.20 | 1200 | |

| 2.20 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1350 | |

| 2.50 ≤ th < 2.60 | 1380 | |

| 2.60 ≤ th < 2.80 | 1410 | |

| 2.80 ≤ th < 3.00 | 1470 | |

| 3.00 ≤ th < 3.30 | 1530 | |

| 3.30 ≤ th < 3.50 | 1630 | |

| 3.50 ≤ th < 4.00 | 1740 | |

| 4.00 ≤ th < 4.50 | 2020 | |

| 4.50 ≤ th < 5.50 | 2150 | |

| 5.50 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.50 | ||

| 6.50 ≤ th < 8.50 | 2130 | |

| 8.50 ≤ th < 9.50 | 2050 | |

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | 1380 | |

| 12.00 ≤ th < 13.00 | - | |

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | 940 | |

| 2.00 ≤ th < 2.20 | 1200 | |

| 2.20 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1350 | |

| 2.50 ≤ th < 2.60 | 1380 | |

| 2.60 ≤ th < 2.80 | 1410 | |

| 2.80 ≤ th < 3.00 | 1470 | |

| 3.00 ≤ th < 3.30 | 1530 | |

| 3.30 ≤ th < 3.50 | 1630 | |

| 3.50 ≤ th < 4.00 | 1740 | |

| 4.00 ≤ th < 4.50 | 2020 | |

| 4.50 ≤ th < 5.50 | 2150 | |

| 5.50 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.50 | ||

| 6.50 ≤ th < 8.50 | 2130 | |

| 8.50 ≤ th < 9.50 | 2050 | |

| 9.50 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | 1380 | |

| 12.00 ≤ th < 13.00 | - | |

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.20 | 1100 | |

| 2.20 ≤ th < 2.40 | 1170 | |

| 2.40 ≤ th < 2.50 | 1200 | |

| 2.50 ≤ th < 2.60 | 1250 | |

| 2.60 ≤ th < 2.80 | 1340 | |

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | 1440 | |

| 4.00 ≤ th < 4.50 | 1540 | |

| 4.50 ≤ th < 5.50 | 1630 | |

| 5.50 ≤ th < 6.00 | 1830 | |

| 6.00 ≤ th < 6.50 | 2135 | |

| 6.50 ≤ th < 8.50 | ||

| 8.50 ≤ th < 9.50 | 1980 | |

| 9.50 ≤ th < 10.00 | 1930 | |

| 10.00 ≤ th < 12.00 | - | |

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.20 | 1100 | |

| 2.20 ≤ th < 2.40 | 1170 | |

| 2.40 ≤ th < 2.50 | 1200 | |

| 2.50 ≤ th < 2.60 | 1250 | |

| 2.60 ≤ th < 2.80 | 1340 | |

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | 1440 | |

| 4.00 ≤ th < 4.50 | 1540 | |

| 4.50 ≤ th < 5.50 | 1630 | |

| 5.50 ≤ th < 6.00 | 1830 | |

| 6.00 ≤ th < 6.50 | 2135 | |

| 6.50 ≤ th < 8.50 | ||

| 8.50 ≤ th < 9.50 | 1980 | |

| 9.50 ≤ th < 10.00 | 1930 | |

| 10.00 ≤ th < 12.00 | - | |

| 12.00 ≤ th < 13.00 | ||

| 13.00 ≤ th < 14.00 | ||

| 14.00 ≤ th < 15.00 | ||

| 15.00 ≤ th < 16.00 |

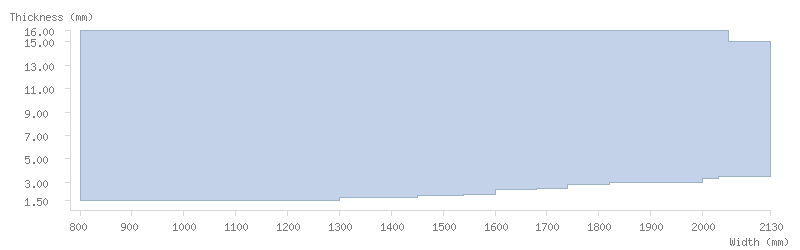

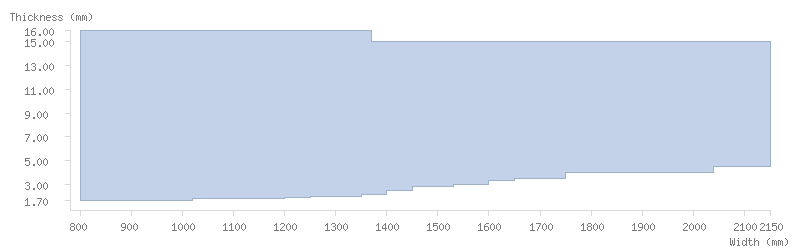

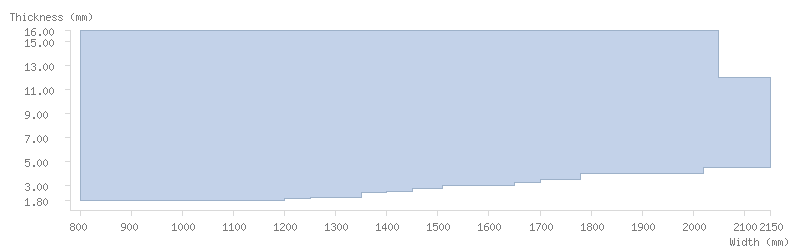

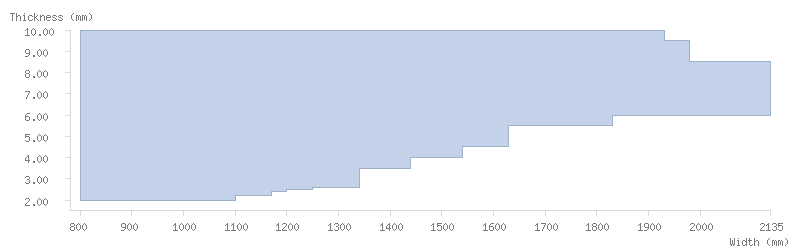

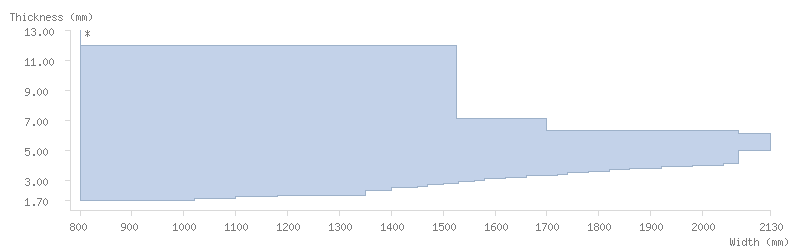

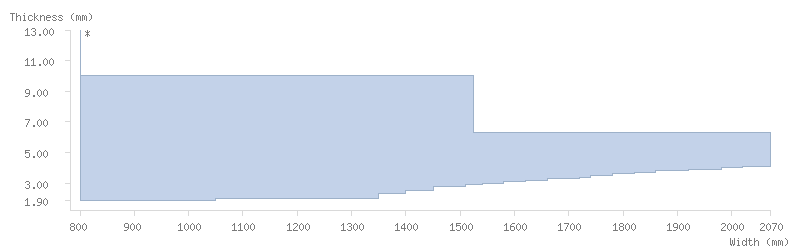

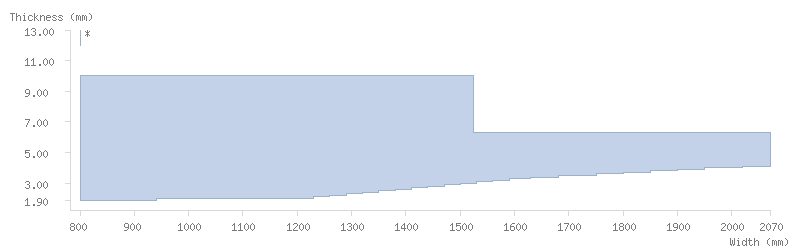

| Thickness (mm) | Min width | Amstrong® 240MC | Amstrong® 280MC | S315MC EN 10149-2, Amstrong® 315MC | S355MC EN 10149-2, Amstrong® 355MC | Amstrong® 390MC |

|---|---|---|---|---|---|---|

| Max width | Max width | Max width | Max width | Max width | ||

| 1.50 ≤ th < 1.60 | 800 | 1540 | 1320 | 1140 | 1090 | - |

| 1.60 ≤ th < 1.70 | 1350 | 1190 | 1160 | |||

| 1.70 ≤ th < 1.80 | 1590 | 1420 | 1270 | 1230 | 1020 | |

| 1.80 ≤ th < 1.90 | 1630 | 1450 | 1320 | 1300 | 1100 | |

| 1.90 ≤ th < 2.00 | 1780 | 1500 | 1540 | 1330 | 1180 | |

| 2.00 ≤ th < 2.10 | 1830 | 1600 | 1450 | 1350 | ||

| 2.10 ≤ th < 2.20 | 1620 | |||||

| 2.20 ≤ th < 2.30 | 1680 | |||||

| 2.30 ≤ th < 2.40 | 1930 | 1740 | 1525 | 1400 | ||

| 2.40 ≤ th < 2.50 | 1800 | 1560 | 1540 | |||

| 2.50 ≤ th < 2.60 | 1980 | 1850 | 1730 | 1560 | 1450 | |

| 2.60 ≤ th < 2.70 | 1880 | 1580 | 1470 | |||

| 2.70 ≤ th < 2.80 | 2030 | 1600 | 1500 | |||

| 2.80 ≤ th < 2.90 | 1630 | 1530 | ||||

| 2.90 ≤ th < 3.00 | 1650 | 1560 | ||||

| 3.00 ≤ th < 3.10 | 1880 | 1730 | 1580 | |||

| 3.10 ≤ th < 3.20 | 1620 | |||||

| 3.20 ≤ th < 3.30 | 1840 | 1660 | ||||

| 3.30 ≤ th < 3.40 | 2130 | 1740 | 1720 | |||

| 3.40 ≤ th < 3.50 | 1740 | |||||

| 3.50 ≤ th < 3.60 | 2130 | 1880 | 1780 | |||

| 3.60 ≤ th < 3.70 | 1820 | |||||

| 3.70 ≤ th < 3.80 | 1860 | |||||

| 3.80 ≤ th < 3.90 | 1920 | 1920 | ||||

| 3.90 ≤ th < 4.00 | 1980 | 1980 | ||||

| 4.00 ≤ th < 4.10 | 2040 | 2040 | ||||

| 4.10 ≤ th < 5.00 | 2070 | 2070 | ||||

| 5.00 ≤ th < 6.00 | 1520 | 2130 | 2130 | |||

| 6.00 ≤ th < 6.10 | 1600 | |||||

| 6.10 ≤ th < 6.30 | 2070 | |||||

| 6.30 ≤ th < 7.00 | 1700 | |||||

| 7.00 ≤ th < 7.10 | 1525 | 1550 | ||||

| 7.10 ≤ th < 8.00 | 1550 | 1525 | ||||

| 8.00 ≤ th < 8.10 | ||||||

| 8.10 ≤ th < 10.00 | 1525 | 1525 | ||||

| 10.00 ≤ th < 12.00 | * | * | ||||

| 12.00 ≤ th < 13.00 | * | * | * |

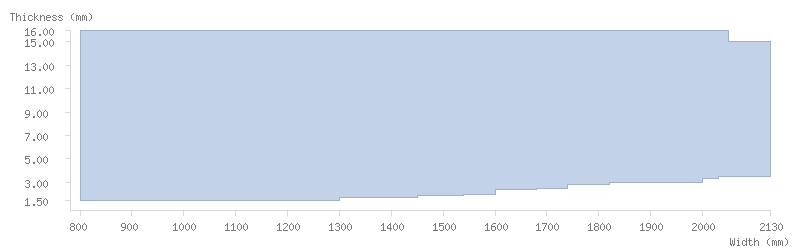

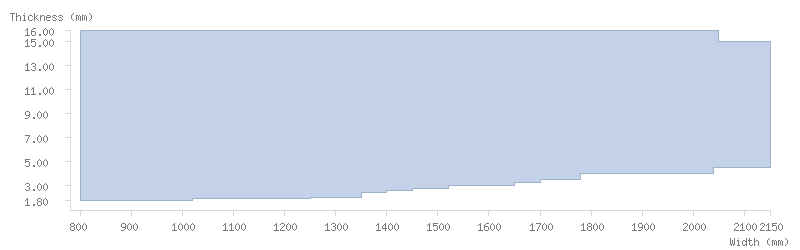

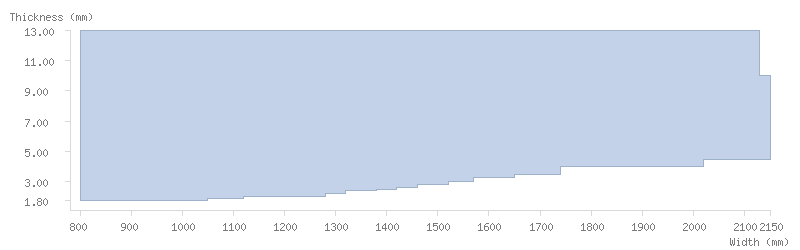

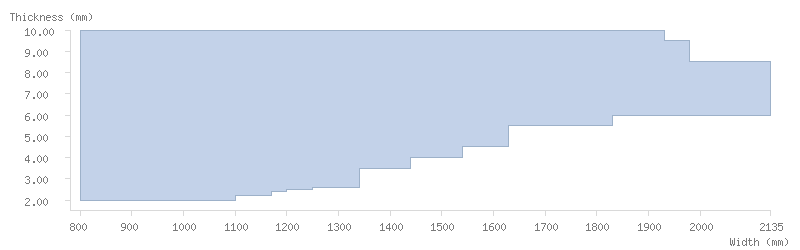

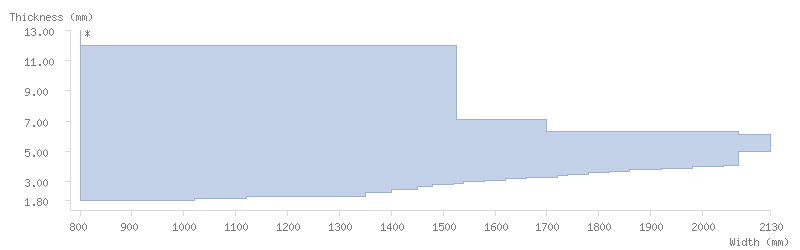

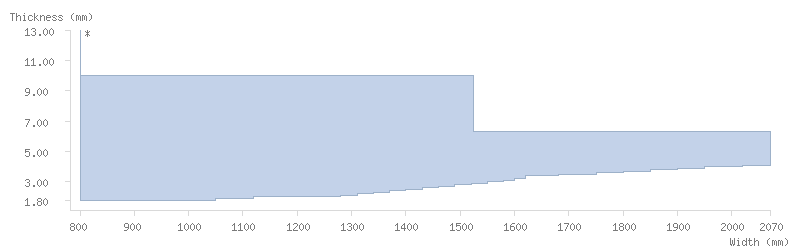

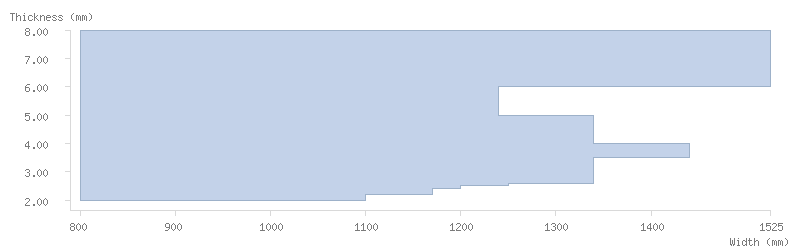

| Thickness (mm) | Min width | S420MC EN 10149-2, Amstrong® 420MC | S460MC EN 10149-2 | Amstrong® 460MC | S500MC EN 10149-2, Amstrong® 500MC | S550MC EN 10149-2 | Amstrong® 550MC | S600MC EN 10149-2, Amstrong® 600MC |

|---|---|---|---|---|---|---|---|---|

| Max width | Max width | Max width | Max width | Max width | Max width | Max width | ||

| 1.50 ≤ th < 1.60 | 800 | - | - | - | - | - | - | - |

| 1.60 ≤ th < 1.70 | ||||||||

| 1.70 ≤ th < 1.80 | ||||||||

| 1.80 ≤ th < 1.90 | 1020 | 1050 | ||||||

| 1.90 ≤ th < 2.00 | 1120 | 1050 | 1050 | 1120 | 940 | 940 | ||

| 2.00 ≤ th < 2.10 | 1350 | 1350 | 1350 | 1280 | 1230 | 1230 | 1100 | |

| 2.10 ≤ th < 2.20 | 1310 | 1260 | 1260 | |||||

| 2.20 ≤ th < 2.30 | 1340 | 1290 | 1290 | 1170 | ||||

| 2.30 ≤ th < 2.40 | 1400 | 1400 | 1400 | 1370 | 1320 | 1320 | ||

| 2.40 ≤ th < 2.50 | 1400 | 1350 | 1350 | 1200 | ||||

| 2.50 ≤ th < 2.60 | 1450 | 1450 | 1450 | 1430 | 1380 | 1380 | 1250 | |

| 2.60 ≤ th < 2.70 | 1460 | 1410 | 1410 | 1340 | ||||

| 2.70 ≤ th < 2.80 | 1480 | 1490 | 1440 | 1440 | ||||

| 2.80 ≤ th < 2.90 | 1520 | 1510 | 1510 | 1520 | 1470 | 1470 | ||

| 2.90 ≤ th < 3.00 | 1540 | 1540 | 1540 | 1550 | 1500 | 1500 | ||

| 3.00 ≤ th < 3.10 | 1580 | 1580 | 1580 | 1580 | 1530 | 1530 | ||

| 3.10 ≤ th < 3.20 | 1620 | 1620 | 1620 | 1600 | 1560 | 1560 | ||

| 3.20 ≤ th < 3.30 | 1660 | 1660 | 1660 | 1620 | 1590 | 1590 | ||

| 3.30 ≤ th < 3.40 | 1720 | 1720 | 1720 | 1630 | 1630 | |||

| 3.40 ≤ th < 3.50 | 1740 | 1740 | 1740 | 1680 | 1680 | 1680 | ||

| 3.50 ≤ th < 3.60 | 1780 | 1780 | 1780 | 1750 | 1750 | 1750 | 1440 | |

| 3.60 ≤ th < 3.70 | 1820 | 1820 | 1820 | 1800 | 1800 | 1800 | ||

| 3.70 ≤ th < 3.80 | 1860 | 1860 | 1860 | 1850 | 1850 | 1850 | ||

| 3.80 ≤ th < 3.90 | 1920 | 1920 | 1920 | 1900 | 1900 | 1900 | ||

| 3.90 ≤ th < 4.00 | 1980 | 1980 | 1980 | 1950 | 1950 | 1950 | ||

| 4.00 ≤ th < 4.10 | 2040 | 2020 | 2020 | 2020 | 2020 | 2020 | 1340 | |

| 4.10 ≤ th < 5.00 | 2070 | 2070 | 2070 | 2070 | 2070 | 2070 | ||

| 5.00 ≤ th < 6.00 | 2130 | 1240 | ||||||

| 6.00 ≤ th < 6.10 | 2130 | 1525 | ||||||

| 6.10 ≤ th < 6.30 | 2070 | 2070 | ||||||

| 6.30 ≤ th < 7.00 | 1700 | 1525 | 1525 | 1525 | 1525 | 1525 | ||

| 7.00 ≤ th < 7.10 | ||||||||

| 7.10 ≤ th < 8.00 | 1525 | |||||||

| 8.00 ≤ th < 8.10 | - | |||||||

| 8.10 ≤ th < 10.00 | ||||||||

| 10.00 ≤ th < 12.00 | * | * | * | * | - | |||

| 12.00 ≤ th < 13.00 | * | * |

* Pickled products with thicknesses up to 15 mm may be delivered after prior agreement: please contact us.

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1590 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.10 | 1830 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1930 | |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | 1980 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | 2030 | |

| 2.80 ≤ th < 2.90 | ||

| 2.90 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.10 | ||

| 3.10 ≤ th < 3.20 | ||

| 3.20 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.40 | 2130 | |

| 3.40 ≤ th < 3.50 | ||

| 3.50 ≤ th < 3.60 | ||

| 3.60 ≤ th < 3.70 | ||

| 3.70 ≤ th < 3.80 | ||

| 3.80 ≤ th < 3.90 | ||

| 3.90 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.10 | ||

| 4.10 ≤ th < 5.00 | ||

| 5.00 ≤ th < 6.00 | 1520 | |

| 6.00 ≤ th < 6.10 | ||

| 6.10 ≤ th < 6.30 | ||

| 6.30 ≤ th < 7.00 | ||

| 7.00 ≤ th < 7.10 | ||

| 7.10 ≤ th < 8.00 | ||

| 8.00 ≤ th < 8.10 | ||

| 8.10 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | * | |

| 12.00 ≤ th < 13.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1320 |

| 1.60 ≤ th < 1.70 | 1350 | |

| 1.70 ≤ th < 1.80 | 1420 | |

| 1.80 ≤ th < 1.90 | 1450 | |

| 1.90 ≤ th < 2.00 | 1500 | |

| 2.00 ≤ th < 2.10 | 1600 | |

| 2.10 ≤ th < 2.20 | 1620 | |

| 2.20 ≤ th < 2.30 | 1680 | |

| 2.30 ≤ th < 2.40 | 1740 | |

| 2.40 ≤ th < 2.50 | 1800 | |

| 2.50 ≤ th < 2.60 | 1850 | |

| 2.60 ≤ th < 2.70 | 1880 | |

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 2.90 | ||

| 2.90 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.10 | ||

| 3.10 ≤ th < 3.20 | ||

| 3.20 ≤ th < 3.30 | 1840 | |

| 3.30 ≤ th < 3.40 | ||

| 3.40 ≤ th < 3.50 | ||

| 3.50 ≤ th < 3.60 | ||

| 3.60 ≤ th < 3.70 | ||

| 3.70 ≤ th < 3.80 | ||

| 3.80 ≤ th < 3.90 | ||

| 3.90 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.10 | ||

| 4.10 ≤ th < 5.00 | ||

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.10 | 1600 | |

| 6.10 ≤ th < 6.30 | ||

| 6.30 ≤ th < 7.00 | ||

| 7.00 ≤ th < 7.10 | 1525 | |

| 7.10 ≤ th < 8.00 | ||

| 8.00 ≤ th < 8.10 | ||

| 8.10 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | * | |

| 12.00 ≤ th < 13.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1140 |

| 1.60 ≤ th < 1.70 | 1190 | |

| 1.70 ≤ th < 1.80 | 1270 | |

| 1.80 ≤ th < 1.90 | 1320 | |

| 1.90 ≤ th < 2.00 | 1540 | |

| 2.00 ≤ th < 2.10 | ||

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1560 | |

| 2.50 ≤ th < 2.60 | 1730 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 2.90 | ||

| 2.90 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.10 | 1880 | |

| 3.10 ≤ th < 3.20 | ||

| 3.20 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.40 | ||

| 3.40 ≤ th < 3.50 | ||

| 3.50 ≤ th < 3.60 | 2130 | |

| 3.60 ≤ th < 3.70 | ||

| 3.70 ≤ th < 3.80 | ||

| 3.80 ≤ th < 3.90 | ||

| 3.90 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.10 | ||

| 4.10 ≤ th < 5.00 | ||

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.10 | ||

| 6.10 ≤ th < 6.30 | ||

| 6.30 ≤ th < 7.00 | ||

| 7.00 ≤ th < 7.10 | 1550 | |

| 7.10 ≤ th < 8.00 | ||

| 8.00 ≤ th < 8.10 | ||

| 8.10 ≤ th < 10.00 | 1525 | |

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | * |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1140 |

| 1.60 ≤ th < 1.70 | 1190 | |

| 1.70 ≤ th < 1.80 | 1270 | |

| 1.80 ≤ th < 1.90 | 1320 | |

| 1.90 ≤ th < 2.00 | 1540 | |

| 2.00 ≤ th < 2.10 | ||

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1560 | |

| 2.50 ≤ th < 2.60 | 1730 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 2.90 | ||

| 2.90 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.10 | 1880 | |

| 3.10 ≤ th < 3.20 | ||

| 3.20 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.40 | ||

| 3.40 ≤ th < 3.50 | ||

| 3.50 ≤ th < 3.60 | 2130 | |

| 3.60 ≤ th < 3.70 | ||

| 3.70 ≤ th < 3.80 | ||

| 3.80 ≤ th < 3.90 | ||

| 3.90 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.10 | ||

| 4.10 ≤ th < 5.00 | ||

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.10 | ||

| 6.10 ≤ th < 6.30 | ||

| 6.30 ≤ th < 7.00 | ||

| 7.00 ≤ th < 7.10 | 1550 | |

| 7.10 ≤ th < 8.00 | ||

| 8.00 ≤ th < 8.10 | ||

| 8.10 ≤ th < 10.00 | 1525 | |

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | * |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1090 |

| 1.60 ≤ th < 1.70 | 1160 | |

| 1.70 ≤ th < 1.80 | 1230 | |

| 1.80 ≤ th < 1.90 | 1300 | |

| 1.90 ≤ th < 2.00 | 1330 | |

| 2.00 ≤ th < 2.10 | 1450 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1525 | |

| 2.40 ≤ th < 2.50 | 1540 | |

| 2.50 ≤ th < 2.60 | 1560 | |

| 2.60 ≤ th < 2.70 | 1580 | |

| 2.70 ≤ th < 2.80 | 1600 | |

| 2.80 ≤ th < 2.90 | 1630 | |

| 2.90 ≤ th < 3.00 | 1650 | |

| 3.00 ≤ th < 3.10 | 1730 | |

| 3.10 ≤ th < 3.20 | ||

| 3.20 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.40 | 1740 | |

| 3.40 ≤ th < 3.50 | ||

| 3.50 ≤ th < 3.60 | 1880 | |

| 3.60 ≤ th < 3.70 | ||

| 3.70 ≤ th < 3.80 | ||

| 3.80 ≤ th < 3.90 | 1920 | |

| 3.90 ≤ th < 4.00 | 1980 | |

| 4.00 ≤ th < 4.10 | 2040 | |

| 4.10 ≤ th < 5.00 | 2070 | |

| 5.00 ≤ th < 6.00 | 2130 | |

| 6.00 ≤ th < 6.10 | ||

| 6.10 ≤ th < 6.30 | ||

| 6.30 ≤ th < 7.00 | ||

| 7.00 ≤ th < 7.10 | ||

| 7.10 ≤ th < 8.00 | 1550 | |

| 8.00 ≤ th < 8.10 | ||

| 8.10 ≤ th < 10.00 | 1525 | |

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | * |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1090 |

| 1.60 ≤ th < 1.70 | 1160 | |

| 1.70 ≤ th < 1.80 | 1230 | |

| 1.80 ≤ th < 1.90 | 1300 | |

| 1.90 ≤ th < 2.00 | 1330 | |

| 2.00 ≤ th < 2.10 | 1450 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1525 | |

| 2.40 ≤ th < 2.50 | 1540 | |

| 2.50 ≤ th < 2.60 | 1560 | |

| 2.60 ≤ th < 2.70 | 1580 | |

| 2.70 ≤ th < 2.80 | 1600 | |

| 2.80 ≤ th < 2.90 | 1630 | |

| 2.90 ≤ th < 3.00 | 1650 | |

| 3.00 ≤ th < 3.10 | 1730 | |

| 3.10 ≤ th < 3.20 | ||

| 3.20 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.40 | 1740 | |

| 3.40 ≤ th < 3.50 | ||

| 3.50 ≤ th < 3.60 | 1880 | |

| 3.60 ≤ th < 3.70 | ||

| 3.70 ≤ th < 3.80 | ||

| 3.80 ≤ th < 3.90 | 1920 | |

| 3.90 ≤ th < 4.00 | 1980 | |

| 4.00 ≤ th < 4.10 | 2040 | |

| 4.10 ≤ th < 5.00 | 2070 | |

| 5.00 ≤ th < 6.00 | 2130 | |

| 6.00 ≤ th < 6.10 | ||

| 6.10 ≤ th < 6.30 | ||

| 6.30 ≤ th < 7.00 | ||

| 7.00 ≤ th < 7.10 | ||

| 7.10 ≤ th < 8.00 | 1550 | |

| 8.00 ≤ th < 8.10 | ||

| 8.10 ≤ th < 10.00 | 1525 | |

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | * |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1020 | |

| 1.80 ≤ th < 1.90 | 1100 | |

| 1.90 ≤ th < 2.00 | 1180 | |

| 2.00 ≤ th < 2.10 | 1350 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1400 | |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | 1450 | |

| 2.60 ≤ th < 2.70 | 1470 | |

| 2.70 ≤ th < 2.80 | 1500 | |

| 2.80 ≤ th < 2.90 | 1530 | |

| 2.90 ≤ th < 3.00 | 1560 | |

| 3.00 ≤ th < 3.10 | 1580 | |

| 3.10 ≤ th < 3.20 | 1620 | |

| 3.20 ≤ th < 3.30 | 1660 | |

| 3.30 ≤ th < 3.40 | 1720 | |

| 3.40 ≤ th < 3.50 | 1740 | |

| 3.50 ≤ th < 3.60 | 1780 | |

| 3.60 ≤ th < 3.70 | 1820 | |

| 3.70 ≤ th < 3.80 | 1860 | |

| 3.80 ≤ th < 3.90 | 1920 | |

| 3.90 ≤ th < 4.00 | 1980 | |

| 4.00 ≤ th < 4.10 | 2040 | |

| 4.10 ≤ th < 5.00 | 2070 | |

| 5.00 ≤ th < 6.00 | 2130 | |

| 6.00 ≤ th < 6.10 | ||

| 6.10 ≤ th < 6.30 | 2070 | |

| 6.30 ≤ th < 7.00 | 1700 | |

| 7.00 ≤ th < 7.10 | ||

| 7.10 ≤ th < 8.00 | 1525 | |

| 8.00 ≤ th < 8.10 | ||

| 8.10 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | * |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | 1020 | |

| 1.90 ≤ th < 2.00 | 1120 | |

| 2.00 ≤ th < 2.10 | 1350 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1400 | |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | 1450 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | 1480 | |

| 2.80 ≤ th < 2.90 | 1520 | |

| 2.90 ≤ th < 3.00 | 1540 | |

| 3.00 ≤ th < 3.10 | 1580 | |

| 3.10 ≤ th < 3.20 | 1620 | |

| 3.20 ≤ th < 3.30 | 1660 | |

| 3.30 ≤ th < 3.40 | 1720 | |

| 3.40 ≤ th < 3.50 | 1740 | |

| 3.50 ≤ th < 3.60 | 1780 | |

| 3.60 ≤ th < 3.70 | 1820 | |

| 3.70 ≤ th < 3.80 | 1860 | |

| 3.80 ≤ th < 3.90 | 1920 | |

| 3.90 ≤ th < 4.00 | 1980 | |

| 4.00 ≤ th < 4.10 | 2040 | |

| 4.10 ≤ th < 5.00 | 2070 | |

| 5.00 ≤ th < 6.00 | 2130 | |

| 6.00 ≤ th < 6.10 | ||

| 6.10 ≤ th < 6.30 | 2070 | |

| 6.30 ≤ th < 7.00 | 1700 | |

| 7.00 ≤ th < 7.10 | ||

| 7.10 ≤ th < 8.00 | 1525 | |

| 8.00 ≤ th < 8.10 | ||

| 8.10 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | * |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | 1020 | |

| 1.90 ≤ th < 2.00 | 1120 | |

| 2.00 ≤ th < 2.10 | 1350 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1400 | |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | 1450 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | 1480 | |

| 2.80 ≤ th < 2.90 | 1520 | |

| 2.90 ≤ th < 3.00 | 1540 | |

| 3.00 ≤ th < 3.10 | 1580 | |

| 3.10 ≤ th < 3.20 | 1620 | |

| 3.20 ≤ th < 3.30 | 1660 | |

| 3.30 ≤ th < 3.40 | 1720 | |

| 3.40 ≤ th < 3.50 | 1740 | |

| 3.50 ≤ th < 3.60 | 1780 | |

| 3.60 ≤ th < 3.70 | 1820 | |

| 3.70 ≤ th < 3.80 | 1860 | |

| 3.80 ≤ th < 3.90 | 1920 | |

| 3.90 ≤ th < 4.00 | 1980 | |

| 4.00 ≤ th < 4.10 | 2040 | |

| 4.10 ≤ th < 5.00 | 2070 | |

| 5.00 ≤ th < 6.00 | 2130 | |

| 6.00 ≤ th < 6.10 | ||

| 6.10 ≤ th < 6.30 | 2070 | |

| 6.30 ≤ th < 7.00 | 1700 | |

| 7.00 ≤ th < 7.10 | ||

| 7.10 ≤ th < 8.00 | 1525 | |

| 8.00 ≤ th < 8.10 | ||

| 8.10 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 | * |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | 1050 | |

| 2.00 ≤ th < 2.10 | 1350 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1400 | |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | 1450 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 2.90 | 1510 | |

| 2.90 ≤ th < 3.00 | 1540 | |

| 3.00 ≤ th < 3.10 | 1580 | |

| 3.10 ≤ th < 3.20 | 1620 | |

| 3.20 ≤ th < 3.30 | 1660 | |

| 3.30 ≤ th < 3.40 | 1720 | |

| 3.40 ≤ th < 3.50 | 1740 | |

| 3.50 ≤ th < 3.60 | 1780 | |

| 3.60 ≤ th < 3.70 | 1820 | |

| 3.70 ≤ th < 3.80 | 1860 | |

| 3.80 ≤ th < 3.90 | 1920 | |

| 3.90 ≤ th < 4.00 | 1980 | |

| 4.00 ≤ th < 4.10 | 2020 | |

| 4.10 ≤ th < 5.00 | 2070 | |

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.10 | 2130 | |

| 6.10 ≤ th < 6.30 | 2070 | |

| 6.30 ≤ th < 7.00 | 1525 | |

| 7.00 ≤ th < 7.10 | ||

| 7.10 ≤ th < 8.00 | ||

| 8.00 ≤ th < 8.10 | ||

| 8.10 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | * | |

| 12.00 ≤ th < 13.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | 1050 | |

| 2.00 ≤ th < 2.10 | 1350 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1400 | |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | 1450 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 2.90 | 1510 | |

| 2.90 ≤ th < 3.00 | 1540 | |

| 3.00 ≤ th < 3.10 | 1580 | |

| 3.10 ≤ th < 3.20 | 1620 | |

| 3.20 ≤ th < 3.30 | 1660 | |

| 3.30 ≤ th < 3.40 | 1720 | |

| 3.40 ≤ th < 3.50 | 1740 | |

| 3.50 ≤ th < 3.60 | 1780 | |

| 3.60 ≤ th < 3.70 | 1820 | |

| 3.70 ≤ th < 3.80 | 1860 | |

| 3.80 ≤ th < 3.90 | 1920 | |

| 3.90 ≤ th < 4.00 | 1980 | |

| 4.00 ≤ th < 4.10 | 2020 | |

| 4.10 ≤ th < 5.00 | 2070 | |

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.10 | ||

| 6.10 ≤ th < 6.30 | ||

| 6.30 ≤ th < 7.00 | 1525 | |

| 7.00 ≤ th < 7.10 | ||

| 7.10 ≤ th < 8.00 | ||

| 8.00 ≤ th < 8.10 | ||

| 8.10 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | * | |

| 12.00 ≤ th < 13.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | 1050 | |

| 1.90 ≤ th < 2.00 | 1120 | |

| 2.00 ≤ th < 2.10 | 1280 | |

| 2.10 ≤ th < 2.20 | 1310 | |

| 2.20 ≤ th < 2.30 | 1340 | |

| 2.30 ≤ th < 2.40 | 1370 | |

| 2.40 ≤ th < 2.50 | 1400 | |

| 2.50 ≤ th < 2.60 | 1430 | |

| 2.60 ≤ th < 2.70 | 1460 | |

| 2.70 ≤ th < 2.80 | 1490 | |

| 2.80 ≤ th < 2.90 | 1520 | |

| 2.90 ≤ th < 3.00 | 1550 | |

| 3.00 ≤ th < 3.10 | 1580 | |

| 3.10 ≤ th < 3.20 | 1600 | |

| 3.20 ≤ th < 3.30 | 1620 | |

| 3.30 ≤ th < 3.40 | ||

| 3.40 ≤ th < 3.50 | 1680 | |

| 3.50 ≤ th < 3.60 | 1750 | |

| 3.60 ≤ th < 3.70 | 1800 | |

| 3.70 ≤ th < 3.80 | 1850 | |

| 3.80 ≤ th < 3.90 | 1900 | |

| 3.90 ≤ th < 4.00 | 1950 | |

| 4.00 ≤ th < 4.10 | 2020 | |

| 4.10 ≤ th < 5.00 | 2070 | |

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.10 | ||

| 6.10 ≤ th < 6.30 | ||

| 6.30 ≤ th < 7.00 | 1525 | |

| 7.00 ≤ th < 7.10 | ||

| 7.10 ≤ th < 8.00 | ||

| 8.00 ≤ th < 8.10 | ||

| 8.10 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | * | |

| 12.00 ≤ th < 13.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | 1050 | |

| 1.90 ≤ th < 2.00 | 1120 | |

| 2.00 ≤ th < 2.10 | 1280 | |

| 2.10 ≤ th < 2.20 | 1310 | |

| 2.20 ≤ th < 2.30 | 1340 | |

| 2.30 ≤ th < 2.40 | 1370 | |

| 2.40 ≤ th < 2.50 | 1400 | |

| 2.50 ≤ th < 2.60 | 1430 | |

| 2.60 ≤ th < 2.70 | 1460 | |

| 2.70 ≤ th < 2.80 | 1490 | |

| 2.80 ≤ th < 2.90 | 1520 | |

| 2.90 ≤ th < 3.00 | 1550 | |

| 3.00 ≤ th < 3.10 | 1580 | |

| 3.10 ≤ th < 3.20 | 1600 | |

| 3.20 ≤ th < 3.30 | 1620 | |

| 3.30 ≤ th < 3.40 | ||

| 3.40 ≤ th < 3.50 | 1680 | |

| 3.50 ≤ th < 3.60 | 1750 | |

| 3.60 ≤ th < 3.70 | 1800 | |

| 3.70 ≤ th < 3.80 | 1850 | |

| 3.80 ≤ th < 3.90 | 1900 | |

| 3.90 ≤ th < 4.00 | 1950 | |

| 4.00 ≤ th < 4.10 | 2020 | |

| 4.10 ≤ th < 5.00 | 2070 | |

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.10 | ||

| 6.10 ≤ th < 6.30 | ||

| 6.30 ≤ th < 7.00 | 1525 | |

| 7.00 ≤ th < 7.10 | ||

| 7.10 ≤ th < 8.00 | ||

| 8.00 ≤ th < 8.10 | ||

| 8.10 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | * | |

| 12.00 ≤ th < 13.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | 940 | |

| 2.00 ≤ th < 2.10 | 1230 | |

| 2.10 ≤ th < 2.20 | 1260 | |

| 2.20 ≤ th < 2.30 | 1290 | |

| 2.30 ≤ th < 2.40 | 1320 | |

| 2.40 ≤ th < 2.50 | 1350 | |

| 2.50 ≤ th < 2.60 | 1380 | |

| 2.60 ≤ th < 2.70 | 1410 | |

| 2.70 ≤ th < 2.80 | 1440 | |

| 2.80 ≤ th < 2.90 | 1470 | |

| 2.90 ≤ th < 3.00 | 1500 | |

| 3.00 ≤ th < 3.10 | 1530 | |

| 3.10 ≤ th < 3.20 | 1560 | |

| 3.20 ≤ th < 3.30 | 1590 | |

| 3.30 ≤ th < 3.40 | 1630 | |

| 3.40 ≤ th < 3.50 | 1680 | |

| 3.50 ≤ th < 3.60 | 1750 | |

| 3.60 ≤ th < 3.70 | 1800 | |

| 3.70 ≤ th < 3.80 | 1850 | |

| 3.80 ≤ th < 3.90 | 1900 | |

| 3.90 ≤ th < 4.00 | 1950 | |

| 4.00 ≤ th < 4.10 | 2020 | |

| 4.10 ≤ th < 5.00 | 2070 | |

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.10 | ||

| 6.10 ≤ th < 6.30 | ||

| 6.30 ≤ th < 7.00 | 1525 | |

| 7.00 ≤ th < 7.10 | ||

| 7.10 ≤ th < 8.00 | ||

| 8.00 ≤ th < 8.10 | ||

| 8.10 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | * | |

| 12.00 ≤ th < 13.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | 940 | |

| 2.00 ≤ th < 2.10 | 1230 | |

| 2.10 ≤ th < 2.20 | 1260 | |

| 2.20 ≤ th < 2.30 | 1290 | |

| 2.30 ≤ th < 2.40 | 1320 | |

| 2.40 ≤ th < 2.50 | 1350 | |

| 2.50 ≤ th < 2.60 | 1380 | |

| 2.60 ≤ th < 2.70 | 1410 | |

| 2.70 ≤ th < 2.80 | 1440 | |

| 2.80 ≤ th < 2.90 | 1470 | |

| 2.90 ≤ th < 3.00 | 1500 | |

| 3.00 ≤ th < 3.10 | 1530 | |

| 3.10 ≤ th < 3.20 | 1560 | |

| 3.20 ≤ th < 3.30 | 1590 | |

| 3.30 ≤ th < 3.40 | 1630 | |

| 3.40 ≤ th < 3.50 | 1680 | |

| 3.50 ≤ th < 3.60 | 1750 | |

| 3.60 ≤ th < 3.70 | 1800 | |

| 3.70 ≤ th < 3.80 | 1850 | |

| 3.80 ≤ th < 3.90 | 1900 | |

| 3.90 ≤ th < 4.00 | 1950 | |

| 4.00 ≤ th < 4.10 | 2020 | |

| 4.10 ≤ th < 5.00 | 2070 | |

| 5.00 ≤ th < 6.00 | ||

| 6.00 ≤ th < 6.10 | ||

| 6.10 ≤ th < 6.30 | ||

| 6.30 ≤ th < 7.00 | 1525 | |

| 7.00 ≤ th < 7.10 | ||

| 7.10 ≤ th < 8.00 | ||

| 8.00 ≤ th < 8.10 | ||

| 8.10 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | - | |

| 12.00 ≤ th < 13.00 | * |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.10 | 1100 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | 1170 | |

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1200 | |

| 2.50 ≤ th < 2.60 | 1250 | |

| 2.60 ≤ th < 2.70 | 1340 | |

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 2.90 | ||

| 2.90 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.10 | ||

| 3.10 ≤ th < 3.20 | ||

| 3.20 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.40 | ||

| 3.40 ≤ th < 3.50 | ||

| 3.50 ≤ th < 3.60 | 1440 | |

| 3.60 ≤ th < 3.70 | ||

| 3.70 ≤ th < 3.80 | ||

| 3.80 ≤ th < 3.90 | ||

| 3.90 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.10 | 1340 | |

| 4.10 ≤ th < 5.00 | ||

| 5.00 ≤ th < 6.00 | 1240 | |

| 6.00 ≤ th < 6.10 | 1525 | |

| 6.10 ≤ th < 6.30 | ||

| 6.30 ≤ th < 7.00 | ||

| 7.00 ≤ th < 7.10 | ||

| 7.10 ≤ th < 8.00 | ||

| 8.00 ≤ th < 8.10 | - | |

| 8.10 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.10 | 1100 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | 1170 | |

| 2.30 ≤ th < 2.40 | ||

| 2.40 ≤ th < 2.50 | 1200 | |

| 2.50 ≤ th < 2.60 | 1250 | |

| 2.60 ≤ th < 2.70 | 1340 | |

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 2.90 | ||

| 2.90 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.10 | ||

| 3.10 ≤ th < 3.20 | ||

| 3.20 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.40 | ||

| 3.40 ≤ th < 3.50 | ||

| 3.50 ≤ th < 3.60 | 1440 | |

| 3.60 ≤ th < 3.70 | ||

| 3.70 ≤ th < 3.80 | ||

| 3.80 ≤ th < 3.90 | ||

| 3.90 ≤ th < 4.00 | ||

| 4.00 ≤ th < 4.10 | 1340 | |

| 4.10 ≤ th < 5.00 | ||

| 5.00 ≤ th < 6.00 | 1240 | |

| 6.00 ≤ th < 6.10 | 1525 | |

| 6.10 ≤ th < 6.30 | ||

| 6.30 ≤ th < 7.00 | ||

| 7.00 ≤ th < 7.10 | ||

| 7.10 ≤ th < 8.00 | ||

| 8.00 ≤ th < 8.10 | - | |

| 8.10 ≤ th < 10.00 | ||

| 10.00 ≤ th < 12.00 | ||

| 12.00 ≤ th < 13.00 |

* Pickled products with thicknesses up to 15 mm may be delivered after prior agreement: please contact us.

| Direction | Thickness (mm) | Re (MPa) | Rm (MPa) | A80 (%) | A 5.65√So (%) | Min. mandrel diameter for 180° bending | KV -20°C (J) | |

|---|---|---|---|---|---|---|---|---|

| Amstrong® 240MC | L | < 3 | 240 - 320 | 340 - 450 | ≥ 27 | - | - | - |

| 3 - 6 | - | ≥ 32 | ||||||

| 6 - 16 | ≥ 40 | |||||||

| T | < 3 | 260 - 340 | 340 - 450 | ≥ 26 | - | 0 | - | |

| 3 - 16 | - | ≥ 31 | ||||||

| Amstrong® 280MC | L | < 3 | 280 - 350 | 370 - 450 | ≥ 26 | - | - | - |

| 3 - 6 | - | ≥ 30 | ||||||

| 6 - 16 | ≥ 40 | |||||||

| T | < 3 | 300 - 380 | 370 - 450 | ≥ 25 | - | 0 | - | |

| 3 - 16 | - | ≥ 29 | ||||||

| S315MC EN 10149-2 | L | 1.5 - 3 | ≥ 315 | 390 - 510 | ≥ 20 | - | - | - |

| 3 - 20 | - | ≥ 24 | ||||||

| T | 1.5 - 20 | - | - | - | - | 0 | - | |

| Amstrong® 315MC | L | < 3 | 315 - 395 | 415 - 495 | ≥ 24 | - | - | - |

| 3 - 6 | - | ≥ 28 | ||||||

| 6 - 16 | ≥ 40 | |||||||

| T | < 3 | 340 - 420 | 420 - 500 | ≥ 23 | - | 0 | - | |

| 3 - 16 | - | ≥ 27 | ||||||

| S355MC EN 10149-2 | L | 1.5 - 3 | ≥ 355 | 430 - 550 | ≥ 19 | - | - | - |

| 3 - 20 | - | ≥ 23 | ||||||

| T | 1.5 - 20 | - | - | - | - | ≥ 0.5 x t | - | |

| Amstrong® 355MC | L | < 3 | 355 - 435 | 430 - 520 | ≥ 22 | - | - | - |

| 3 - 6 | - | ≥ 25 | ||||||

| 6 - 16 | ≥ 40 | |||||||

| T | < 3 | 380 - 460 | 440 - 530 | ≥ 21 | - | 0 | - | |

| 3 - 16 | - | ≥ 24 | ||||||

| Amstrong® 390MC | L | < 3 | 390 - 480 | 460 - 560 | ≥ 20 | - | - | - |

| 3 - 6 | - | ≥ 24 | ||||||

| 6 - 16 | ≥ 40 | |||||||

| T | < 3 | 420 - 500 | 470 - 570 | ≥ 19 | - | 0 | - | |

| 3 - 16 | - | ≥ 23 | ||||||

| S420MC EN 10149-2 | L | 1.5 - 3 | ≥ 420 | 480 - 620 | ≥ 16 | - | - | - |

| 3 - 20 | - | ≥ 19 | ||||||

| T | 1.5 - 20 | - | - | - | - | ≥ 0.5 x t | - | |

| Amstrong® 420MC | L | < 3 | 420 - 520 | 490 - 600 | ≥ 18 | - | - | - |

| 3 - 6 | - | ≥ 22 | ||||||

| 6 - 16 | ≥ 40 | |||||||

| T | < 3 | 450 - 550 | 500 - 600 | ≥ 17 | - | ≥ 0.2 x t | - | |

| 3 - 13 | - | ≥ 21 | ||||||

| 13 - 16 | ≥ 0.5 x t | |||||||

| S460MC EN 10149-2 | L | 1.5 - 3 | ≥ 460 | 520 - 670 | ≥ 14 | - | - | - |

| 3 - 20 | - | ≥ 17 | ||||||

| T | 1.5 - 20 | - | - | - | - | ≥ 1 x t | - | |

| Amstrong® 460MC | L | < 3 | 460 - 560 | 520 - 640 | ≥ 15 | - | - | - |

| 3 - 6 | - | ≥ 18 | ||||||

| 6 - 16 | ≥ 40 | |||||||

| T | < 3 | 490 - 590 | 530 - 640 | ≥ 14 | - | ≥ 0.6 x t | - | |

| 3 - 6 | - | ≥ 17 | ||||||

| 6 - 16 | ≥ 1 x t | |||||||

| S500MC EN 10149-2 | L | 1.5 - 3 | ≥ 500 | 550 - 700 | ≥ 12 | - | - | - |

| 3 - 16 | - | ≥ 14 | ||||||

| 16 - 20 | - | |||||||

| T | 1.5 - 16 | - | - | - | - | ≥ 1 x t | - | |

| Amstrong® 500MC | L | < 2 | 500 - 600 | 560 - 700 | ≥ 15 | - | - | - |

| 2 - 3 | ≥ 16 | |||||||

| 3 - 6 | - | ≥ 19 | ||||||

| 6 - 16 | ≥ 40 | |||||||

| T | < 2 | 530 - 630 | 570 - 700 | ≥ 14 | - | ≥ 0.6 x t | - | |

| 2 - 3 | ≥ 15 | |||||||

| 3 - 6 | - | ≥ 18 | ||||||

| 6 - 16 | ≥ 1 x t | |||||||

| S550MC EN 10149-2 | L | 1.5 - 3 | ≥ 550 | 600 - 760 | ≥ 12 | - | - | - |

| 3 - 16 | - | ≥ 14 | ||||||

| 16 - 20 | - | |||||||

| T | 1.5 - 16 | - | - | - | - | ≥ 1.5 x t | - | |

| Amstrong® 550MC | L | < 3 | 550 - 650 | 620 - 750 | ≥ 12 | - | - | - |

| 3 - 6 | - | ≥ 14 | ||||||

| 6 - 16 | ≥ 40 | |||||||

| T | < 3 | 580 - 680 | 630 - 750 | ≥ 11 | - | ≥ 0.8 x t | - | |

| 3 - 6 | - | ≥ 13 | ||||||

| 6 - 16 | ≥ 1.5 x t | |||||||

| S600MC EN 10149-2 | L | 2 - 3 | ≥ 600 | 650 - 820 | ≥ 11 | - | - | - |

| 3 - 10 | - | ≥ 13 | ||||||

| T | 2 - 10 | - | - | - | - | ≥ 1.5 x t | - | |

| Amstrong® 600MC | L | 2 - 3 | ≥ 600 | 650 - 820 | ≥ 11 | - | - | - |

| 3 - 6 | - | ≥ 13 | ||||||

| 6 - 10 | ≥ 40 | |||||||

| T | 2 - 3 | ≥ 620 | 660 - 820 | ≥ 10 | - | ≥ 1.5 x t | - | |

| 3 - 10 | - | ≥ 12 |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

For Amstrong® grades, the mechanical properties are guaranteed in both directions.

Minimum specified mandrel diameter for bending angles up to 180° according to EN 10149-2:2013

t = nominal thickness

Toughness guarantee at -40°C: on request

| Direction | Thickness (mm) | Amstrong® 240MC | |

|---|---|---|---|

| Re (MPa) | L | < 16 | 240 - 320 |

| T | < 16 | 260 - 340 | |

| Rm (MPa) | L | < 16 | 340 - 450 |

| T | < 16 | 340 - 450 | |

| A80 (%) | L | < 3 | ≥ 27 |

| T | < 3 | ≥ 26 | |

| A 5.65√So (%) | L | 3 - 16 | ≥ 32 |

| T | 3 - 16 | ≥ 31 | |

| Min. mandrel diameter for 180° bending | T | < 16 | 0 |

| KV -20°C (J) | L | 6 - 16 | ≥ 40 |

Grades in italics: not included in the standard

| Direction | Thickness (mm) | Amstrong® 280MC | |

|---|---|---|---|

| Re (MPa) | L | < 16 | 280 - 350 |

| T | < 16 | 300 - 380 | |

| Rm (MPa) | L | < 16 | 370 - 450 |

| T | < 16 | 370 - 450 | |

| A80 (%) | L | < 3 | ≥ 26 |

| T | < 3 | ≥ 25 | |

| A 5.65√So (%) | L | 3 - 16 | ≥ 30 |

| T | 3 - 16 | ≥ 29 | |

| Min. mandrel diameter for 180° bending | T | < 16 | 0 |

| KV -20°C (J) | L | 6 - 16 | ≥ 40 |

Grades in italics: not included in the standard

| Direction | Thickness (mm) | S315MC EN 10149-2 | |

|---|---|---|---|

| Re (MPa) | L | 1.5 - 20 | ≥ 315 |

| Rm (MPa) | L | 1.5 - 20 | 390 - 510 |

| A80 (%) | L | 1.5 - 3 | ≥ 20 |

| A 5.65√So (%) | L | 3 - 20 | ≥ 24 |

| Min. mandrel diameter for 180° bending | T | 1.5 - 20 | 0 |

| Direction | Thickness (mm) | Amstrong® 315MC | |

|---|---|---|---|

| Re (MPa) | L | < 16 | 315 - 395 |

| T | < 16 | 340 - 420 | |

| Rm (MPa) | L | < 16 | 415 - 495 |

| T | < 16 | 420 - 500 | |

| A80 (%) | L | < 3 | ≥ 24 |

| T | < 3 | ≥ 23 | |

| A 5.65√So (%) | L | 3 - 16 | ≥ 28 |

| T | 3 - 16 | ≥ 27 | |

| Min. mandrel diameter for 180° bending | T | < 16 | 0 |

| KV -20°C (J) | L | 6 - 16 | ≥ 40 |

Values in bold: tighter than the standard

| Direction | Thickness (mm) | S355MC EN 10149-2 | |

|---|---|---|---|

| Re (MPa) | L | 1.5 - 20 | ≥ 355 |

| Rm (MPa) | L | 1.5 - 20 | 430 - 550 |

| A80 (%) | L | 1.5 - 3 | ≥ 19 |

| A 5.65√So (%) | L | 3 - 20 | ≥ 23 |

| Min. mandrel diameter for 180° bending | T | 1.5 - 20 | ≥ 0.5 x t |

| Direction | Thickness (mm) | Amstrong® 355MC | |

|---|---|---|---|

| Re (MPa) | L | < 16 | 355 - 435 |

| T | < 16 | 380 - 460 | |

| Rm (MPa) | L | < 16 | 430 - 520 |

| T | < 16 | 440 - 530 | |

| A80 (%) | L | < 3 | ≥ 22 |

| T | < 3 | ≥ 21 | |

| A 5.65√So (%) | L | 3 - 16 | ≥ 25 |

| T | 3 - 16 | ≥ 24 | |

| Min. mandrel diameter for 180° bending | T | < 16 | 0 |

| KV -20°C (J) | L | 6 - 16 | ≥ 40 |

Values in bold: tighter than the standard

| Direction | Thickness (mm) | Amstrong® 390MC | |

|---|---|---|---|

| Re (MPa) | L | < 16 | 390 - 480 |

| T | < 16 | 420 - 500 | |

| Rm (MPa) | L | < 16 | 460 - 560 |

| T | < 16 | 470 - 570 | |

| A80 (%) | L | < 3 | ≥ 20 |

| T | < 3 | ≥ 19 | |

| A 5.65√So (%) | L | 3 - 16 | ≥ 24 |

| T | 3 - 16 | ≥ 23 | |

| Min. mandrel diameter for 180° bending | T | < 16 | 0 |

| KV -20°C (J) | L | 6 - 16 | ≥ 40 |

Grades in italics: not included in the standard

| Direction | Thickness (mm) | S420MC EN 10149-2 | |

|---|---|---|---|

| Re (MPa) | L | 1.5 - 20 | ≥ 420 |

| Rm (MPa) | L | 1.5 - 20 | 480 - 620 |

| A80 (%) | L | 1.5 - 3 | ≥ 16 |

| A 5.65√So (%) | L | 3 - 20 | ≥ 19 |

| Min. mandrel diameter for 180° bending | T | 1.5 - 20 | ≥ 0.5 x t |

| Direction | Thickness (mm) | Amstrong® 420MC | |

|---|---|---|---|

| Re (MPa) | L | < 16 | 420 - 520 |

| T | < 16 | 450 - 550 | |

| Rm (MPa) | L | < 16 | 490 - 600 |

| T | < 16 | 500 - 600 | |

| A80 (%) | L | < 3 | ≥ 18 |

| T | < 3 | ≥ 17 | |

| A 5.65√So (%) | L | 3 - 16 | ≥ 22 |

| T | 3 - 16 | ≥ 21 | |

| Min. mandrel diameter for 180° bending | T | < 13 | ≥ 0.2 x t |

| 13 - 16 | ≥ 0.5 x t | ||

| KV -20°C (J) | L | 6 - 16 | ≥ 40 |

Values in bold: tighter than the standard

| Direction | Thickness (mm) | S460MC EN 10149-2 | |

|---|---|---|---|

| Re (MPa) | L | 1.5 - 20 | ≥ 460 |

| Rm (MPa) | L | 1.5 - 20 | 520 - 670 |

| A80 (%) | L | 1.5 - 3 | ≥ 14 |

| A 5.65√So (%) | L | 3 - 20 | ≥ 17 |

| Min. mandrel diameter for 180° bending | T | 1.5 - 20 | ≥ 1 x t |

| Direction | Thickness (mm) | Amstrong® 460MC | |

|---|---|---|---|

| Re (MPa) | L | < 16 | 460 - 560 |

| T | < 16 | 490 - 590 | |

| Rm (MPa) | L | < 16 | 520 - 640 |

| T | < 16 | 530 - 640 | |

| A80 (%) | L | < 3 | ≥ 15 |

| T | < 3 | ≥ 14 | |

| A 5.65√So (%) | L | 3 - 16 | ≥ 18 |

| T | 3 - 16 | ≥ 17 | |

| Min. mandrel diameter for 180° bending | T | < 6 | ≥ 0.6 x t |

| 6 - 16 | ≥ 1 x t | ||

| KV -20°C (J) | L | 6 - 16 | ≥ 40 |

Values in bold: tighter than the standard

| Direction | Thickness (mm) | S500MC EN 10149-2 | |

|---|---|---|---|

| Re (MPa) | L | 1.5 - 20 | ≥ 500 |

| Rm (MPa) | L | 1.5 - 20 | 550 - 700 |

| A80 (%) | L | 1.5 - 3 | ≥ 12 |

| A 5.65√So (%) | L | 3 - 16 | ≥ 14 |

| Min. mandrel diameter for 180° bending | T | 1.5 - 16 | ≥ 1 x t |

| Direction | Thickness (mm) | Amstrong® 500MC | |

|---|---|---|---|

| Re (MPa) | L | < 16 | 500 - 600 |

| T | < 16 | 530 - 630 | |

| Rm (MPa) | L | < 16 | 560 - 700 |

| T | < 16 | 570 - 700 | |

| A80 (%) | L | < 2 | ≥ 15 |

| 2 - 3 | ≥ 16 | ||

| T | < 2 | ≥ 14 | |

| 2 - 3 | ≥ 15 | ||

| A 5.65√So (%) | L | 3 - 16 | ≥ 19 |

| T | 3 - 16 | ≥ 18 | |

| Min. mandrel diameter for 180° bending | T | < 6 | ≥ 0.6 x t |

| 6 - 16 | ≥ 1 x t | ||

| KV -20°C (J) | L | 6 - 16 | ≥ 40 |

Values in bold: tighter than the standard

| Direction | Thickness (mm) | S550MC EN 10149-2 | |

|---|---|---|---|

| Re (MPa) | L | 1.5 - 20 | ≥ 550 |

| Rm (MPa) | L | 1.5 - 20 | 600 - 760 |

| A80 (%) | L | 1.5 - 3 | ≥ 12 |

| A 5.65√So (%) | L | 3 - 16 | ≥ 14 |

| Min. mandrel diameter for 180° bending | T | 1.5 - 16 | ≥ 1.5 x t |

| Direction | Thickness (mm) | Amstrong® 550MC | |

|---|---|---|---|

| Re (MPa) | L | < 16 | 550 - 650 |

| T | < 16 | 580 - 680 | |

| Rm (MPa) | L | < 16 | 620 - 750 |

| T | < 16 | 630 - 750 | |

| A80 (%) | L | < 3 | ≥ 12 |

| T | < 3 | ≥ 11 | |

| A 5.65√So (%) | L | 3 - 16 | ≥ 14 |

| T | 3 - 16 | ≥ 13 | |

| Min. mandrel diameter for 180° bending | T | < 6 | ≥ 0.8 x t |

| 6 - 16 | ≥ 1.5 x t | ||

| KV -20°C (J) | L | 6 - 16 | ≥ 40 |

Values in bold: tighter than the standard

| Direction | Thickness (mm) | S600MC EN 10149-2 | |

|---|---|---|---|

| Re (MPa) | L | 2 - 10 | ≥ 600 |

| Rm (MPa) | L | 2 - 10 | 650 - 820 |

| A80 (%) | L | 2 - 3 | ≥ 11 |

| A 5.65√So (%) | L | 3 - 10 | ≥ 13 |

| Min. mandrel diameter for 180° bending | T | 2 - 10 | ≥ 1.5 x t |

| Direction | Thickness (mm) | Amstrong® 600MC | |

|---|---|---|---|

| Re (MPa) | L | 2 - 10 | ≥ 600 |

| T | 2 - 10 | ≥ 620 | |

| Rm (MPa) | L | 2 - 10 | 650 - 820 |

| T | 2 - 10 | 660 - 820 | |

| A80 (%) | L | 2 - 3 | ≥ 11 |

| T | 2 - 3 | ≥ 10 | |

| A 5.65√So (%) | L | 3 - 10 | ≥ 13 |

| T | 3 - 10 | ≥ 12 | |

| Min. mandrel diameter for 180° bending | T | 2 - 10 | ≥ 1.5 x t |

| KV -20°C (J) | L | 6 - 10 | ≥ 40 |

Values in bold: tighter than the standard

Grades in italics: not included in the standard

Values in bold: tighter than the standard

For Amstrong® grades, the mechanical properties are guaranteed in both directions.

Minimum specified mandrel diameter for bending angles up to 180° according to EN 10149-2:2013

t = nominal thickness

Toughness guarantee at -40°C: on request

| C (%) | Mn (%) | P (%) | S (%) | Si (%) | Al (%) | Nb (%) | V (%) | Ti (%) | Ceq (%) | Mo (%) | B (%) | Galvanisation | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Amstrong® 240MC | ≤ 0.100 | ≤ 0.80 | ≤ 0.020 | ≤ 0.020 | ≤ 0.03 | ≥ 0.015 | ≤ 0.025 | ≤ 0.200 | ≤ 0.150 | ≤ 0.18 | - | - | Class 1 |

| Amstrong® 280MC | ≤ 0.080 | ≤ 0.80 | ≤ 0.020 | ≤ 0.015 | ≤ 0.03 | ≥ 0.015 | ≤ 0.025 | ≤ 0.200 | ≤ 0.150 | ≤ 0.23 | - | - | Class 1 |

| S315MC EN 10149-2 | ≤ 0.120 | ≤ 1.30 | ≤ 0.025 | ≤ 0.020 | ≤ 0.50 | ≥ 0.015 | ≤ 0.090 | ≤ 0.200 | ≤ 0.150 | - | - | - | No |

| Amstrong® 315MC | ≤ 0.100 | ≤ 0.70 | ≤ 0.020 | ≤ 0.015 | ≤ 0.03 | ≥ 0.015 | ≤ 0.045 | ≤ 0.200 | ≤ 0.150 | ≤ 0.25 | - | - | Class 1 |

| S355MC EN 10149-2 | ≤ 0.120 | ≤ 1.50 | ≤ 0.025 | ≤ 0.020 | ≤ 0.50 | ≥ 0.015 | ≤ 0.090 | ≤ 0.200 | ≤ 0.150 | - | - | - | No |

| Amstrong® 355MC | ≤ 0.100 | ≤ 1.40 | ≤ 0.020 | ≤ 0.015 | ≤ 0.03 | ≥ 0.015 | ≤ 0.065 | ≤ 0.200 | ≤ 0.150 | ≤ 0.32 | - | - | Class 1 |

| Amstrong® 390MC | ≤ 0.100 | ≤ 1.50 | ≤ 0.020 | ≤ 0.012 | ≤ 0.03 | ≥ 0.015 | ≤ 0.065 | ≤ 0.200 | ≤ 0.150 | ≤ 0.36 | - | - | Class 1 |

| S420MC EN 10149-2 | ≤ 0.120 | ≤ 1.60 | ≤ 0.025 | ≤ 0.015 | ≤ 0.50 | ≥ 0.015 | ≤ 0.090 | ≤ 0.200 | ≤ 0.150 | - | - | - | No |

| Amstrong® 420MC | ≤ 0.110 | ≤ 1.50 | ≤ 0.020 | ≤ 0.012 | ≤ 0.03 | ≥ 0.015 | ≤ 0.065 | ≤ 0.200 | ≤ 0.150 | ≤ 0.38 | - | - | Class 1 |

| S460MC EN 10149-2 | ≤ 0.120 | ≤ 1.60 | ≤ 0.025 | ≤ 0.015 | ≤ 0.50 | ≥ 0.015 | ≤ 0.090 | ≤ 0.200 | ≤ 0.150 | - | - | - | No |

| Amstrong® 460MC | ≤ 0.120 | ≤ 1.50 | ≤ 0.020 | ≤ 0.012 | ≤ 0.03 | ≥ 0.015 | ≤ 0.080 | ≤ 0.200 | ≤ 0.150 | ≤ 0.40 | - | - | Class 1 |

| S500MC EN 10149-2 | ≤ 0.120 | ≤ 1.70 | ≤ 0.025 | ≤ 0.015 | ≤ 0.50 | ≥ 0.015 | ≤ 0.090 | ≤ 0.200 | ≤ 0.150 | - | - | - | No |

| Amstrong® 500MC | ≤ 0.120 | ≤ 1.70 | ≤ 0.020 | ≤ 0.012 | ≤ 0.03 | ≥ 0.015 | ≤ 0.090 | ≤ 0.200 | ≤ 0.150 | ≤ 0.42 | - | - | Class 1 |

| S550MC EN 10149-2 | ≤ 0.120 | ≤ 1.80 | ≤ 0.025 | ≤ 0.015 | ≤ 0.50 | ≥ 0.015 | ≤ 0.090 | ≤ 0.200 | ≤ 0.150 | - | - | - | No |

| Amstrong® 550MC | ≤ 0.100 | ≤ 1.70 | ≤ 0.020 | ≤ 0.012 | ≤ 0.03 | ≥ 0.015 | ≤ 0.090 | ≤ 0.200 | ≤ 0.150 | ≤ 0.44 | - | - | Class 1 |

| S600MC EN 10149-2 | ≤ 0.120 | ≤ 1.90 | ≤ 0.025 | ≤ 0.015 | ≤ 0.50 | ≥ 0.015 | ≤ 0.090 | ≤ 0.200 | ≤ 0.220 | - | ≤ 0.50 | ≤ 0.0050 | No |

| Amstrong® 600MC | ≤ 0.120 | ≤ 1.90 | ≤ 0.020 | ≤ 0.015 | ≤ 0.03 | ≥ 0.015 | ≤ 0.090 | ≤ 0.200 | ≤ 0.220 | ≤ 0.44 | ≤ 0.50 | ≤ 0.0050 | Class 1 |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

The chemical properties given are based on cast analysis data.

V+Nb+Ti ≤ 0.22%.

Suitability for hot-dip zinc coating is defined as per the requirements of EN ISO 14713-2 Table 1 and NFA 35-503.

| Amstrong® 240MC | |

|---|---|

| C (%) | ≤ 0.100 |

| Mn (%) | ≤ 0.80 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.020 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.025 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.150 |

| Mo (%) | - |

| B (%) | - |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

| Amstrong® 280MC | |

|---|---|

| C (%) | ≤ 0.080 |

| Mn (%) | ≤ 0.80 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.015 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.025 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.150 |

| Mo (%) | - |

| B (%) | - |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

| S315MC EN 10149-2 | |

|---|---|

| C (%) | ≤ 0.120 |

| Mn (%) | ≤ 1.30 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.020 |

| Si (%) | ≤ 0.50 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.090 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.150 |

| Mo (%) | - |

| B (%) | - |

| Galvanisation | No |

| Amstrong® 315MC | |

|---|---|

| C (%) | ≤ 0.100 |

| Mn (%) | ≤ 0.70 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.015 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.045 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.150 |

| Mo (%) | - |

| B (%) | - |

| Galvanisation | Class 1 |

Values in bold: tighter than the standard

| S355MC EN 10149-2 | |

|---|---|

| C (%) | ≤ 0.120 |

| Mn (%) | ≤ 1.50 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.020 |

| Si (%) | ≤ 0.50 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.090 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.150 |

| Mo (%) | - |

| B (%) | - |

| Galvanisation | No |

| Amstrong® 355MC | |

|---|---|

| C (%) | ≤ 0.100 |

| Mn (%) | ≤ 1.40 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.015 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.065 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.150 |

| Mo (%) | - |

| B (%) | - |

| Galvanisation | Class 1 |

Values in bold: tighter than the standard

| Amstrong® 390MC | |

|---|---|

| C (%) | ≤ 0.100 |

| Mn (%) | ≤ 1.50 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.012 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.065 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.150 |

| Mo (%) | - |

| B (%) | - |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

Values in bold: tighter than the standard

| S420MC EN 10149-2 | |

|---|---|

| C (%) | ≤ 0.120 |

| Mn (%) | ≤ 1.60 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.015 |

| Si (%) | ≤ 0.50 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.090 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.150 |

| Mo (%) | - |

| B (%) | - |

| Galvanisation | No |

| Amstrong® 420MC | |

|---|---|

| C (%) | ≤ 0.110 |

| Mn (%) | ≤ 1.50 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.012 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.065 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.150 |

| Mo (%) | - |

| B (%) | - |

| Galvanisation | Class 1 |

Values in bold: tighter than the standard

| S460MC EN 10149-2 | |

|---|---|

| C (%) | ≤ 0.120 |

| Mn (%) | ≤ 1.60 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.015 |

| Si (%) | ≤ 0.50 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.090 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.150 |

| Mo (%) | - |

| B (%) | - |

| Galvanisation | No |

| Amstrong® 460MC | |

|---|---|

| C (%) | ≤ 0.120 |

| Mn (%) | ≤ 1.50 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.012 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.080 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.150 |

| Mo (%) | - |

| B (%) | - |

| Galvanisation | Class 1 |

Values in bold: tighter than the standard

| S500MC EN 10149-2 | |

|---|---|

| C (%) | ≤ 0.120 |

| Mn (%) | ≤ 1.70 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.015 |

| Si (%) | ≤ 0.50 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.090 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.150 |

| Mo (%) | - |

| B (%) | - |

| Galvanisation | No |

| Amstrong® 500MC | |

|---|---|

| C (%) | ≤ 0.120 |

| Mn (%) | ≤ 1.70 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.012 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.090 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.150 |

| Mo (%) | - |

| B (%) | - |

| Galvanisation | Class 1 |

Values in bold: tighter than the standard

| S550MC EN 10149-2 | |

|---|---|

| C (%) | ≤ 0.120 |

| Mn (%) | ≤ 1.80 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.015 |

| Si (%) | ≤ 0.50 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.090 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.150 |

| Mo (%) | - |

| B (%) | - |

| Galvanisation | No |

| Amstrong® 550MC | |

|---|---|

| C (%) | ≤ 0.100 |

| Mn (%) | ≤ 1.70 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.012 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.090 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.150 |

| Mo (%) | - |

| B (%) | - |

| Galvanisation | Class 1 |

Values in bold: tighter than the standard

| S600MC EN 10149-2 | |

|---|---|

| C (%) | ≤ 0.120 |

| Mn (%) | ≤ 1.90 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.015 |

| Si (%) | ≤ 0.50 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.090 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.220 |

| Mo (%) | ≤ 0.50 |

| B (%) | ≤ 0.0050 |

| Galvanisation | No |

| Amstrong® 600MC | |

|---|---|

| C (%) | ≤ 0.120 |

| Mn (%) | ≤ 1.90 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.015 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.015 |

| Nb (%) | ≤ 0.090 |

| V (%) | ≤ 0.200 |

| Ti (%) | ≤ 0.220 |

| Mo (%) | ≤ 0.50 |

| B (%) | ≤ 0.0050 |

| Galvanisation | Class 1 |

Values in bold: tighter than the standard

Grades in italics: not included in the standard

Values in bold: tighter than the standard

The chemical properties given are based on cast analysis data.

V+Nb+Ti ≤ 0.22%.

Suitability for hot-dip zinc coating is defined as per the requirements of EN ISO 14713-2 Table 1 and NFA 35-503.

Any questions?

Ask them via our contact form on

https://industry.arcelormittal.com/getintouch

All details provided in the ArcelorMittal Flat Carbon Europe S.A. catalogue are for information purposes only. ArcelorMittal Flat Carbon Europe S.A. reserves the right to change its product range at any time without prior notice.

Download

Download