In order to offer you the best possible experience, we suggest that you accept the deposit and reading of cookies and the use of technology necessary for their proper functioning:

ArcelorMittal offers, in the form of semi-finished products, grades specified by European standards after a complete cycle of re-rolling and batch or continuous annealing.

A full range of re-rolled or coated products can be made from the coils supplied to re-rollers.

ArcelorMittal can supply grades to comply with EN 10130 after:

The main advantage of steels for re-rolling is their combination of strength, stiffness and ductility. Moreover, ArcelorMittal offers a full range of grades in compliance with the EN 10130 standard: from DC01 to DC06.

Steels for re-rolling are suitable, after processing, for cold forming by bending, drawing etc. They are also suitable for surface coating, with the exception of enamelling. Various examples of applications include:

| Old brand names | |

|---|---|

| DC01RB AM FCE | |

| DC03RB AM FCE | |

| DC04RB AM FCE | |

| DC05RB AM FCE | |

| DC06RB AM FCE |

Grades in italics: not included in the standard

| DC01RB AM FCE | |

|---|---|

Grades in italics: not included in the standard

| DC03RB AM FCE | |

|---|---|

Grades in italics: not included in the standard

| DC04RB AM FCE | |

|---|---|

Grades in italics: not included in the standard

| DC05RB AM FCE | |

|---|---|

Grades in italics: not included in the standard

| DC06RB AM FCE | |

|---|---|

Grades in italics: not included in the standard

Grades in italics: not included in the standard

| Old brand names | |

|---|---|

| DC01RC AM FCE | |

| DC03RC AM FCE | |

| DC04RC AM FCE | |

| DC05RC AM FCE | |

| DC06RC AM FCE |

Grades in italics: not included in the standard

| DC01RC AM FCE | |

|---|---|

Grades in italics: not included in the standard

| DC03RC AM FCE | |

|---|---|

Grades in italics: not included in the standard

| DC04RC AM FCE | |

|---|---|

Grades in italics: not included in the standard

| DC05RC AM FCE | |

|---|---|

Grades in italics: not included in the standard

| DC06RC AM FCE | |

|---|---|

Grades in italics: not included in the standard

Grades in italics: not included in the standard

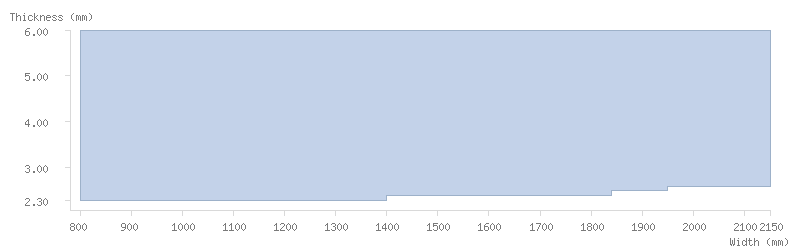

| Thickness (mm) | Min width | DC01RB AM FCE, DC03RB AM FCE, DC05RB AM FCE, DC01RC AM FCE | DC04RB AM FCE | DC06RB AM FCE, DC04RC AM FCE, DC05RC AM FCE, DC06RC AM FCE | DC03RC AM FCE |

|---|---|---|---|---|---|

| Max width | Max width | Max width | Max width | ||

| 1.50 ≤ th < 1.60 | 800 | 1540 | 1540 | - | 1300 |

| 1.60 ≤ th < 1.70 | 1400 | ||||

| 1.70 ≤ th < 1.80 | 1590 | 1590 | 1500 | ||

| 1.80 ≤ th < 1.90 | 1630 | 1630 | 1600 | ||

| 1.90 ≤ th < 2.00 | 1780 | 1780 | 1650 | ||

| 2.00 ≤ th < 2.10 | 1830 | 1830 | 1700 | ||

| 2.10 ≤ th < 2.20 | 1730 | ||||

| 2.20 ≤ th < 2.30 | 1830 | ||||

| 2.30 ≤ th < 2.40 | 1930 | 1930 | 1400 | 1870 | |

| 2.40 ≤ th < 2.50 | 2000 | 1840 | 2000 | ||

| 2.50 ≤ th < 2.60 | 2100 | 1980 | 1950 | 2100 | |

| 2.60 ≤ th < 2.70 | 2150 | 2150 | 2150 | ||

| 2.70 ≤ th < 2.80 | 2030 | ||||

| 2.80 ≤ th < 3.00 | |||||

| 3.00 ≤ th < 3.30 | |||||

| 3.30 ≤ th < 3.50 | 2130 | ||||

| 3.50 ≤ th < 4.00 | |||||

| 4.00 ≤ th < 6.00 |

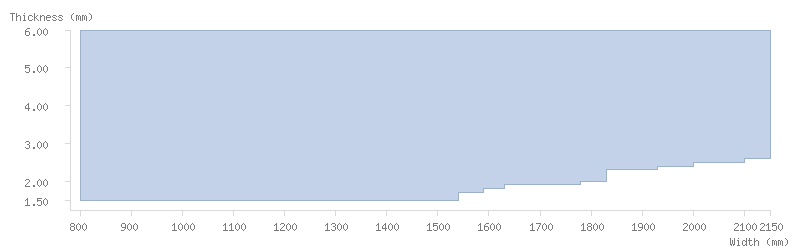

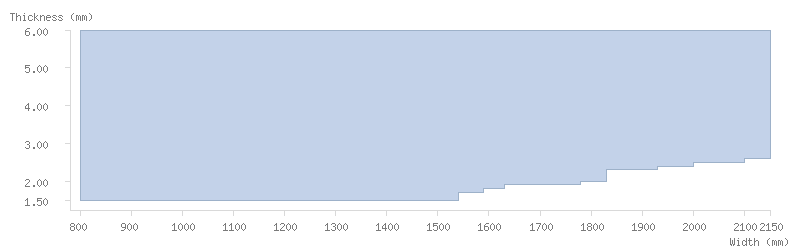

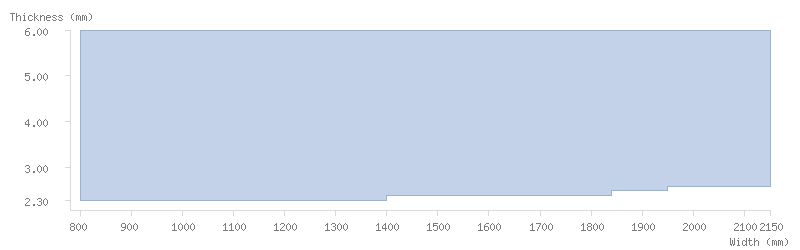

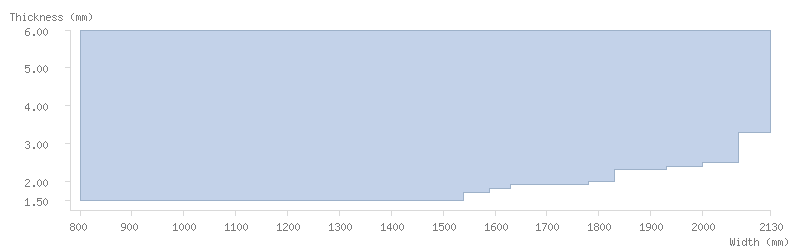

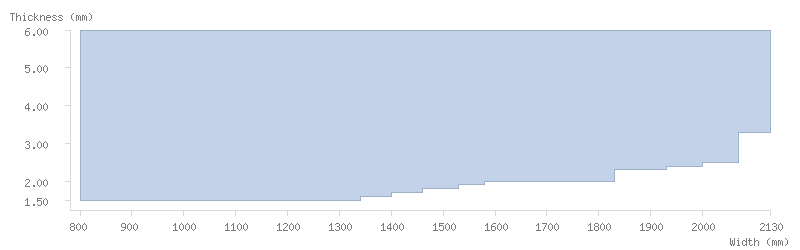

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1590 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.10 | 1830 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1930 | |

| 2.40 ≤ th < 2.50 | 2000 | |

| 2.50 ≤ th < 2.60 | 2100 | |

| 2.60 ≤ th < 2.70 | 2150 | |

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 6.00 |

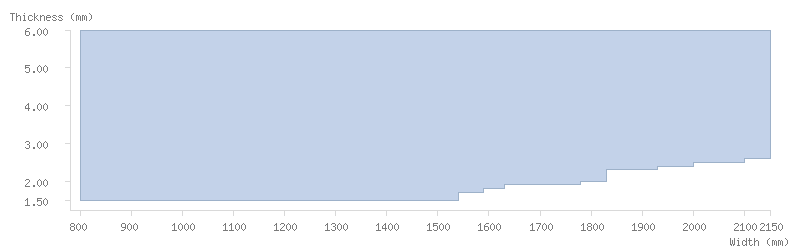

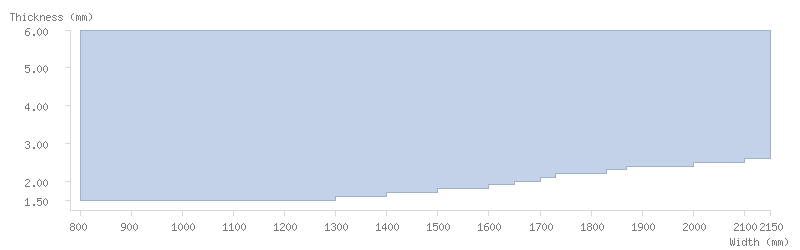

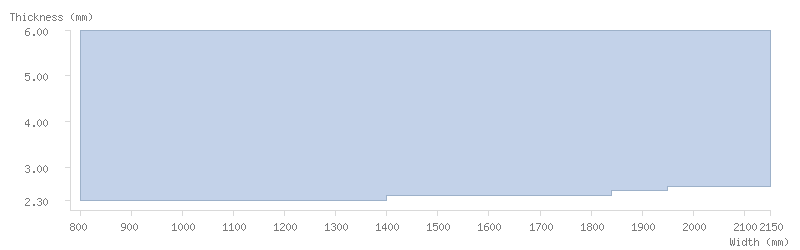

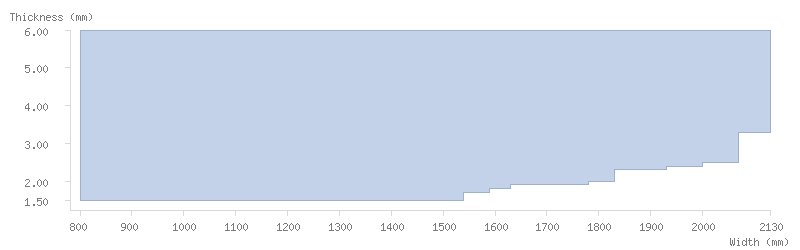

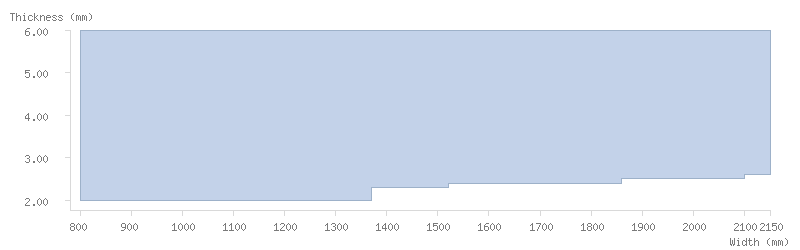

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1590 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.10 | 1830 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1930 | |

| 2.40 ≤ th < 2.50 | 2000 | |

| 2.50 ≤ th < 2.60 | 2100 | |

| 2.60 ≤ th < 2.70 | 2150 | |

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 6.00 |

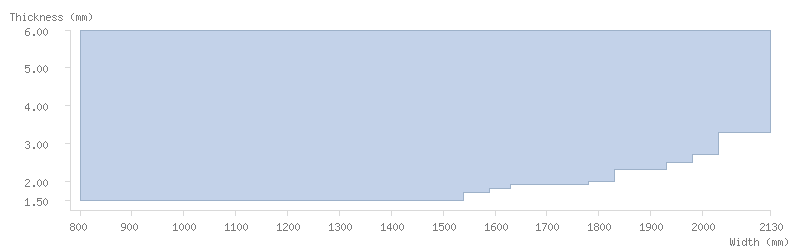

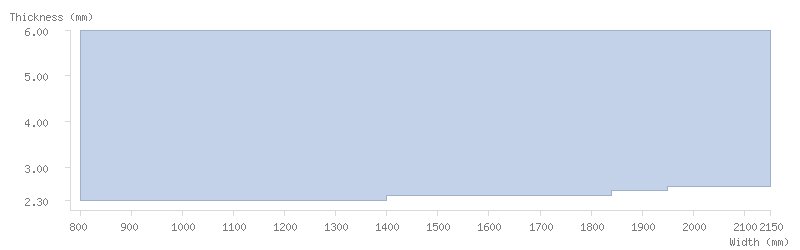

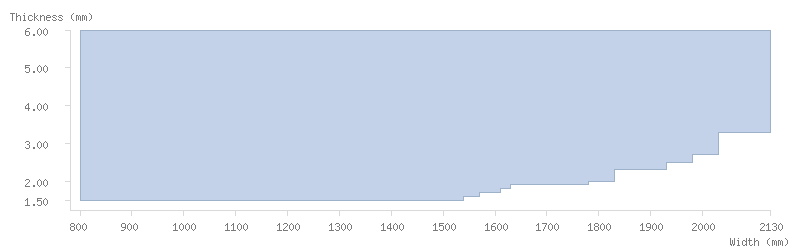

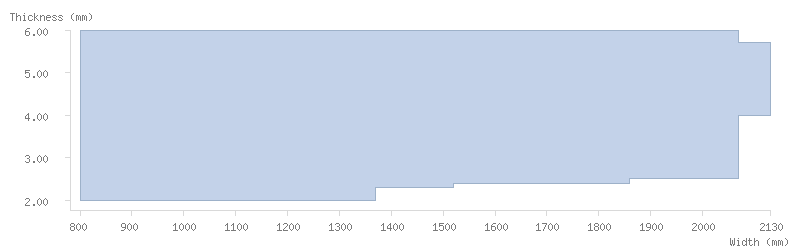

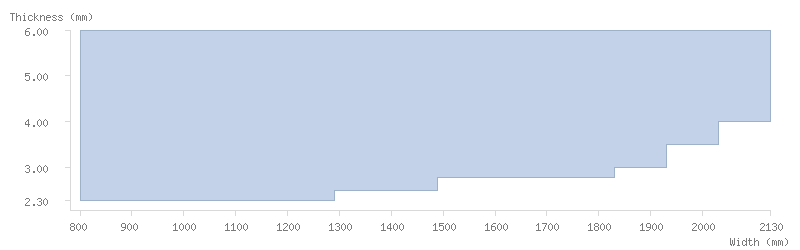

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1590 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.10 | 1830 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1930 | |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | 1980 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | 2030 | |

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | 2130 | |

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 6.00 |

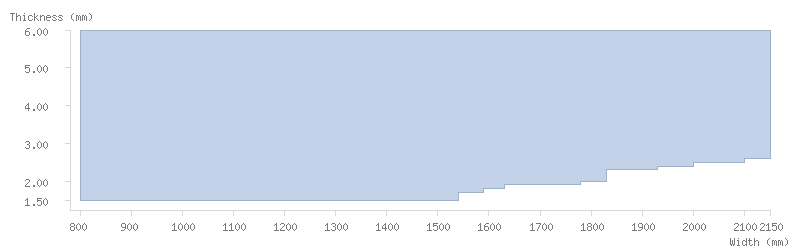

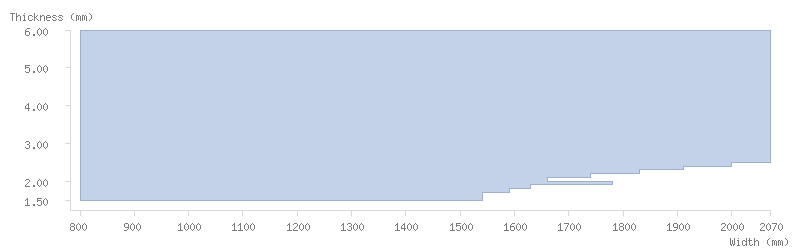

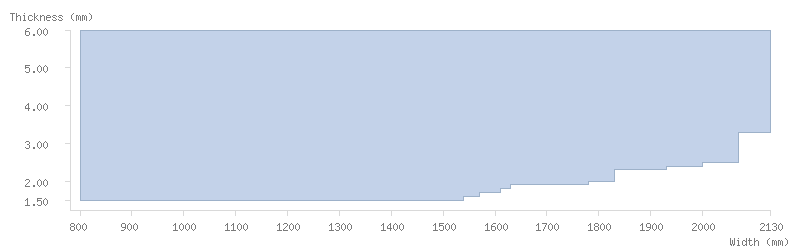

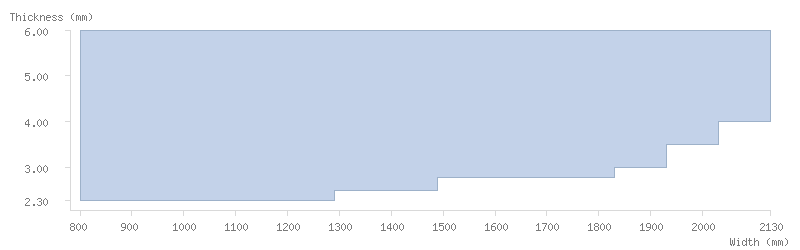

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1590 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.10 | 1830 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1930 | |

| 2.40 ≤ th < 2.50 | 2000 | |

| 2.50 ≤ th < 2.60 | 2100 | |

| 2.60 ≤ th < 2.70 | 2150 | |

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 6.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.10 | ||

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1400 | |

| 2.40 ≤ th < 2.50 | 1840 | |

| 2.50 ≤ th < 2.60 | 1950 | |

| 2.60 ≤ th < 2.70 | 2150 | |

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 6.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1590 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.10 | 1830 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1930 | |

| 2.40 ≤ th < 2.50 | 2000 | |

| 2.50 ≤ th < 2.60 | 2100 | |

| 2.60 ≤ th < 2.70 | 2150 | |

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 6.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1300 |

| 1.60 ≤ th < 1.70 | 1400 | |

| 1.70 ≤ th < 1.80 | 1500 | |

| 1.80 ≤ th < 1.90 | 1600 | |

| 1.90 ≤ th < 2.00 | 1650 | |

| 2.00 ≤ th < 2.10 | 1700 | |

| 2.10 ≤ th < 2.20 | 1730 | |

| 2.20 ≤ th < 2.30 | 1830 | |

| 2.30 ≤ th < 2.40 | 1870 | |

| 2.40 ≤ th < 2.50 | 2000 | |

| 2.50 ≤ th < 2.60 | 2100 | |

| 2.60 ≤ th < 2.70 | 2150 | |

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 6.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.10 | ||

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1400 | |

| 2.40 ≤ th < 2.50 | 1840 | |

| 2.50 ≤ th < 2.60 | 1950 | |

| 2.60 ≤ th < 2.70 | 2150 | |

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 6.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.10 | ||

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1400 | |

| 2.40 ≤ th < 2.50 | 1840 | |

| 2.50 ≤ th < 2.60 | 1950 | |

| 2.60 ≤ th < 2.70 | 2150 | |

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 6.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.10 | ||

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1400 | |

| 2.40 ≤ th < 2.50 | 1840 | |

| 2.50 ≤ th < 2.60 | 1950 | |

| 2.60 ≤ th < 2.70 | 2150 | |

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 6.00 |

| Thickness (mm) | Min width | DC01RB AM FCE | DC03RB AM FCE | DC04RB AM FCE, DC05RB AM FCE | DC06RB AM FCE | DC01RC AM FCE | DC03RC AM FCE | DC04RC AM FCE, DC06RC AM FCE | DC05RC AM FCE |

|---|---|---|---|---|---|---|---|---|---|

| Max width | Max width | Max width | Max width | Max width | Max width | Max width | Max width | ||

| 1.50 ≤ th < 1.60 | 800 | 1540 | 1540 | 1540 | - | 1540 | 1340 | - | - |

| 1.60 ≤ th < 1.70 | 1570 | 1570 | 1400 | ||||||

| 1.70 ≤ th < 1.80 | 1610 | 1590 | 1590 | 1610 | 1460 | ||||

| 1.80 ≤ th < 1.90 | 1630 | 1630 | 1630 | 1630 | 1530 | ||||

| 1.90 ≤ th < 2.00 | 1780 | 1780 | 1780 | 1780 | 1580 | ||||

| 2.00 ≤ th < 2.10 | 1830 | 1660 | 1830 | 1370 | 1830 | 1830 | 1370 | ||

| 2.10 ≤ th < 2.20 | 1740 | ||||||||

| 2.20 ≤ th < 2.30 | 1830 | ||||||||

| 2.30 ≤ th < 2.40 | 1930 | 1910 | 1930 | 1520 | 1930 | 1930 | 1290 | 1520 | |

| 2.40 ≤ th < 2.50 | 2000 | 2000 | 1860 | 2000 | 2000 | 1860 | |||

| 2.50 ≤ th < 2.60 | 1980 | 2070 | 2070 | 2070 | 2070 | 2070 | 1490 | 2100 | |

| 2.60 ≤ th < 2.70 | 2150 | ||||||||

| 2.70 ≤ th < 2.80 | 2030 | ||||||||

| 2.80 ≤ th < 3.00 | 1830 | ||||||||

| 3.00 ≤ th < 3.30 | 1930 | ||||||||

| 3.30 ≤ th < 3.50 | 2130 | 2130 | 2130 | 2130 | |||||

| 3.50 ≤ th < 4.00 | 2030 | ||||||||

| 4.00 ≤ th < 5.70 | 2130 | 2130 | |||||||

| 5.70 ≤ th < 6.00 | 2070 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | 1570 | |

| 1.70 ≤ th < 1.80 | 1610 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.10 | 1830 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1930 | |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | 1980 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | 2030 | |

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | 2130 | |

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 5.70 | ||

| 5.70 ≤ th < 6.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1590 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.10 | 1660 | |

| 2.10 ≤ th < 2.20 | 1740 | |

| 2.20 ≤ th < 2.30 | 1830 | |

| 2.30 ≤ th < 2.40 | 1910 | |

| 2.40 ≤ th < 2.50 | 2000 | |

| 2.50 ≤ th < 2.60 | 2070 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 5.70 | ||

| 5.70 ≤ th < 6.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1590 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.10 | 1830 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1930 | |

| 2.40 ≤ th < 2.50 | 2000 | |

| 2.50 ≤ th < 2.60 | 2070 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | 2130 | |

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 5.70 | ||

| 5.70 ≤ th < 6.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | 1590 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.10 | 1830 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1930 | |

| 2.40 ≤ th < 2.50 | 2000 | |

| 2.50 ≤ th < 2.60 | 2070 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | 2130 | |

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 5.70 | ||

| 5.70 ≤ th < 6.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.10 | 1370 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1520 | |

| 2.40 ≤ th < 2.50 | 1860 | |

| 2.50 ≤ th < 2.60 | 2070 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 5.70 | 2130 | |

| 5.70 ≤ th < 6.00 | 2070 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1540 |

| 1.60 ≤ th < 1.70 | 1570 | |

| 1.70 ≤ th < 1.80 | 1610 | |

| 1.80 ≤ th < 1.90 | 1630 | |

| 1.90 ≤ th < 2.00 | 1780 | |

| 2.00 ≤ th < 2.10 | 1830 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1930 | |

| 2.40 ≤ th < 2.50 | 2000 | |

| 2.50 ≤ th < 2.60 | 2070 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | 2130 | |

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 5.70 | ||

| 5.70 ≤ th < 6.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | 1340 |

| 1.60 ≤ th < 1.70 | 1400 | |

| 1.70 ≤ th < 1.80 | 1460 | |

| 1.80 ≤ th < 1.90 | 1530 | |

| 1.90 ≤ th < 2.00 | 1580 | |

| 2.00 ≤ th < 2.10 | 1830 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1930 | |

| 2.40 ≤ th < 2.50 | 2000 | |

| 2.50 ≤ th < 2.60 | 2070 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | 2130 | |

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 5.70 | ||

| 5.70 ≤ th < 6.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.10 | ||

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1290 | |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | 1490 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | 1830 | |

| 3.00 ≤ th < 3.30 | 1930 | |

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | 2030 | |

| 4.00 ≤ th < 5.70 | 2130 | |

| 5.70 ≤ th < 6.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.10 | 1370 | |

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1520 | |

| 2.40 ≤ th < 2.50 | 1860 | |

| 2.50 ≤ th < 2.60 | 2100 | |

| 2.60 ≤ th < 2.70 | 2150 | |

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | ||

| 3.00 ≤ th < 3.30 | ||

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | ||

| 4.00 ≤ th < 5.70 | ||

| 5.70 ≤ th < 6.00 |

| Thickness (mm) | Min width | Max width |

|---|---|---|

| 1.50 ≤ th < 1.60 | 800 | - |

| 1.60 ≤ th < 1.70 | ||

| 1.70 ≤ th < 1.80 | ||

| 1.80 ≤ th < 1.90 | ||

| 1.90 ≤ th < 2.00 | ||

| 2.00 ≤ th < 2.10 | ||

| 2.10 ≤ th < 2.20 | ||

| 2.20 ≤ th < 2.30 | ||

| 2.30 ≤ th < 2.40 | 1290 | |

| 2.40 ≤ th < 2.50 | ||

| 2.50 ≤ th < 2.60 | 1490 | |

| 2.60 ≤ th < 2.70 | ||

| 2.70 ≤ th < 2.80 | ||

| 2.80 ≤ th < 3.00 | 1830 | |

| 3.00 ≤ th < 3.30 | 1930 | |

| 3.30 ≤ th < 3.50 | ||

| 3.50 ≤ th < 4.00 | 2030 | |

| 4.00 ≤ th < 5.70 | 2130 | |

| 5.70 ≤ th < 6.00 |

| C (%) | Mn (%) | P (%) | S (%) | Si (%) | Al (%) | Cu (%) | Cr (%) | Ni (%) | Nb (%) | V (%) | Ti (%) | B (%) | Galvanisation | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DC01RB AM FCE | 0.015 - 0.100 | 0.15 - 0.50 | ≤ 0.030 | ≤ 0.030 | ≤ 0.03 | ≥ 0.010 | ≤ 0.15 | ≤ 0.10 | ≤ 0.15 | ≤ 0.008 | ≤ 0.008 | ≤ 0.010 | ≤ 0.0010 | Class 1 |

| DC03RB AM FCE | 0.015 - 0.080 | 0.15 - 0.45 | ≤ 0.025 | ≤ 0.025 | ≤ 0.03 | ≥ 0.020 | ≤ 0.10 | ≤ 0.10 | ≤ 0.10 | ≤ 0.003 | ≤ 0.005 | ≤ 0.008 | ≤ 0.0010 | Class 1 |

| DC04RB AM FCE | 0.015 - 0.060 | 0.15 - 0.35 | ≤ 0.020 | ≤ 0.025 | ≤ 0.03 | ≥ 0.020 | ≤ 0.10 | ≤ 0.10 | ≤ 0.10 | ≤ 0.003 | ≤ 0.005 | ≤ 0.008 | ≤ 0.0010 | Class 1 |

| DC05RB AM FCE | 0.015 - 0.050 | 0.15 - 0.25 | ≤ 0.015 | ≤ 0.025 | ≤ 0.03 | ≥ 0.020 | ≤ 0.10 | ≤ 0.10 | ≤ 0.10 | ≤ 0.003 | ≤ 0.005 | ≤ 0.008 | ≤ 0.0010 | Class 1 |

| DC06RB AM FCE | ≤ 0.010 | ≤ 0.25 | ≤ 0.020 | ≤ 0.020 | ≤ 0.03 | ≤ 0.100 | ≤ 0.10 | ≤ 0.10 | ≤ 0.10 | - | ≤ 0.005 | 0.030 - 0.150 | ≤ 0.0010 | Class 1 |

Grades in italics: not included in the standard

| DC01RB AM FCE | |

|---|---|

| C (%) | 0.015 - 0.100 |

| Mn (%) | 0.15 - 0.50 |

| P (%) | ≤ 0.030 |

| S (%) | ≤ 0.030 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.010 |

| Cu (%) | ≤ 0.15 |

| Cr (%) | ≤ 0.10 |

| Ni (%) | ≤ 0.15 |

| Nb (%) | ≤ 0.008 |

| V (%) | ≤ 0.008 |

| Ti (%) | ≤ 0.010 |

| B (%) | ≤ 0.0010 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

| DC03RB AM FCE | |

|---|---|

| C (%) | 0.015 - 0.080 |

| Mn (%) | 0.15 - 0.45 |

| P (%) | ≤ 0.025 |

| S (%) | ≤ 0.025 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.020 |

| Cu (%) | ≤ 0.10 |

| Cr (%) | ≤ 0.10 |

| Ni (%) | ≤ 0.10 |

| Nb (%) | ≤ 0.003 |

| V (%) | ≤ 0.005 |

| Ti (%) | ≤ 0.008 |

| B (%) | ≤ 0.0010 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

| DC04RB AM FCE | |

|---|---|

| C (%) | 0.015 - 0.060 |

| Mn (%) | 0.15 - 0.35 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.025 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.020 |

| Cu (%) | ≤ 0.10 |

| Cr (%) | ≤ 0.10 |

| Ni (%) | ≤ 0.10 |

| Nb (%) | ≤ 0.003 |

| V (%) | ≤ 0.005 |

| Ti (%) | ≤ 0.008 |

| B (%) | ≤ 0.0010 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

| DC05RB AM FCE | |

|---|---|

| C (%) | 0.015 - 0.050 |

| Mn (%) | 0.15 - 0.25 |

| P (%) | ≤ 0.015 |

| S (%) | ≤ 0.025 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.020 |

| Cu (%) | ≤ 0.10 |

| Cr (%) | ≤ 0.10 |

| Ni (%) | ≤ 0.10 |

| Nb (%) | ≤ 0.003 |

| V (%) | ≤ 0.005 |

| Ti (%) | ≤ 0.008 |

| B (%) | ≤ 0.0010 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

| DC06RB AM FCE | |

|---|---|

| C (%) | ≤ 0.010 |

| Mn (%) | ≤ 0.25 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.020 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≤ 0.100 |

| Cu (%) | ≤ 0.10 |

| Cr (%) | ≤ 0.10 |

| Ni (%) | ≤ 0.10 |

| Nb (%) | - |

| V (%) | ≤ 0.005 |

| Ti (%) | 0.030 - 0.150 |

| B (%) | ≤ 0.0010 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

Grades in italics: not included in the standard

| C (%) | Mn (%) | P (%) | S (%) | Si (%) | Al (%) | Cu (%) | Cr (%) | Ni (%) | Nb (%) | V (%) | Ti (%) | B (%) | Galvanisation | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DC01RC AM FCE | 0.020 - 0.100 | 0.15 - 0.50 | ≤ 0.030 | ≤ 0.025 | ≤ 0.03 | ≥ 0.010 | ≤ 0.15 | ≤ 0.10 | ≤ 0.15 | ≤ 0.005 | ≤ 0.005 | ≤ 0.010 | ≤ 0.0010 | Class 1 |

| DC03RC AM FCE | 0.020 - 0.060 | 0.15 - 0.35 | ≤ 0.020 | ≤ 0.025 | ≤ 0.03 | ≥ 0.020 | ≤ 0.10 | ≤ 0.10 | ≤ 0.10 | ≤ 0.003 | ≤ 0.005 | ≤ 0.010 | ≤ 0.0010 | Class 1 |

| DC04RC AM FCE | 0.015 - 0.050 | 0.15 - 0.25 | ≤ 0.015 | ≤ 0.025 | ≤ 0.03 | ≥ 0.020 | ≤ 0.10 | ≤ 0.10 | ≤ 0.10 | ≤ 0.003 | ≤ 0.005 | ≤ 0.010 | ≤ 0.0010 | Class 1 |

| DC05RC AM FCE | ≤ 0.010 | ≤ 0.30 | ≤ 0.020 | ≤ 0.025 | ≤ 0.03 | ≤ 0.100 | ≤ 0.10 | ≤ 0.10 | ≤ 0.10 | - | ≤ 0.005 | ≤ 0.150 | ≤ 0.0010 | Class 1 |

| DC06RC AM FCE | ≤ 0.010 | ≤ 0.25 | ≤ 0.020 | ≤ 0.020 | ≤ 0.03 | ≤ 0.100 | ≤ 0.10 | ≤ 0.10 | ≤ 0.10 | - | ≤ 0.005 | 0.030 - 0.150 | ≤ 0.0010 | Class 1 |

Grades in italics: not included in the standard

| DC01RC AM FCE | |

|---|---|

| C (%) | 0.020 - 0.100 |

| Mn (%) | 0.15 - 0.50 |

| P (%) | ≤ 0.030 |

| S (%) | ≤ 0.025 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.010 |

| Cu (%) | ≤ 0.15 |

| Cr (%) | ≤ 0.10 |

| Ni (%) | ≤ 0.15 |

| Nb (%) | ≤ 0.005 |

| V (%) | ≤ 0.005 |

| Ti (%) | ≤ 0.010 |

| B (%) | ≤ 0.0010 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

| DC03RC AM FCE | |

|---|---|

| C (%) | 0.020 - 0.060 |

| Mn (%) | 0.15 - 0.35 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.025 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.020 |

| Cu (%) | ≤ 0.10 |

| Cr (%) | ≤ 0.10 |

| Ni (%) | ≤ 0.10 |

| Nb (%) | ≤ 0.003 |

| V (%) | ≤ 0.005 |

| Ti (%) | ≤ 0.010 |

| B (%) | ≤ 0.0010 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

| DC04RC AM FCE | |

|---|---|

| C (%) | 0.015 - 0.050 |

| Mn (%) | 0.15 - 0.25 |

| P (%) | ≤ 0.015 |

| S (%) | ≤ 0.025 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≥ 0.020 |

| Cu (%) | ≤ 0.10 |

| Cr (%) | ≤ 0.10 |

| Ni (%) | ≤ 0.10 |

| Nb (%) | ≤ 0.003 |

| V (%) | ≤ 0.005 |

| Ti (%) | ≤ 0.010 |

| B (%) | ≤ 0.0010 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

| DC05RC AM FCE | |

|---|---|

| C (%) | ≤ 0.010 |

| Mn (%) | ≤ 0.30 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.025 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≤ 0.100 |

| Cu (%) | ≤ 0.10 |

| Cr (%) | ≤ 0.10 |

| Ni (%) | ≤ 0.10 |

| Nb (%) | - |

| V (%) | ≤ 0.005 |

| Ti (%) | ≤ 0.150 |

| B (%) | ≤ 0.0010 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

| DC06RC AM FCE | |

|---|---|

| C (%) | ≤ 0.010 |

| Mn (%) | ≤ 0.25 |

| P (%) | ≤ 0.020 |

| S (%) | ≤ 0.020 |

| Si (%) | ≤ 0.03 |

| Al (%) | ≤ 0.100 |

| Cu (%) | ≤ 0.10 |

| Cr (%) | ≤ 0.10 |

| Ni (%) | ≤ 0.10 |

| Nb (%) | - |

| V (%) | ≤ 0.005 |

| Ti (%) | 0.030 - 0.150 |

| B (%) | ≤ 0.0010 |

| Galvanisation | Class 1 |

Grades in italics: not included in the standard

Grades in italics: not included in the standard

Any questions?

Ask them via our contact form on

https://industry.arcelormittal.com/getintouch

All details provided in the ArcelorMittal Flat Carbon Europe S.A. catalogue are for information purposes only. ArcelorMittal Flat Carbon Europe S.A. reserves the right to change its product range at any time without prior notice.

Download

Download